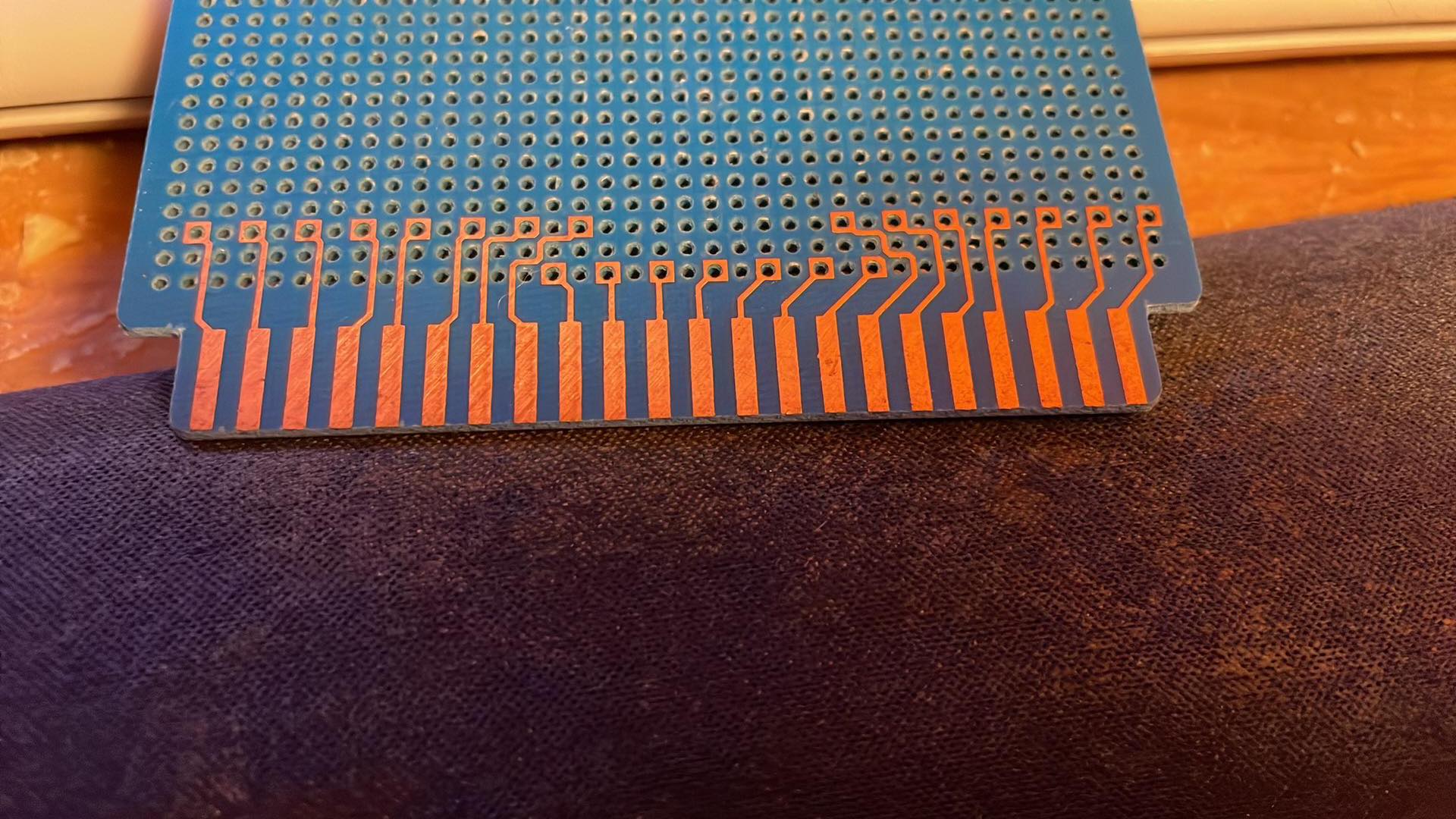

Is there a consensus on a real-world part for this yet? I was going through my old electronics pile and found a blue board that looks like a nice match:

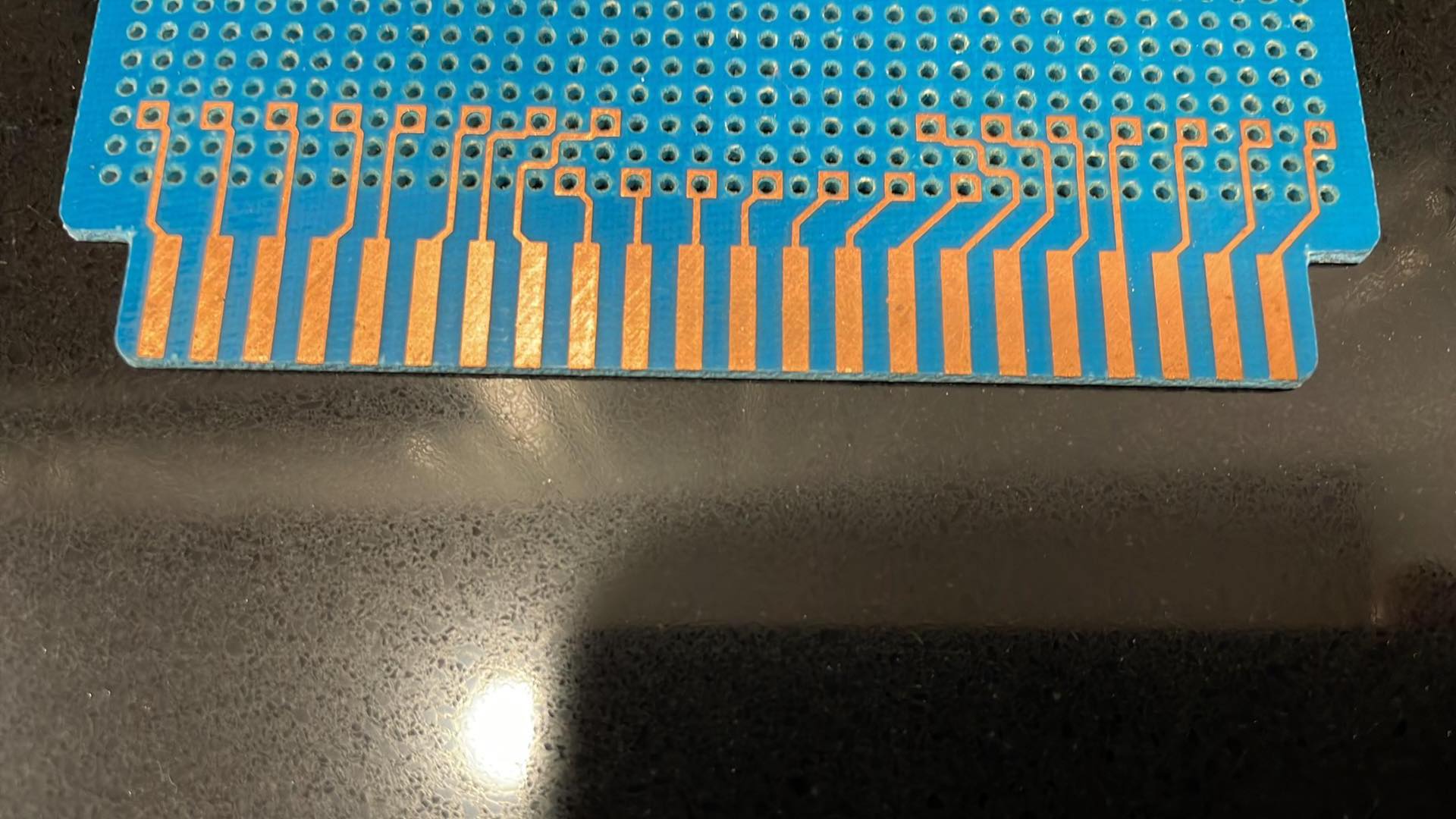

I specifically tried to take that picture in weird lighting so you can see how the blue shifts. Here is the same card under VERY bright white light against a black background:

It's got the right spacing, 13 traces per 2 inch section, and would fit well in the clamp when trimmed.

So what do you all think? I looked around a bit but didn't find an official find of the correct card, but of course I could have overlooked that.

I specifically tried to take that picture in weird lighting so you can see how the blue shifts. Here is the same card under VERY bright white light against a black background:

It's got the right spacing, 13 traces per 2 inch section, and would fit well in the clamp when trimmed.

So what do you all think? I looked around a bit but didn't find an official find of the correct card, but of course I could have overlooked that.