SportsRacer

New Member

Got my resin parts, they're really nice and now I have a target for improving my resin printing skills.

Amazing work, stefe2!! I just started printing my own pack, and like you I'm blown away by the quality of gnolivos models! I am curious about your helmet though - which STL did you use for that? I've seen a few of varying quality, but yours looks like the best I've found! Would be very intereted in where that came fromHi everyone,

I started printing Veepy files in may 2021 and worked part time on the Jetpack and helmet until october. I had to take a break to finish other projects... I always start to many projects at the same timeAnyway I am back and planing on finishing it in the next few weeks. gnolivos files are just extraordinary. Still the weathering to do and finish coding the electronic. I am planing on thruster lights, sound and smoke.

Thanks again gnolivos to make a dream come true

(SNIPPED images for size)

The model is from Do3D... The helmet is great but the Jepack is nowhere near Veepy quality.Amazing work, stefe2!! I just started printing my own pack, and like you I'm blown away by the quality of gnolivos models! I am curious about your helmet though - which STL did you use for that? I've seen a few of varying quality, but yours looks like the best I've found! Would be very intereted in where that came from

www.do3d.com

www.do3d.com

I took the same approach as you. I took extra care when assembling not to ruin the finish. Then added at the end the rivets.Hey all, I'm back to work on my Veepy, but I'm approaching the painting a little different than what I'm seeing in this thread. It seems that most of you are assembling before painting...I've been approaching mine by sanding, filling, and painting each piece prior to any assembly. Other than the risk of scratching the finish, does it really matter?

I ask because I'm concerned I might be missing something important.

Thanks!

I took the same approach as you. I took extra care when assembling not to ruin the finish. Then added at the end the rivets.

Definitely sand and paint first and before assembly!

I never released it. I performed some trials and it printed almost perfectly but there were still some issues. Problem is the thinner areas. Would need some serious modification to thicken certain areas and then the overall accuracy is lost. I never pursued further …Was the all-in-one mini version released? I've gone through the tread and I'm only finding download info for the full scale.

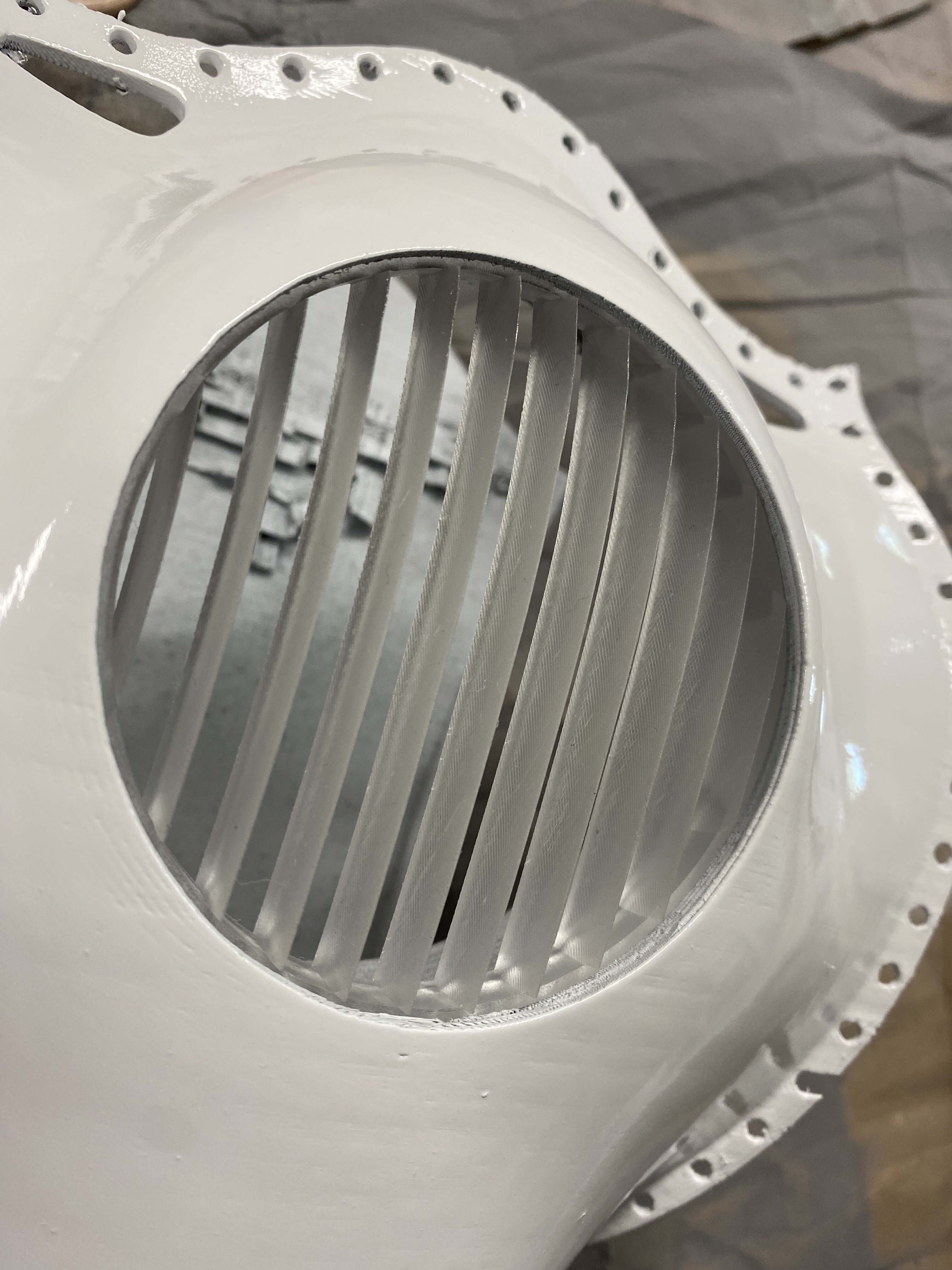

I think, and that's my thought on the possibilities of 3-D printing that part, the overall shape; that is: the two main jets pipes + cones and middle part connecting both shouldn't be too difficult to print. Maybe the little fins and some of the vents are? As a model maker, it would be easy to add any little details missing from that overall shapeI never released it. I performed some trials and it printed almost perfectly but there were still some issues. Problem is the thinner areas. Would need some serious modification to thicken certain areas and then the overall accuracy is lost. I never pursued further …

They are immediate. Check your spam folder. You can request link again to same email or a new one.How long do the links take to email? I'm worried I did it in the past, and I can't find it... and that was my one shot.

Copper tubing is readily available. Find a cheap brake tubing bender at Walmart or Harbor freight and bend it to your needs.

If you want a good smooth bend on copper tube use this trick: put soapy water in the tube by blocking the ends with a rubber plug or hot glue from a glue-gun. Freeze for 24 hours; remove from the freezer and bend it right away. Thaw and remove water + plugsWhich question; the copper pipe doesn’t come bent in the shape I need so it’s gotta be fabricated somehow or do I have to use a different material and make it look like copper?

View attachment 1661224