epochcraig

New Member

here is my skull of the dug up variety i started by making a 2 part silicone mould of the original sculpt this was the first time ive used silicone as a full moulding solutions.

as i was concentrating on silicone moulding and getting it right as its expensive material.. here is the first pic ive got of the moulding process, i made boxes for the skull cap main head and the jaw.

.jpg)

once the moulds had cured over night i then dismantled the 3 separate mould boxes and split the 2 part moulds up giving me the moulds ready to cast resin into, i was very surprised at the amount of detail that the silicone got.

here are the two moulds for the skull cap and the jaw bone came out really nice and not much seem work to do iether

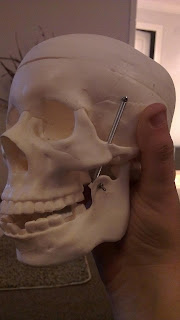

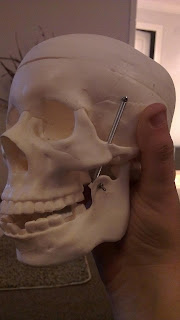

bellow is the skull its self

this is the first pour of resin im using the easy flo 60 for pour casting followed by casting the head and jaw, it has a 2.5 min work time and 30 min de mould time, although i leave it for an hour to harden properly.

these pics bellow are the first pull of the skull from the mould as you can see the seems are pretty clean so not much work need to clean them up. i made the pour hole in place that if there was any chance of trapped air it would be in place which would hide them or be easy to fill in later.

i decided to put it all together for a test fit before i did all the fine finishings, ive attached the jaw with a return spring which works great and holds the jaw in place perfectly.

once i finished the seems and was happy with it i gave the skull a paint over with a white primer as a base coat ready for ageing.

i aged the skull and teeth and attached the skull cap

which has come out really good, but for some reason

when i take a pic i get the green glow on the from of the

skull which isnt there i think its the florescent lights in

my workshop.

im now in two mind as to weather or not i ad flesh to the skull for more effect maybe i will with latex and post up a pic.

as i was concentrating on silicone moulding and getting it right as its expensive material.. here is the first pic ive got of the moulding process, i made boxes for the skull cap main head and the jaw.

.jpg)

once the moulds had cured over night i then dismantled the 3 separate mould boxes and split the 2 part moulds up giving me the moulds ready to cast resin into, i was very surprised at the amount of detail that the silicone got.

here are the two moulds for the skull cap and the jaw bone came out really nice and not much seem work to do iether

bellow is the skull its self

this is the first pour of resin im using the easy flo 60 for pour casting followed by casting the head and jaw, it has a 2.5 min work time and 30 min de mould time, although i leave it for an hour to harden properly.

these pics bellow are the first pull of the skull from the mould as you can see the seems are pretty clean so not much work need to clean them up. i made the pour hole in place that if there was any chance of trapped air it would be in place which would hide them or be easy to fill in later.

i decided to put it all together for a test fit before i did all the fine finishings, ive attached the jaw with a return spring which works great and holds the jaw in place perfectly.

once i finished the seems and was happy with it i gave the skull a paint over with a white primer as a base coat ready for ageing.

i aged the skull and teeth and attached the skull cap

which has come out really good, but for some reason

when i take a pic i get the green glow on the from of the

skull which isnt there i think its the florescent lights in

my workshop.

im now in two mind as to weather or not i ad flesh to the skull for more effect maybe i will with latex and post up a pic.

Last edited: