Analyzer

Master Member

I picked up the stls from Gambody

There are two scales. 1/34 designed for FDM style printes and 1/68 for DLP/SLA style printers

I debated shrinking it down by 6% to get to 1/72 but I did not want to risk screwing anything by making a part too thin to support etc..

1/68 is close enough anyway considering Bandai's 1/72 kits aren't all true 1/72 scale anyway (B-WIng and A-Wing I am looking at you for starters)

Besides, if all goes well I can always try printing out a scaled down one later and give this one to my brother or someone as a gift

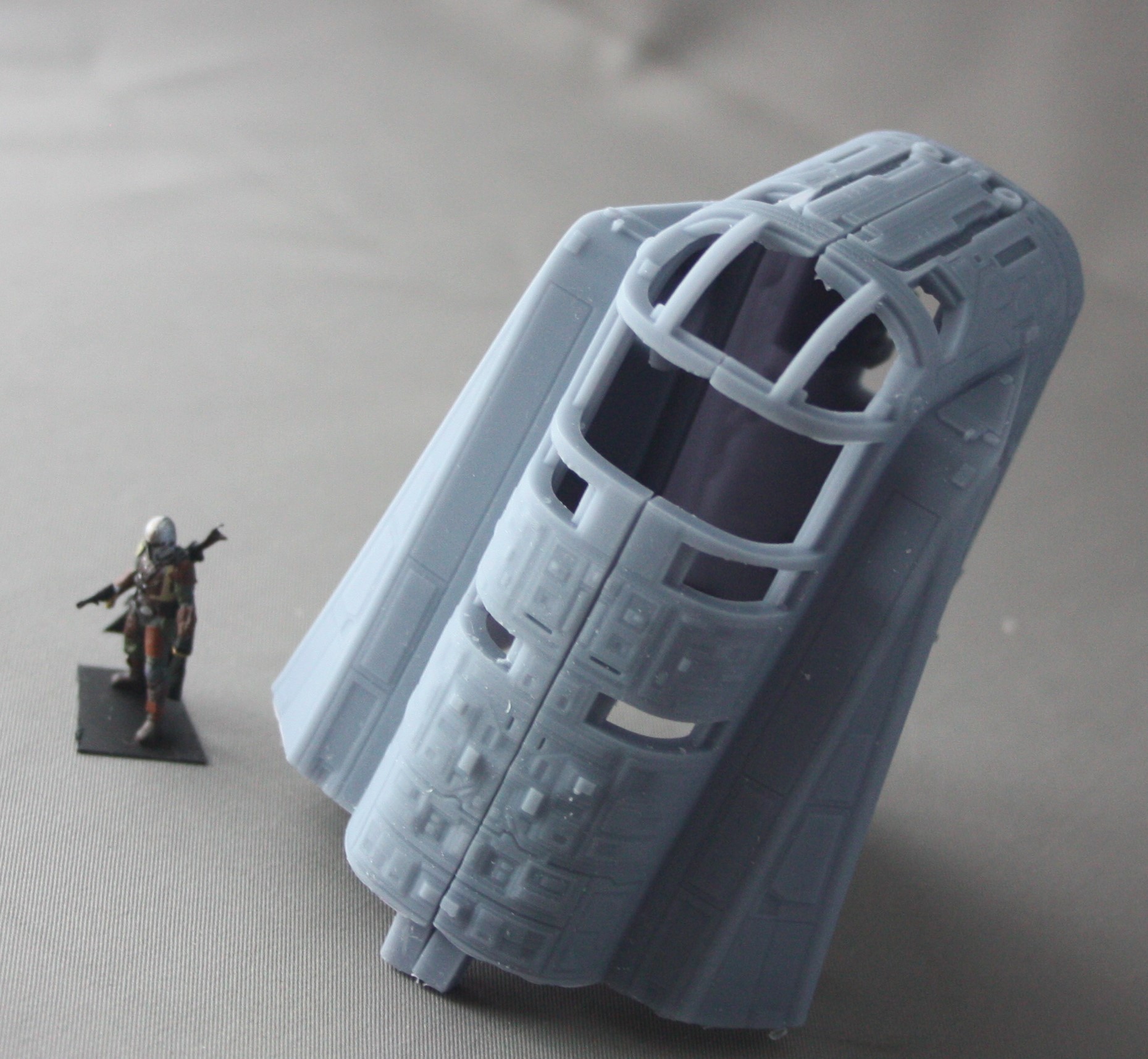

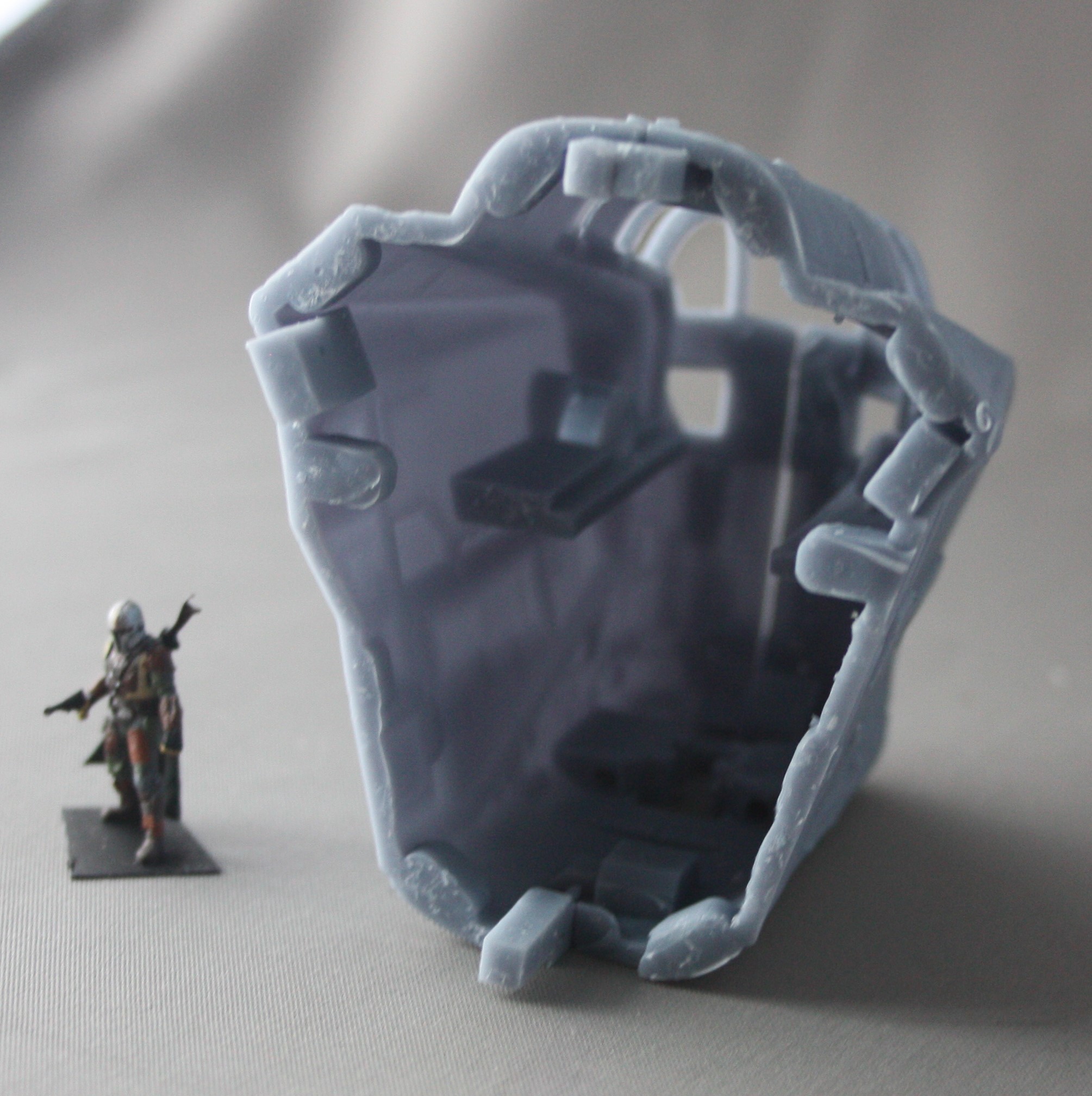

At any rate. after 12 hours of printing on the Anycubic Photon (upgraded) I have the front halves printed

IF anyone else has built, or plans on building this, please feel free to join in and post here as a group build or with any tips or problems you ran into

1/72 Mandalorian for size

There are two scales. 1/34 designed for FDM style printes and 1/68 for DLP/SLA style printers

I debated shrinking it down by 6% to get to 1/72 but I did not want to risk screwing anything by making a part too thin to support etc..

1/68 is close enough anyway considering Bandai's 1/72 kits aren't all true 1/72 scale anyway (B-WIng and A-Wing I am looking at you for starters)

Besides, if all goes well I can always try printing out a scaled down one later and give this one to my brother or someone as a gift

At any rate. after 12 hours of printing on the Anycubic Photon (upgraded) I have the front halves printed

IF anyone else has built, or plans on building this, please feel free to join in and post here as a group build or with any tips or problems you ran into

1/72 Mandalorian for size

Last edited: