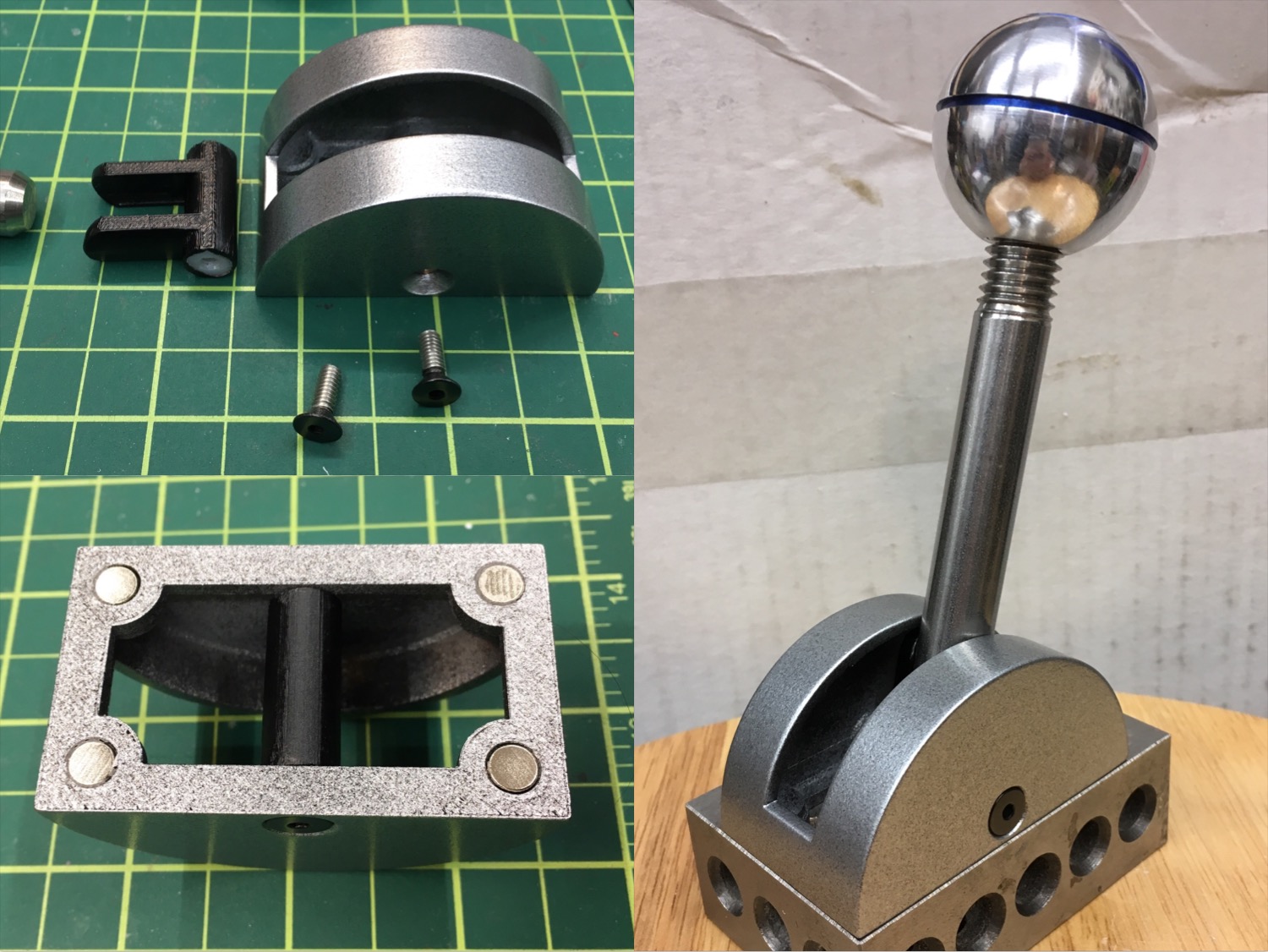

Here's a stand for Grogu's toy ball! It's an attempt to make a more or less screen accurate lever base as seen on the Razor Crest cockpit set.

It features recesses for magnets in the bottom for attaching to metal surfaces - doesn't your fridge need a control lever?

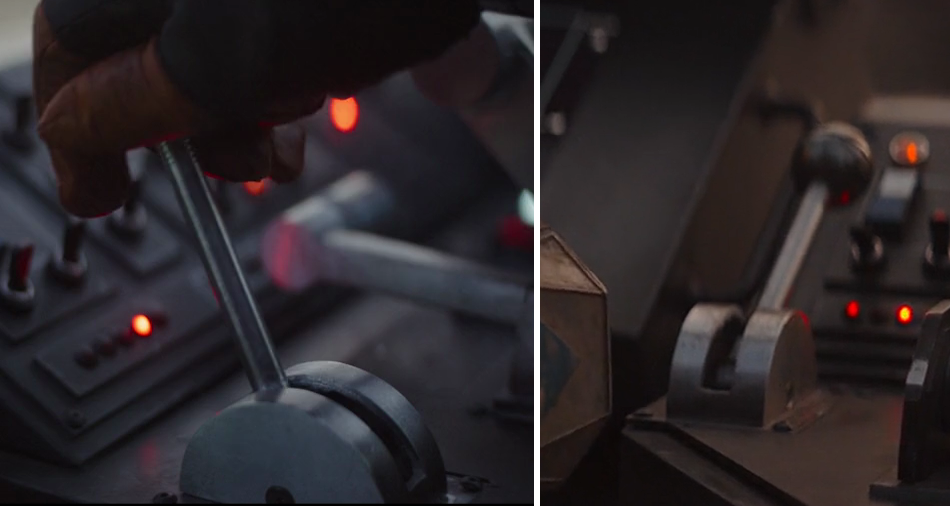

Reference:

2nd episode:

Other episodes (longer lever?)

I used these parts from McMaster for the ball and arm:

Aluminum Ball Knob with 1/2"-13 Threaded Hole, 1-3/8" Head Diameter

https://www.mcmaster.com/6940K47/

18-8 Stainless Steel Partially Threaded Stud 1/2"-13 Thread, 4" Long

https://www.mcmaster.com/97042A552/

The 4" stud is pictured, but I think the 5" or 6" versions are more screen accurate to the actual set.

18-8 Stainless Steel Partially Threaded Stud 1/2"-13 Thread, 5" Long -

https://www.mcmaster.com/97042A119/

18-8 Stainless Steel Partially Threaded Stud 1/2"-13 Thread, 6" Long -

https://www.mcmaster.com/97042A568/

If you already have a ball replica with different threading, here's the overall category page:

https://www.mcmaster.com/partially-threaded-studs/partially-threaded-studs-5/

Optionally, epoxy 4 neodymium disc magnets into the base, either 6x3 mm or 1/4" x 1/8"

You'll also need two 8-32 x 1/2" flat head hex drive screws for the pivot, in black oxide or stainless steel (pictured are two stainless ones, painted black as that's what the local store had, though I now see that the lever in the second episode has stainless screws):

McMaster-Carr

NOTE: When assembling, use a dab of super glue gel to lock the threads of the screws within the pivot piece. The heads of the screw will rotate against the holes in the base (apply some silicone grease under the heads). Without the glue, the screws will loosen as the lever is moved.

Files here:

www.thingiverse.com

www.thingiverse.com

It features recesses for magnets in the bottom for attaching to metal surfaces - doesn't your fridge need a control lever?

Reference:

2nd episode:

Other episodes (longer lever?)

I used these parts from McMaster for the ball and arm:

Aluminum Ball Knob with 1/2"-13 Threaded Hole, 1-3/8" Head Diameter

https://www.mcmaster.com/6940K47/

18-8 Stainless Steel Partially Threaded Stud 1/2"-13 Thread, 4" Long

https://www.mcmaster.com/97042A552/

The 4" stud is pictured, but I think the 5" or 6" versions are more screen accurate to the actual set.

18-8 Stainless Steel Partially Threaded Stud 1/2"-13 Thread, 5" Long -

https://www.mcmaster.com/97042A119/

18-8 Stainless Steel Partially Threaded Stud 1/2"-13 Thread, 6" Long -

https://www.mcmaster.com/97042A568/

If you already have a ball replica with different threading, here's the overall category page:

https://www.mcmaster.com/partially-threaded-studs/partially-threaded-studs-5/

Optionally, epoxy 4 neodymium disc magnets into the base, either 6x3 mm or 1/4" x 1/8"

You'll also need two 8-32 x 1/2" flat head hex drive screws for the pivot, in black oxide or stainless steel (pictured are two stainless ones, painted black as that's what the local store had, though I now see that the lever in the second episode has stainless screws):

McMaster-Carr

NOTE: When assembling, use a dab of super glue gel to lock the threads of the screws within the pivot piece. The heads of the screw will rotate against the holes in the base (apply some silicone grease under the heads). Without the glue, the screws will loosen as the lever is moved.

Files here:

Stand for Grogu's Toy Ball (Razor Crest control lever) by mooslug

A stand for a Baby Yoda toy ball! It's an attempt to make a screen accurate lever base as seen on the Razor Crest cockpit set. It features recesses for magnets in the bottom for attaching to metal surfaces - doesn't your fridge need a control lever? There are two versions of the base...

Attachments

Last edited: