firebirdman

New Member

Ok, it's time to get this build going. I've been dragging my feet long enough, and I figured if I posted a WIP thread in here, that'll force me to actually finish the bloody thing!

So, I'm planning on building the original Pip-Boy, as seen in Fallout 1, Fallout 2 and Fallout Tactics. There's not much reference material available, but that just lets me get creative on the parts that we've never seen.

In short:

- Wrist mounted, like the later models

- Functional, as in Raspberry Pi and a 5" LCD stuffed inside

- Working buttons and other UI elements

- 3D printed

- Based on screenshots from the games

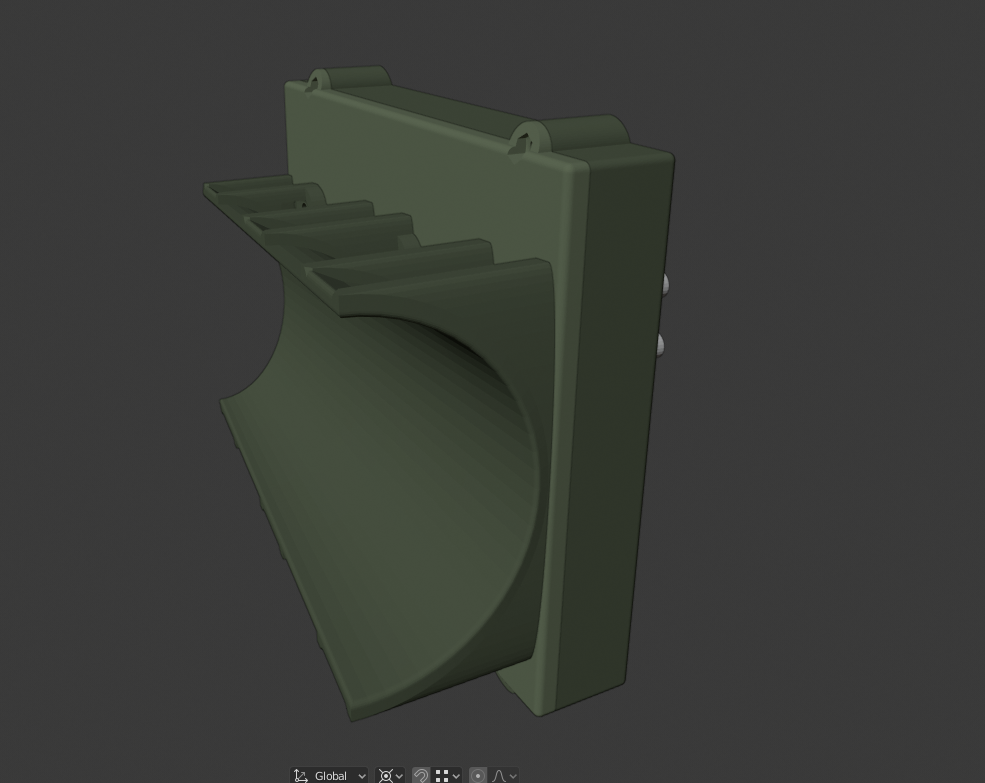

Here's the current state of the design:

Needs a few more details, but I should be able to start printing the pieces fairly soon.

I go to a bit more detail about the design in my blog: Fallout 1/2 style Pip-Boy 2000 replica - Part 1: Design - ampli.fi blog

So, I'm planning on building the original Pip-Boy, as seen in Fallout 1, Fallout 2 and Fallout Tactics. There's not much reference material available, but that just lets me get creative on the parts that we've never seen.

In short:

- Wrist mounted, like the later models

- Functional, as in Raspberry Pi and a 5" LCD stuffed inside

- Working buttons and other UI elements

- 3D printed

- Based on screenshots from the games

Here's the current state of the design:

Needs a few more details, but I should be able to start printing the pieces fairly soon.

I go to a bit more detail about the design in my blog: Fallout 1/2 style Pip-Boy 2000 replica - Part 1: Design - ampli.fi blog