machzeropoint2

New Member

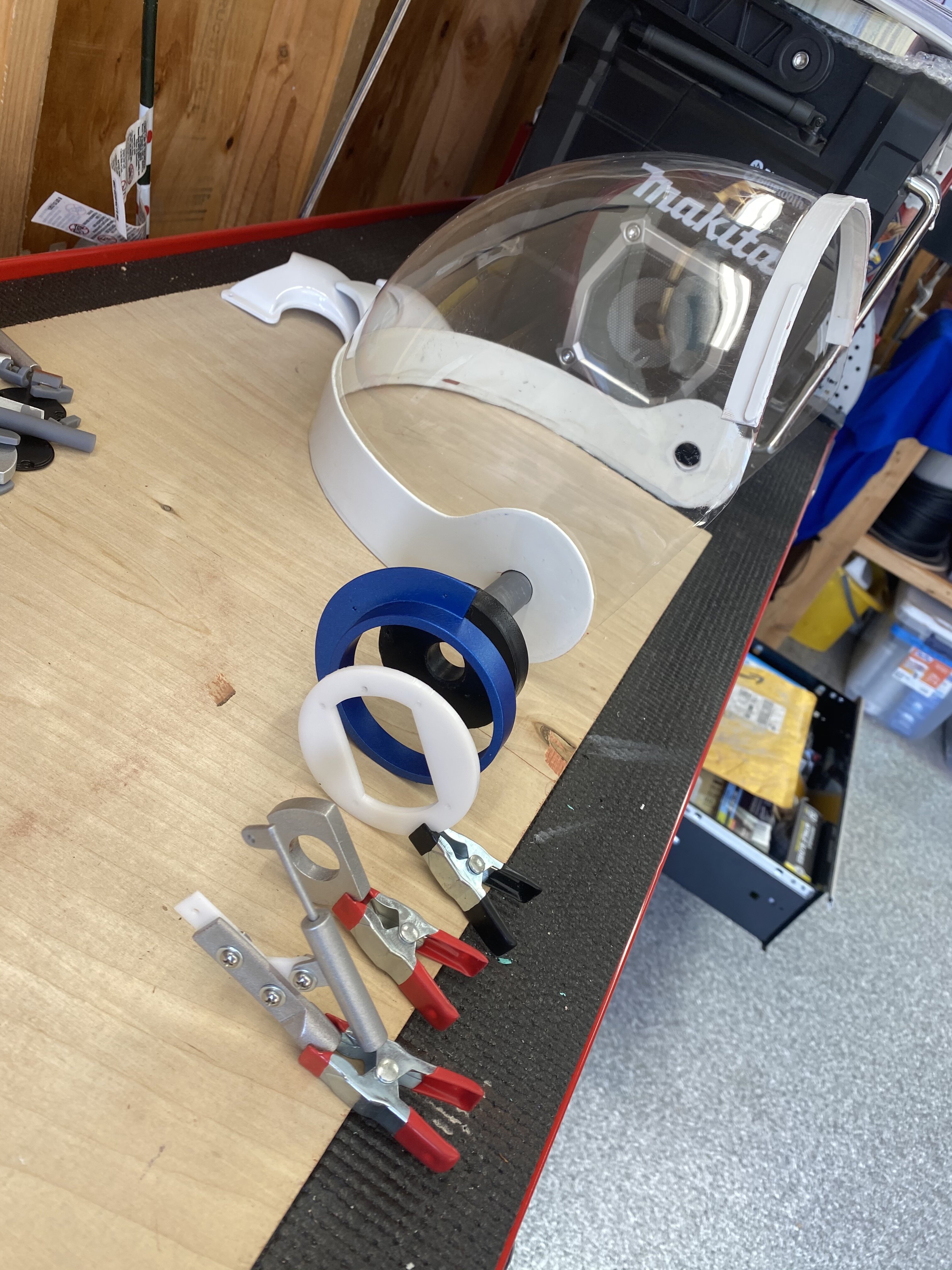

Didn't make quite as much progress as I thought I would this weekend but such is life. The visors took way more finagling then expected to get them just the right shape and size., but hey its starting to look like an actual space helmet!! I tried to take a few picture of the ear assembly as well. I think I will need to come up with some sort of spacer for the ear core (the center cylinder which everything rotates around). When designing I arbitrary said make it 20% longer, with the plan of cutting off the excess, and I think it may still be too short. Also asavage the pictures look great, you could almost be on a gantry somewhere!

It occurs to me after I uploaded the pictures, I mounted the smoke visor upside down...whoops

It occurs to me after I uploaded the pictures, I mounted the smoke visor upside down...whoops