rogerrabt

Active Member

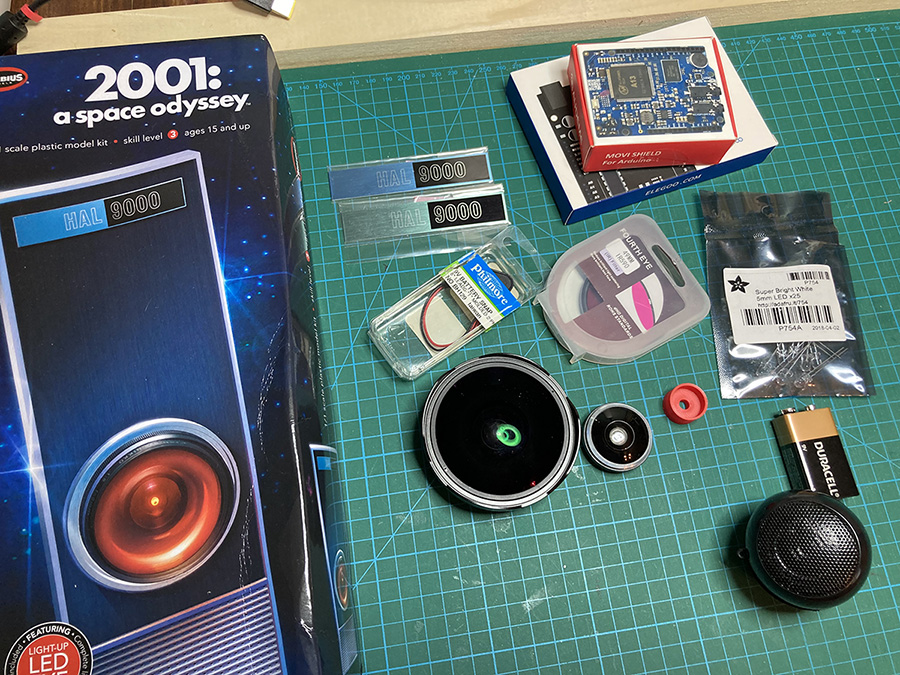

After the incredible disappointment that was the Master Replica fiasco, it's time to build a HAL 9000 that fills that little niche for me. I saw j_holtslander's work from last year and was able to find a few of the parts he used. More on the way.

The Moebius model kit - for dimensions.

HAL 9000 labels - from am Custom Plaques

Arduino and MOVI shield - going to try and make this talk! We all need a psychopathic companion, right?

Red filter from aliexpress

White LEDs

Primary lens from Aliexpress - VELEDGE Ultra Fisheye Lens 37MM 0.3X

Secondary lens from Aliexpress - Cell phone fisheye

Mini-amplified "hamburger" speaker

I have an idea on the red eye. Seems the original Nikkor lens had a 600nm filter built in. I can't find a 600nm filter, but I can find 590 for a reasonable price. Just a touch more orange than 600, but I hope it looks better than a red diode which VERY red at, usually, 630nm.

The Moebius model kit - for dimensions.

HAL 9000 labels - from am Custom Plaques

Arduino and MOVI shield - going to try and make this talk! We all need a psychopathic companion, right?

Red filter from aliexpress

White LEDs

Primary lens from Aliexpress - VELEDGE Ultra Fisheye Lens 37MM 0.3X

Secondary lens from Aliexpress - Cell phone fisheye

Mini-amplified "hamburger" speaker

I have an idea on the red eye. Seems the original Nikkor lens had a 600nm filter built in. I can't find a 600nm filter, but I can find 590 for a reasonable price. Just a touch more orange than 600, but I hope it looks better than a red diode which VERY red at, usually, 630nm.

Last edited: