I’ve been tail chasing a bit here with the grips..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

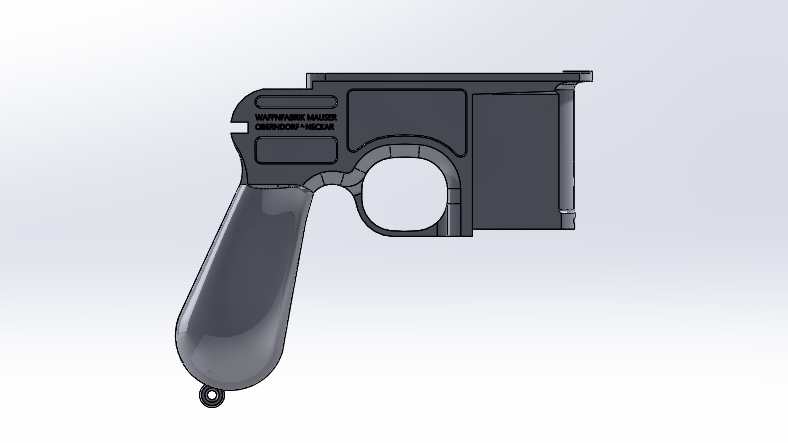

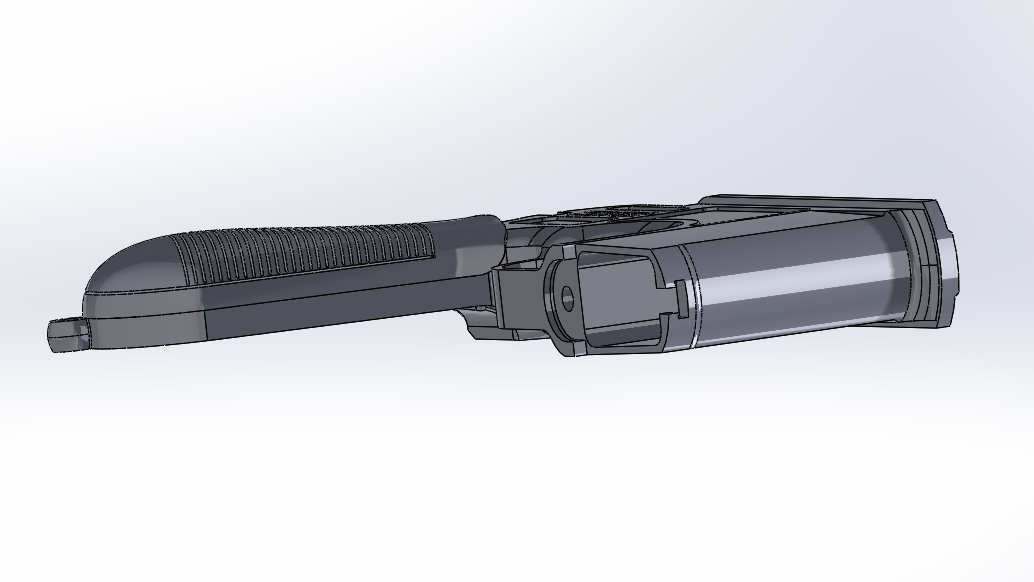

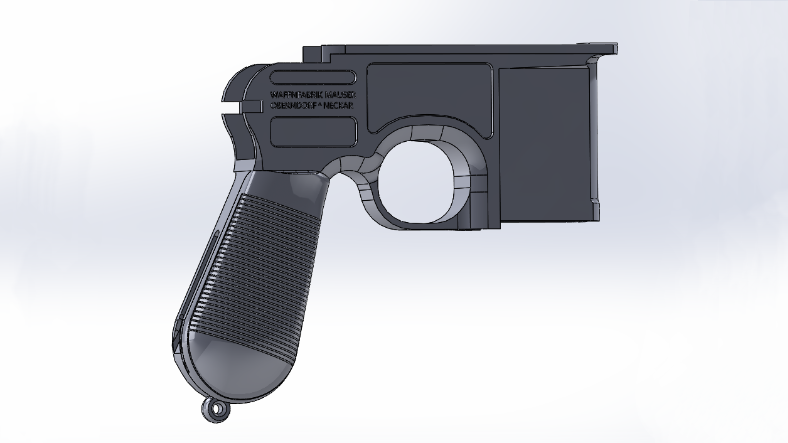

DL-44 FDM c96 & MGC replicas…

- Thread starter chubsANDdoggers

- Start date

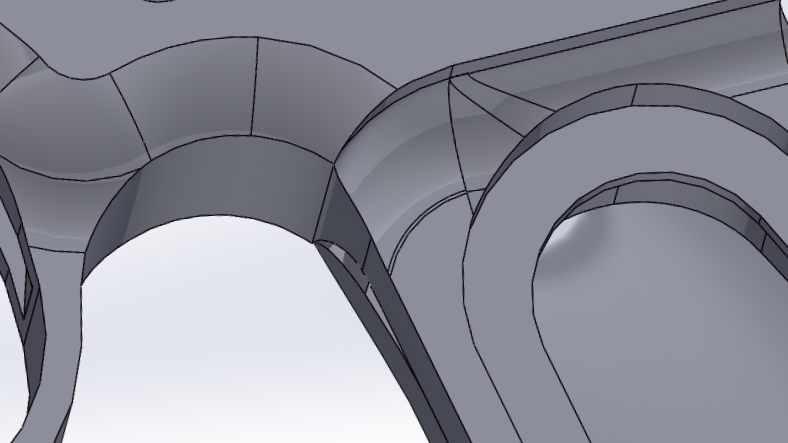

I'm with Deadbolt on how the grips were originally made, as I think I mentioned before. Turned on a lathe then cut in half (this became apparent when trying to make some from wood). Yours are looking good, perhaps a little squared off around the outer edge of the inward curve? (not quite cylindrical enough, if that makes sense). It's a bit hard to tell with rendered pics. The rest of the gun, well damn man, looks very nearly perfect! I'm amazed.

Can I talk you into further explanation on this?I mocked up a grip model for Dave and he built a jig to hold the halves. fairly simple to cut if the jig is correct. You get the shape and grooves at the same time.

I think a 3d scan would be of help to me at least haha! It's an MGC? I'd love to get my hands on the scan if possible. I should add that if dibs as a thing, John should get it!Would a 3D scan be of any help to you?

Last edited:

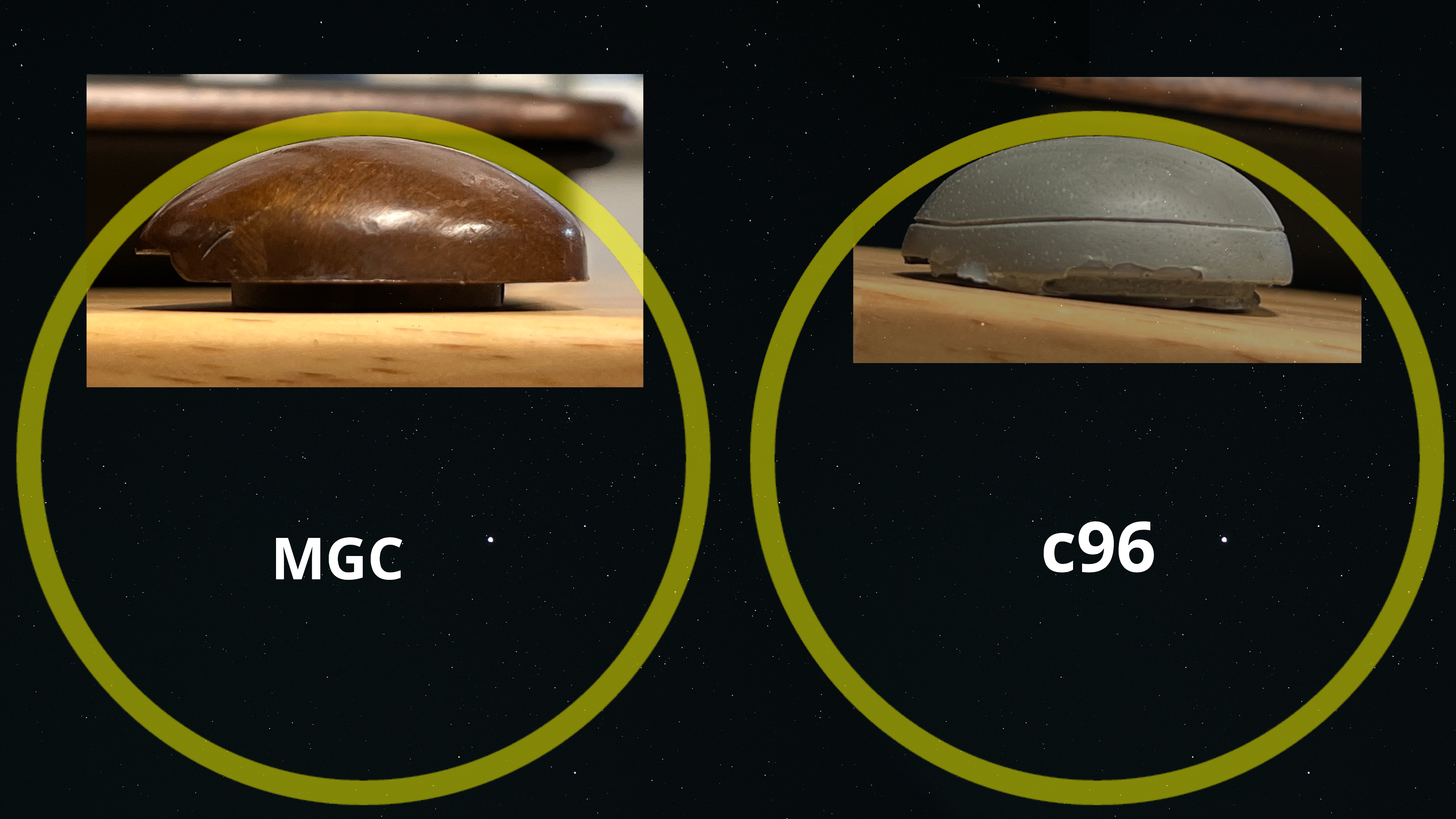

There are also many variations of these Mauser grips over the years which isn’t helping my OCDness in pining down the exact details I’m after. Obviously trying to focus in on the prewar Mauser as (correct me if I’m wrong) that was what was used for the hero itself. MGC and c96 grips are very different in detail as the MGC grips are more form fitting right into the Mauser itself as they where casted. The c96 seem to be more simply “fitted”. There is also a subtle over lap of the wood and the Mauser handle itself which isn’t on the MGC. Mostly on the top inside of each grip it looks like. The outside shape is another issue. I don’t think the grips where simply turned in a lathe.. but I also don’t own or have ever operated one either so? The shape of the grips seem to have some work that a lathe couldn’t do?? These are the best pics I’ve found of the grips themselves for reference..

deadbolt

Sr Member

There certainly seems to have been a lot of hand work/fitting, especially on the bottom-side towards the top for them to fit the contours there on the originals.

The initial shape all the way down to the large radius on the bottom seem to have been done by lathe, the grip blanks (small blocks of wood) just need to be separated to match the center-point of all of the radius'. I don't know solid works at all, but if you're able to find the center point of any of the radius' on your grips (which look great btw!), that center will be the same for all other radius' on the grips from top to bottom. Just the outside shape, slight flat around the outer edge, hand-fitting and the long line around the side lining around the grip where the bottom-most of the top lines end are likely done by hand. The shape itself and the top lines can be done with Pat's/Dave's/Mauser's jig and will cover the majority of the work.. I just wish I realized that when I was modeling them, I had a hell of a time 'trying' to do mine simply because I hadn't thought about them being spaced apart and turned. Pat and Dave figured it out!..would have made modeling them much easier and realistic. =b

Here's an example of Dave's grips on my Mauser, they're fully turned on the top-side, machined on the outside profile and the bottom, then hand worked the rest of the way from there:

Real vs. Dave's,

Keep up the good work, man!

P.S. note the difference Mauser had over the years as far as the quantity of grip lines too, and we're not fully sure if the Hero had that outer line running around the outside beneath the top-most lines..simply because we don't have any clear photos showing it there or not. Same as the rear serial #'s sadly.. We simply can't see them, there's likely two different full serial numbers there between the lock frame and the lower frame because of the Bapty frame swap.

-Carson

The initial shape all the way down to the large radius on the bottom seem to have been done by lathe, the grip blanks (small blocks of wood) just need to be separated to match the center-point of all of the radius'. I don't know solid works at all, but if you're able to find the center point of any of the radius' on your grips (which look great btw!), that center will be the same for all other radius' on the grips from top to bottom. Just the outside shape, slight flat around the outer edge, hand-fitting and the long line around the side lining around the grip where the bottom-most of the top lines end are likely done by hand. The shape itself and the top lines can be done with Pat's/Dave's/Mauser's jig and will cover the majority of the work.. I just wish I realized that when I was modeling them, I had a hell of a time 'trying' to do mine simply because I hadn't thought about them being spaced apart and turned. Pat and Dave figured it out!..would have made modeling them much easier and realistic. =b

Here's an example of Dave's grips on my Mauser, they're fully turned on the top-side, machined on the outside profile and the bottom, then hand worked the rest of the way from there:

Real vs. Dave's,

Keep up the good work, man!

P.S. note the difference Mauser had over the years as far as the quantity of grip lines too, and we're not fully sure if the Hero had that outer line running around the outside beneath the top-most lines..simply because we don't have any clear photos showing it there or not. Same as the rear serial #'s sadly.. We simply can't see them, there's likely two different full serial numbers there between the lock frame and the lower frame because of the Bapty frame swap.

-Carson

Last edited:

Thank you for that! I follow fully what you are saying and that back picture is perfect. I haven't been able to find one directly from behind showing the full grip itself. The last picture is that still with the real c96 grip on the opposite side? You can really see the overhang there if it is..

Pedro that link also has some nice pics as well. Great pic from behind. Thank you P!

Here’s the problem I don’t understand and maybe it’s more the fact that I don’t know all the things lathes are capable of? Baseball bats I believe are made on lathes so that’s where my mind always goes. My question is in this pic. I have a pair of resin c96 grips and the ones I have are clearly not symmetrical. Not like the MGC grips or am I misunderstanding something basic..

Here’s the problem I don’t understand and maybe it’s more the fact that I don’t know all the things lathes are capable of? Baseball bats I believe are made on lathes so that’s where my mind always goes. My question is in this pic. I have a pair of resin c96 grips and the ones I have are clearly not symmetrical. Not like the MGC grips or am I misunderstanding something basic..

Last edited:

I sometimes scour auction sites for pictures of guns, best place to find high resolution straight on shots!

Again, this is all in my mind for now, so grains of salt...

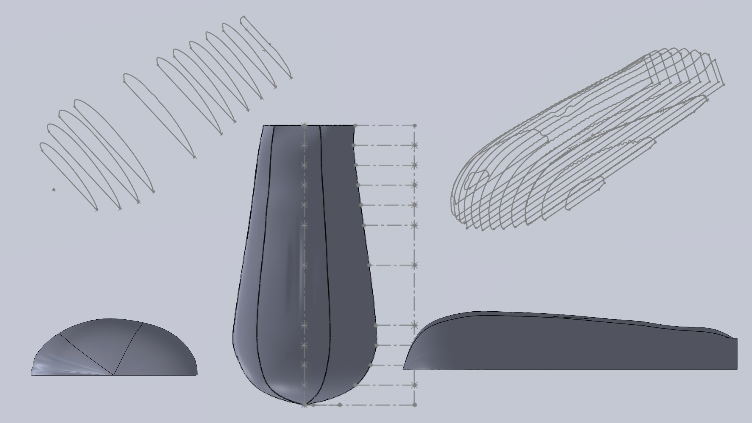

Picture cutting a cone shape on the lathe, probably steeper taper than a baseball bat, and you round off the butt (possibly indicated by the bottom side profile of the grip?). I imagine that the thin side is around 4" diameter, maybe 6-7" on the other, about 5" long? (total guess!)

Then you cut slices from the side of the cone, but don't cut it down the center, instead cut more parallel to the taper. Chop the end off of the skinnier side of your slice and you have the basic grip shape. The sides might then need flattened a bit, and whatever that curvy business up at the top is. Then you have the step in the back etc. I don't know that they were made like this, but that's the best way I can imagine doing it. I think. I hope that clarifies the idea anyway?

I hope that clarifies the idea anyway?

I have some real grips and resin casts of old serial numbered grips, I'll try to post some pictures for you soon.

Again, this is all in my mind for now, so grains of salt...

Picture cutting a cone shape on the lathe, probably steeper taper than a baseball bat, and you round off the butt (possibly indicated by the bottom side profile of the grip?). I imagine that the thin side is around 4" diameter, maybe 6-7" on the other, about 5" long? (total guess!)

Then you cut slices from the side of the cone, but don't cut it down the center, instead cut more parallel to the taper. Chop the end off of the skinnier side of your slice and you have the basic grip shape. The sides might then need flattened a bit, and whatever that curvy business up at the top is. Then you have the step in the back etc. I don't know that they were made like this, but that's the best way I can imagine doing it. I think.

I have some real grips and resin casts of old serial numbered grips, I'll try to post some pictures for you soon.

deadbolt

Sr Member

I think Mauser just used a smaller/tighter radius than what MGC went for, then the sanding and hand worked stuff comes in. Note where the grip lines end, that would be the point where the handwork and such ends causing flats, different radius' and no visible lines around the edge. Otherwise the lines would go all the way to the bottom edge of the grips. But of course all wartime Mausers were made in a rush too, so they all vary quite a bit here and there..

I noticed how clean the machining is on the pre-war Mauser above that Pedro posted, especially in the pockets above the trigger etc., vs. the wartime Mausers. Time = money, especially during war unfortunately..

-Carson

I noticed how clean the machining is on the pre-war Mauser above that Pedro posted, especially in the pockets above the trigger etc., vs. the wartime Mausers. Time = money, especially during war unfortunately..

-Carson

kpax

Sr Member

There were no doubt secondary operations after the basic shaping that would include rasping and scraping/finishing etc.

After the upper turning the edges would be rasped and rounded.

The grip grooves are different shapes and sizes but mostly V grooves. The grooves fade at the edges as groove meets the "round turning" edge. The final shaping and sanding cause the rounding and blending of the shapes.

The slight scribed line on the outside edge was likely made by a simple height gauge scraper after the turning as a finishing touch. A worker would just run a scraper around the grip edge by hand which is why the lines are not all exactly the same and perfect. Some start and stop at different points.

Some hand work after the basic shaping makes the DEC grips match really well.

Note that some examples have a slight shaping on the top front edge that blends with the trigger guard a bit. This was likely done by rasp. They would rough fit the wood on a frame and rasp to shape. Maybe this was for the slightly better finished versions? Maybe they had several levels of finish?

Like Carson said, Mausers were made pretty rough and fast. They didn't worry about perfect fit. The tolerances were not tight and barely interchangeable if at all. Even for grips which is why there are spaces and gaps or overhangs on some examples.

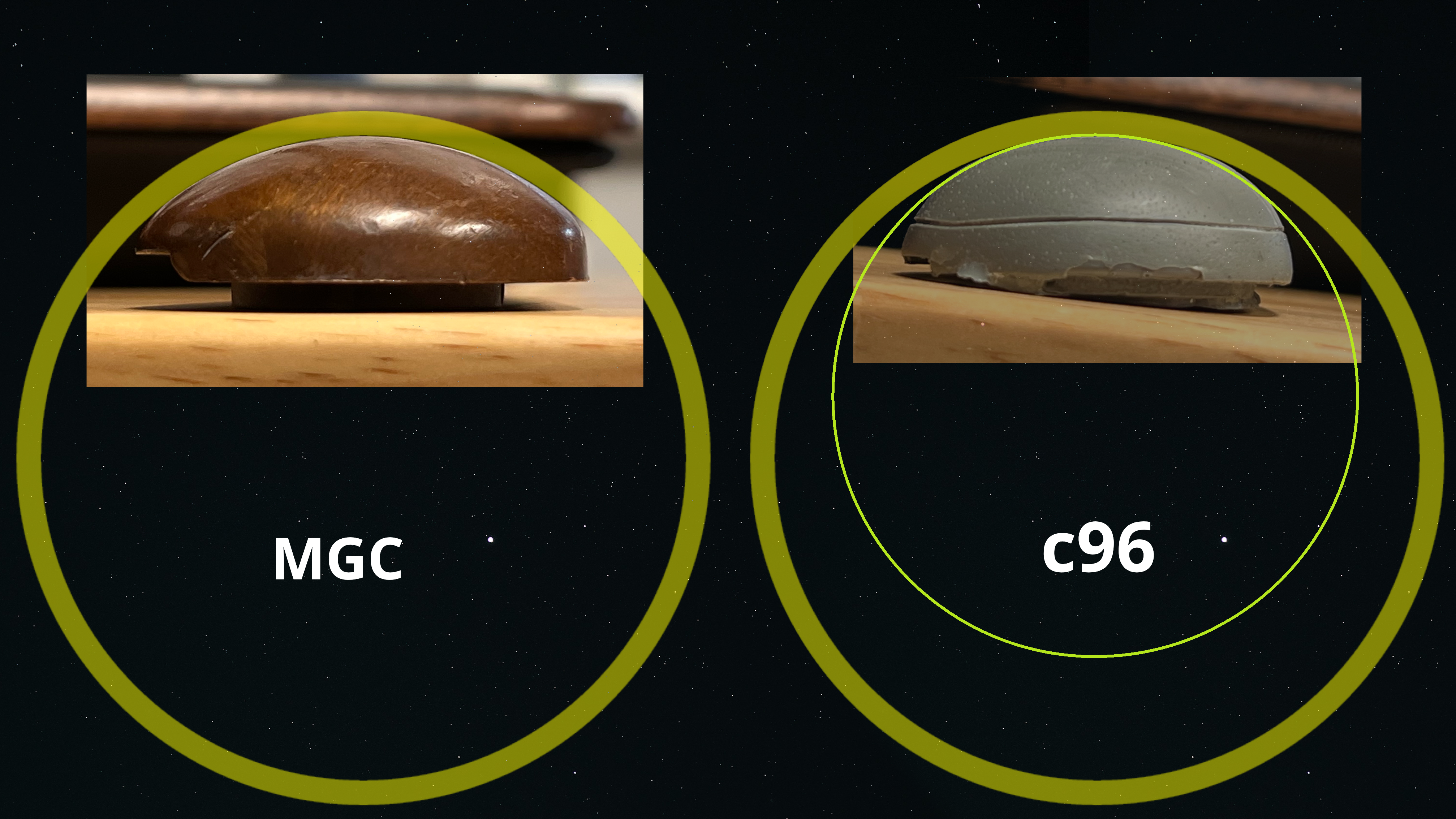

Basic set up below.

blue line is the grip groove depth

After the upper turning the edges would be rasped and rounded.

The grip grooves are different shapes and sizes but mostly V grooves. The grooves fade at the edges as groove meets the "round turning" edge. The final shaping and sanding cause the rounding and blending of the shapes.

The slight scribed line on the outside edge was likely made by a simple height gauge scraper after the turning as a finishing touch. A worker would just run a scraper around the grip edge by hand which is why the lines are not all exactly the same and perfect. Some start and stop at different points.

Some hand work after the basic shaping makes the DEC grips match really well.

Note that some examples have a slight shaping on the top front edge that blends with the trigger guard a bit. This was likely done by rasp. They would rough fit the wood on a frame and rasp to shape. Maybe this was for the slightly better finished versions? Maybe they had several levels of finish?

Like Carson said, Mausers were made pretty rough and fast. They didn't worry about perfect fit. The tolerances were not tight and barely interchangeable if at all. Even for grips which is why there are spaces and gaps or overhangs on some examples.

Basic set up below.

blue line is the grip groove depth

Last edited:

Just a heads up, the hero was believed to be a wartime commercial model.

Last edited:

MastahBlastah Thank you for that.

Just an update..

Last edited:

Thanks P! And yes as Pedro just said great breakdown on the grip kpax! Thank you. I’ve been so caught up in trying to break the code with these grips I didn’t reply here myself to your post. But it’s very helpful and informative. Those groves I fear will be another headache to do but I’ve been thinking about how to do those as well. Because the surface is not “even” I think I’m going to have to do each one individually and that adds up to 31 individual lines on 31 individual planes. Ouch! But fingers cross it will look the part

kpax

Sr Member

Just remember that the surface is “ supposed to be” even. When made fresh and new.

The unevenness comes from wear. This washes away some surface making some grooves “look” thinner or misshaped in places.

When turned, the grooves naturally follow whatever contour/side profile the grip shape is.

Just a negative drop.

The unevenness comes from wear. This washes away some surface making some grooves “look” thinner or misshaped in places.

When turned, the grooves naturally follow whatever contour/side profile the grip shape is.

Just a negative drop.

I'm not sure how to do this in solid works, but in Fusion I'd create a drawing of the lines going across the grip (basically thing rectangles, with the long sides being top and bottom of each scribed groove). Then use this to slice the grip piece (a couple ways to do that), and extrude the thin slices downward to create the grove, probably with a bit of taper to make a V shape. Good luck!

I decided to do a quick 3d test of this method and see what happens. I didn't actually use any measurements, this is a complete approximation and not at all accurate, but it does show how this can work! Hope this is appropriate to post here.

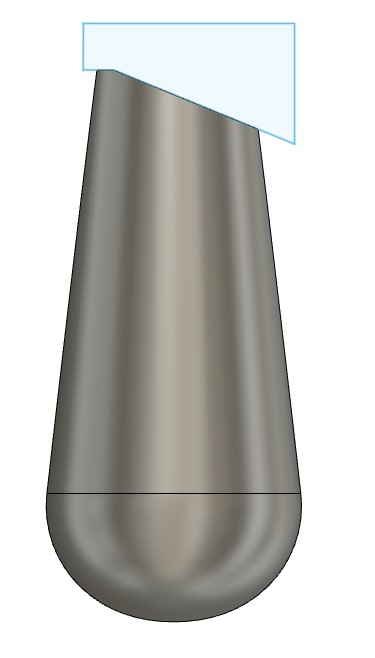

A simple cone:

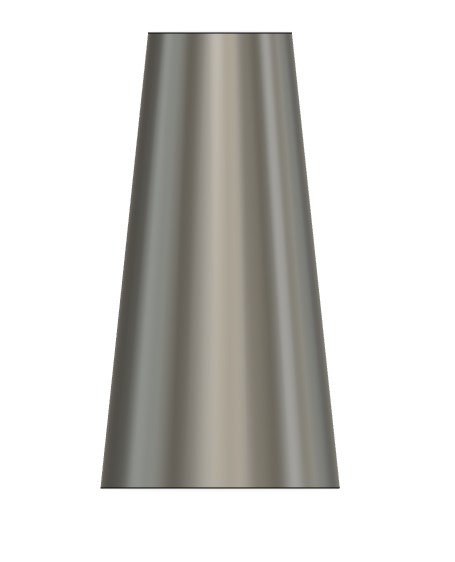

Fillet the long edge (cone should be more tapered, oh well):

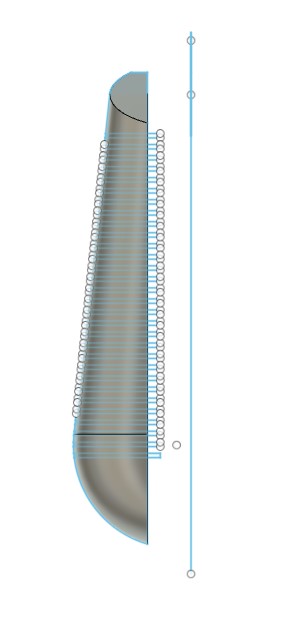

Slice the hone horizontally, off-center (this measurement can be gleaned from the thickest part of the real grip):

Chop off the top:

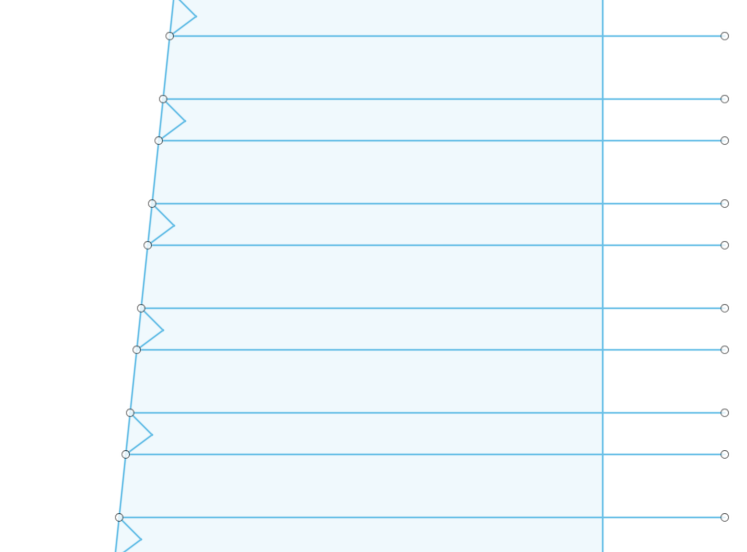

Lay out the scribed lines. These are way off, sloppy (looks like an eBay replacement grip ha!). The line on the right is the original center of the cone. You need this.:

What I did was draw triangles (profile of the cuts you want) between the lines, then revolve them around the original cone center. This is like a lathe, it rotates the profile around a center line. I'm not sure what the SW equivalent would be, but I'm sure there's a function. Here's a closeup of the layout above:

Cutting the revolved triangles into the cone, you get this. Other than being mal-proportioned, I think it works! The rest is hand work, or fillets and stuff if working in 3d.

I hope this is helpful, or at least interesting. Keep up the great work, you're almost there! I expect to see a BUNCH of blasters built on this.

Keep up the great work, you're almost there! I expect to see a BUNCH of blasters built on this.

A simple cone:

Fillet the long edge (cone should be more tapered, oh well):

Slice the hone horizontally, off-center (this measurement can be gleaned from the thickest part of the real grip):

Chop off the top:

Lay out the scribed lines. These are way off, sloppy (looks like an eBay replacement grip ha!). The line on the right is the original center of the cone. You need this.:

What I did was draw triangles (profile of the cuts you want) between the lines, then revolve them around the original cone center. This is like a lathe, it rotates the profile around a center line. I'm not sure what the SW equivalent would be, but I'm sure there's a function. Here's a closeup of the layout above:

Cutting the revolved triangles into the cone, you get this. Other than being mal-proportioned, I think it works! The rest is hand work, or fillets and stuff if working in 3d.

I hope this is helpful, or at least interesting.

Similar threads

- Replies

- 2

- Views

- 595

- Replies

- 9

- Views

- 745

- Replies

- 0

- Views

- 338