MastahBlastah your not derailing anything. The more info the better for us who are not as familiar with other details. My obsession has been these blasters but I know when it come to breaking this stuff down hi res pics are as good as gold and you sometimes need someone to point out the obvious for it to shine just a little brighter. Thanks for sharing what catches ur eye!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

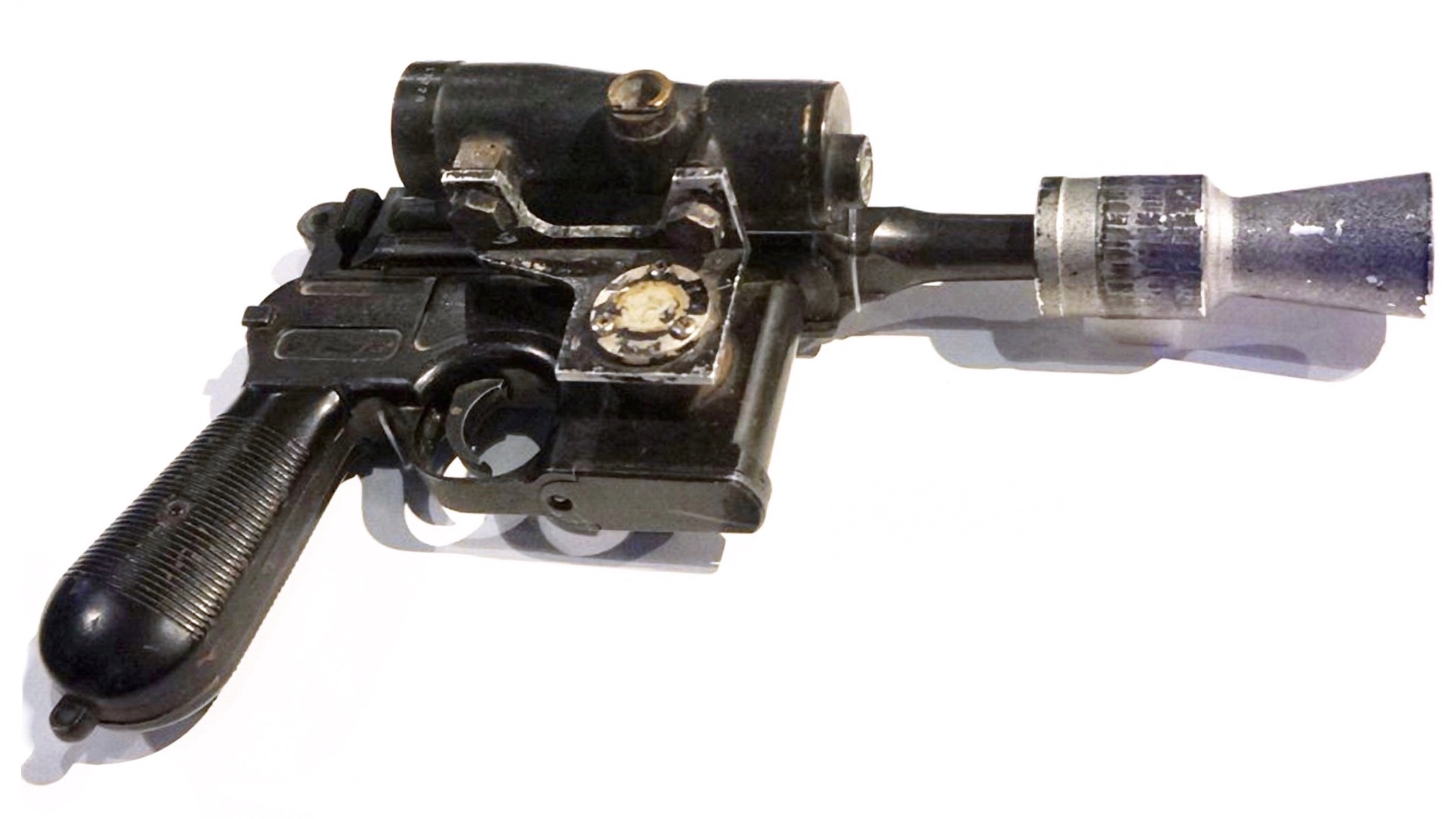

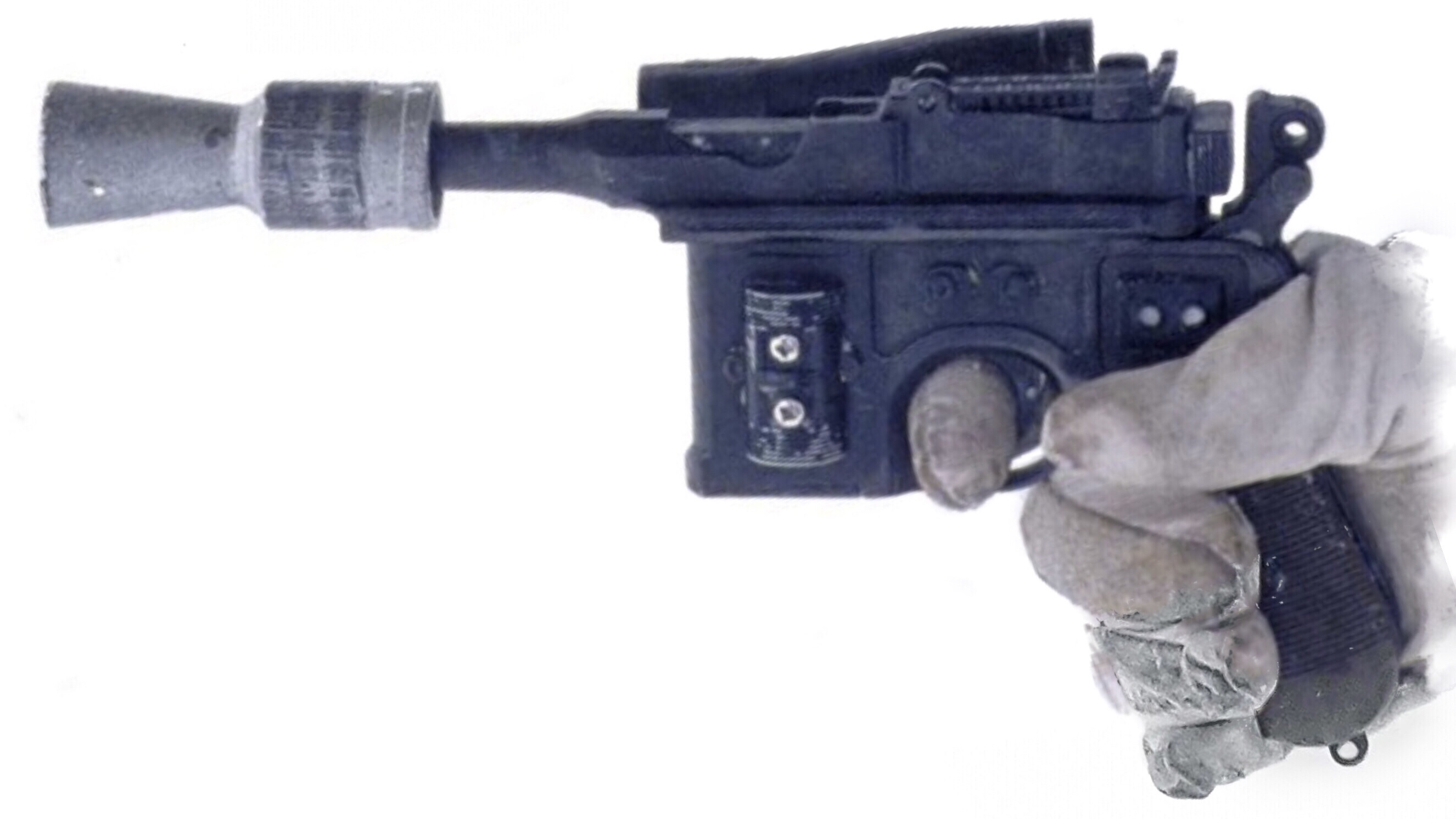

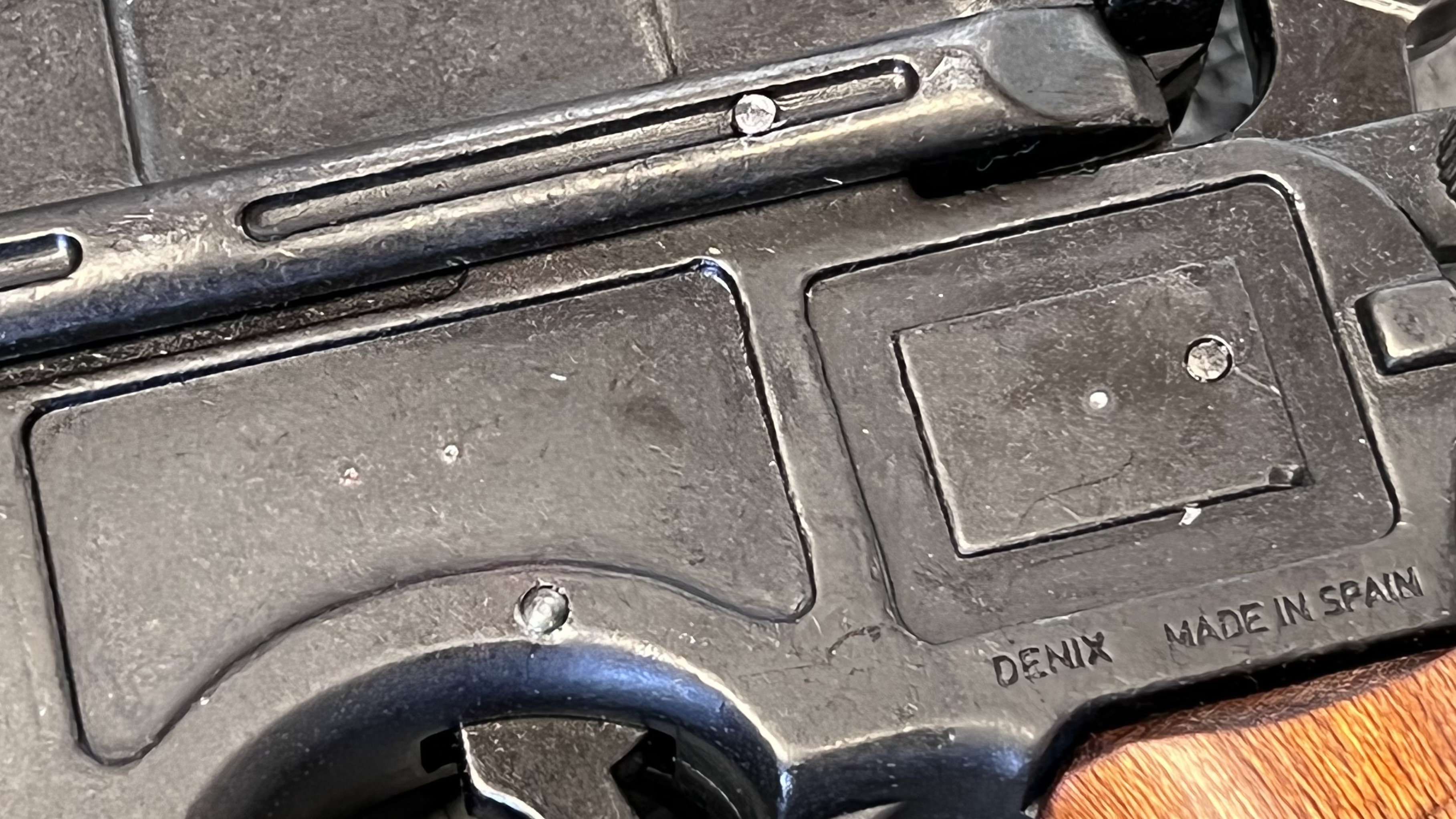

DL-44 FDM c96 & MGC replicas…

- Thread starter chubsANDdoggers

- Start date

Beautiful build! Really amazing work you've done. Thanks for sharing

Beautiful build! Really amazing work you've done. Thanks for sharing

Much appreciated Anakin! I know u have a great attention to detail yourself so thank you for the compliment!

Last edited:

deadbolt

Sr Member

I'll take this info to their appropriate threads

Please do!

As I mentioned, I myself haven't followed that prop or the belt greeblies very much either.. I've mostly focused on the Hero DL-44, Merr Sonn and the ESB/ROTJ stunts, as far as SW goes.....and I would so much love to see something new of the ANH Comlink! I've always been obsessed with that prop as well

..Work and family life kinda gets in the way nowadays to study as much as I'd like to, but I think most of us here have experienced that a time or two over the years. =b

-Carson

deadbolt

Sr Member

Also, great work on your Merr Sonn parts too, and thank you for sharing everything! I too (Pat can attest as well, haha) with my very first CAD model, before the project, was done the same way. By measuring from a screen, in this case my home computer screen. But then I realized how to insert and scale the photos we had at the time into my CAD software, and it made a huge difference.

The first model I ever made when I started out in modeling (never posted, but Pat saw pictures of it when we first met), was of the grill. It looked barely okay, but when the project really started publicly, Pat noticed the offset top portion of the Hero's 3 piece grill. Initially I couldn't figure out why mine and all the others weren't setting close enough to the mag-well of the Mauser as the real prop's did.. It was a huge revelation for me personally when Pat pointed out the offset top, that changed the geometry completely and everything finally made sense, came together and fell right in place.

The only thing I would suggest is, always measure your photos from the largest 'known/found' part, in this case the Mauser. If you measure from the very front of the mag-well to the back of the frame, you'll get much closer measurements when working from photos and all of the smaller parts on it. Measuring from a short/much smaller area like the mag-well base plate, it can cause an illusion of accuracy. Always measure from the largest known part is what I learned. If I measured from the MG81 FH then everything would have been waay off on my models back when, rather than within fractions of a .mm as they turned out.

The first Mega-Run grills were actually modeled from a much, much lower quality Merr Sonn photo we had at the time, and the primary basing was the length of the Mauser's lower frame for scaling to get the closest dimensions I could get of the Veron cylinder-halves, which hadn't been found yet.

Best of luck buddy, and keep up the good work!

-Carson

The first model I ever made when I started out in modeling (never posted, but Pat saw pictures of it when we first met), was of the grill. It looked barely okay, but when the project really started publicly, Pat noticed the offset top portion of the Hero's 3 piece grill. Initially I couldn't figure out why mine and all the others weren't setting close enough to the mag-well of the Mauser as the real prop's did.. It was a huge revelation for me personally when Pat pointed out the offset top, that changed the geometry completely and everything finally made sense, came together and fell right in place.

The only thing I would suggest is, always measure your photos from the largest 'known/found' part, in this case the Mauser. If you measure from the very front of the mag-well to the back of the frame, you'll get much closer measurements when working from photos and all of the smaller parts on it. Measuring from a short/much smaller area like the mag-well base plate, it can cause an illusion of accuracy. Always measure from the largest known part is what I learned. If I measured from the MG81 FH then everything would have been waay off on my models back when, rather than within fractions of a .mm as they turned out.

The first Mega-Run grills were actually modeled from a much, much lower quality Merr Sonn photo we had at the time, and the primary basing was the length of the Mauser's lower frame for scaling to get the closest dimensions I could get of the Veron cylinder-halves, which hadn't been found yet.

Best of luck buddy, and keep up the good work!

-Carson

Last edited:

Thanks deadbolt!

My only limitation is my calipers won’t allow me to measure that distance I don’t think. But I definitely understand what you are saying and very much appreciate the guidance. In all honesty one of the things I learned very quickly with solidworks was infact the ability to bring in pictures. It is/was also very frustrating to think just how long I did things the hard way. It’s all a learning experience though and you still need to fully understand CAD and how it works.. but damn if it doesn’t make things just that much easier.

We are in a much better place today simply because of the ground work that’s already been laid. Much respect to those before us who wore the hard hats and did the dirty work. Cheers!!

My only limitation is my calipers won’t allow me to measure that distance I don’t think. But I definitely understand what you are saying and very much appreciate the guidance. In all honesty one of the things I learned very quickly with solidworks was infact the ability to bring in pictures. It is/was also very frustrating to think just how long I did things the hard way. It’s all a learning experience though and you still need to fully understand CAD and how it works.. but damn if it doesn’t make things just that much easier.

We are in a much better place today simply because of the ground work that’s already been laid. Much respect to those before us who wore the hard hats and did the dirty work. Cheers!!

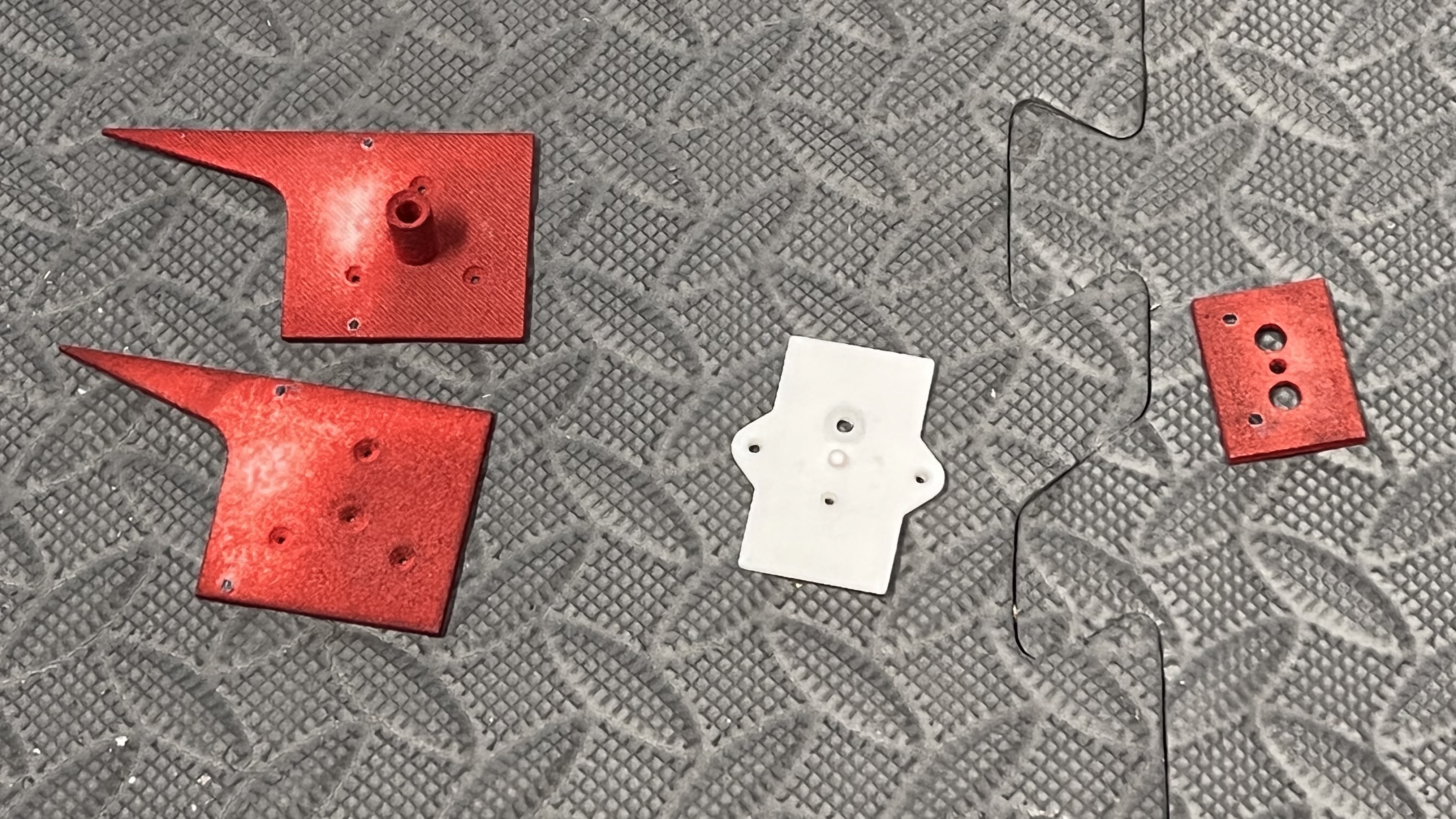

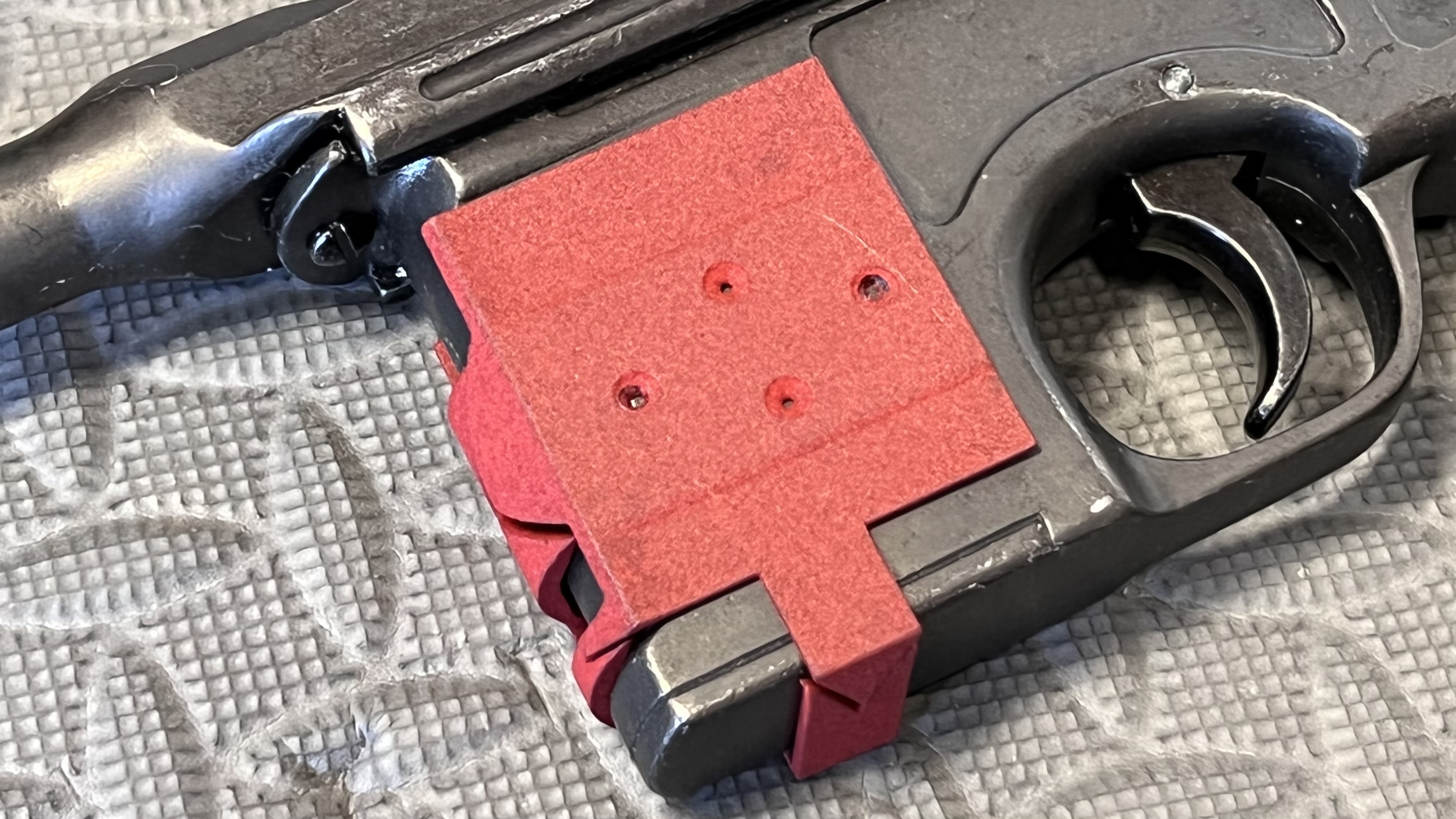

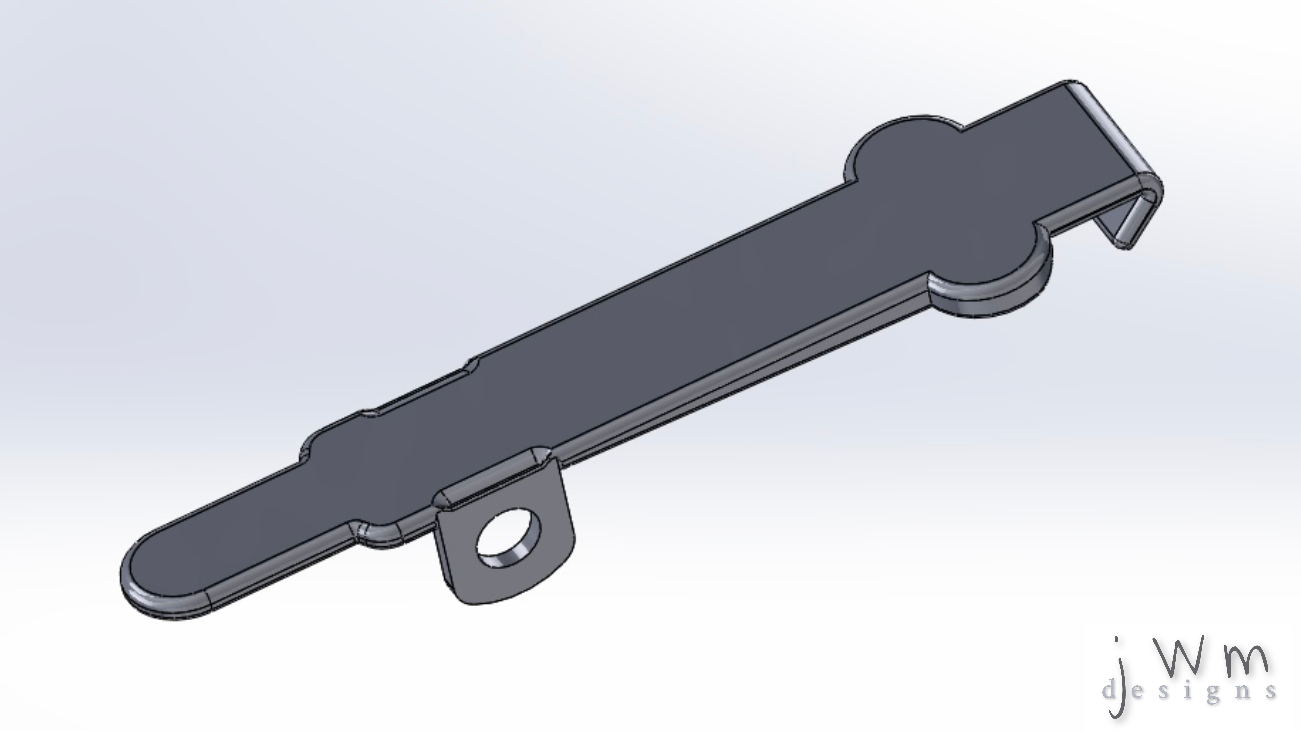

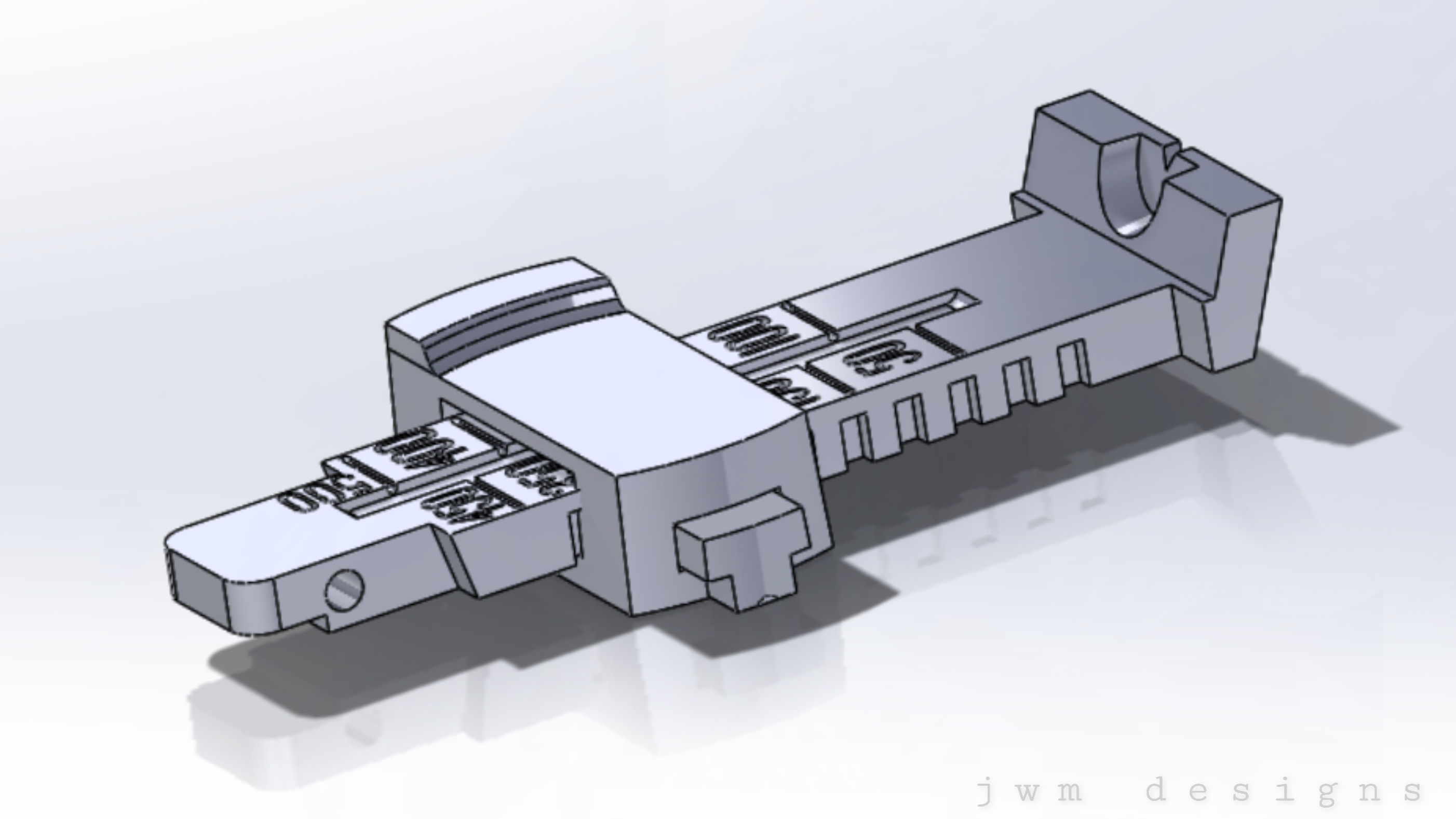

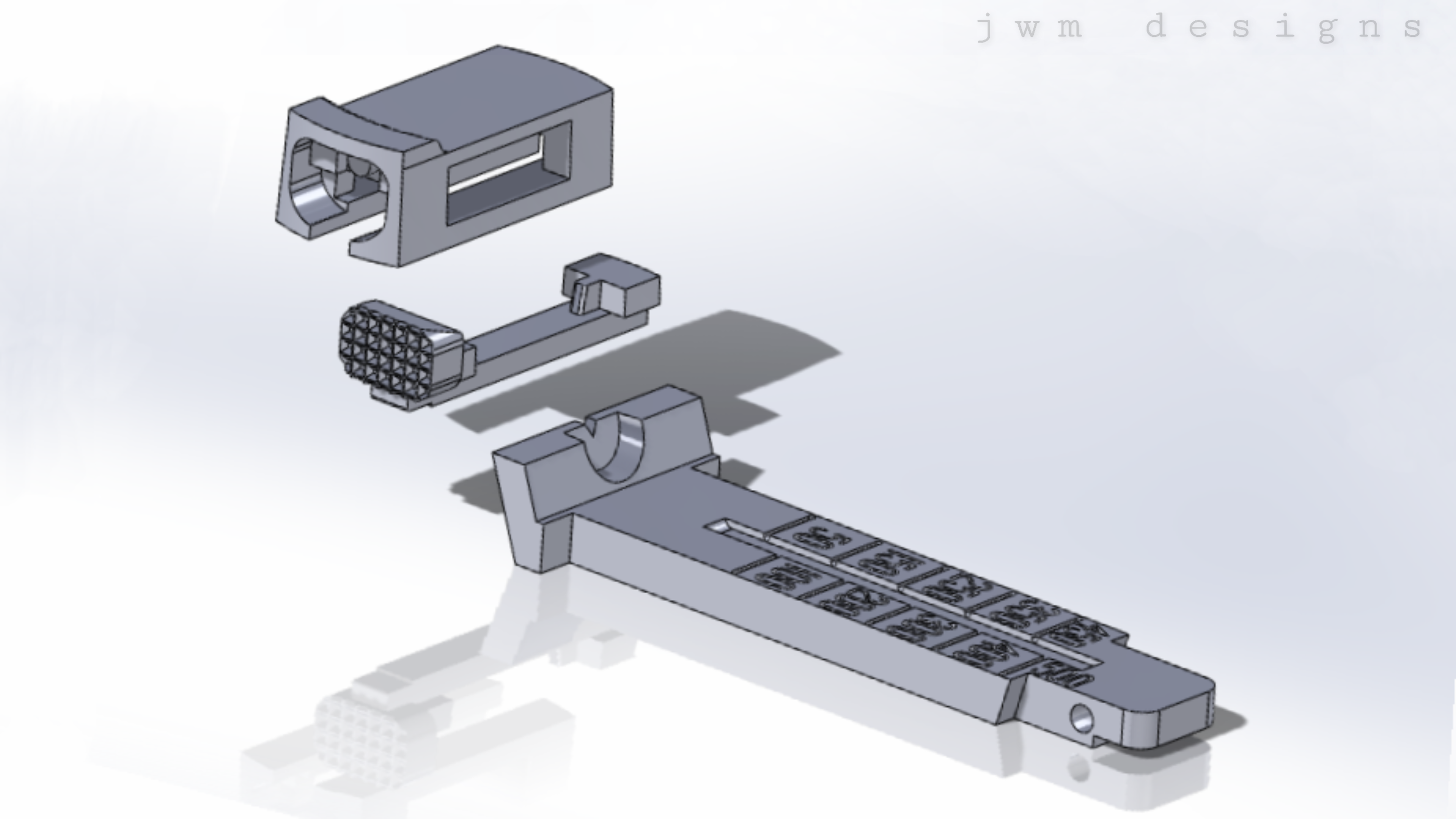

Here’s something I wanted to try and see if I could create. A template that would make life a little easier when building the Hoth blaster.

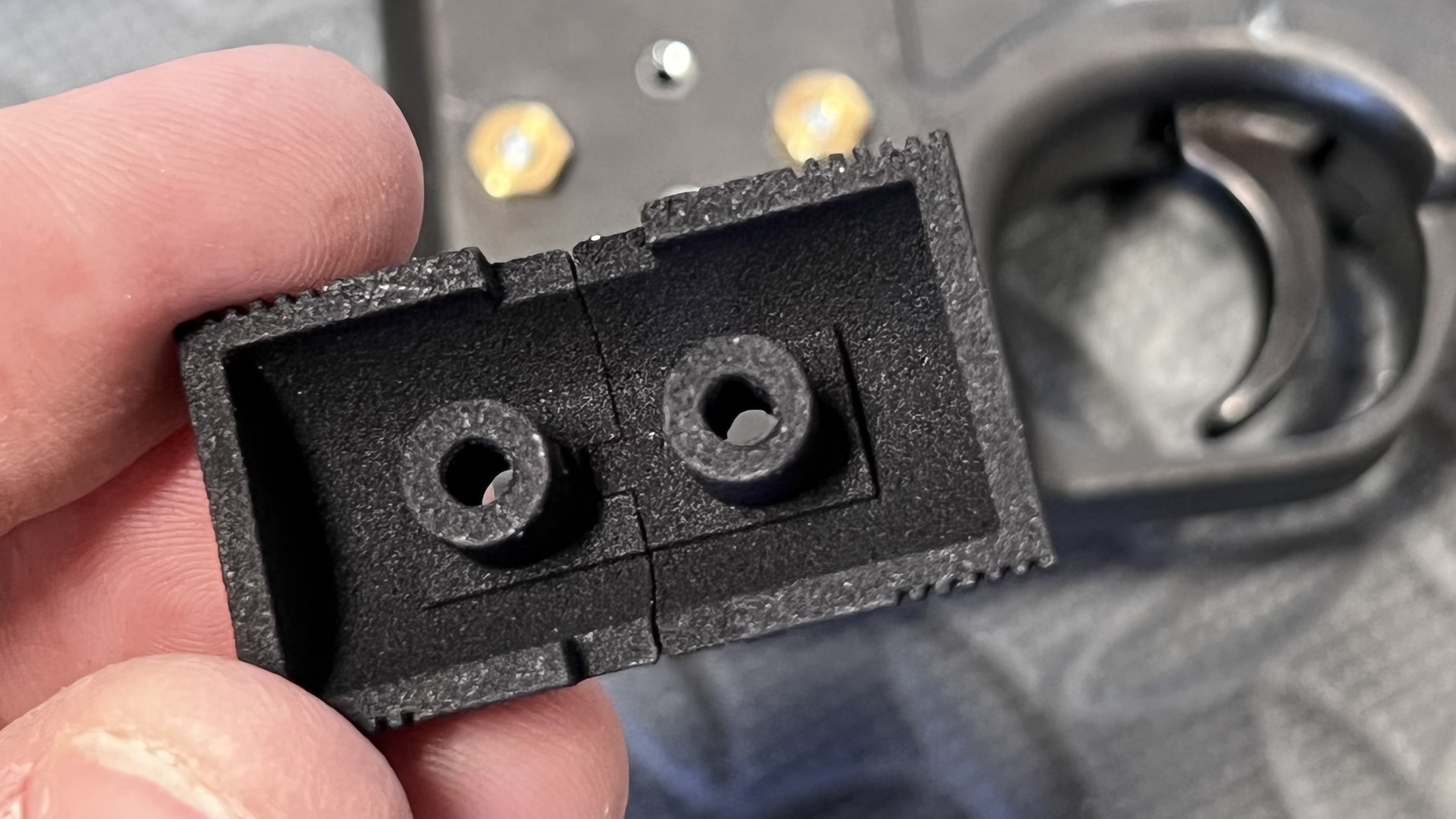

It’s believed that there are two screws that attach the mount spacer to the Mausers itself that go all the way through to the other side and are held on with screw nuts that are visible to the left/right of the center front greeblie..

I had these template already designed up and they originally did the trick but this also lead to a build that was mostly cosmetic..

So I thought it would be fun to try and see if a template could be created that would allow the build to be a little more “accurate” to how it’s perceived to be built in the first place. I had to design some new parts and redesign some of my old parts (mount & spacer mostly) but this is what I’ve come up with. The teeth in the design holds everything in place so next up is to simply use a hole punch..

It’s believed that there are two screws that attach the mount spacer to the Mausers itself that go all the way through to the other side and are held on with screw nuts that are visible to the left/right of the center front greeblie..

I had these template already designed up and they originally did the trick but this also lead to a build that was mostly cosmetic..

So I thought it would be fun to try and see if a template could be created that would allow the build to be a little more “accurate” to how it’s perceived to be built in the first place. I had to design some new parts and redesign some of my old parts (mount & spacer mostly) but this is what I’ve come up with. The teeth in the design holds everything in place so next up is to simply use a hole punch..

Last edited:

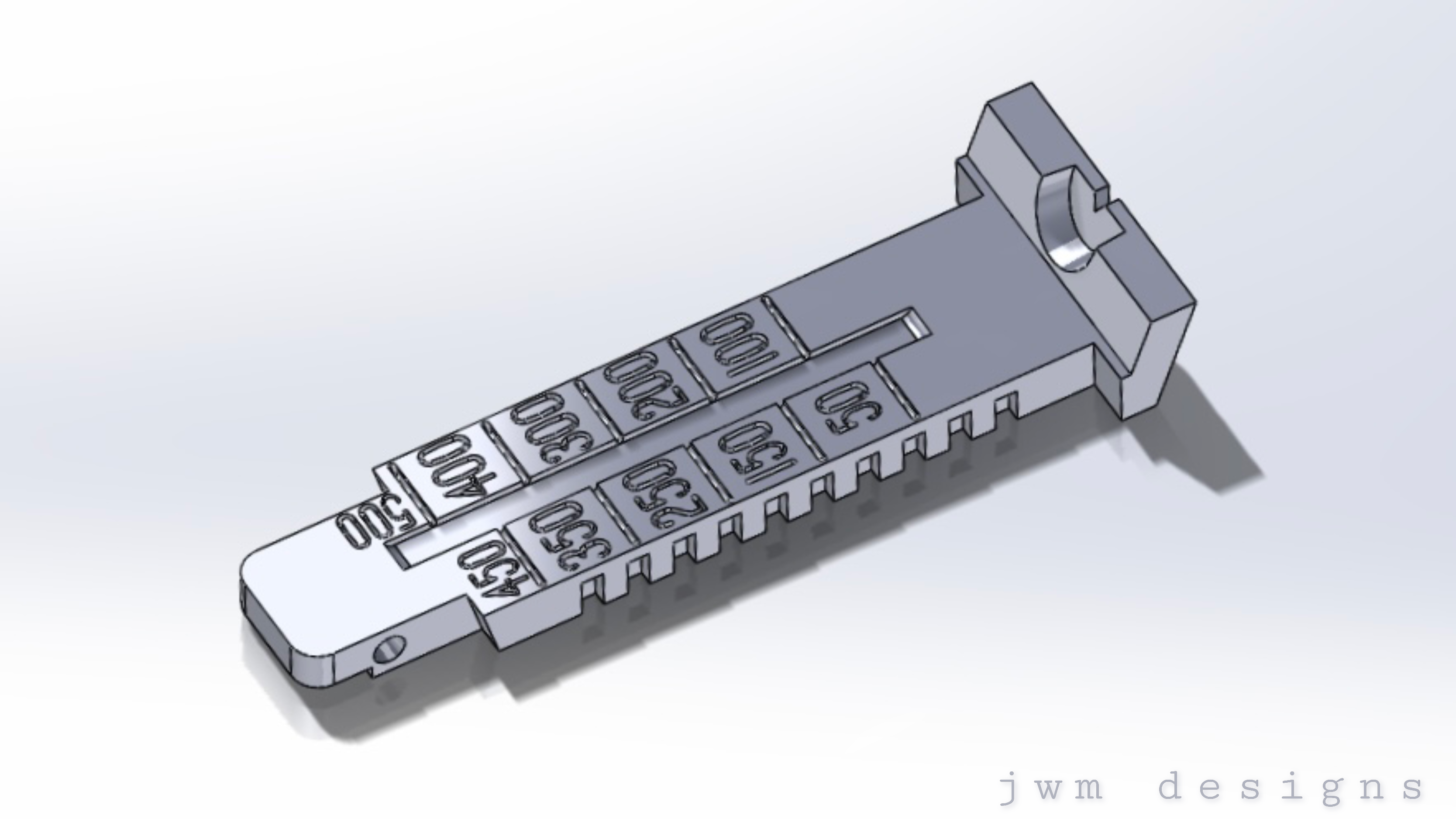

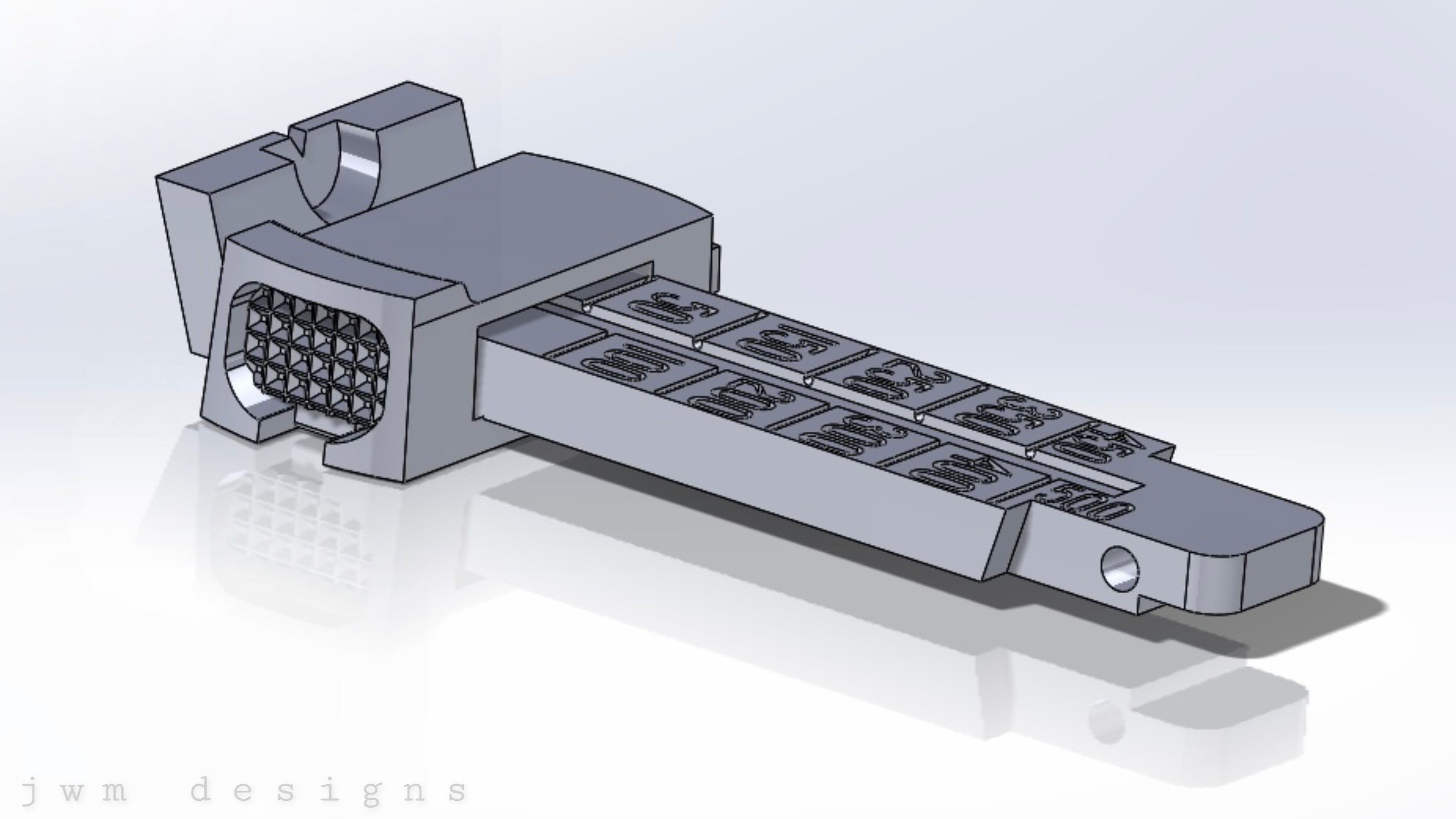

I already created some templates for the center/back greeblies and use legs (or pins) in the design so those greeblies can be glued into place more cleanly..

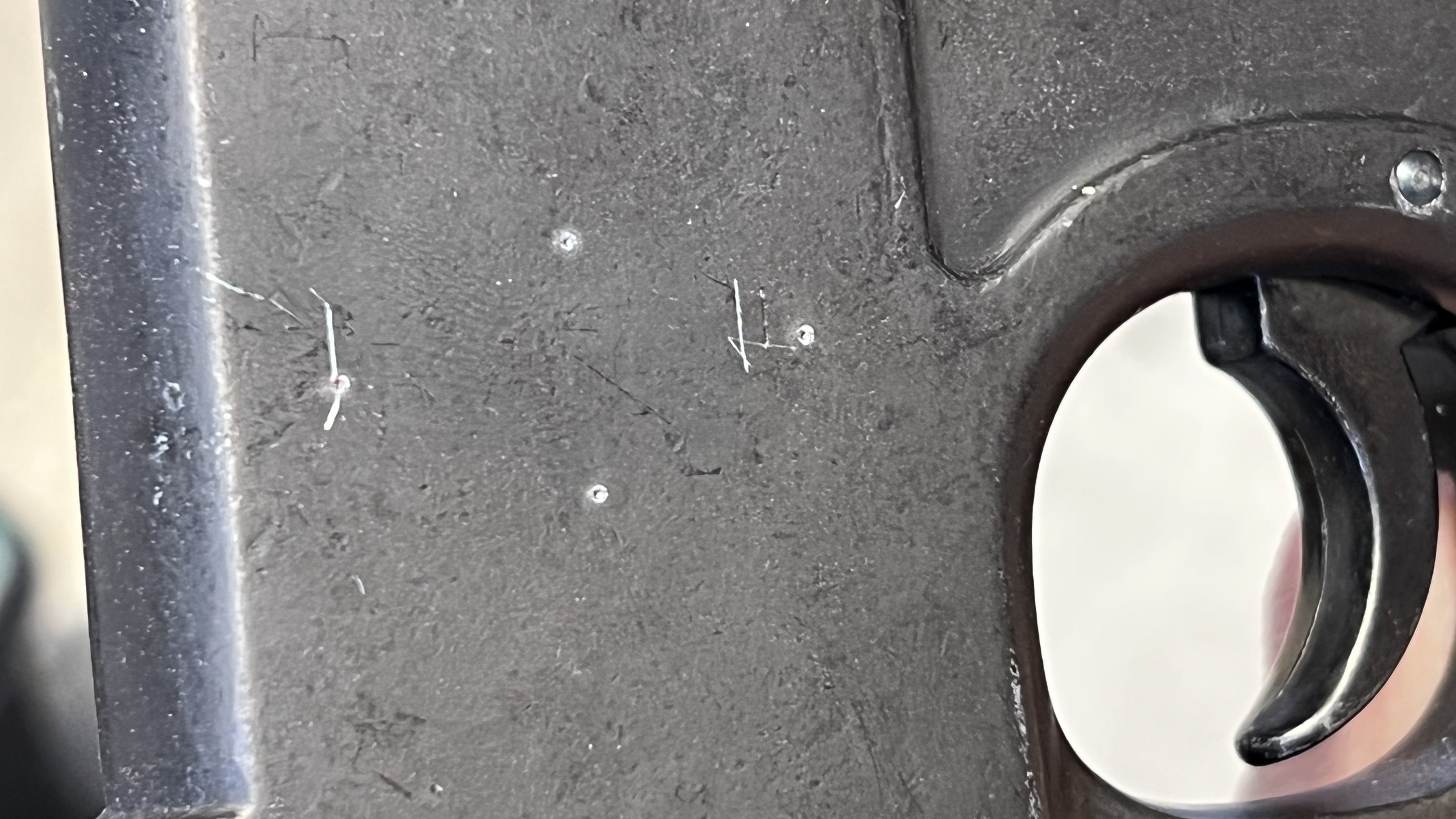

Once I got those punched holes drilled out you can see how everything lines up..

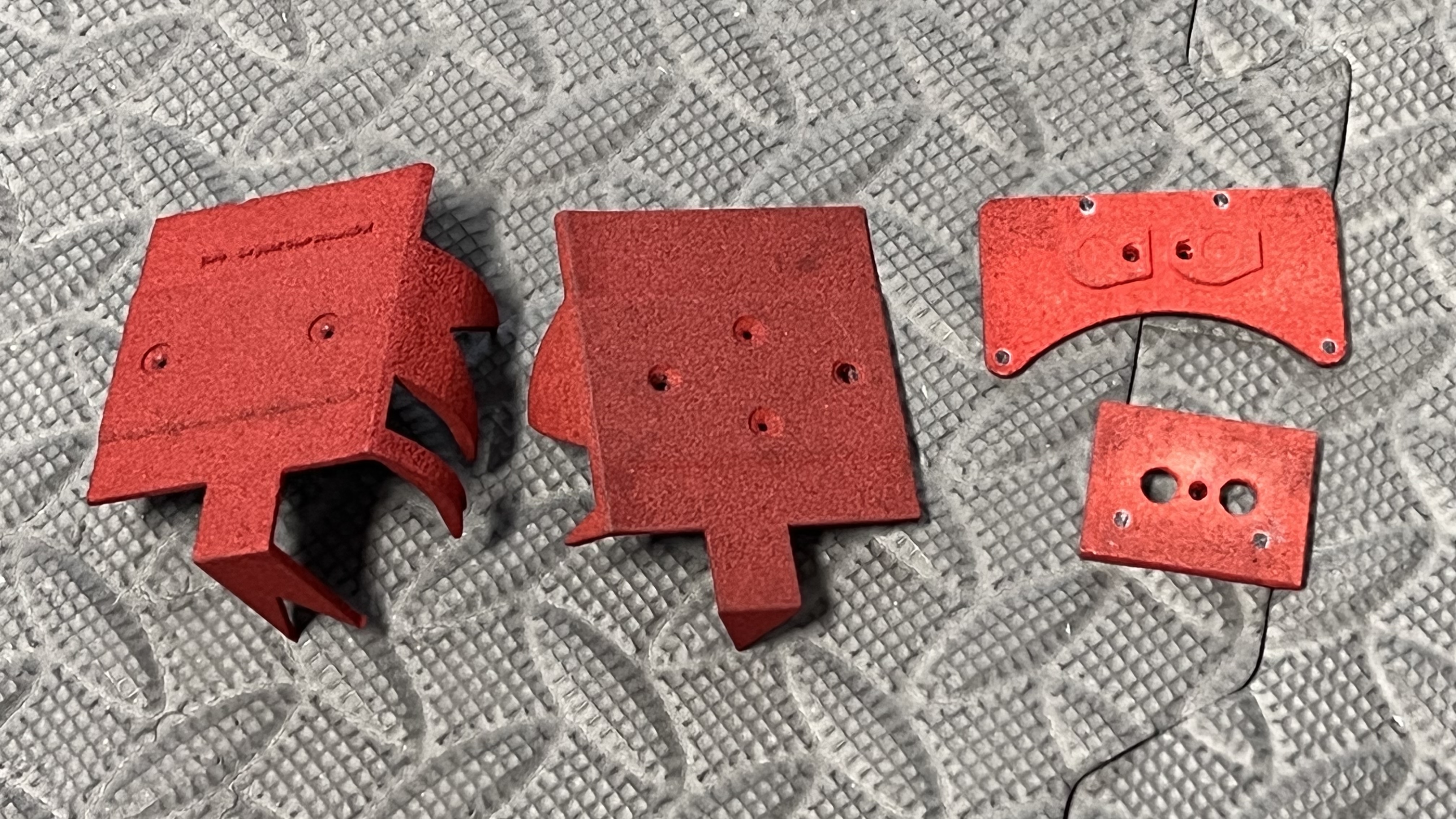

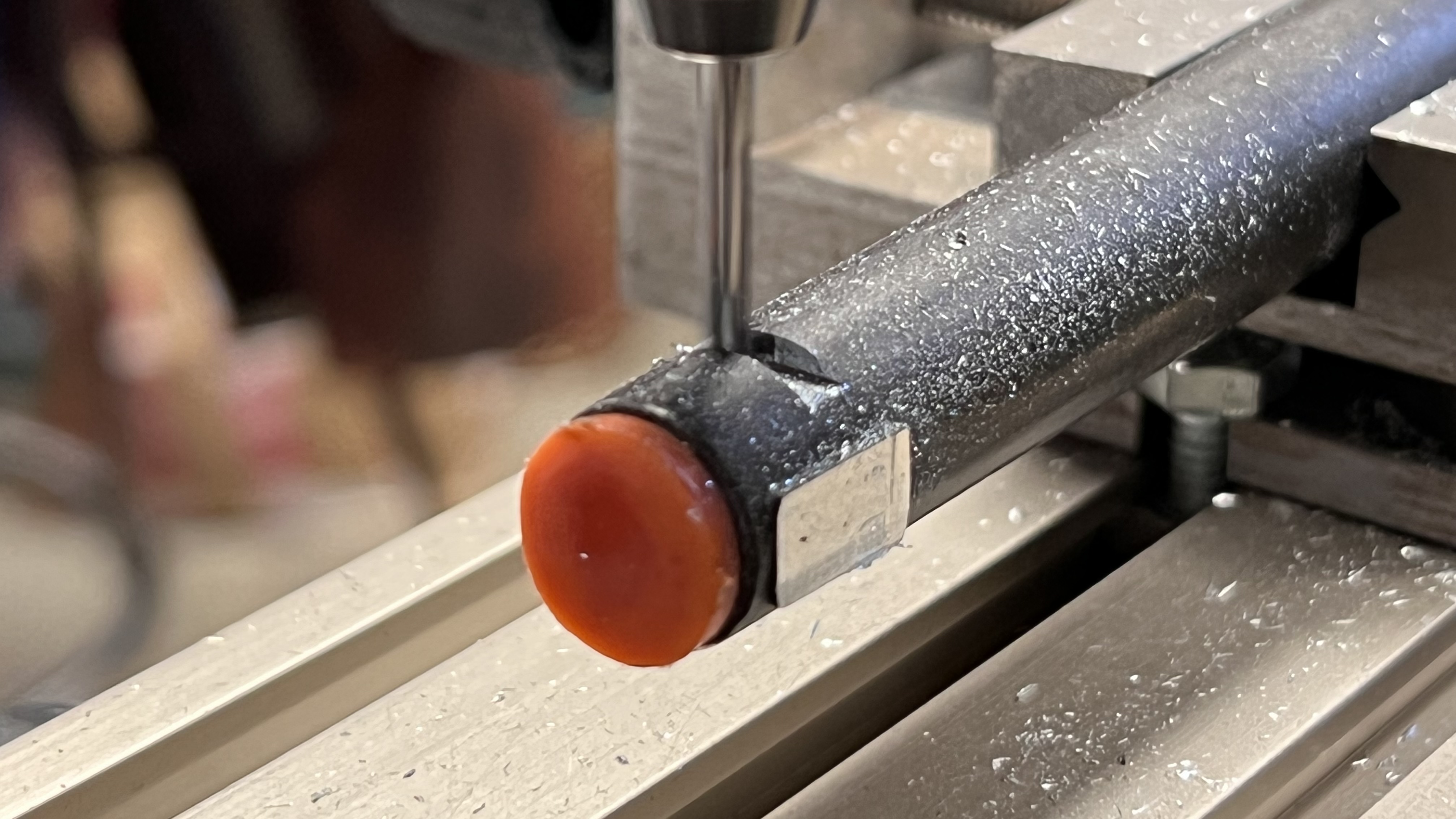

Now because the Mauser it’s tapered towards the front I had to design the new spacer so the front screw would come to a rest a little earlier than the back screw so each would only stick out on the other side equally (if this makes sense?). Then simply add the hex nut to each to hold the spacer in place..

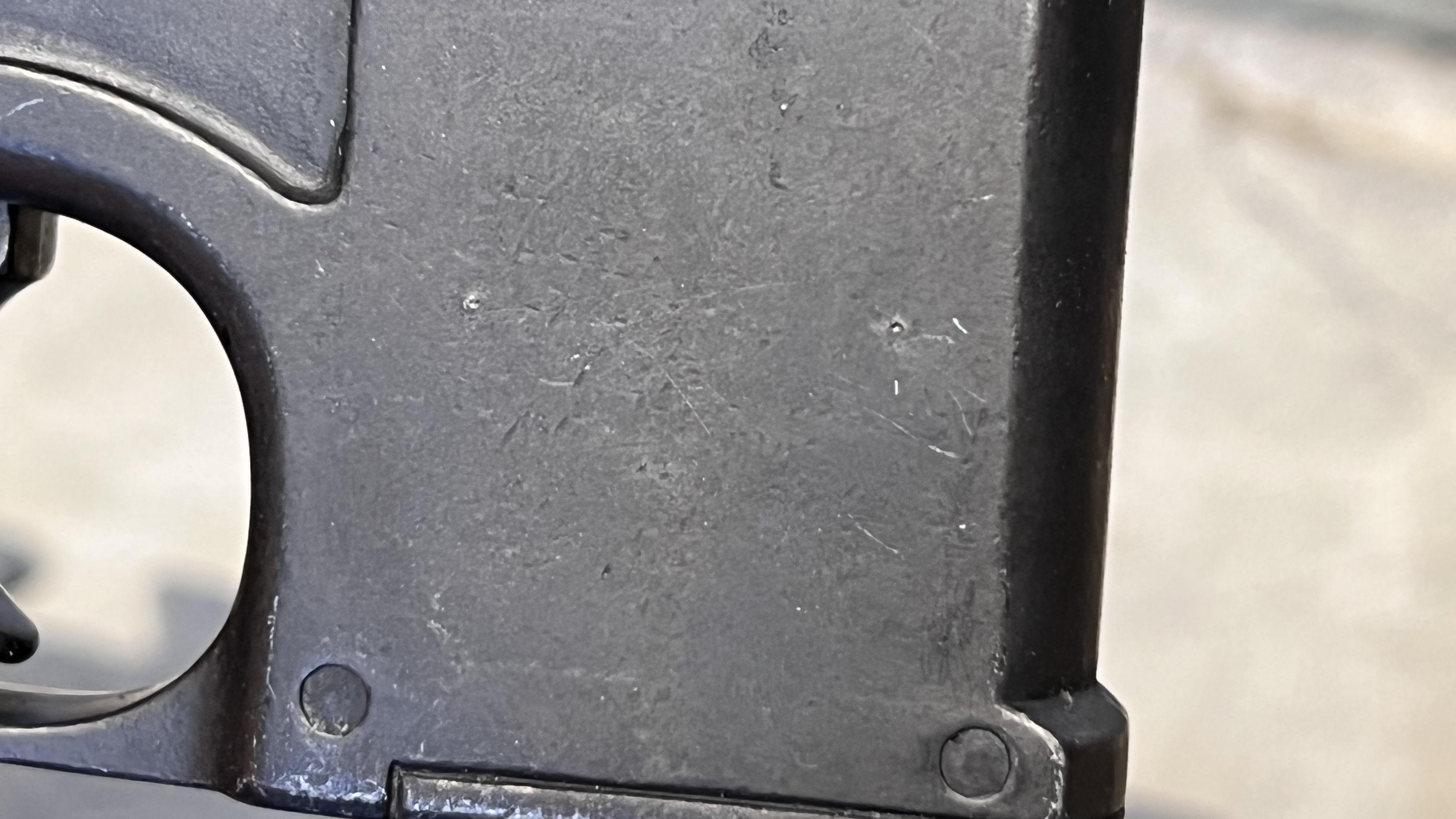

I also redesigned my greeblies (every so slightly) once again. This time I separated them as they where two individual parts to begin with. I added a little tab to each so one would find the other and hold each in place. Then simply screw them onto the Mauser itself..

Once I got those punched holes drilled out you can see how everything lines up..

Now because the Mauser it’s tapered towards the front I had to design the new spacer so the front screw would come to a rest a little earlier than the back screw so each would only stick out on the other side equally (if this makes sense?). Then simply add the hex nut to each to hold the spacer in place..

I also redesigned my greeblies (every so slightly) once again. This time I separated them as they where two individual parts to begin with. I added a little tab to each so one would find the other and hold each in place. Then simply screw them onto the Mauser itself..

Last edited:

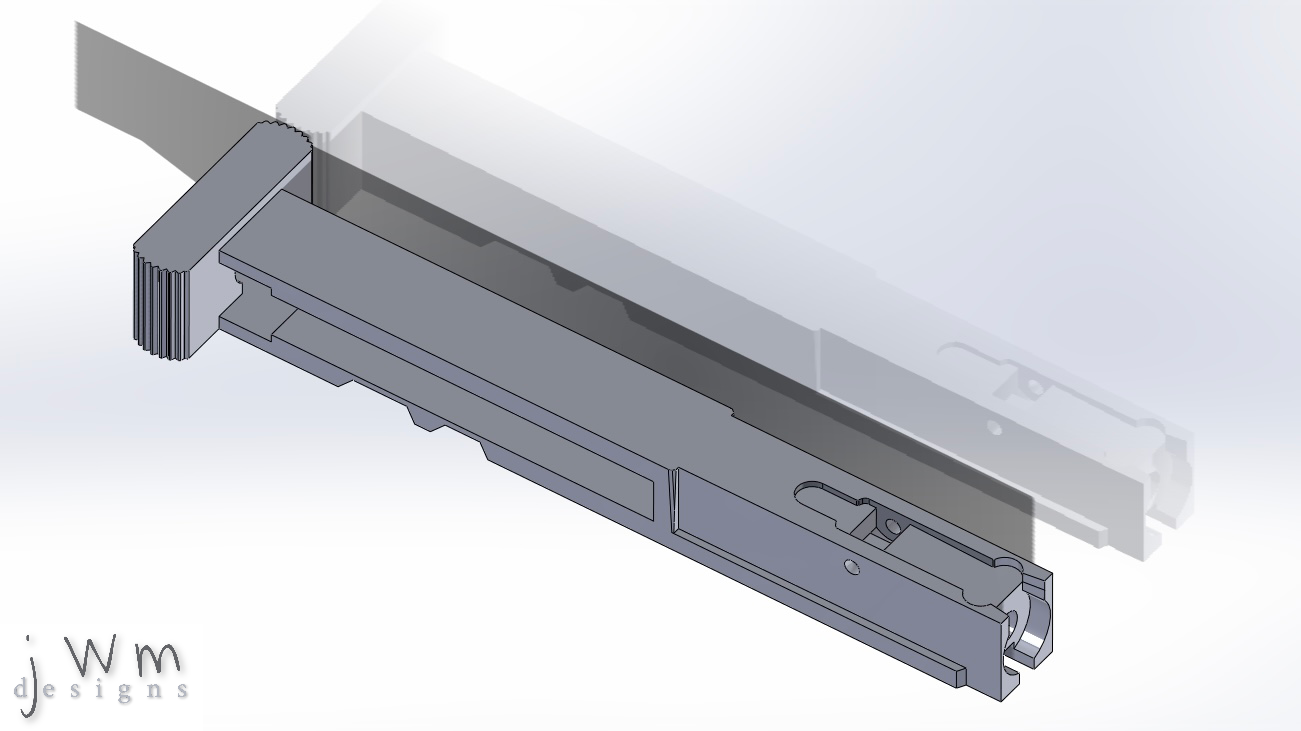

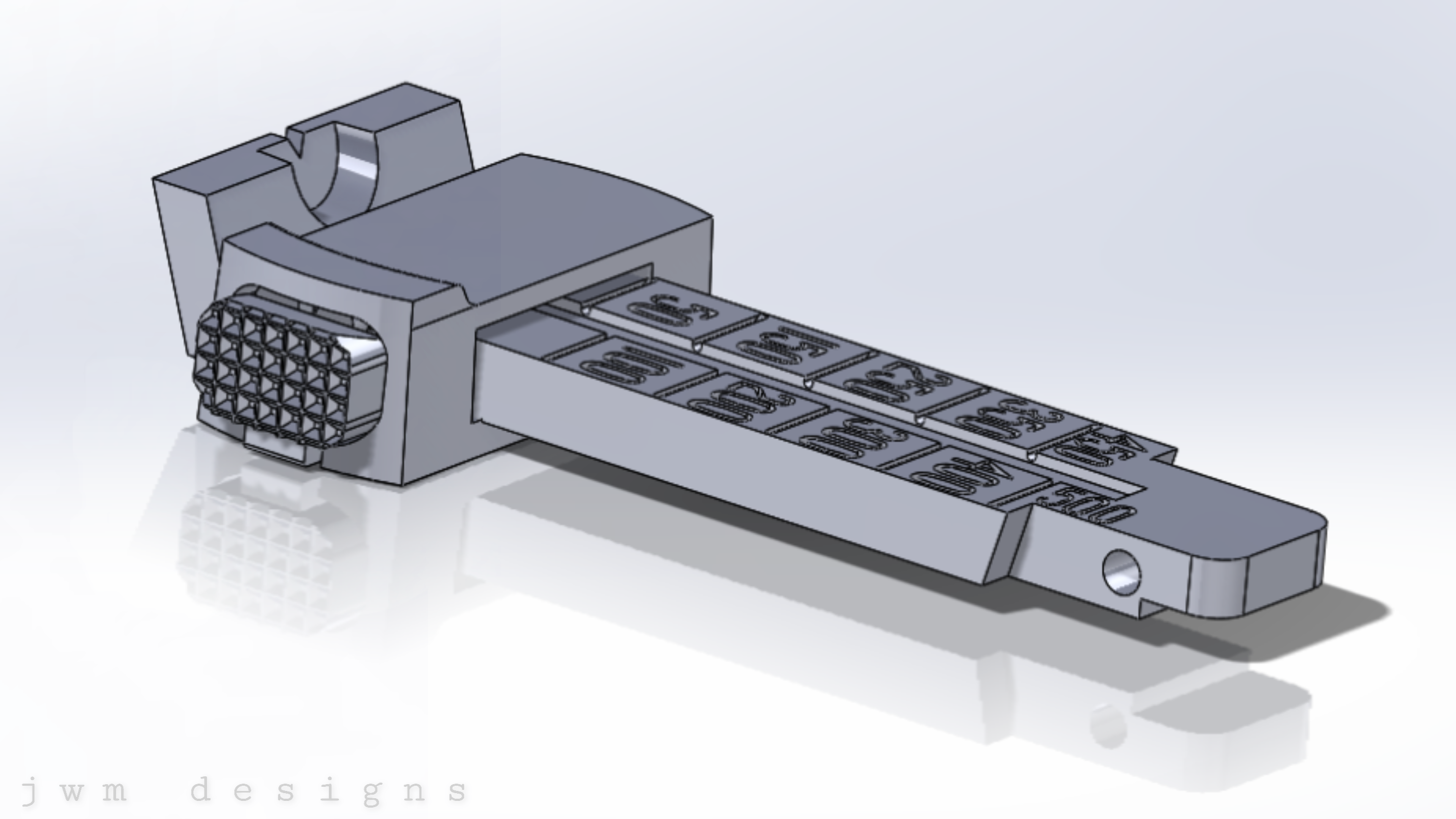

Now for the mount I added a little male/female onto the back of the mount and the spacer itself with some “teeth” so it holds each in place. This simply allows for everything to line up and stay connected untill I can add the 3 final visible screws..

Now back to the other side. With all the punched holes drilled out it as well makes attaching the greeblies easier and more cleanly..

Now back to the other side. With all the punched holes drilled out it as well makes attaching the greeblies easier and more cleanly..

Last edited:

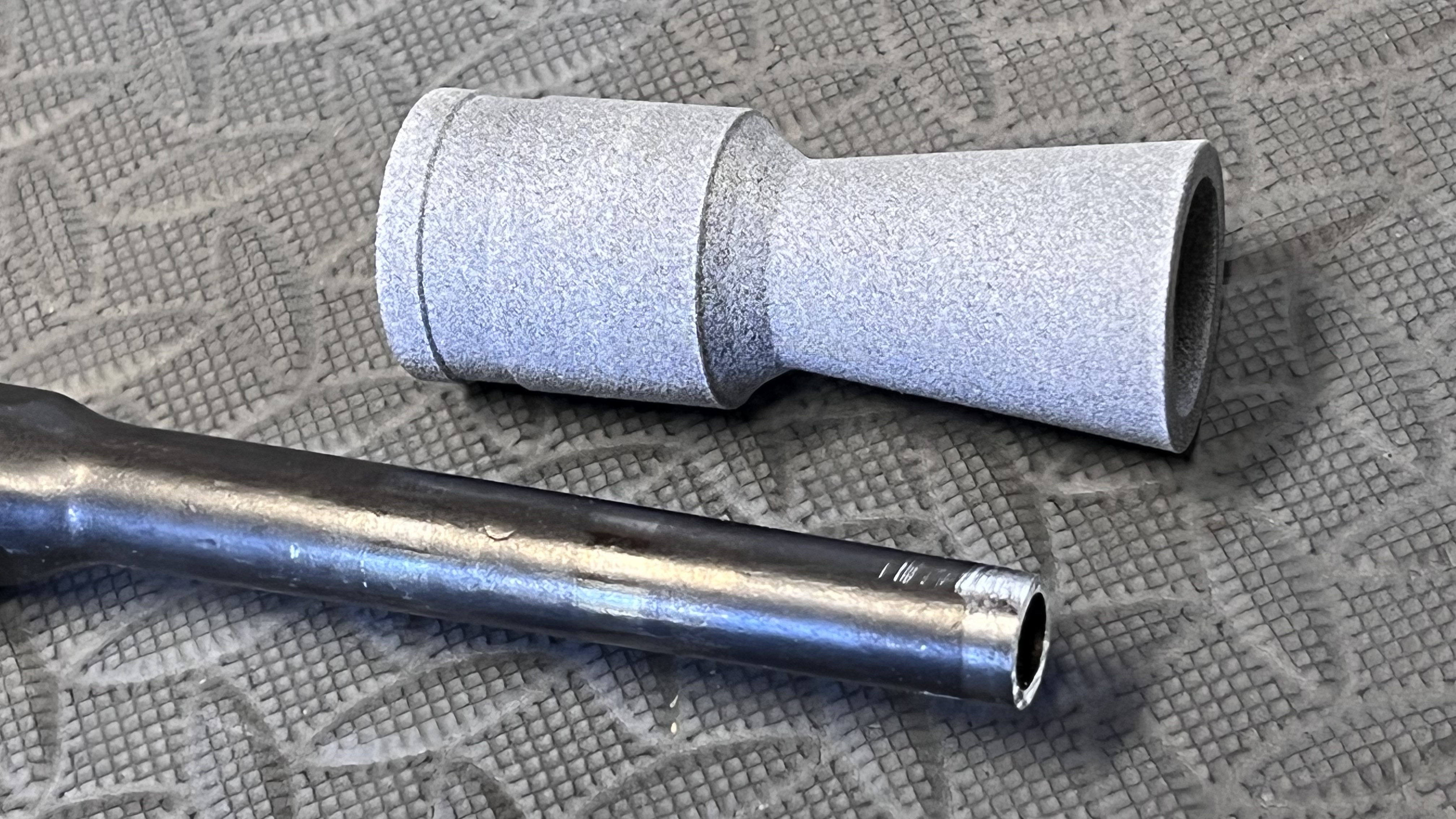

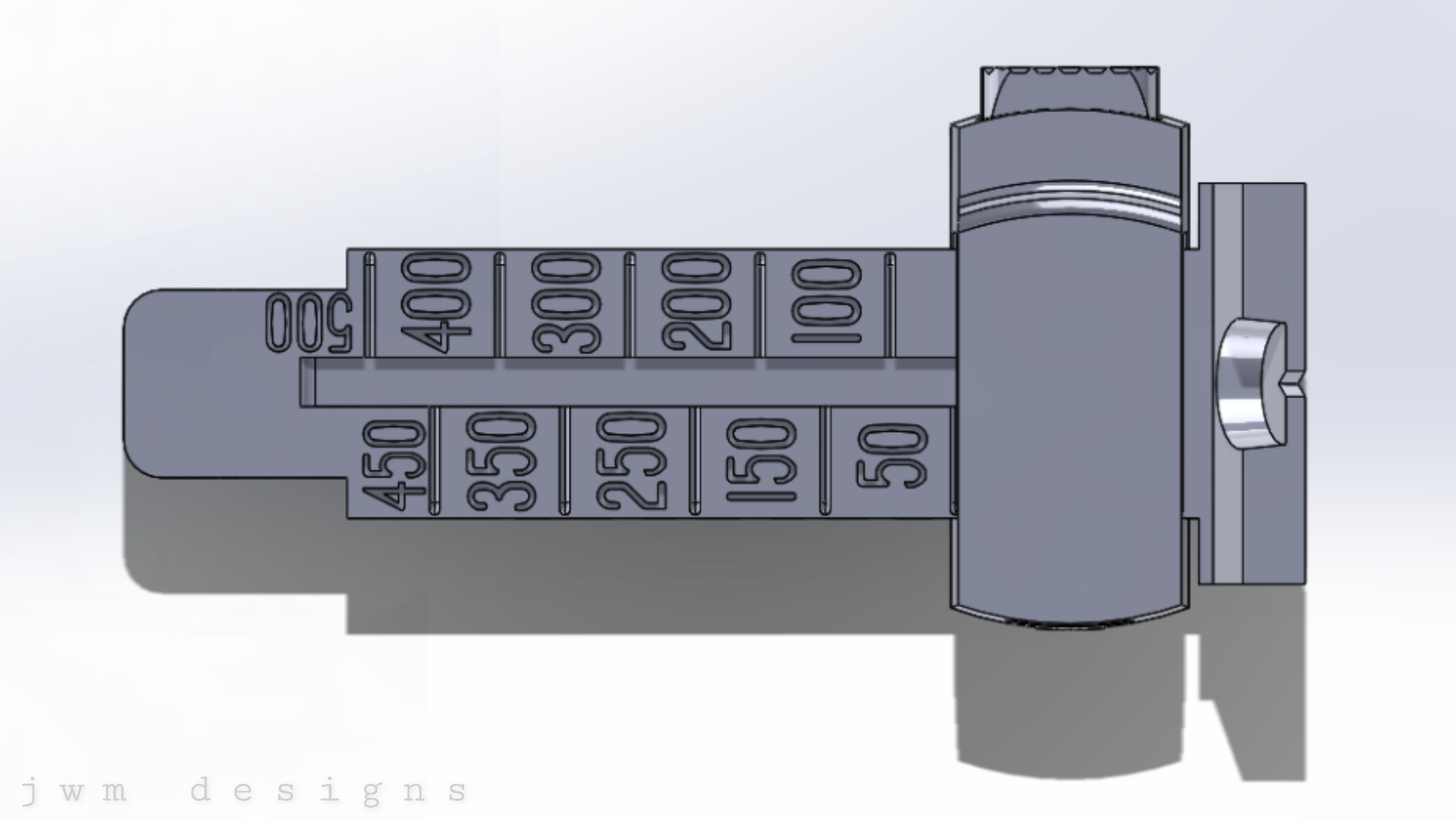

Next is the m19 scope..

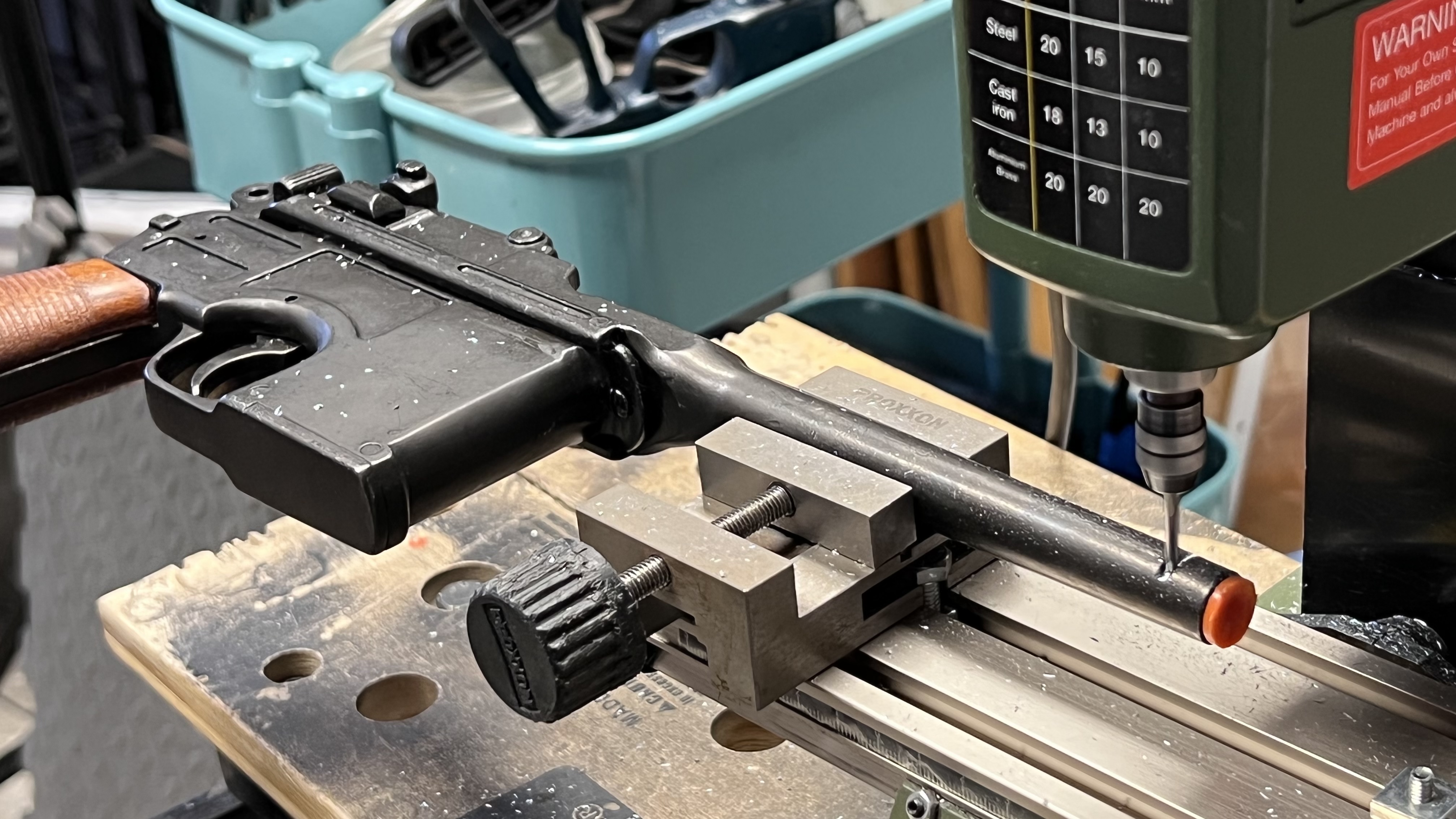

I created some jigs so I can easily add threading to the front screw which is a little thicker than back screw. This front screw had to be designed up as well and this is where these templates came in handy.

You can also get a good idea just how strong these MJF prints actually are here..

Next up is simply screwing everything into place and adding the 3/4 light port..

I created some jigs so I can easily add threading to the front screw which is a little thicker than back screw. This front screw had to be designed up as well and this is where these templates came in handy.

You can also get a good idea just how strong these MJF prints actually are here..

Next up is simply screwing everything into place and adding the 3/4 light port..

Last edited:

Before adding the flash hider (or before everything above really) I did have to remove the sight and cut down the barrel just a bit..

Then simply assemble everything into place..

Then simply assemble everything into place..

Last edited:

Lastly I added some color by using a gold, silver and black sharpie for fun..

Last edited:

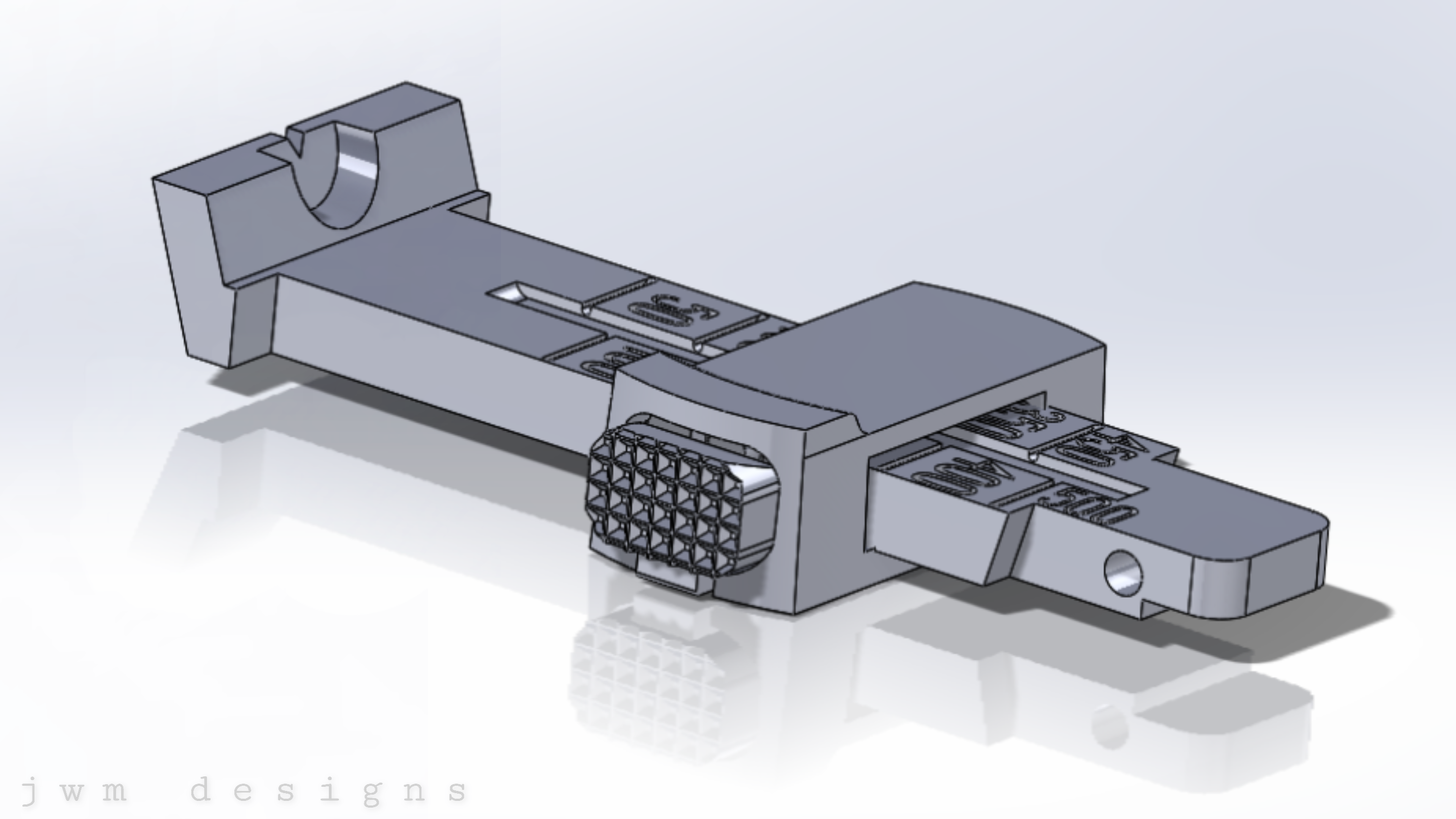

Starting a long and hopefully rewardable journey..

Slide is coming along nicely..

I appreciate the encouragement.

Indulge me as I enjoy these details..

Last edited:

Similar threads

- Replies

- 2

- Views

- 596

- Replies

- 9

- Views

- 745

- Replies

- 0

- Views

- 338