woodywaverider

Sr Member

Edited the title to continue with further builds/finds.

Update:

link index:

My fist props: a couple of light sabers with crystal chambers note the goes to a different thread.

My first thread: light up saber stand with back didplay- note the goes to a different thread.

#1 metal thermal detonator: starts on this page.

#53 Neuro-Saab ND.621 range finder

#71 in universe Leitz Wetzlar droid caller

Small P37 bag

#75 krate dragon detonator

#91 grogu’s chainmail armour and cloth bundle wrap

#130 glowing spotchka bottle

#140 EH-17 scout blaster and star destroyer capacitor bearing

Metal thermal detonator scratch build with light and sound, on a budget.

I know KR/OR offer a really nice kit, but it’s price is too prohibitive to justify. So I thought I’d try and make one myself.

A bit of background for those that don’t know, I don’t own a 3d printer, pro paint set up or have access to any machining, so this will all be done with hand tools.

I’ve done a fair bit of research and realise I may have to sacrifice some screen accuracy - I can live with that.

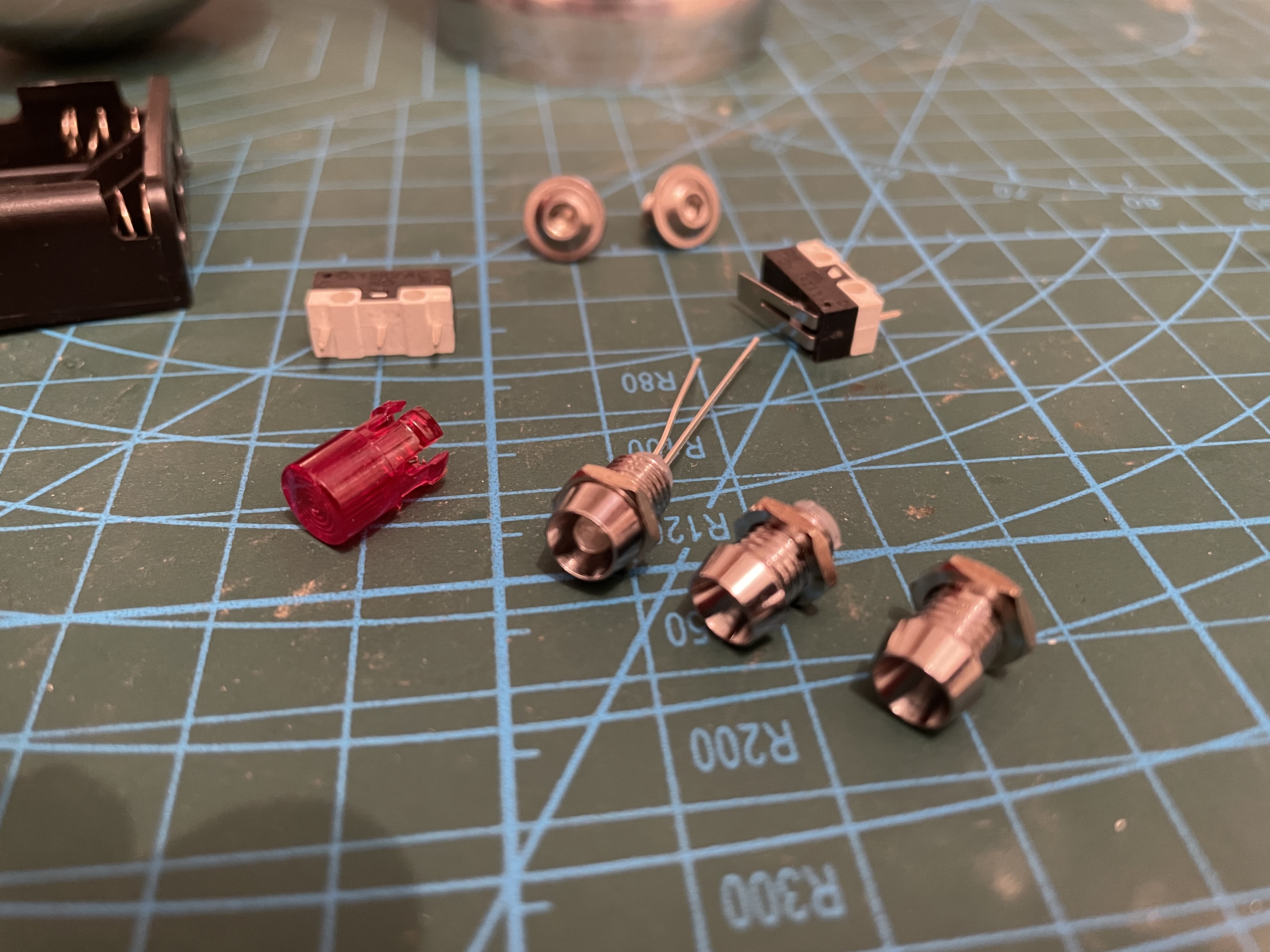

Here are the parts I have so far which is pretty much everything I need:

there is:

2 1/2 inch stainless steel ball (a garden decoration) £2.75 - which I’ll cut in half

2 1/4 inch aluminium hose connector for the middle section - £2.63

2 3/4 inch aluminium round billet - I plan to cut the activation switch from this then grind the back it to fit - £7.80

a recordable sound model from a greetings card/music box - I plan to modify to include the lights and different switches - £6

type N battery holder and batteries to replace the larger AAA with (the module still works on 3v)

3mm yellow flashing leds and metal led holders

6mm red led lens, red 5mm led (not in the pic)

2 micro lever switch, one to run the sound, the other for the lights, all running back to the same battery holder, but otherwise 2 separate circuits.

a couple of flanged screws to hold the activation switch on, I’ll probably use a couple of rubber o-rings on these for a smoother movement.

I plan to electro etch the grooves using 9v battery.

hopefully I can figure out away to make the bottom screw on. I’m thinking this will just be a cross brace and a bolt.

I did source a Fuman 1/48 panther G tank kit with the correct track for the top of the activation switch, but it cost more than all the other parts combined, so I’m still looking for an alternative.

I’ll see what I can find at the local hardware or toy store. failing that I can always cut something out of black styrene. But I’d welcome any other suggestions for that part.

Update:

link index:

My fist props: a couple of light sabers with crystal chambers note the goes to a different thread.

My first thread: light up saber stand with back didplay- note the goes to a different thread.

#1 metal thermal detonator: starts on this page.

#53 Neuro-Saab ND.621 range finder

#71 in universe Leitz Wetzlar droid caller

Small P37 bag

#75 krate dragon detonator

#91 grogu’s chainmail armour and cloth bundle wrap

#130 glowing spotchka bottle

#140 EH-17 scout blaster and star destroyer capacitor bearing

Metal thermal detonator scratch build with light and sound, on a budget.

I know KR/OR offer a really nice kit, but it’s price is too prohibitive to justify. So I thought I’d try and make one myself.

A bit of background for those that don’t know, I don’t own a 3d printer, pro paint set up or have access to any machining, so this will all be done with hand tools.

I’ve done a fair bit of research and realise I may have to sacrifice some screen accuracy - I can live with that.

Here are the parts I have so far which is pretty much everything I need:

there is:

2 1/2 inch stainless steel ball (a garden decoration) £2.75 - which I’ll cut in half

2 1/4 inch aluminium hose connector for the middle section - £2.63

2 3/4 inch aluminium round billet - I plan to cut the activation switch from this then grind the back it to fit - £7.80

a recordable sound model from a greetings card/music box - I plan to modify to include the lights and different switches - £6

type N battery holder and batteries to replace the larger AAA with (the module still works on 3v)

3mm yellow flashing leds and metal led holders

6mm red led lens, red 5mm led (not in the pic)

2 micro lever switch, one to run the sound, the other for the lights, all running back to the same battery holder, but otherwise 2 separate circuits.

a couple of flanged screws to hold the activation switch on, I’ll probably use a couple of rubber o-rings on these for a smoother movement.

I plan to electro etch the grooves using 9v battery.

hopefully I can figure out away to make the bottom screw on. I’m thinking this will just be a cross brace and a bolt.

I did source a Fuman 1/48 panther G tank kit with the correct track for the top of the activation switch, but it cost more than all the other parts combined, so I’m still looking for an alternative.

I’ll see what I can find at the local hardware or toy store. failing that I can always cut something out of black styrene. But I’d welcome any other suggestions for that part.

Last edited: