So the hand plates I printed had some warping, which, I’m guessing, was due to the lack of supports and the high temps at which you need to print ABS.

So I went back and reprinted in a different orientation with supports. Came out pretty good! A few printing goobers, but the 0.1mm layer height really produces some impressive results!

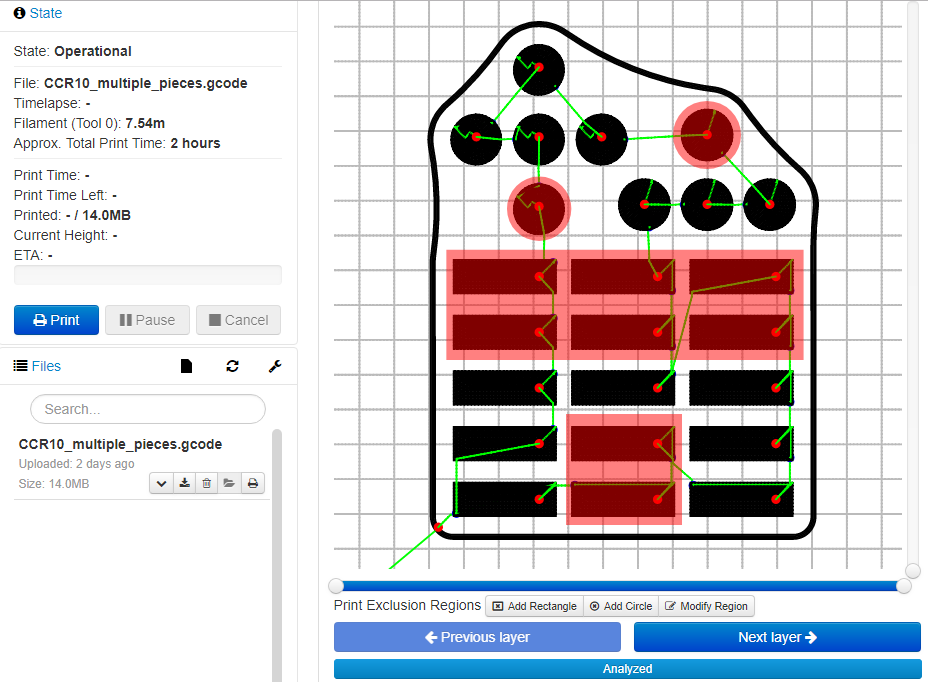

My Octoprint kit showed up yesterday, so I’ll be working on setting that up today.

Sean

So I went back and reprinted in a different orientation with supports. Came out pretty good! A few printing goobers, but the 0.1mm layer height really produces some impressive results!

My Octoprint kit showed up yesterday, so I’ll be working on setting that up today.

Sean