Thought I'd put my 2 cents worth here onanel cutting.

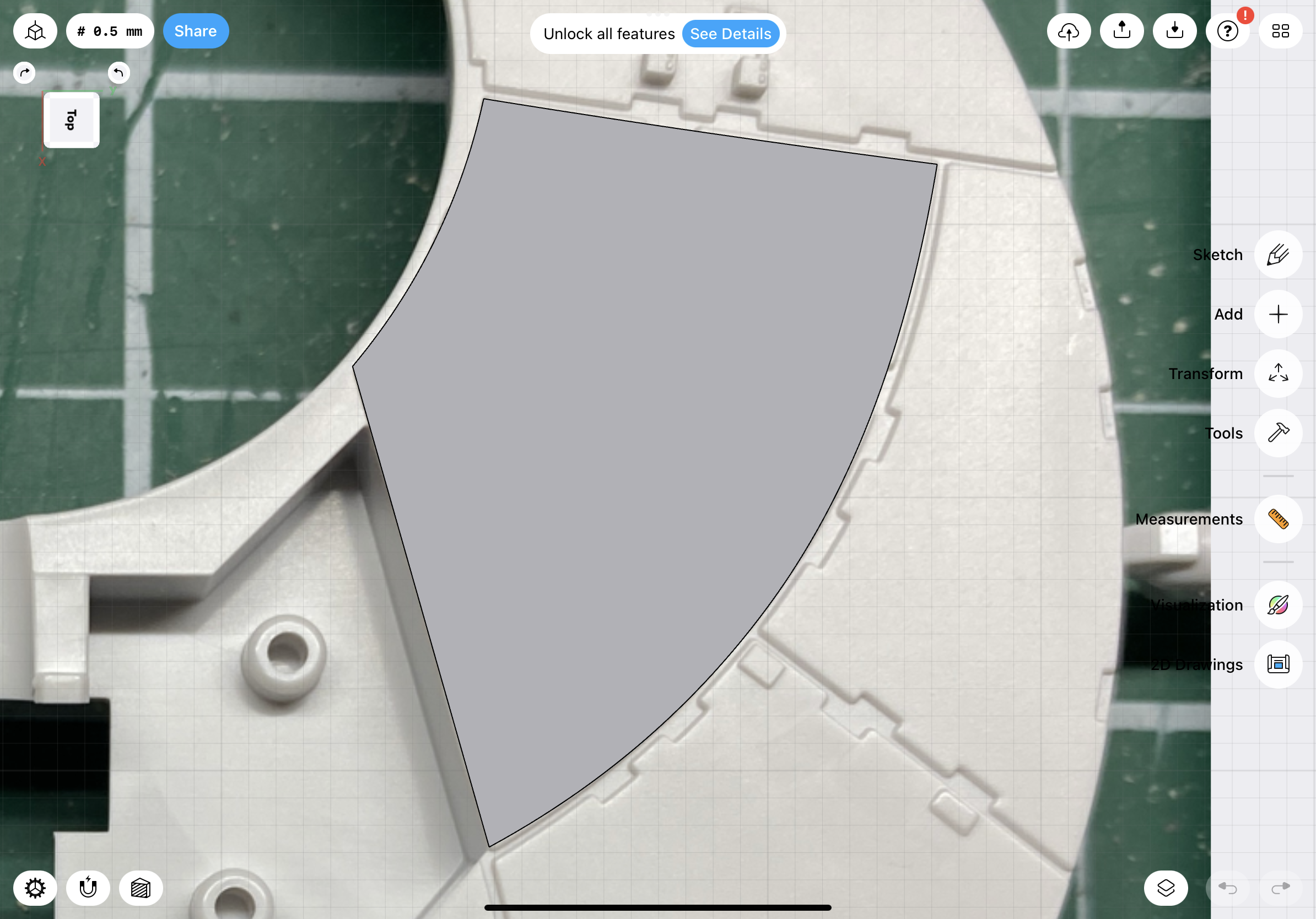

Guys, there is no issue with the styrene curved panels sitting on the hull flat!. Because they do. Even the bigger panels sit perfectly on the hull, believe me!. As they are curved, they match the long length of curvature. There's no issue to be had here ok.

As for my personal panel cutting preference, I use thin card templates on the trickier panels & transfer to the styrene sheet to cut out the panel proper.

If you make a mistake on an edge, as I have done on quite a few, then you cut off a goodly strip, say more than 10mm & butt up a new piece of styrene & sand to it is as one again & continue. It's pointless in most cases to fabricate an entirely new panel.