Star fleet battles pieces, yeahUpdate #98

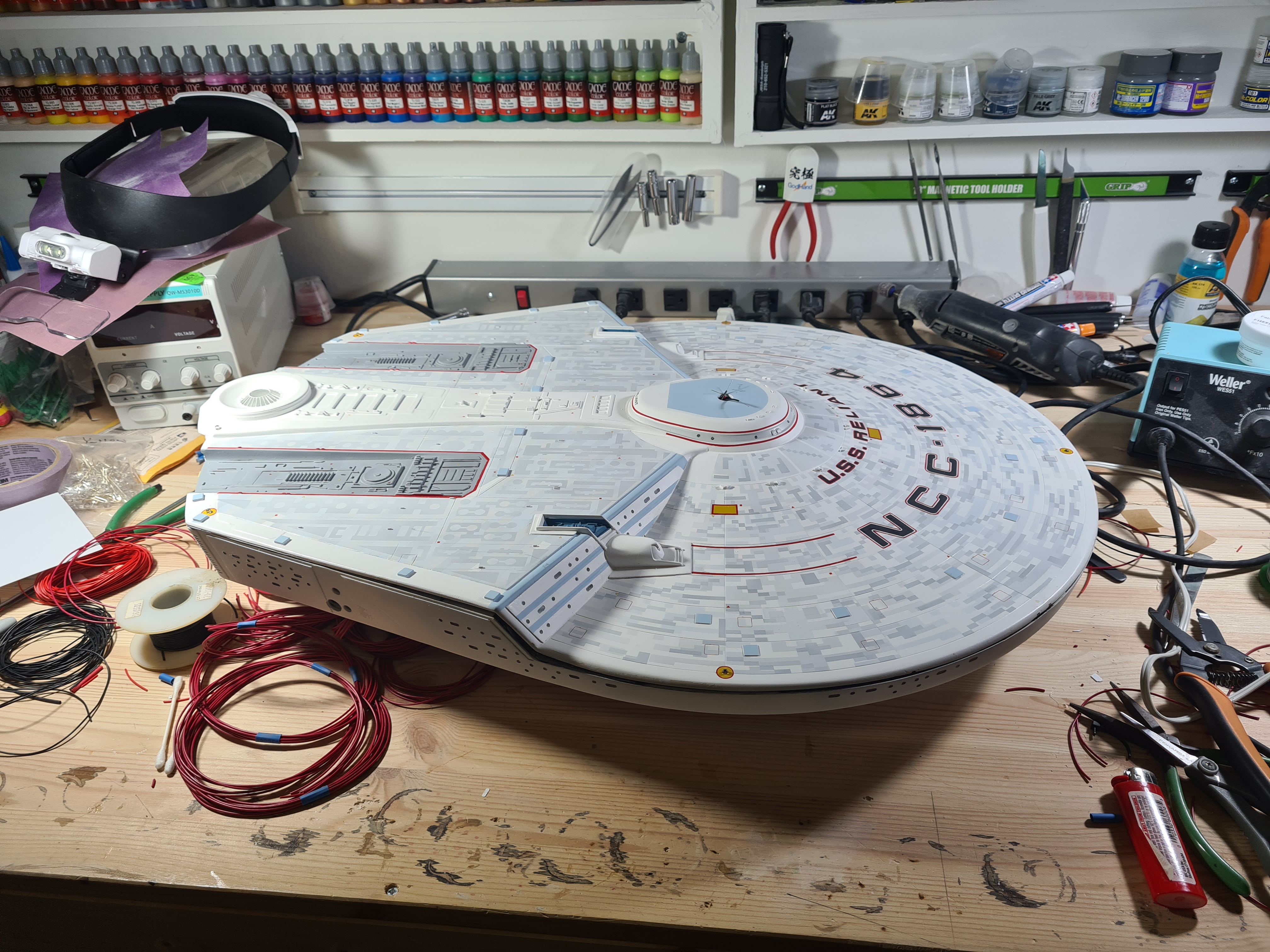

I finally got off of the pot and made some decisions and did ‘stuff’. Since I am still waiting on my parts from China for the Rev 2 boards if I wanted to make progress, had to do modeling work and paint. Soooo I drilled a ton of holes, spent several days sanding and getting the base coat on the Reliant finished. Which I did on both the top and bottom, woohoo! I also decide on several issues so I could

move forward. The main one being the removal of the sensor band lines. I can’t scribe on this model worth a damn, the resin has different hardness as you move through it, so it is impossible for me at least to have consistent depth and width of scribe lines. I made a morale roll and failed. ☹ However, I sanded them all of and plan on just painting a solid line back in. I looked at another Reliant that had done this and it look pretty good up till about 4 inches away from the model, so I am ok with that. The only other negative is that I lost some detail on the docking ports. I am thinking of putting that back in via PE or a 3d print off of a resin printer. But, that is a long ways down the road. Also, I cut some styrene parts to cover up some ****** looking scribe lines on the bottom. I still get the same design cue but without the anger inducing crappy looking lines. Will have a pic, I am sure a purist won’t like it. Oh well. Got the rear docking port holes looking pretty good. I also came up with a way to over come the last remaining fish eye. I ended up base coating with the McKenzie paint, then sanded the area down a bit and went over that with 2 layers of AK flat white, then again with the McKenzie white, looks very good. Will have a pic of the fish eye. I am now shooting color onto the model, which is super exciting! I took some time off from work, due to an already long weekend, and spent a lot of it on the model. I also tested out my make shift air brush booth and it works quite well. A great last week or so on the models! Lots of progress!

Oh one last thing, I am now really running into issues with the hand built model. Everything is not symmetrical which is cool but I am probably going to have to go seek help for my quest for perfect symmetry, which I am not going to get to on this.

Cheers,

View attachment 1425928View attachment 1425929View attachment 1425930View attachment 1425931View attachment 1425932View attachment 1425933View attachment 1425934

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mutara Nebula DeBoers E and R Build

- Thread starter jwood314

- Start date

Thanks!! I love SFB, but the counters are from Federation and Empire an even more unknown monster wargame!

Update #103

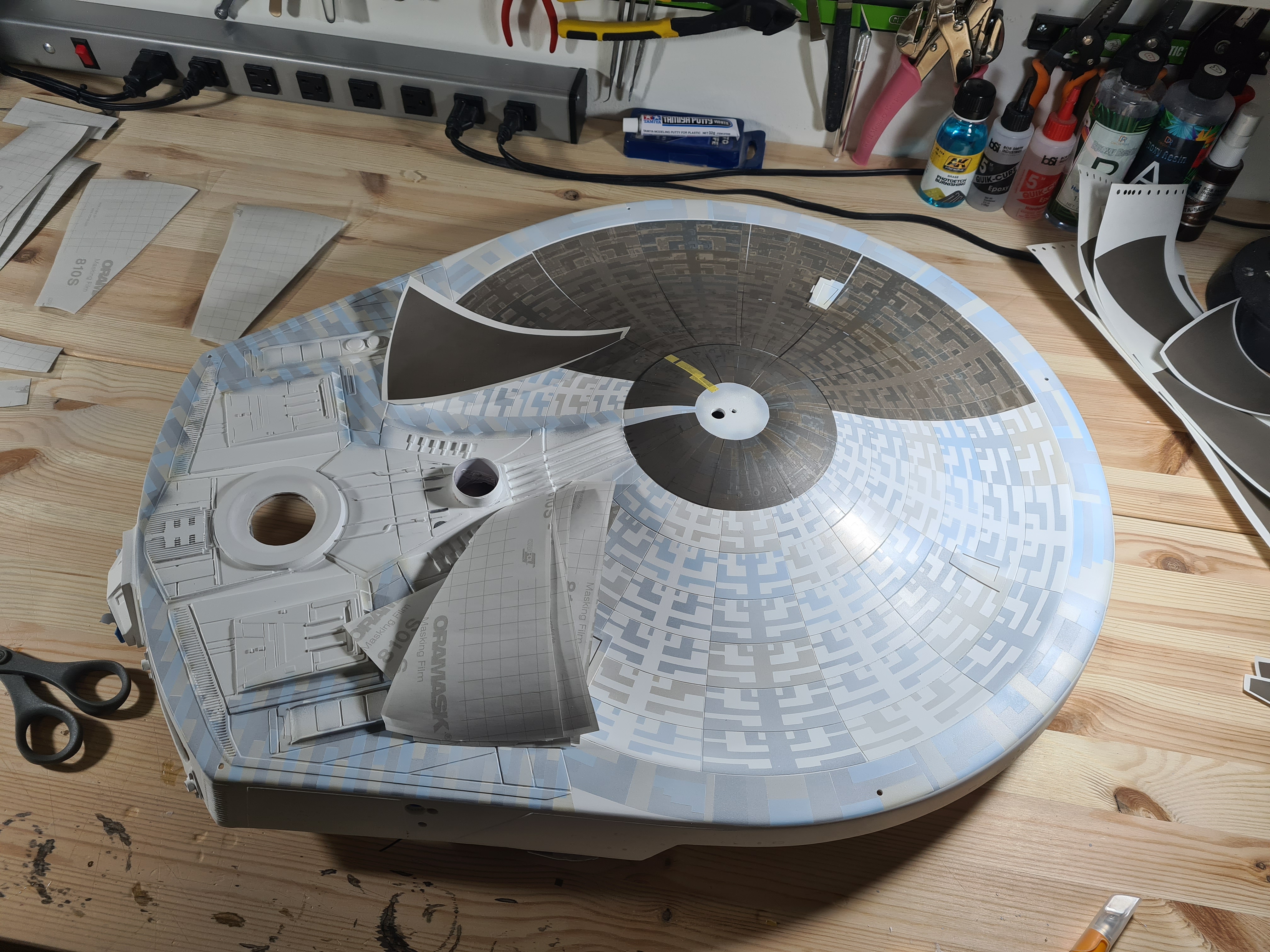

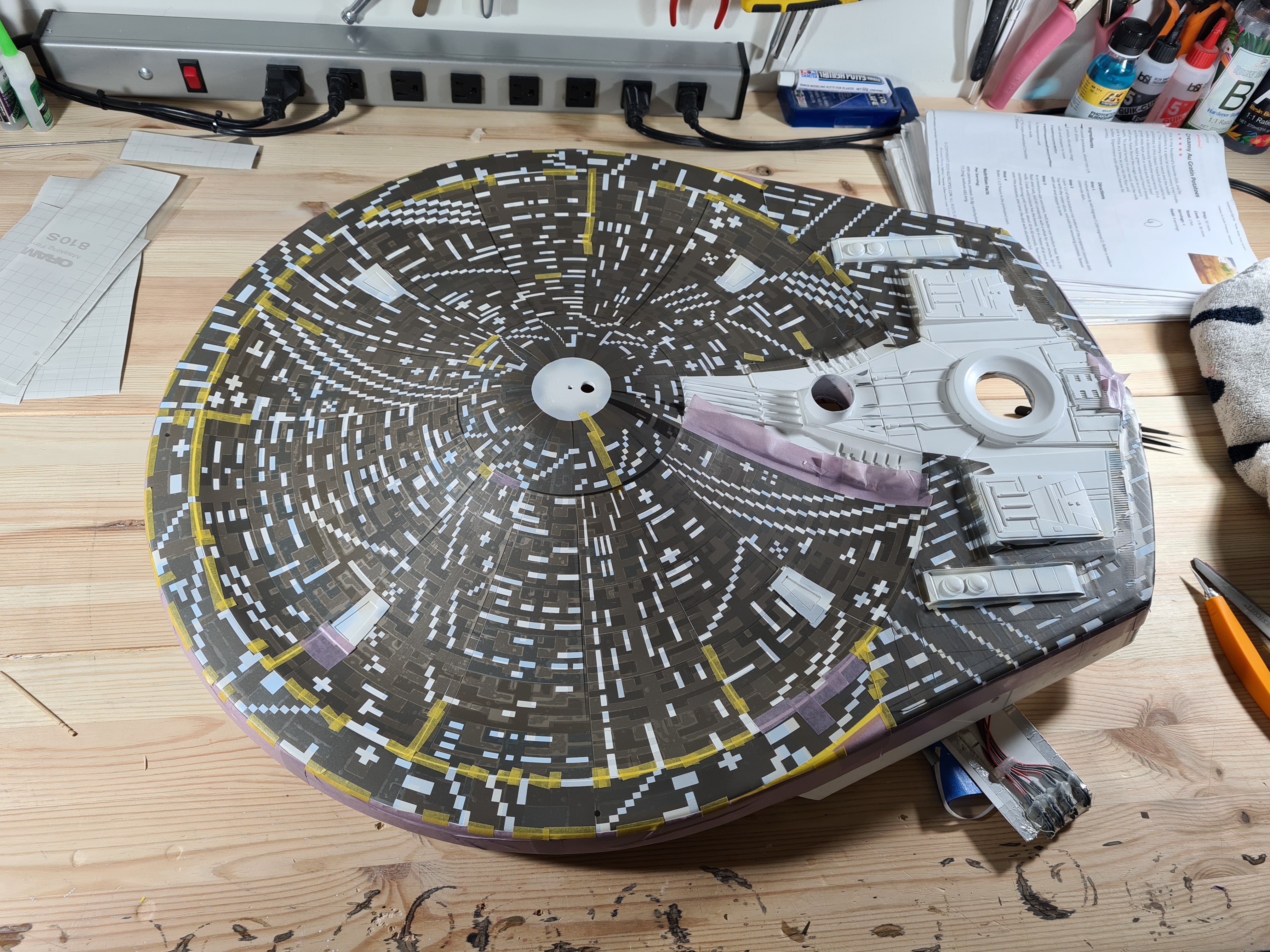

Took about a week of solid work to get the first layer of secondary aztecing down on the bottom. Had to make all of the new masks, lots of time to get them onto the model, weed them, paint them and pull them. Very happy with the outcome. Traveling for work so, will not be doing much for the next week, but then, will get that third layer on.

Cheers,

James

Update #103

Took about a week of solid work to get the first layer of secondary aztecing down on the bottom. Had to make all of the new masks, lots of time to get them onto the model, weed them, paint them and pull them. Very happy with the outcome. Traveling for work so, will not be doing much for the next week, but then, will get that third layer on.

Cheers,

James

Update #104

My morale broke. I have spent weeks on trying to get this problem area into something that I could live with and NEVER fing got there. I can’t tell you how much effort I have put into this failure, UGGG. The first pic is of the best I got on these and I not good enough for me. So, I am filling in all of the holes and going to paint the details on. So, from 2 feet away it will look correct but close up, someone who really knows will notice the difference. The next time I do this, I will design the parts and print on my resin print, and splice them in. I will lose way too much of my paint job doing that at this point. I have one clear part on each nacelle, then touch ups and these two parts are ready to be glued onto the hull. At least I will quit wasting time on this area and move on.

Cheers,

James

My morale broke. I have spent weeks on trying to get this problem area into something that I could live with and NEVER fing got there. I can’t tell you how much effort I have put into this failure, UGGG. The first pic is of the best I got on these and I not good enough for me. So, I am filling in all of the holes and going to paint the details on. So, from 2 feet away it will look correct but close up, someone who really knows will notice the difference. The next time I do this, I will design the parts and print on my resin print, and splice them in. I will lose way too much of my paint job doing that at this point. I have one clear part on each nacelle, then touch ups and these two parts are ready to be glued onto the hull. At least I will quit wasting time on this area and move on.

Cheers,

James

Edge and Neo – HUGE thanks for the support. I travel for work, so sometimes gone for a week or so, which really helped in this case, got some time to decompress, so to speak. That pylon is REALLY bad. My two are not nearly in that shape. Looks like he no longer pressure casts the parts. I also do resin casting and putting things in a pressure cooker to well cook, gets rid of these little air bubbles.

Neo – I have spent a tremendous amount of time filling in pin holes with super glue and sanding them flat again, le sigh.

Update #105

Took some time away from model due to work and got a bunch of stuff done. I painted the details on, not as good as if there were recessed, but still looks 10000% better than my crappy modeling skills would allow me to get to on the recessed panel areas. When I do this on the Enterprise’s pylons, I think I will do this with a resin part and blend it in. I also plan on doing the garden and shuttle bay on my resin printer. They will turn out the best that way. Funny how much technology improves when you take 5+ years to complete a model, LOL. Actually I don’t know if I should laugh or cry…..

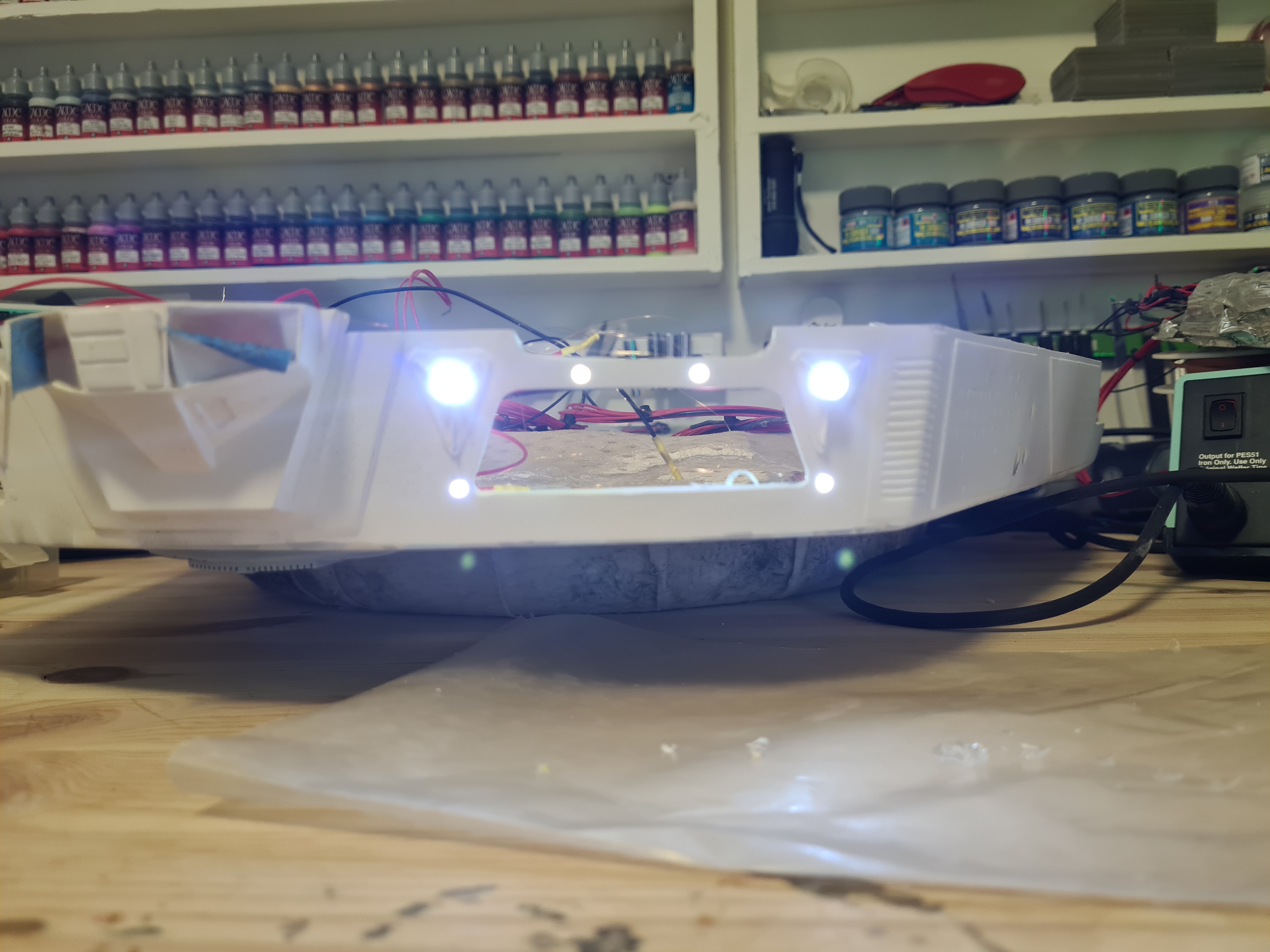

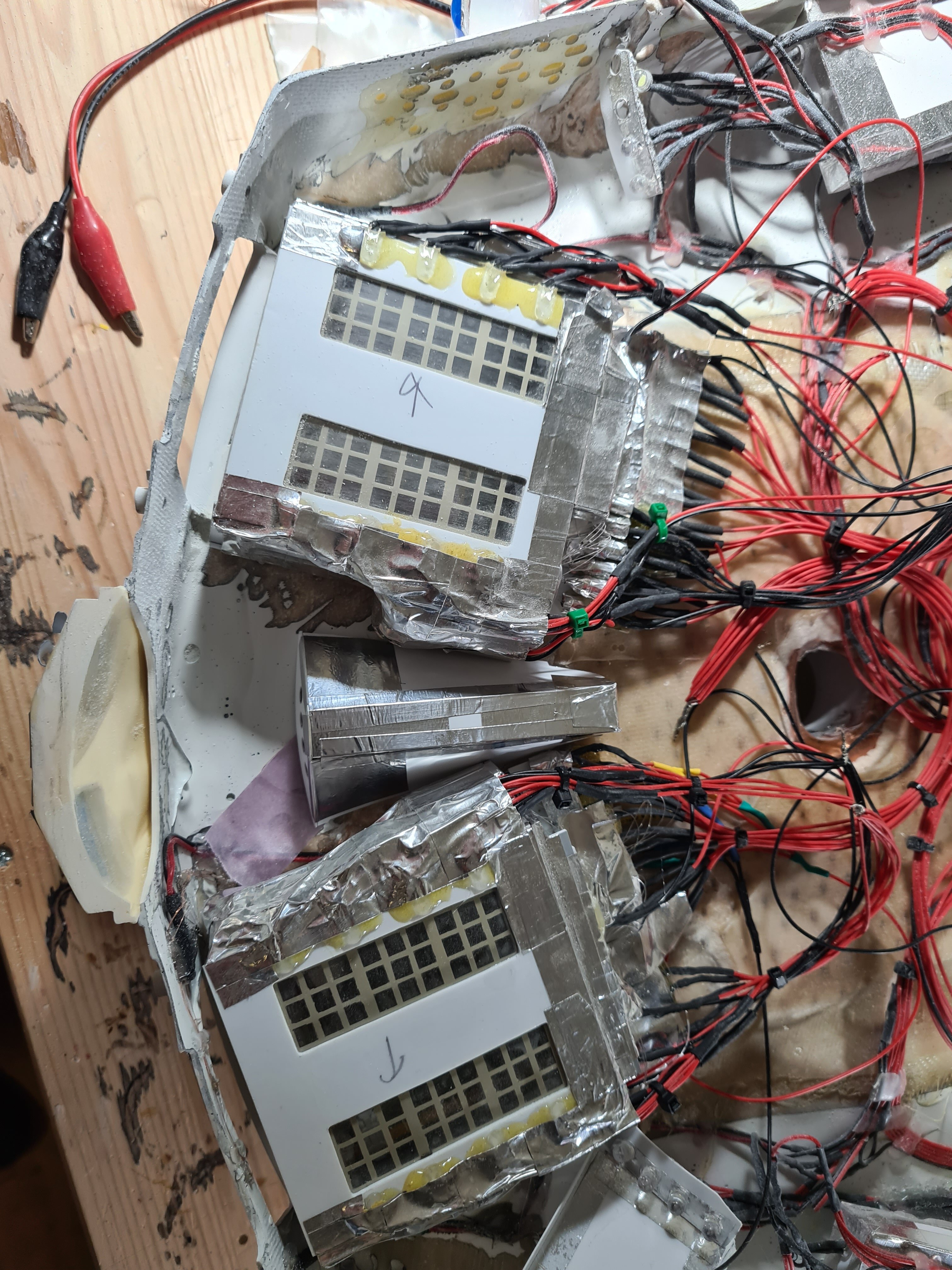

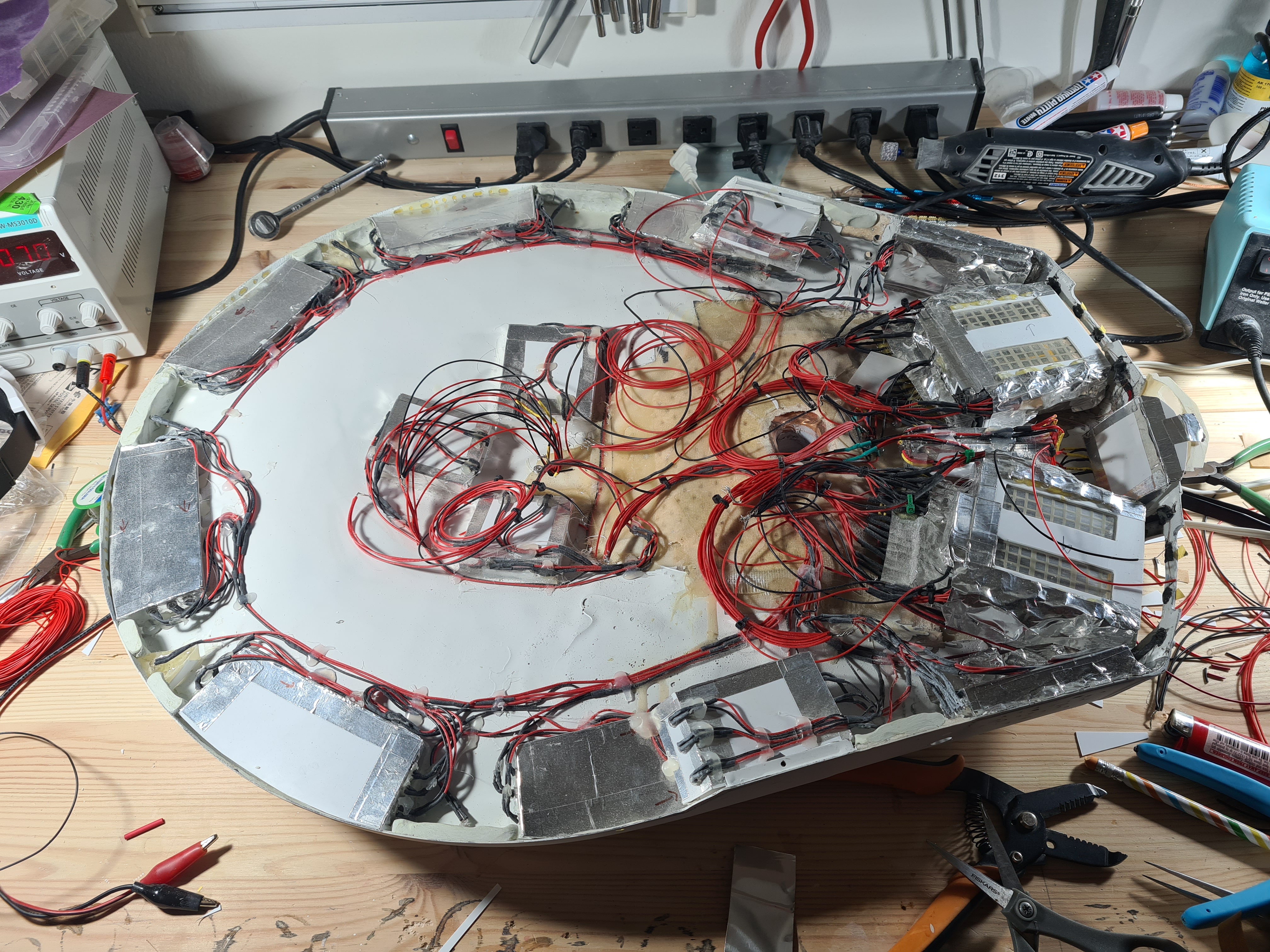

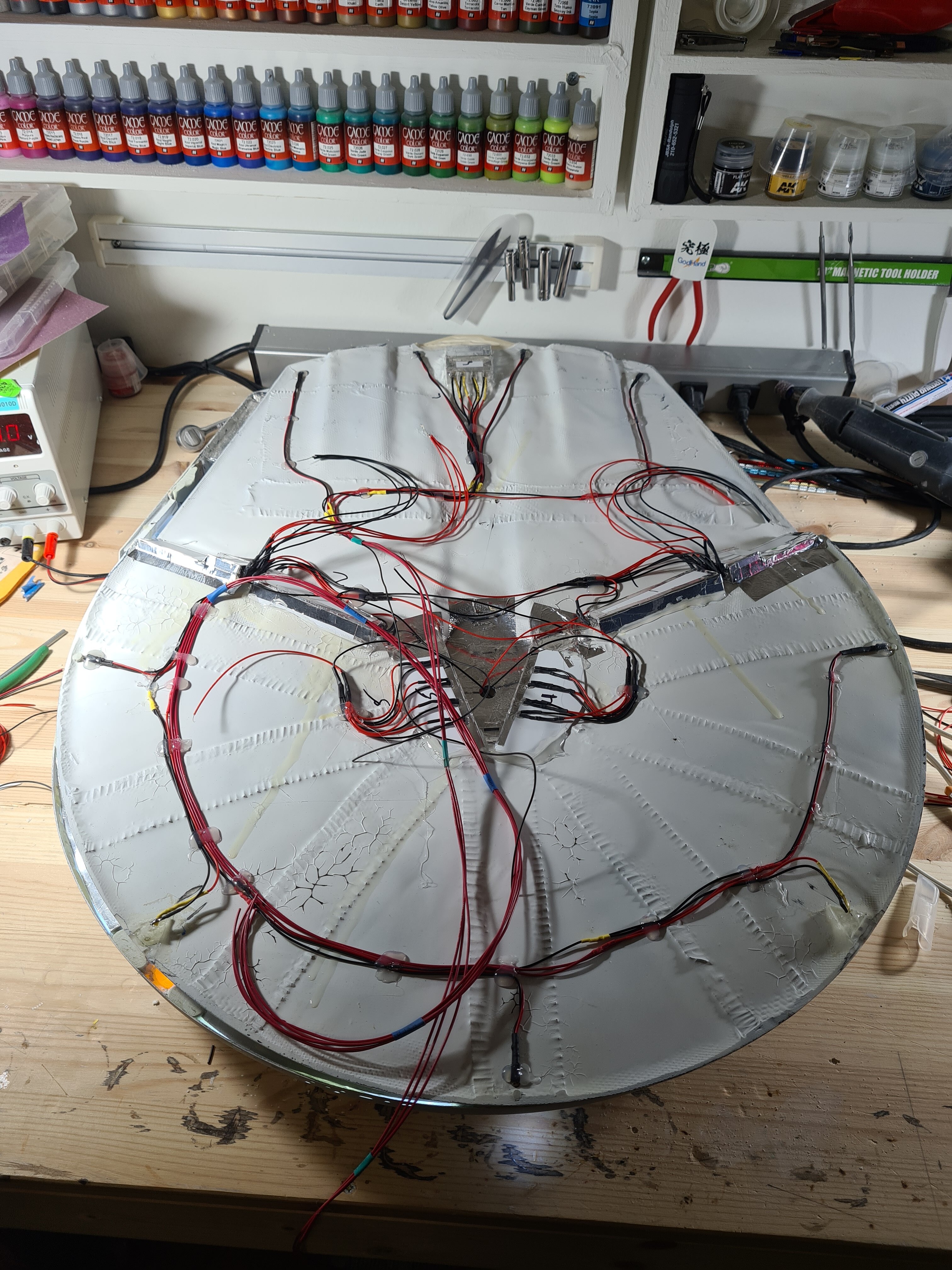

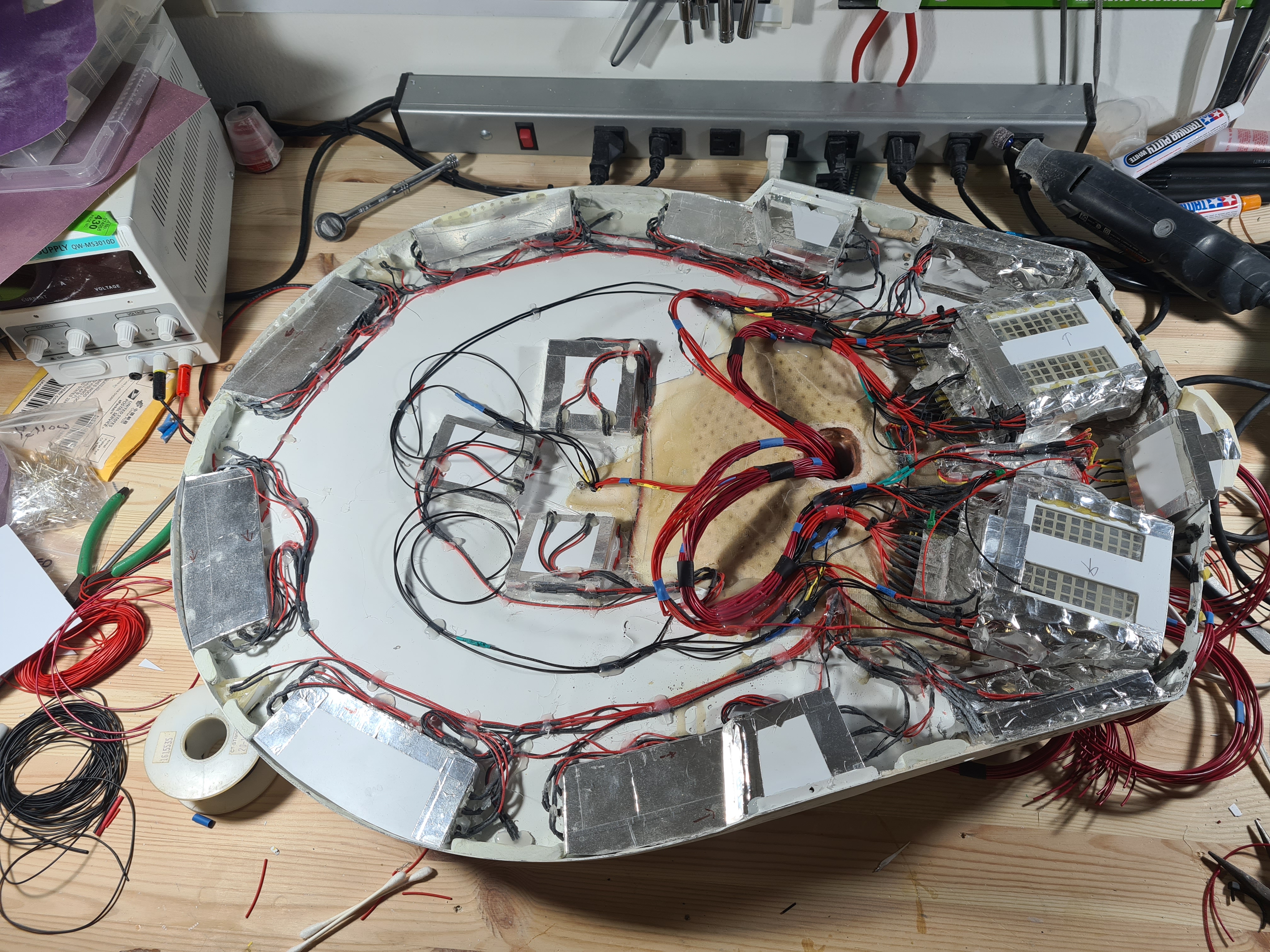

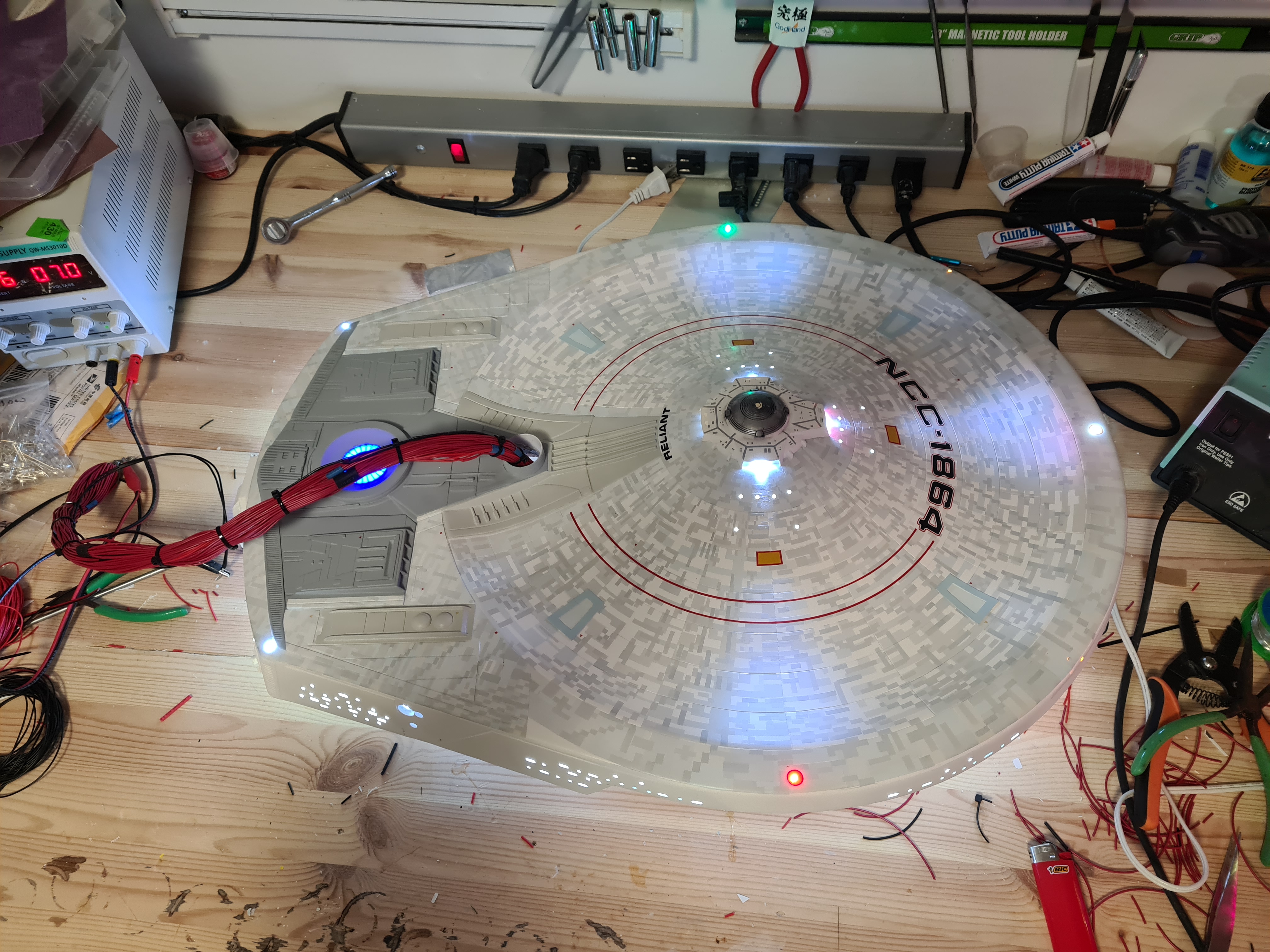

I got the two nacelles completed. When they are glued in I will extend their wiring harness then, so they are wrapped up in cloth and on the shelf, waiting on me to finish the bottom. I have done a light check on all of the bottom lights and have a burnt out/damaged LED on one of the shuttle bays, need to replace that. I finished the bottom impulse crystal. I know in the movie the Reliant only had a blinky light there, but I much prefer a soft blue glow, not movie accurate, but I prefer it this way. I installed all of the LEDs on the rear of the Reliant. I am doing the light blocking later tonight, these hull LEDs even at a low voltage are bright enough to light up the shuttle bays, which is no Bueno. I got the bottom sensor dome and all of the lighting in there complete. I have a money shot of that, along with the two red LEDs. The red LEDs are lit when the Reliant is evil, lol. I still working on how to get the top saucer stuff, stuffed into a little space. The picture shows some light leakage that isn’t there when I bolted the part on. Lots of progress, will have the shuttle bays glue in this week, and maybe even have them blended in and painted in. At that point, I will be ready to glue the nacelles onto the bottom part of the hull, which is SCARY! The end is in sight!

Cheers,

James

Neo – I have spent a tremendous amount of time filling in pin holes with super glue and sanding them flat again, le sigh.

Update #105

Took some time away from model due to work and got a bunch of stuff done. I painted the details on, not as good as if there were recessed, but still looks 10000% better than my crappy modeling skills would allow me to get to on the recessed panel areas. When I do this on the Enterprise’s pylons, I think I will do this with a resin part and blend it in. I also plan on doing the garden and shuttle bay on my resin printer. They will turn out the best that way. Funny how much technology improves when you take 5+ years to complete a model, LOL. Actually I don’t know if I should laugh or cry…..

I got the two nacelles completed. When they are glued in I will extend their wiring harness then, so they are wrapped up in cloth and on the shelf, waiting on me to finish the bottom. I have done a light check on all of the bottom lights and have a burnt out/damaged LED on one of the shuttle bays, need to replace that. I finished the bottom impulse crystal. I know in the movie the Reliant only had a blinky light there, but I much prefer a soft blue glow, not movie accurate, but I prefer it this way. I installed all of the LEDs on the rear of the Reliant. I am doing the light blocking later tonight, these hull LEDs even at a low voltage are bright enough to light up the shuttle bays, which is no Bueno. I got the bottom sensor dome and all of the lighting in there complete. I have a money shot of that, along with the two red LEDs. The red LEDs are lit when the Reliant is evil, lol. I still working on how to get the top saucer stuff, stuffed into a little space. The picture shows some light leakage that isn’t there when I bolted the part on. Lots of progress, will have the shuttle bays glue in this week, and maybe even have them blended in and painted in. At that point, I will be ready to glue the nacelles onto the bottom part of the hull, which is SCARY! The end is in sight!

Cheers,

James

Update #106

Been a long while on an update but the work has been tedious and not very photogenic. Also, in July I was traveling for work or vacation for 23 of the 31 days, hard to work on the model when either leaving or coming back from somewhere. The good news though is that my whole family is vaccinated now, and Italy was pretty empty. Getting to Venice and Florence with 20% of the normal amount of people was amazing. However, I would prefer 100% and no COVID. So here is a breakdown of what I have been working on.

I have put a few nics into the paint job, I see everyone of them, but I doubt anyone else can, I will fix as many as possible once I get it glued up and into the stand. I will have to do the seam around the hull pieces and paint that area also, so plenty of time to get that all sorted out. Sounds off but there is a little anxiety thinking about that glue up! 5 years to get here!

Oh, I have wired all of the LEDS on the hull to turn on at the same time so I can do an operations check on them. I all wanted to know where I sat on how much power the thing is going to draw. So at 12Vs, pulling 3.5As, so 42W of power, which is a crap load. I am glad that most of the model will be run at much lower voltages for two reasons. One, it looks better <- the most important reason and the second is the LED will last waaaaaayyyy longer when you under current them.

Cheers,

James

Been a long while on an update but the work has been tedious and not very photogenic. Also, in July I was traveling for work or vacation for 23 of the 31 days, hard to work on the model when either leaving or coming back from somewhere. The good news though is that my whole family is vaccinated now, and Italy was pretty empty. Getting to Venice and Florence with 20% of the normal amount of people was amazing. However, I would prefer 100% and no COVID. So here is a breakdown of what I have been working on.

- Wire loom – the wiring harness for the main hull is done, there is some work left on each nacelle and the top. The nacelles carry all of the wires from the hull to the roll bar, so I will be able to glue up the main hull and then go to work on the roll bar.

- Fixing all of the interference between the top of the hull and the bottom hull. You would think that with all of the space inside the model no issues, but, yes lots of issues. I have all but 2 of them fixed and these last two are going to take a bit, but sooooooooo close.

- Finishing up the top hull piece. I have almost all of the light boxes and running lights installed. I still have the bridge lighting to do.

- Bridge lighting – I am still thinking about how to do the red LEDs and the spot light effect. I am still not sure if I can actually do both. I think the spot light effect is more important to me than the red LED effect, but uggg, need both.

- Working on getting all of the light boxes on the bottom of the hull put back into good shape and I am probably going to have to put in some sort of stabilizers inside the box to make sure they don’t collapse over time, that would suck if one did.

- Came up with a plan to increase the amount of surface area for the top and bottom to glue to. I will be installing apoxie sculpt on the top of the hull, will take a pic on how hat is going to work when I get there.

I have put a few nics into the paint job, I see everyone of them, but I doubt anyone else can, I will fix as many as possible once I get it glued up and into the stand. I will have to do the seam around the hull pieces and paint that area also, so plenty of time to get that all sorted out. Sounds off but there is a little anxiety thinking about that glue up! 5 years to get here!

Oh, I have wired all of the LEDS on the hull to turn on at the same time so I can do an operations check on them. I all wanted to know where I sat on how much power the thing is going to draw. So at 12Vs, pulling 3.5As, so 42W of power, which is a crap load. I am glad that most of the model will be run at much lower voltages for two reasons. One, it looks better <- the most important reason and the second is the LED will last waaaaaayyyy longer when you under current them.

Cheers,

James

This may seem to be an odd link...but bear with me:

Penn state found a way to print circuits with light:

www.mri.psu.edu

www.mri.psu.edu

Now what this means...is that you could print an aztek in a flash! Actual Metal!

The team also explored options to convert the printed biodegradable zinc circuits into permanent circuits.

Now for Bezos to invest in Art Asylum...

Penn state found a way to print circuits with light:

Printing circuits on irregular surfaces with pulses of light | Printing circuits on irregular surfaces with pulses of light

Printing circuits on irregular surfaces with pulses of light

Now what this means...is that you could print an aztek in a flash! Actual Metal!

The team also explored options to convert the printed biodegradable zinc circuits into permanent circuits.

Now for Bezos to invest in Art Asylum...

modelerdave

Sr Member

Love this! Just noticed the Cylon Raider and Colonial Viper in the shuttle bay! lol

Update #108

I have been working the hull seam forever, but I have been out of town for work 90% of the last 6 months, so progress is slow. I get massive wife agro if I spend more than an hour on it at night when everyone else is asleep! Hopefully, work will slow down here and I can get more time in on the Reliant, she is getting close to being down with the model, still have a lot of base work left. Oh, one reason I need it perfect the first time, I have to carry the model up and downstairs and open several doors. I have visions of me falling down the stairs with the model in hand and it ends up in 100,763.2 pieces……

Will get the top side prepped for paint then flip it over and prep the bottom.

Cheers,

James

I have been working the hull seam forever, but I have been out of town for work 90% of the last 6 months, so progress is slow. I get massive wife agro if I spend more than an hour on it at night when everyone else is asleep! Hopefully, work will slow down here and I can get more time in on the Reliant, she is getting close to being down with the model, still have a lot of base work left. Oh, one reason I need it perfect the first time, I have to carry the model up and downstairs and open several doors. I have visions of me falling down the stairs with the model in hand and it ends up in 100,763.2 pieces……

Will get the top side prepped for paint then flip it over and prep the bottom.

Cheers,

James

Attachments

Mancave2020

New Member

This build is fantastic. Outstanding work.

Thanks for the kind words! I can't wait to be done with this one and get her off to whoever is willing to pay for her!

Update #109

WOW, has been a long time, but work has been nuts and some personal stuff I had to take care of. I was able to take a few days of leave and knock out a ton of work, even though it doesn’t look like much. I am almost done with the seem line on the two hull pieces. I have gone through 3 rounds of clean up and down to about 5 tiny minor issues, should be done some day this week. I have also built the outline of the stencil needed to complete the aztecing on the hull seem and to also be able to lay out the sensor lines, they are going to be painted on for this ship. The lines that were in the original mold were wonky and not very parallel. I have also been cranking away on the roll bar. The amount of work that resin models take is stupid crazy. Lots of hours, to get the parts to a point where I can start gluing up and then fixing the gaps and other part problems. Got a few more LEDs to wire in the roll bar, and I have a way to get the part 95% painted and finished and then will put in the wires that run down into the hull. Easier to take a pic when I get there. I put together a Yamato Tamiya model and WOW, plastic models are the bomb compared to garage resin kits, lol.

The last picture is of all of the parts laid out when I received them from DeBoers and the pic was taken on 27 August 2018, and almost done with the Reliant. I am hopeful that the front and rear acrylic panel for the base will get done this coming week, fingers crossed. I need the panels to install the model into the base and start wiring up all of the switches and electronic hardware that I have built for the model.

Lots of hours, but sure doesn’t look like it!

Cheers,

James

Update #109

WOW, has been a long time, but work has been nuts and some personal stuff I had to take care of. I was able to take a few days of leave and knock out a ton of work, even though it doesn’t look like much. I am almost done with the seem line on the two hull pieces. I have gone through 3 rounds of clean up and down to about 5 tiny minor issues, should be done some day this week. I have also built the outline of the stencil needed to complete the aztecing on the hull seem and to also be able to lay out the sensor lines, they are going to be painted on for this ship. The lines that were in the original mold were wonky and not very parallel. I have also been cranking away on the roll bar. The amount of work that resin models take is stupid crazy. Lots of hours, to get the parts to a point where I can start gluing up and then fixing the gaps and other part problems. Got a few more LEDs to wire in the roll bar, and I have a way to get the part 95% painted and finished and then will put in the wires that run down into the hull. Easier to take a pic when I get there. I put together a Yamato Tamiya model and WOW, plastic models are the bomb compared to garage resin kits, lol.

The last picture is of all of the parts laid out when I received them from DeBoers and the pic was taken on 27 August 2018, and almost done with the Reliant. I am hopeful that the front and rear acrylic panel for the base will get done this coming week, fingers crossed. I need the panels to install the model into the base and start wiring up all of the switches and electronic hardware that I have built for the model.

Lots of hours, but sure doesn’t look like it!

Cheers,

James

And, here you go! lol

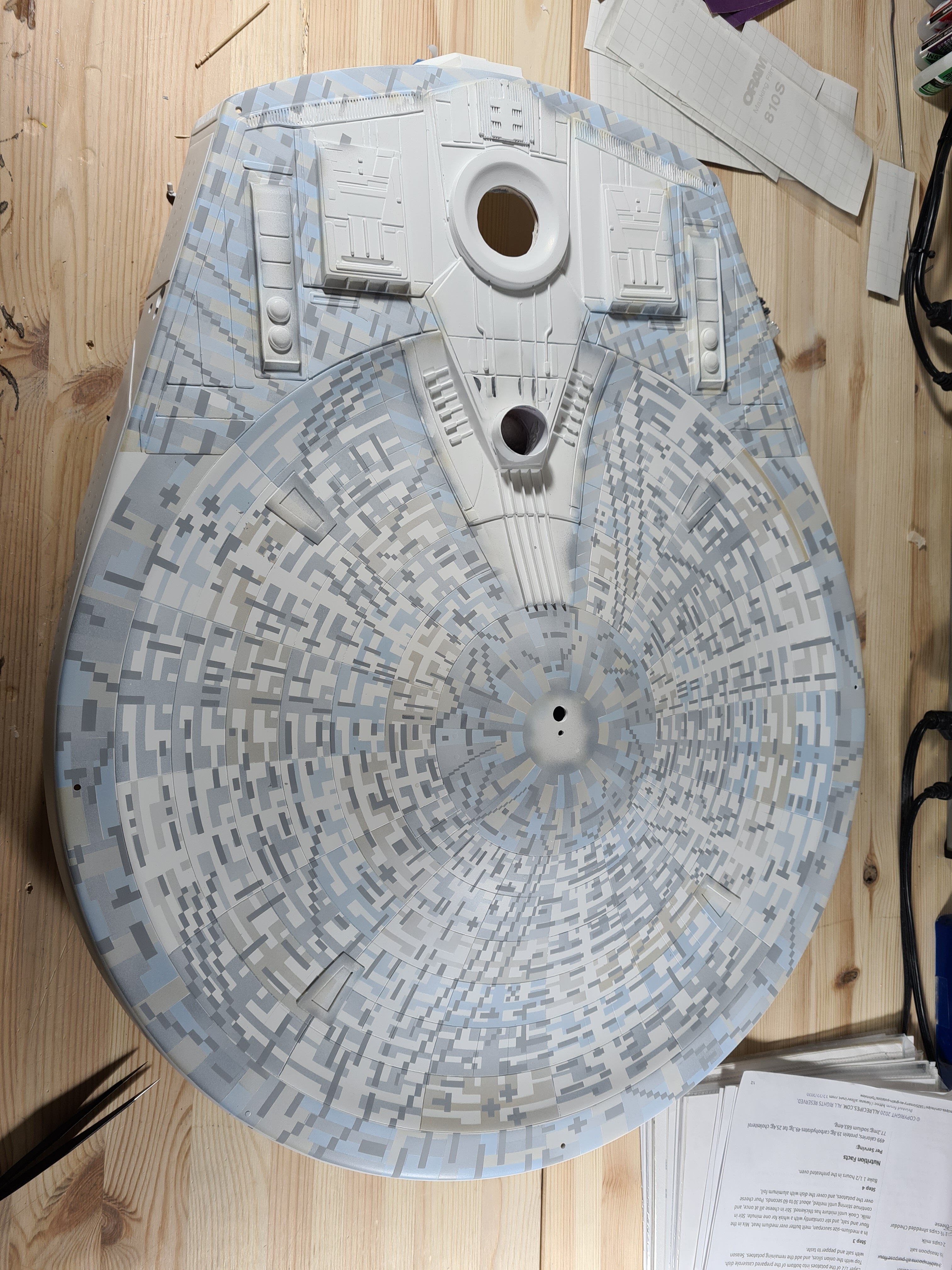

Update #110

Not so long this time. I took a few days off from work to crank out some paint on the Reliant. I have the aztecing completed on the edge of the Reliant. I am finishing up the design for the sensor bands, they will have to be painted on, then cut them out, slap em on and shoot some light blue on em. Then I off to the butt of the Reliant, then clean up the top and bottom, and then install the roll bar!

Cheers,

James

Update #110

Not so long this time. I took a few days off from work to crank out some paint on the Reliant. I have the aztecing completed on the edge of the Reliant. I am finishing up the design for the sensor bands, they will have to be painted on, then cut them out, slap em on and shoot some light blue on em. Then I off to the butt of the Reliant, then clean up the top and bottom, and then install the roll bar!

Cheers,

James

Similar threads

- Replies

- 11

- Views

- 993