Update #79

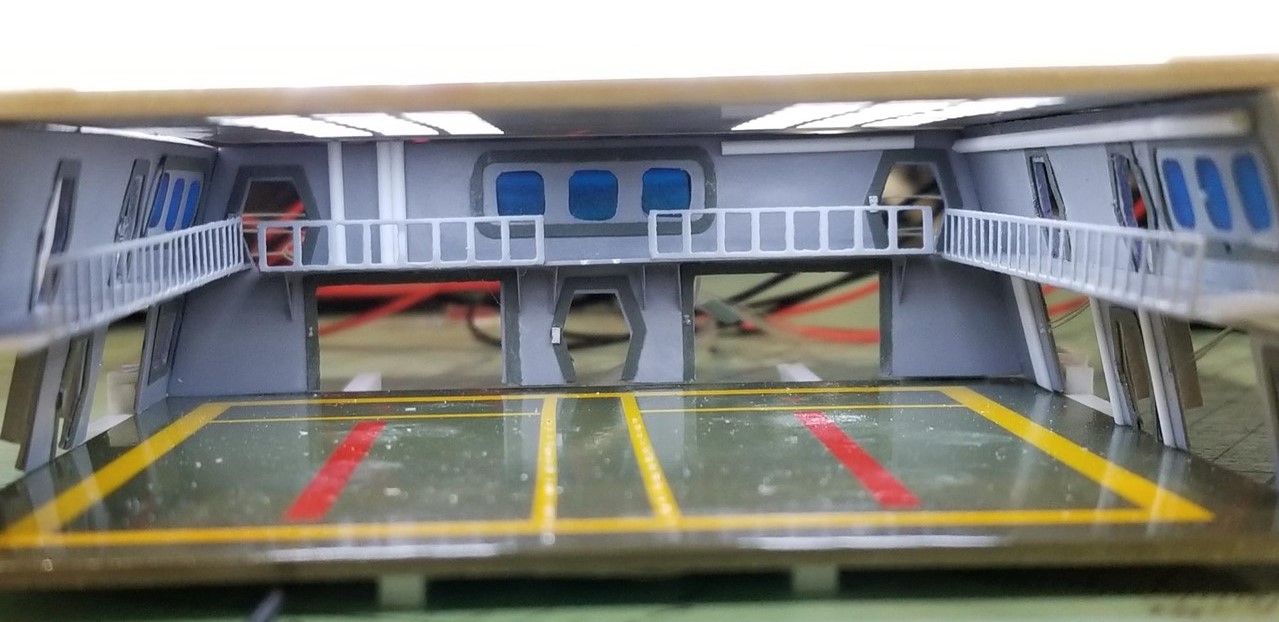

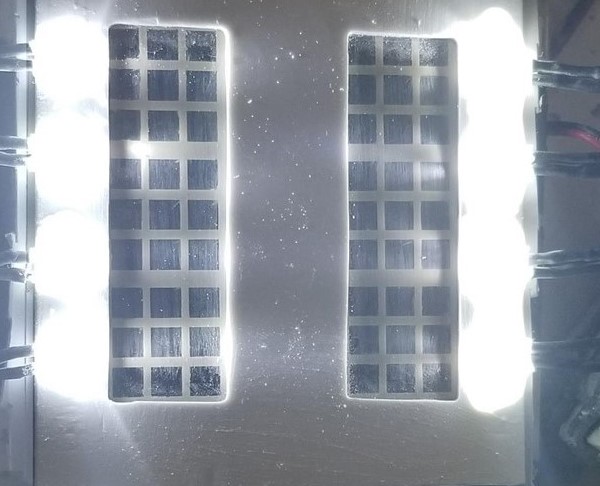

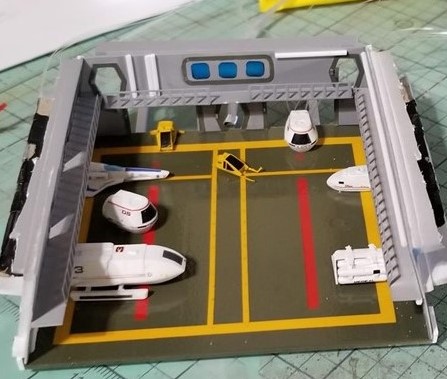

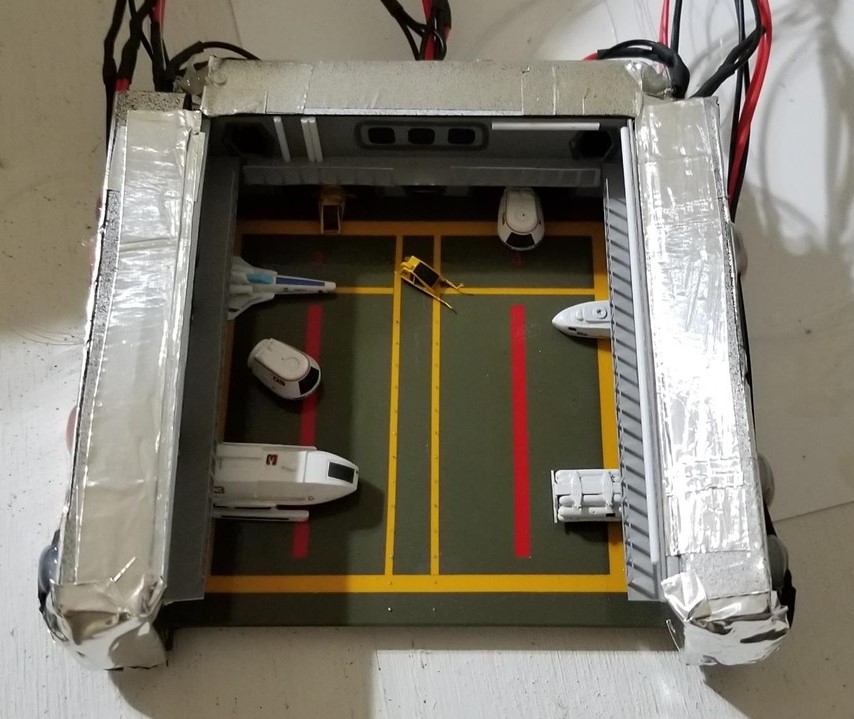

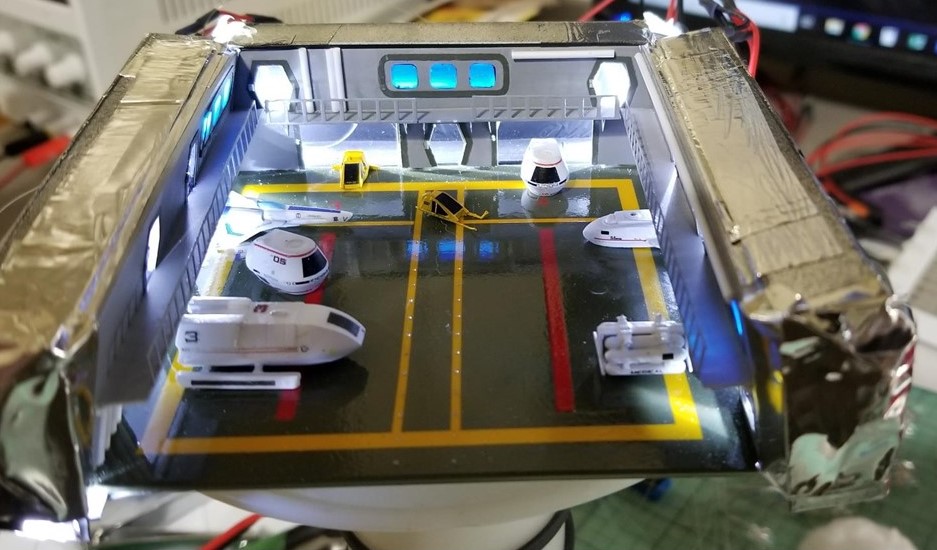

Good and bad update. The good news, every 3 years I build a new PC, and push all my hardware down. Basically, wife gets upgraded and kids get upgraded. Reload the OS, redo all of the heat sink compound, clean everything out, dust, etc. Got 3 of the PCs done, down to 1 PC and the server. A few more days, lots of data on the server to move around. The new machine is super fast, and everyone is happy with their upgrades. I had to vacuum up 974.7 dust bunnies though. So, the model build, I have started to Apoxi sculpt reinforce the Reliant hull and to build up the areas needed to install the shuttle bay. That is the first pic. A lot of writing on failure. First off, you would think with such HUGE models, there would be plenty of room inside the model to do what you need to do. NOT even close. So, the first pic is of a light box enabled way to get light down into the shuttle bays, it of course works perfectly, however, if I want to glue the top of the model onto the bottom of the model, this will not work so good. Pic 3 and pic 4 are shots of the shuttle bay inside with that light box on top. Looks great, but does not fit. So, my solution was to flatten 8 LEDs and glue them onto the top of the shuttle bay light piece. I do not have any pics, but the shuttle bay looks as good as pic 3 and 4. Next pic is of the shuttles glued into the bay. I still have to put the ladder back in, but will wait to do that. I keep knocking it off with my big thumbs. Pic 7 is of the really cool light boxes on the shuttle bay, and pic 8 is of what they look like. I was conflicted on how I like the look but decided that it was cool, even if you could see some of the fiber and LEDs in light boxes. HOWEVER, this will not fit into the model, because the model is not big enough, LOL. So, I am going to close off all of the openings I worked very hard to get put into the model with some sort of door or something, not sure and only light the shuttle bay from the top down. Something like 5 hours of work flushed, but oh well, life goes on. On another note, much more work on the base completed. Matt at LaserFire Creations is an awesome dude helping me out on this build. The base size is settled on, and I am looking for some cool wood veneer to add to the base.

Cheers,

James

Good and bad update. The good news, every 3 years I build a new PC, and push all my hardware down. Basically, wife gets upgraded and kids get upgraded. Reload the OS, redo all of the heat sink compound, clean everything out, dust, etc. Got 3 of the PCs done, down to 1 PC and the server. A few more days, lots of data on the server to move around. The new machine is super fast, and everyone is happy with their upgrades. I had to vacuum up 974.7 dust bunnies though. So, the model build, I have started to Apoxi sculpt reinforce the Reliant hull and to build up the areas needed to install the shuttle bay. That is the first pic. A lot of writing on failure. First off, you would think with such HUGE models, there would be plenty of room inside the model to do what you need to do. NOT even close. So, the first pic is of a light box enabled way to get light down into the shuttle bays, it of course works perfectly, however, if I want to glue the top of the model onto the bottom of the model, this will not work so good. Pic 3 and pic 4 are shots of the shuttle bay inside with that light box on top. Looks great, but does not fit. So, my solution was to flatten 8 LEDs and glue them onto the top of the shuttle bay light piece. I do not have any pics, but the shuttle bay looks as good as pic 3 and 4. Next pic is of the shuttles glued into the bay. I still have to put the ladder back in, but will wait to do that. I keep knocking it off with my big thumbs. Pic 7 is of the really cool light boxes on the shuttle bay, and pic 8 is of what they look like. I was conflicted on how I like the look but decided that it was cool, even if you could see some of the fiber and LEDs in light boxes. HOWEVER, this will not fit into the model, because the model is not big enough, LOL. So, I am going to close off all of the openings I worked very hard to get put into the model with some sort of door or something, not sure and only light the shuttle bay from the top down. Something like 5 hours of work flushed, but oh well, life goes on. On another note, much more work on the base completed. Matt at LaserFire Creations is an awesome dude helping me out on this build. The base size is settled on, and I am looking for some cool wood veneer to add to the base.

Cheers,

James