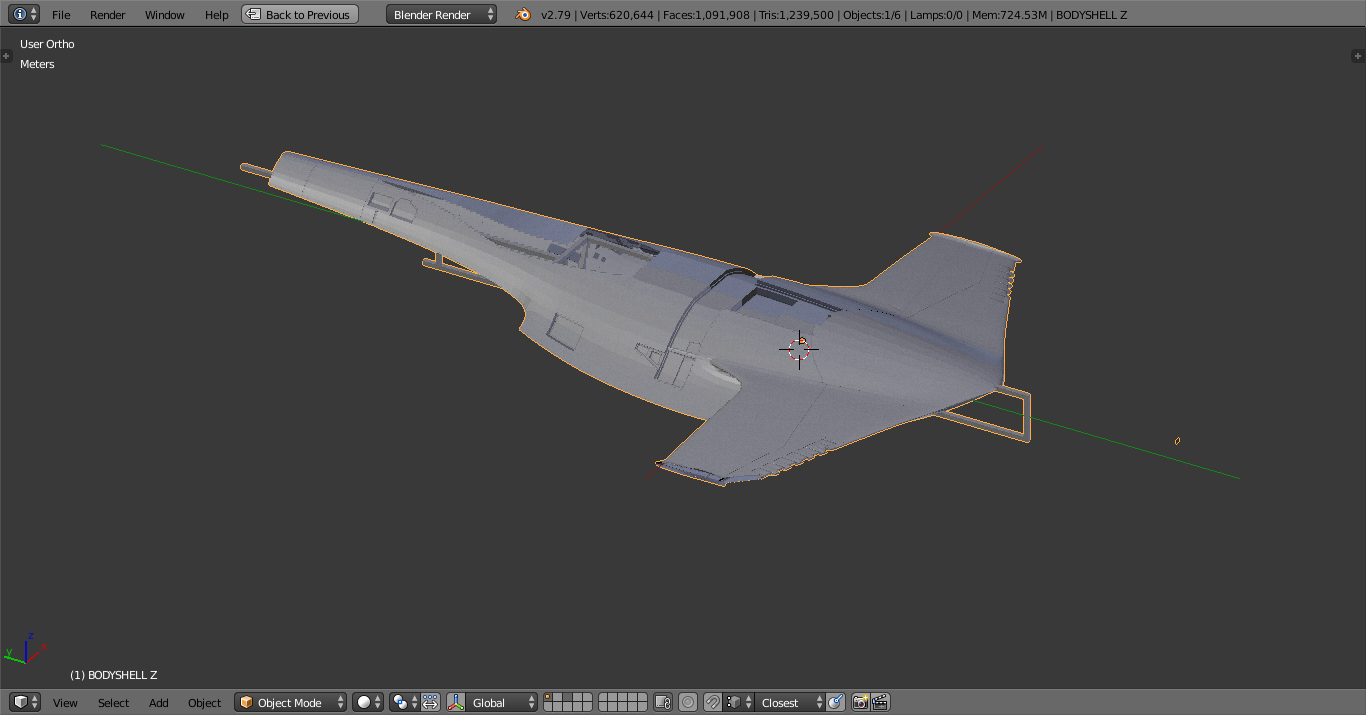

OK I got all the steel cut and welded...I had to totally remove the moulds in the end but they should go back on ok

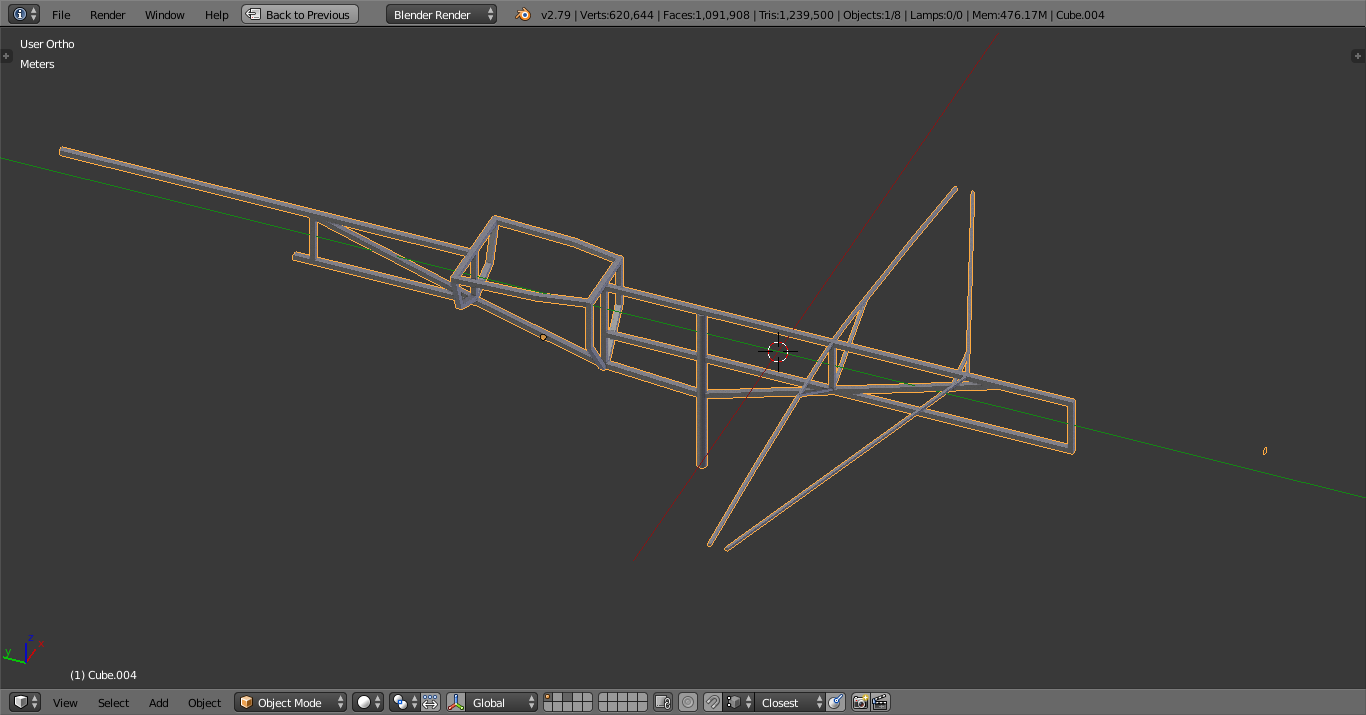

This is the CAD of the Armature

and this is the steel all fitted

Next step is to flip her over 180, attach the moulds and finish the underneath of the ship first, so she can be flipped back again to do the top

This is the CAD of the Armature

and this is the steel all fitted

Next step is to flip her over 180, attach the moulds and finish the underneath of the ship first, so she can be flipped back again to do the top