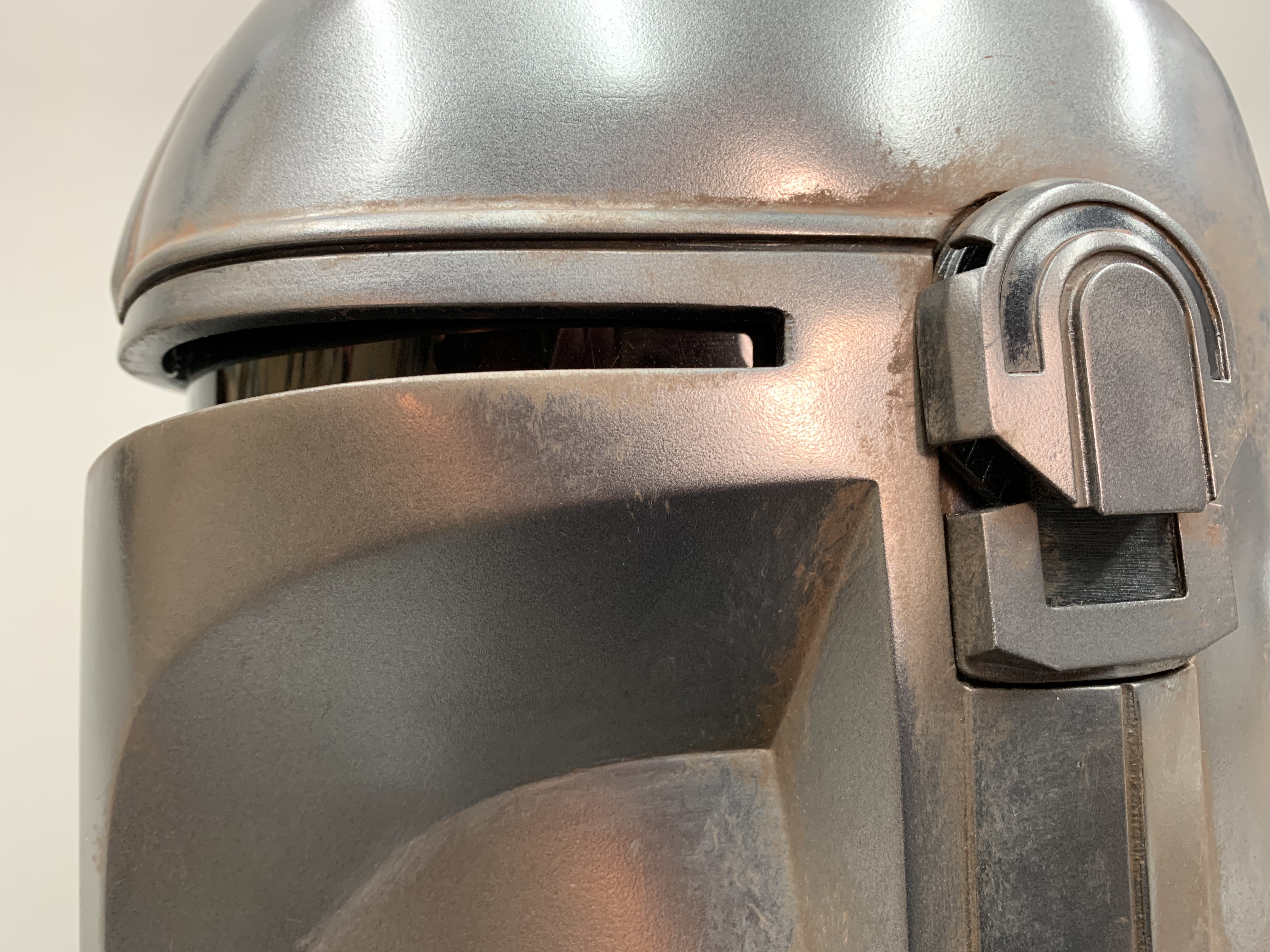

Jumping on The Mandalorian helmet bandwagon here. I did not make the 3D file. It is by TheBrokenNerd. I printed out the file on my 3D printer, but I modified the ear cups to be more screen accurate. (Although I see he has just posted a revised file with correct ear cups). The paint was a new technique for me. After I painted a base coat of Rustoleum Dark Steel, I rubbed graphite powder into the dried paint. It provided a really deep metallic look.

I clear-coated everything with Alclad Aqua Gloss. Then everything was weathered.

I hate when you pick up a cool helmet and the inside is blank. So I wanted to finish the inside properly. Also, the hero on the show never removes his helmet so I got to make up what I think the inner structures, padding, and mechanicals might look like.

I clear-coated everything with Alclad Aqua Gloss. Then everything was weathered.

I hate when you pick up a cool helmet and the inside is blank. So I wanted to finish the inside properly. Also, the hero on the show never removes his helmet so I got to make up what I think the inner structures, padding, and mechanicals might look like.