xl97

Master Member

they are probably wired differently..?

I wouldnt suggest using them (as discussed in this thread already)

regular, individual leds..or a purpose made eye pcb would be best..

and (again) using 9v also isnt recommended...

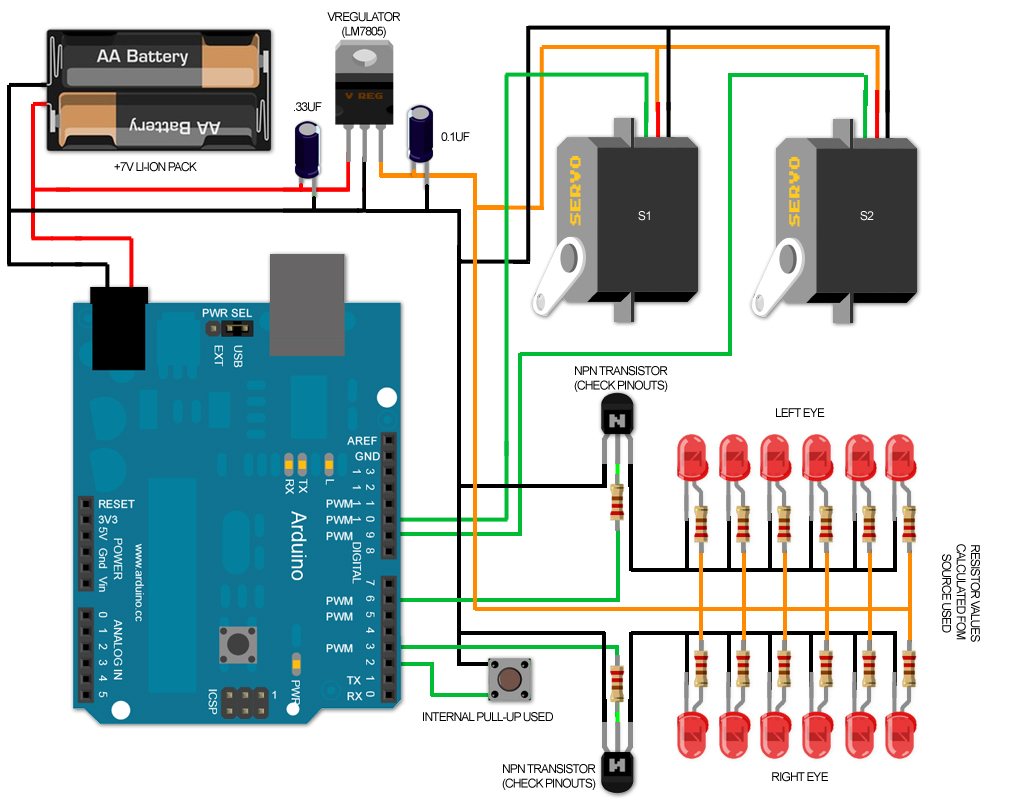

5 x alkaline to get the voltage difference a bit closer to the board/components needs..without too much being burned off as heat.

or

2 x 3.7v li-ions in a 7.4v pack would be best.. IMHO..

I wouldnt suggest using them (as discussed in this thread already)

regular, individual leds..or a purpose made eye pcb would be best..

and (again) using 9v also isnt recommended...

5 x alkaline to get the voltage difference a bit closer to the board/components needs..without too much being burned off as heat.

or

2 x 3.7v li-ions in a 7.4v pack would be best.. IMHO..