I have been following quite a few iron man builds, foam or otherwise and I have not really seen much in the way of assembly instructions or advice.

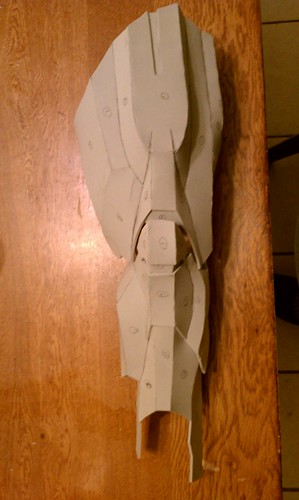

Last night I tried my chest/back section with the abs section and I think i need to add velcro to stop the chest riding up and do something at the back where there appeared a bigger gap, I also found fixing the shoulder bells to the main check back section worked a lot better than trying to secure them with elestic around my arm as in my bikerscout.

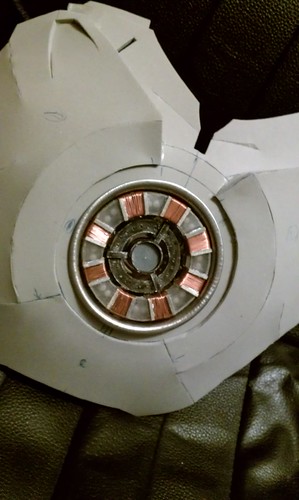

These issues are what lead me to this post to see what you guys have done to assemble your suits once all the parts are made and painted. I have not even thought about mounting the arc reactor. these are issues the pepakura files don't help with and people don't always mention in their build threds.

I do appologise if this has been covered in depth and i'm just missing it.

Last night I tried my chest/back section with the abs section and I think i need to add velcro to stop the chest riding up and do something at the back where there appeared a bigger gap, I also found fixing the shoulder bells to the main check back section worked a lot better than trying to secure them with elestic around my arm as in my bikerscout.

These issues are what lead me to this post to see what you guys have done to assemble your suits once all the parts are made and painted. I have not even thought about mounting the arc reactor. these are issues the pepakura files don't help with and people don't always mention in their build threds.

I do appologise if this has been covered in depth and i'm just missing it.