You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you were to buy a resin printer today...

- Thread starter ID10T

- Start date

I bought an epax x10 and x1-n-dj. I got them because they were solid metal and built like tanks compared to the other printers. Print quality is 2 parts one is the printer and the other is person driving the printer. You can give 5 people the same printer/resin/file and get 5 different results. So quality of the machine is what I look at first. At the end of the day the small printers are 300 or less so your not wasting too much money if you decided to stop using it.

I also just bought a uniz IBEE and have it coming in a few days, their resin and new light system is producing some amazing prints. They do have a steeper learning curve with their soft resin and the slicing software work around seems to be annoying.

I also just bought a uniz IBEE and have it coming in a few days, their resin and new light system is producing some amazing prints. They do have a steeper learning curve with their soft resin and the slicing software work around seems to be annoying.

JNordgren42

Sr Member

My birthday is coming up in a couple of weeks and I think I'm going to treat myself to a resin printer. Looking at the current and near future offerings, the new Mars 3 Ultra 4K is the front runner. Even though I'm too late for the $245 early bird price, $300 isn't bad. I'd love to spring for a larger model, but that's a significant jump in cost and I don't think I can get the boss to approve. They say all preorders will be shipped by August 30th, does anyone have any direct experience with Elegoo order fulfillment and have an over/under for the likelihood of it going on time?

Maybe a dumb question, but how do you clean off the excess resin off your print once it's finished? I've heard people say they are really messy, but maybe the operators posting that are.

How do you guys do in the really cold winter months? How well can these be vented?

xeno

Sr Member

You wash it in isopropyl-alcohol 99%.Maybe a dumb question, but how do you clean off the excess resin off your print once it's finished? I've heard people say they are really messy, but maybe the operators posting that are.

This can be done by hand, ultrasonic cleaner or in a washing station, then you cure the print with an UV lamp.

There are wash and cure stations, that can do all the dirty work in one machine

Hunk a Junk

Sr Member

For what it's worth, I have two printers: an Elegoo Mars resin and an Ender 5-Pro filament. I like them both and they are good for different things. The Mars does a better job at fine detail, so I use it primarily for intricate detail pieces and figures since the layer lines are fairly invisible. The standard grey resin sands nicely. The down side of the Mars, for me, (and for all 3D printing technology) is that it's pretty finicky. The print failure rate is pretty high -- like around 40%. And that's with me cleaning and prepping the FEP and handling everything as if I was working with plutonium. Subsequently, I stick to smaller models when printing in resin just to reduce the amount of waste from failed prints. As time goes by and I get better, I'm hopeful the fail rate will go down. The other downside of resin is that it's messy. There's a big vat of goo and even while cleaning tools and the machine really well there is still a residue stickiness. I use spray bottles of cleaner -- one IPA and another with Green cleaner -- to clean my resin prints. I have a large tinfoil baking pan that I set the print in, spray it down really well, use a soft toothbrush to gently scrub, and then clean with water and paper towels. I built a UV curing station using a UV light, a solar powered (or UV powered) turntable, and some foil-sided foam core to contain and bounce the light around. My Ender-5 Pro I use for larger builds and structural items, like making supports or internal light blocking boxes. I had some trouble initially with prints sticking to the build plate, but running a hobby glue stick over the plate surface first adds enough tension to hold things down. I'm upgrading to a glass plate soon. The layer lines are much more visible on the filament printer, so I don't use it for really detailed models. The failure rate is much lower than with resin, at least for me, more around 15-20%. Neither printer smells particularly bad and my wife has never complained about fumes. When I'm printing with resin I'll leave my paint booth fan running just to keep the air moving in my man cave. Bottom line, both printers are good at what they do, albeit with plenty of fiddling around and inevitable failures. I'm glad I have both, at least until the technology improves -- which it will.

The cleaning process is largely the same, but varies a bit depending on the resin used. I switched over from ABS-like to Water Washable, and it has made a world of difference in my printing workflow. The resin doesn't smell as bad, the cleanup is easier because it's water instead of IPA, etc...

SB

SB

ID10T

Sr Member

Now that I have some experience, I can post some things here.

1) Resin smell. It was a big roadblock for me for a while. I read and watched a lot of reviews on this subject. Look, if you run the printer without a cover (or use one with a venting fan, like the Mars Pro 2), then you will smell it. I have a Mars 2 (non-pro) and the smell is insignificant. Keep the lid on. Even if it sits overnight, because it finished in the middle of the night or whatever, the smell is non-existent until you lift the lid. Do what you need to do quickly and efficiently, and the smell is a non-issue. MAYBE a box of baking soda would absorb the smell, but I haven't tried it.

2) Washing. I wash with denatured alcohol. It's cheap and abundant (unlike isopropyl). Effectiveness is about similar in my opinion. The smell is stronger than the resin smell. So like the printer and resin containers, keep covered until ready to use and cover again ASAP when done.

3) Waster-washable. I have tried it, as I got a sample of it with my printer. It works fine; no up or down side to it as far as I can tell. Smell is about the same. CLEANUP: if you wash in the sink, you are putting resin down the drain... Environmental concerns aside, maybe it sludges up the pipes too. It still needs to be done in a container of some sort, and the resin drawn off, cured and disposed of as a solid (to do it "right").

4) Alcohol recycling. I have printed about three liters worth so far, and used less than a gallon of denatured alcohol. I let the container (that fits on the washer) sit for several days and the resin settles out. I pour it through a coffee filter and hold it aside while I clean the container. I put the sludge in the sun and the alcohol evaporates and the resin solidifies, for disposal in the regular trash.

5) Tricks:

1) Resin smell. It was a big roadblock for me for a while. I read and watched a lot of reviews on this subject. Look, if you run the printer without a cover (or use one with a venting fan, like the Mars Pro 2), then you will smell it. I have a Mars 2 (non-pro) and the smell is insignificant. Keep the lid on. Even if it sits overnight, because it finished in the middle of the night or whatever, the smell is non-existent until you lift the lid. Do what you need to do quickly and efficiently, and the smell is a non-issue. MAYBE a box of baking soda would absorb the smell, but I haven't tried it.

2) Washing. I wash with denatured alcohol. It's cheap and abundant (unlike isopropyl). Effectiveness is about similar in my opinion. The smell is stronger than the resin smell. So like the printer and resin containers, keep covered until ready to use and cover again ASAP when done.

3) Waster-washable. I have tried it, as I got a sample of it with my printer. It works fine; no up or down side to it as far as I can tell. Smell is about the same. CLEANUP: if you wash in the sink, you are putting resin down the drain... Environmental concerns aside, maybe it sludges up the pipes too. It still needs to be done in a container of some sort, and the resin drawn off, cured and disposed of as a solid (to do it "right").

4) Alcohol recycling. I have printed about three liters worth so far, and used less than a gallon of denatured alcohol. I let the container (that fits on the washer) sit for several days and the resin settles out. I pour it through a coffee filter and hold it aside while I clean the container. I put the sludge in the sun and the alcohol evaporates and the resin solidifies, for disposal in the regular trash.

5) Tricks:

- I wash the build plate with acetone. Washing with alcohol, it still has a "damp" appearance. Acetone leaves it "dry" looking, and since switching to this, I have not had a failed print due to not attaching to the plate. Acetone does not seem to attack the uncured resin. I've used it a few times to clean the vat and denatured or reagent grade isopropyl work better to clean the vat.

- I use lens cleaning wipes to clean the screen face and the underside of the plastic film.

- I "stir" my resin for a good 15 minutes prior to use on an old Harbor Freight rock tumbler (I mix my rattle cans the same way- works great!)

- Drain holes! I had a print shatter on me (very high internal stress) and when it did, a good bit of raw resin leaked all over the place. Since this lesson, I include tiny holes at each end of my prints to allow air in and the resin out. I don't understand the high stress issue, but one it broke, the pieces would not line back up to be "repaired".

- Have spare vats ready to go. I have three now, and being able to dump the resin into a new vat and get printing again quickly if things decide to stick to the plastic, is great. Also handy to have a dedicated vat for clear resin, so the print does not get contaminated.

- Standard resin is brittle. Really brittle. I switched to ABS-like resin and I like it much better. Same curing specs (for the same color) as standard resin, so no need to upgrade my print files to use it.

- A thought: If you don't have a curing station, it seems to me you could increase the layer cure time to the same as the base layer cure time. The advantage, as I see it, is that the resin will be fully cured across it's full depth, rather than just a "shell" of fully cured resin on the outside after curing. Downside is the time will be significantly increased to print. And you didn't buy a curing station.

- Know your limitations! After purchasing this printer, I have still relied on outside service for some larger pieces. Think it through before you commit to a large print that will end up pieced together from your smaller printer.

Thanks. I haven't looked into them much beyond what I read whenever my head says to pop into one of these threads. I had no idea you needed to cure resin prints. For some reason I thought the printer was doing it as it printed.

Jun Austria

Well-Known Member

Can't resist not to jump in...

My local supplier only sell Creality products. So I got me the LD-002R. The Wash and Cure is a Creality from Bangggod.

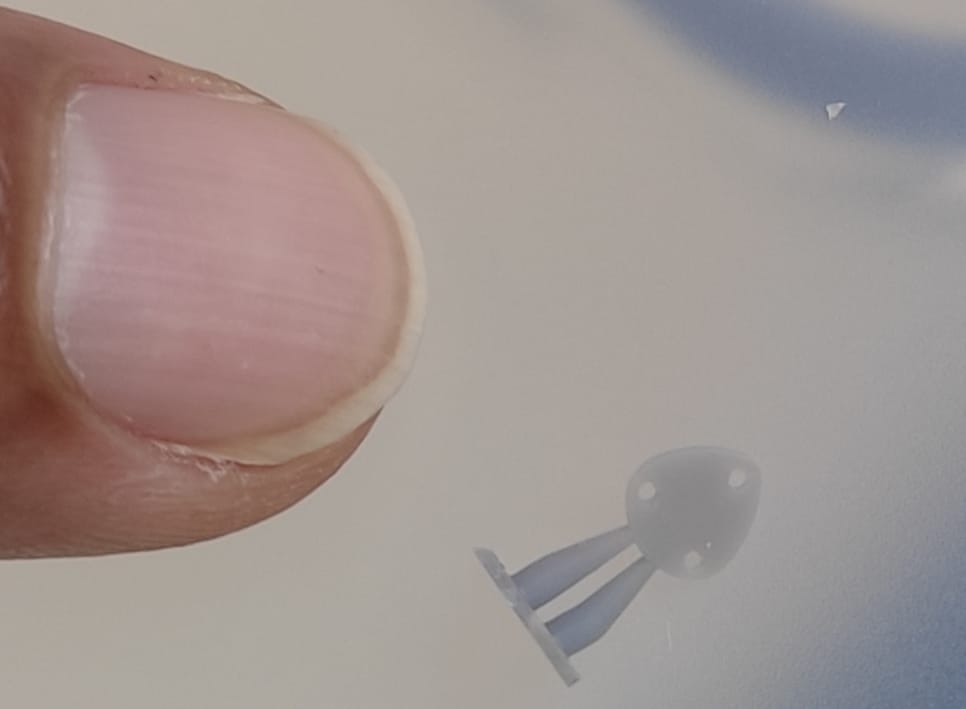

Seeing the result just blew my mind. Casting parts using rubber molds is now a thing of the past for my workflow. Also, I'm using Simple Green for cleaning the resin.

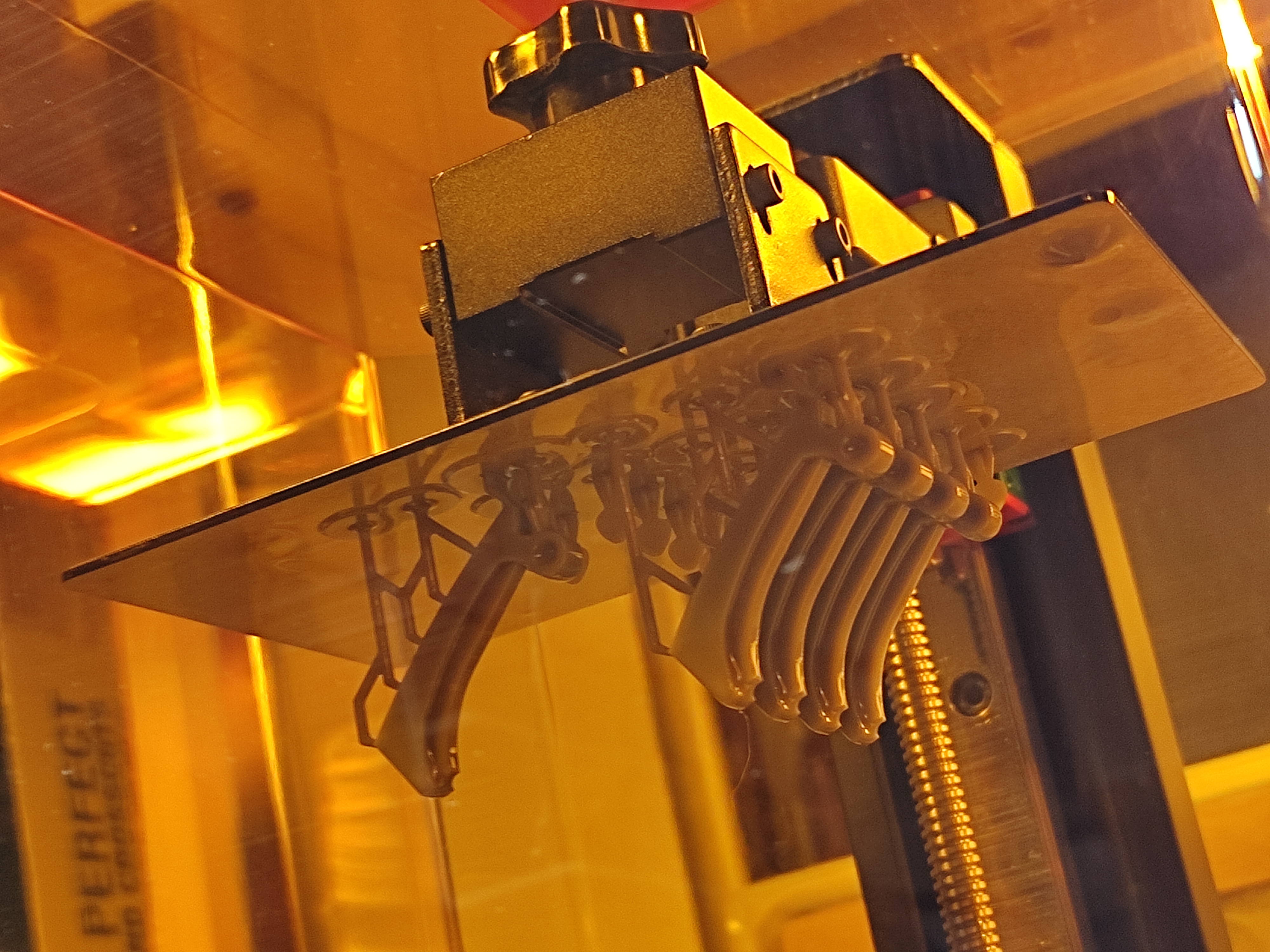

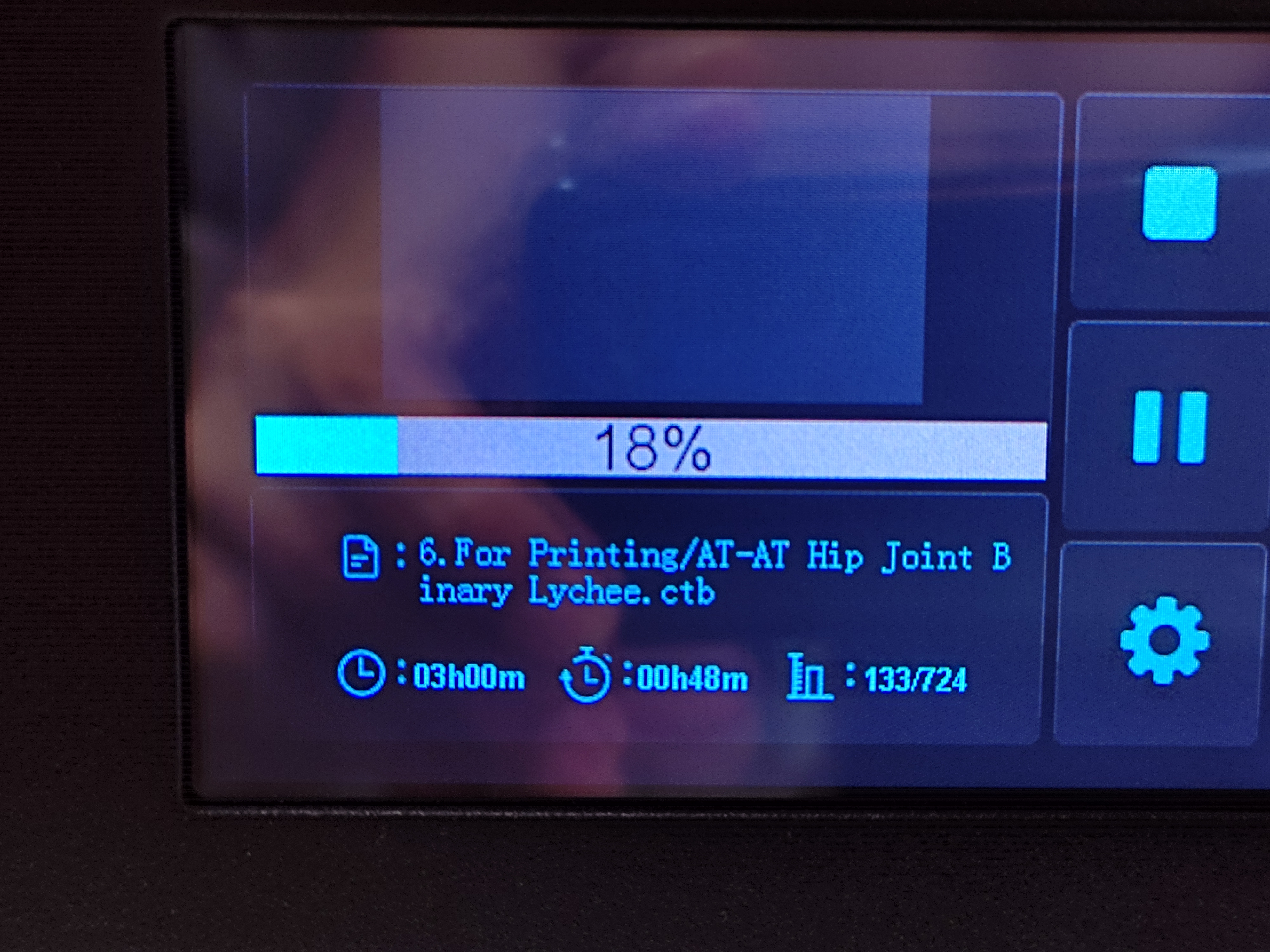

It took almost 4 hours to print. But its worth the wait. So yeah, 3d printers is now part of my workbench.

My local supplier only sell Creality products. So I got me the LD-002R. The Wash and Cure is a Creality from Bangggod.

Seeing the result just blew my mind. Casting parts using rubber molds is now a thing of the past for my workflow. Also, I'm using Simple Green for cleaning the resin.

It took almost 4 hours to print. But its worth the wait. So yeah, 3d printers is now part of my workbench.

Having started with a used Elegoo Mars printer and now adding a Photon Mono X, I can say if I had to start over, I'd go with the Mono X. The main reason is build volume. You can't really beat if you get it on sale. The second reason is the software... Photon Workshop is more stable than Chitubox or any other I've used, more accurate with auto supports, and a bit easier to use. Straight out of the box I was printing with only a couple failed prints due to user error.

It has gotten faster and more stable, but I have yet to have Photon Workshop crash on me in the middle of adding supports. I think some of it has to do with the printer, too.I had some issues with the older Chitubox as well, but the latest version runs well and is much faster than the old version.

The other software may be better but just thought I’d mention this for those who have not upgraded yet.

I’ve been using Lychee with my Mono X. Since I got the resin settings dialed in, I haven’t had an issue.Having started with a used Elegoo Mars printer and now adding a Photon Mono X, I can say if I had to start over, I'd go with the Mono X. The main reason is build volume. You can't really beat if you get it on sale. The second reason is the software... Photon Workshop is more stable than Chitubox or any other I've used, more accurate with auto supports, and a bit easier to use. Straight out of the box I was printing with only a couple failed prints due to user error.

Sean

Just downloaded and tried it... This program changes my mind, almost 100%. Importing my resin and print settings was easy. The program has zero stutter even with the bed full. Auto supports is so easy, it's ridiculous. I will be buying the Pro version for sure. I still think I would go with a 4k printer like the Mono X because it's newer technology and the build volume. Thanks for sharing that!I’ve been using Lychee with my Mono X. Since I got the resin settings dialed in, I haven’t had an issue.

Sean

Glad you like it!Just downloaded and tried it... This program changes my mind, almost 100%. Importing my resin and print settings was easy. The program has zero stutter even with the bed full. Auto supports is so easy, it's ridiculous. I will be buying the Pro version for sure. I still think I would go with a 4k printer like the Mono X because it's newer technology and the build volume. Thanks for sharing that!

When I was researching, I spent some time in Chitubox. It was fine, but the shortcomings became pretty obvious relatively quickly.

And then I tried the AnyCubic slicer…pretty basic.

I found Lychee’s interface much nicer and easier to use. The auto-support function works pretty well. And the manual controls are a nice touch.

I spent about 1 month on it before I sprang for the Pro version. Haven’t looked back.

Sean

Madhatter

Sr Member

I would like to tack on a couple of questions regarding 3D printing if you don't mind. I am also looking very seriously at buying the Mono X (my very first 3D printer) and was checking out CGTrader at some of the 3D models there and the STL file sizes for some were only 539mb which seems very small. Is that the right sort of file size for a 3D model or is that just a render size only? How big are STL files in general that are printable ones?

I saw a couple of really cool subjects there but they were very cheap. Like $9 cheap. That seems too cheap to me for the amount of effort required to make a 3D model. Like the old say, if it seems to good to be true then it isn't. Or am I just being to cynical and thats what the real cost is?

Where is the best place to buy 3D printable files from?

This has been an awesome thread and extremely useful so far.

I saw a couple of really cool subjects there but they were very cheap. Like $9 cheap. That seems too cheap to me for the amount of effort required to make a 3D model. Like the old say, if it seems to good to be true then it isn't. Or am I just being to cynical and thats what the real cost is?

Where is the best place to buy 3D printable files from?

This has been an awesome thread and extremely useful so far.

1) File size is entirely dependant on the complexity of the model, but 539mb sounds *BIG*. Geometric models can take up surprisingly little space, organic or heavily detailed models tend to be larger. As an example, a Mandalorian helmet might be 2mb, a Predator mask 26mb.I would like to tack on a couple of questions regarding 3D printing if you don't mind. I am also looking very seriously at buying the Mono X (my very first 3D printer) and was checking out CGTrader at some of the 3D models there and the STL file sizes for some were only 539mb which seems very small. Is that the right sort of file size for a 3D model or is that just a render size only? How big are STL files in general that are printable ones?

I saw a couple of really cool subjects there but they were very cheap. Like $9 cheap. That seems too cheap to me for the amount of effort required to make a 3D model. Like the old say, if it seems to good to be true then it isn't. Or am I just being to cynical and thats what the real cost is?

Where is the best place to buy 3D printable files from?

This has been an awesome thread and extremely useful so far.

2) The people selling files have to make them affordable and rely on quantity of sales to pay for their time. If you commission a modeller then you pay their hourly rate but this is a different setup.

3) There are a lot of good quality free files on Thingiverse (as well as some complete rubbish). I would look there first before shelling out for print files. I usually make my own models but I have purchased files from was Etsy in the past, and purchasing was a good experience. I'm sure other forum users might be able to provide some alternative options.

Similar threads

- Replies

- 18

- Views

- 1,036

- Replies

- 2

- Views

- 398