Pilot

Sr Member

So anyway, yeah. I built a hot wire foam cutting machine this weekend, mostly out of stuff I had laying around the house. Rather than bore you with the "why," other than its obvious usefulness in cutting foam sheets and blocks for various hobby/prop projects, I'll move right to showing you the "what" and talking just a little bit about the "how."

Keep in mind that while this is in fact an operational cutting table, it's still very much in its larval stage and will be improved upon - mostly to make it as safe as possible - as I keep working on and with it.

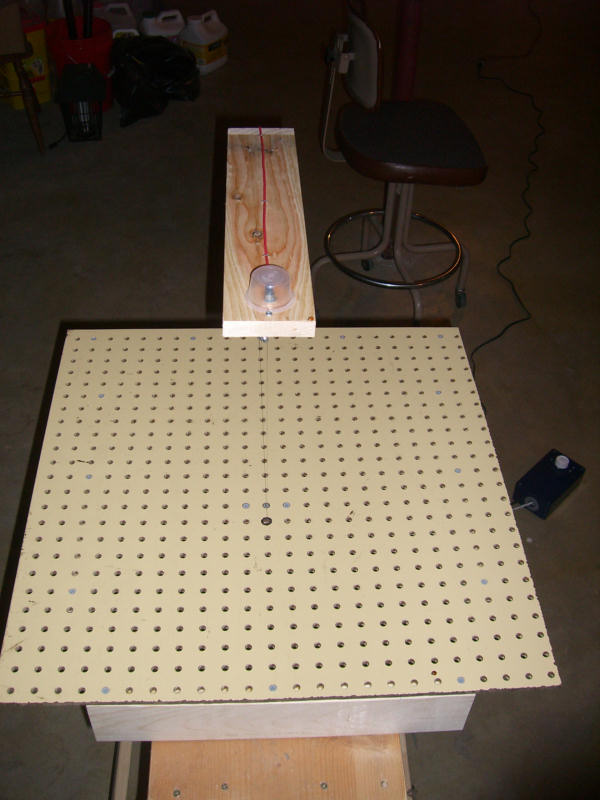

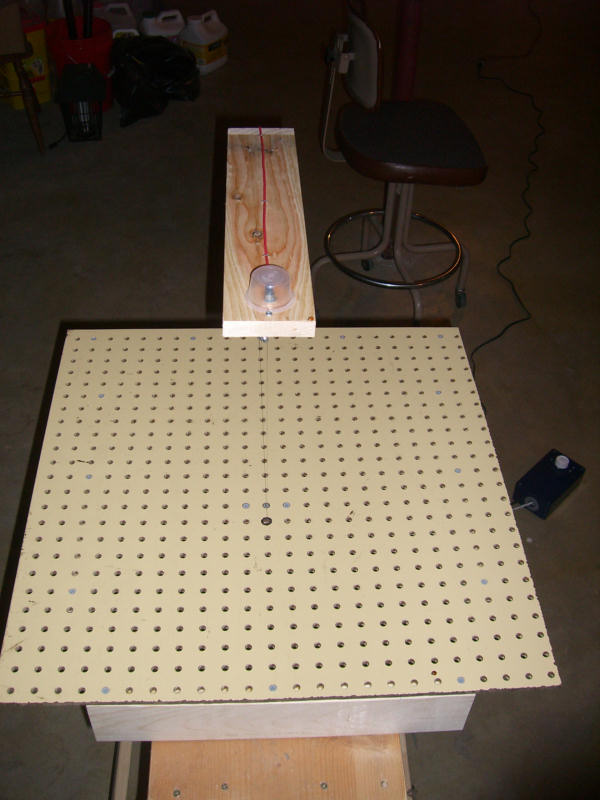

The two pictures above show an overall view of the table. It's just about two feet square and is pretty much made from dimensional lumber and some pegboard. You can *just barely* make out the cutting wire extending down from the arm and going through the hole in the pegboard that's outlined in black.

The wire is suspended from a small diameter bolt that was heated with a propane torch and bent 90 degrees. You can't really see it under my high-tech insulator (it's a Crystal Light drink mix container) but red wire is connected to the bolt with a crimped terminal eye. The picture below shows the bent part of the bolt pretty clearly.

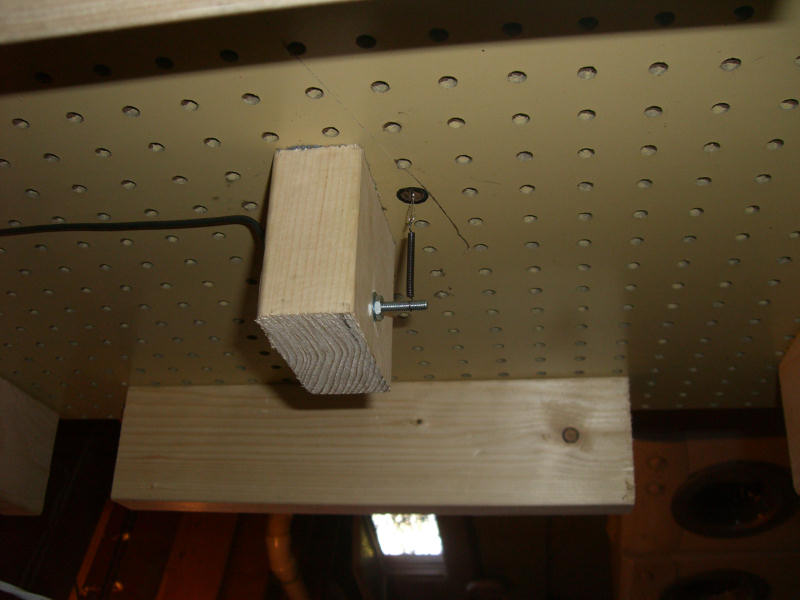

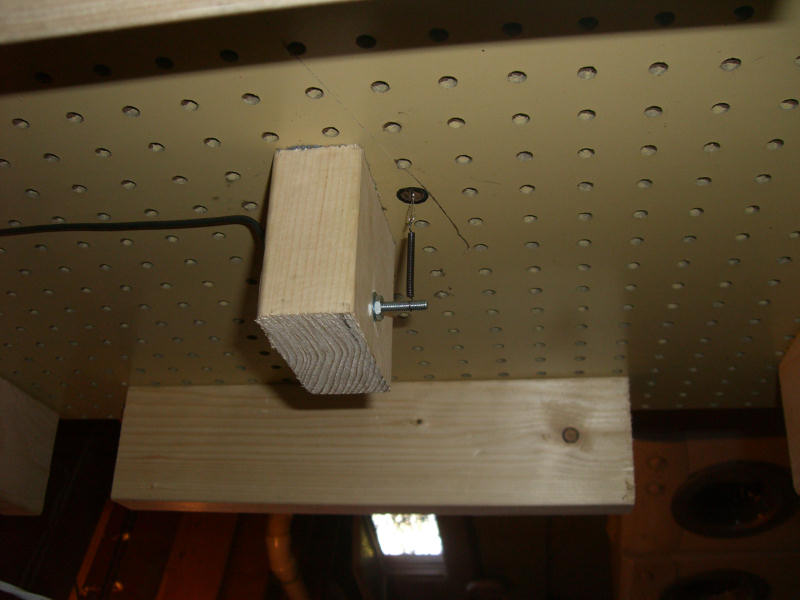

Looking up under the arm.

Closer in, you can (almost) see the looped end of the cutting wire hanging from the bolt threads. This is 30-gauge nichrome wire, and it's pretty tiny stuff. It's simply looped over and twisted to make the eye.

From the back, you can see the terminal board that connects the power supply wiring to the table. The black wire runs underneath to the...

...lower cutting wire connection. Again, the power wire connects to the bolt with a terminal eye. The lower loop of the cutting wire is connected to the bolt with a spring - the nichrome wire lengthens quite noticeably as it heats up, so the spring maintains tension to help keep it from stretching side-to-side when you're running foam through it.

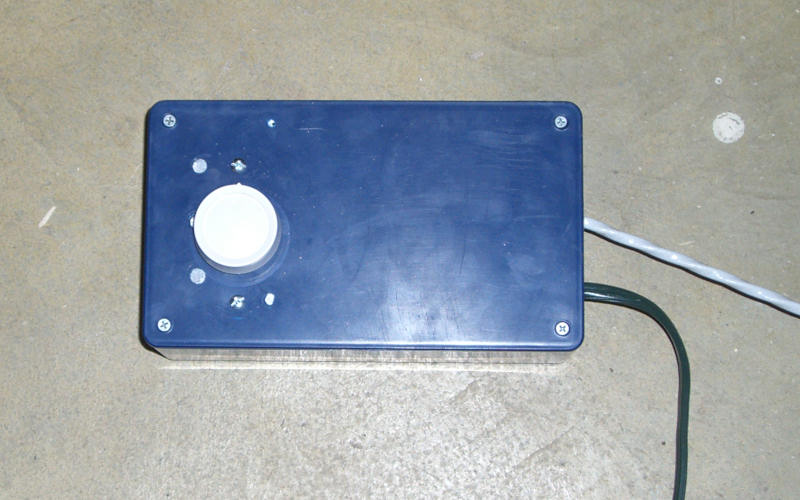

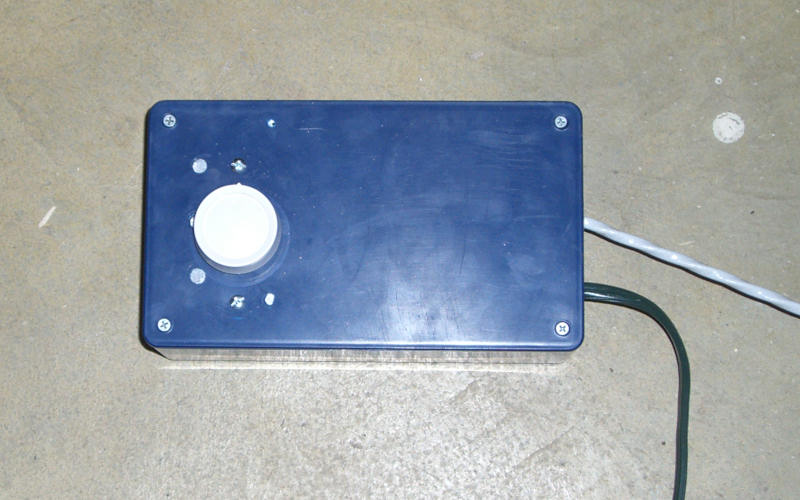

I'm too lazy to take the cover off again, but this recycled project box contains the electrical transformer that actually powers and heats the wire. I salvaged the transformer from an ancient dot matrix printer quite some time ago, and finally found a use for it in this project.

The knob you see is a standard rotary light dimmer switch, and it's used to control the voltage going into the transformer. Normally it would be 120 volts AC power in, providing 20 volts AC power out to the table. That's WAY too much juice for the small 30-gauge wire, so the dimmer (variable resistor) is used to control the voltage and, as a result, the temperature of the wire. It also serves as the ON/OFF switch - pushing the knob inward toggles the power. Here's where Safety Improvement #1 will come in - there's presently no visual indication of when it's turned on. That'll be resolved shortly.

This is the only thing I've cut so far that's worth sharing. Just a little kitty shape, about 6" tall, made for my eternally tolerant and patient wife in gratitude for letting me play mad scientist in her house. :lol

What looks like scorching is actually just a very, VERY thin spot. The initial shape was cut from 1/2" thick styrofoam, and then I sliced it freehand down to about 1/8"...somewhat poorly.

I've obviously left out an enormous amount of actual construction detail. If you do a web search for "hot wire foam cutter," or some variation thereof, you'll have access to all the same learning material I used to make this thing. I'll certainly be glad to answer questions about mine, though, and will be glad to help where I can!

Keep in mind that while this is in fact an operational cutting table, it's still very much in its larval stage and will be improved upon - mostly to make it as safe as possible - as I keep working on and with it.

The two pictures above show an overall view of the table. It's just about two feet square and is pretty much made from dimensional lumber and some pegboard. You can *just barely* make out the cutting wire extending down from the arm and going through the hole in the pegboard that's outlined in black.

The wire is suspended from a small diameter bolt that was heated with a propane torch and bent 90 degrees. You can't really see it under my high-tech insulator (it's a Crystal Light drink mix container) but red wire is connected to the bolt with a crimped terminal eye. The picture below shows the bent part of the bolt pretty clearly.

Looking up under the arm.

Closer in, you can (almost) see the looped end of the cutting wire hanging from the bolt threads. This is 30-gauge nichrome wire, and it's pretty tiny stuff. It's simply looped over and twisted to make the eye.

From the back, you can see the terminal board that connects the power supply wiring to the table. The black wire runs underneath to the...

...lower cutting wire connection. Again, the power wire connects to the bolt with a terminal eye. The lower loop of the cutting wire is connected to the bolt with a spring - the nichrome wire lengthens quite noticeably as it heats up, so the spring maintains tension to help keep it from stretching side-to-side when you're running foam through it.

I'm too lazy to take the cover off again, but this recycled project box contains the electrical transformer that actually powers and heats the wire. I salvaged the transformer from an ancient dot matrix printer quite some time ago, and finally found a use for it in this project.

The knob you see is a standard rotary light dimmer switch, and it's used to control the voltage going into the transformer. Normally it would be 120 volts AC power in, providing 20 volts AC power out to the table. That's WAY too much juice for the small 30-gauge wire, so the dimmer (variable resistor) is used to control the voltage and, as a result, the temperature of the wire. It also serves as the ON/OFF switch - pushing the knob inward toggles the power. Here's where Safety Improvement #1 will come in - there's presently no visual indication of when it's turned on. That'll be resolved shortly.

This is the only thing I've cut so far that's worth sharing. Just a little kitty shape, about 6" tall, made for my eternally tolerant and patient wife in gratitude for letting me play mad scientist in her house. :lol

What looks like scorching is actually just a very, VERY thin spot. The initial shape was cut from 1/2" thick styrofoam, and then I sliced it freehand down to about 1/8"...somewhat poorly.

I've obviously left out an enormous amount of actual construction detail. If you do a web search for "hot wire foam cutter," or some variation thereof, you'll have access to all the same learning material I used to make this thing. I'll certainly be glad to answer questions about mine, though, and will be glad to help where I can!

Last edited: