For years, the go-to material for making skins for creatures has been foam latex because of its flexibility and other skin mimicking qualities. The drawback of foam latex is that it does not have prolonged shelf life, as it deteriorates over time due to the high water content of latex, as well as UV rays, etc., etc. When it comes to making predator body stuff here on the Lair, the best solution is regular latex rubber, which has a lot of the same qualities, but will last much longer if taken care of.

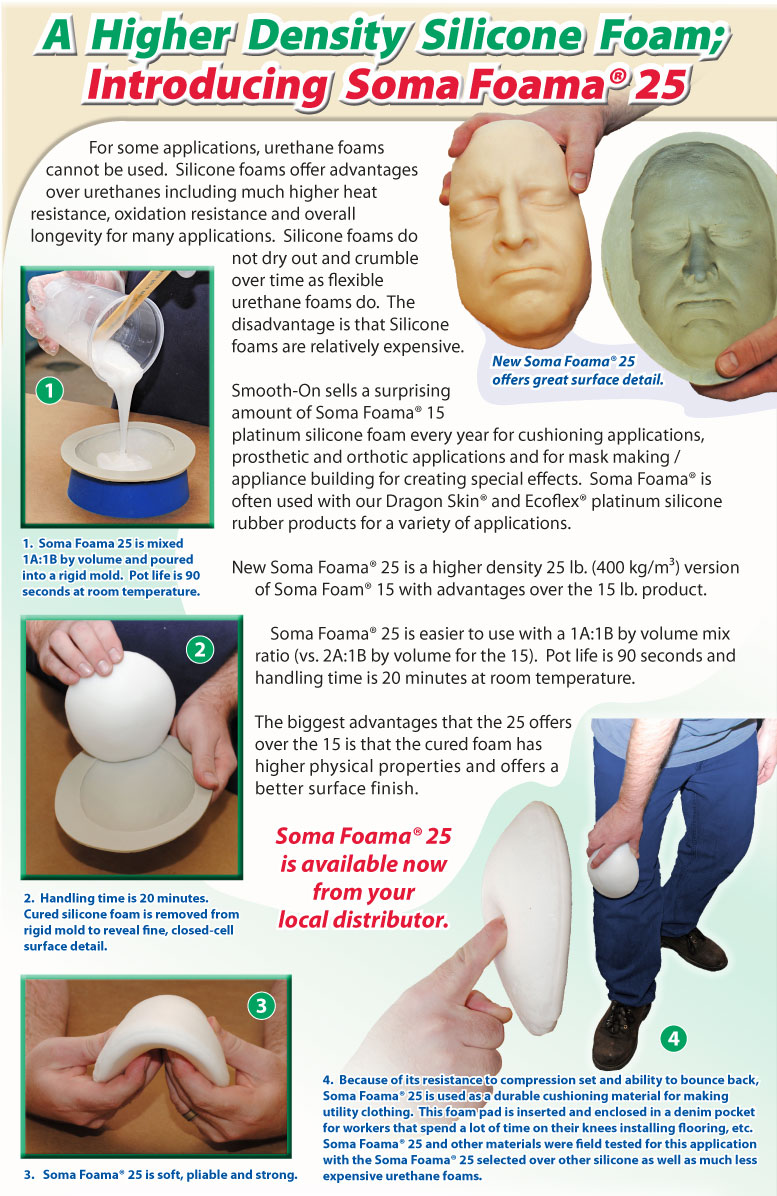

It looks as though that has all changed with the release of a new material from Smooth On called Soma Foama 25. It's a platinum SILICONE based foam that has the following characteristics:

- It's denser than the current Soma Foama 15, therefore the cured skin can capture more detail.

- It does not shrink after curing, so you don't have to oversize your sculpt to compensate for shrinkage like you do for latex casting.

- It does not crumble or deteriorate over time like latex-based foam, so your costume will stay intact for a long, long time.

I learned all this after calling Smooth On the other day and talking with one of their material specialists over there. It seems like the Holy Grail of practical predator body parts duplication now exists! The only drawback would be having to scoop/ hollow out the foam from your castings so they can be worn. The nice thing is that they'll already have foam backing them up so there doesn't need to be expanding foam like Smooth On's urethane-based Foam It added to the back of a traditional latex casting to maintain it's shape.

At some point down the road, I'm going to give a go at sculpting a P1 head, with the idea of pouring this stuff into my Ultra Cal or Hydra Cal mould. In the meantime I look forward to somebody else trying it out. Needless to say it is not compatible with tin or platinum silicone moulds.

Check out the attached sheet.

It looks as though that has all changed with the release of a new material from Smooth On called Soma Foama 25. It's a platinum SILICONE based foam that has the following characteristics:

- It's denser than the current Soma Foama 15, therefore the cured skin can capture more detail.

- It does not shrink after curing, so you don't have to oversize your sculpt to compensate for shrinkage like you do for latex casting.

- It does not crumble or deteriorate over time like latex-based foam, so your costume will stay intact for a long, long time.

I learned all this after calling Smooth On the other day and talking with one of their material specialists over there. It seems like the Holy Grail of practical predator body parts duplication now exists! The only drawback would be having to scoop/ hollow out the foam from your castings so they can be worn. The nice thing is that they'll already have foam backing them up so there doesn't need to be expanding foam like Smooth On's urethane-based Foam It added to the back of a traditional latex casting to maintain it's shape.

At some point down the road, I'm going to give a go at sculpting a P1 head, with the idea of pouring this stuff into my Ultra Cal or Hydra Cal mould. In the meantime I look forward to somebody else trying it out. Needless to say it is not compatible with tin or platinum silicone moulds.

Check out the attached sheet.