tubachris85x

Master Member

I've decided to push through and get this sucker done. I desperatly need to make a transition mold, but I really don't want to spend $$ for silicone that I'm literally going to only need for one casting.

So, my alternative is to make a plaster mold and a plaster cast (or resin?). The thing though, is that this is going to be a massive mold. I have planned it as such that I'll have to break it up into 2 sections, maybe 3 or even 4. I just need input!

To give you an idea of scale, the helmet eats an MR clonetrooper bucket like nothing!

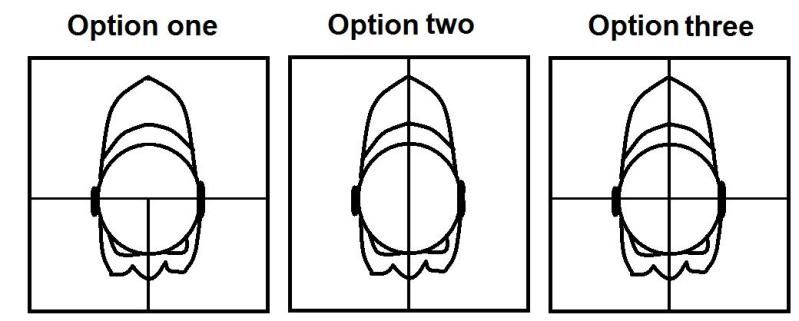

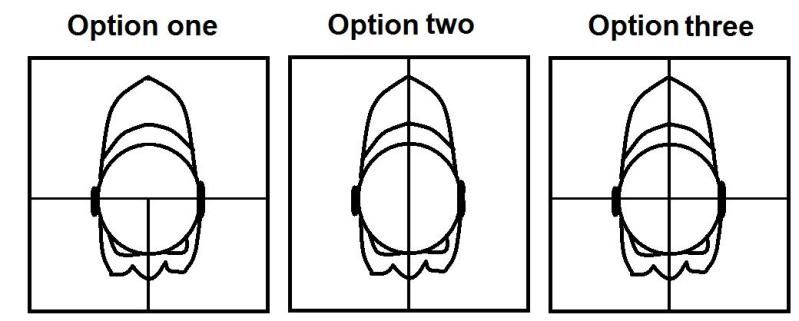

So here are the options for the mold break up that I was thinking about. Any input would be greatly appreiciated!

-TC

So, my alternative is to make a plaster mold and a plaster cast (or resin?). The thing though, is that this is going to be a massive mold. I have planned it as such that I'll have to break it up into 2 sections, maybe 3 or even 4. I just need input!

To give you an idea of scale, the helmet eats an MR clonetrooper bucket like nothing!

So here are the options for the mold break up that I was thinking about. Any input would be greatly appreiciated!

-TC