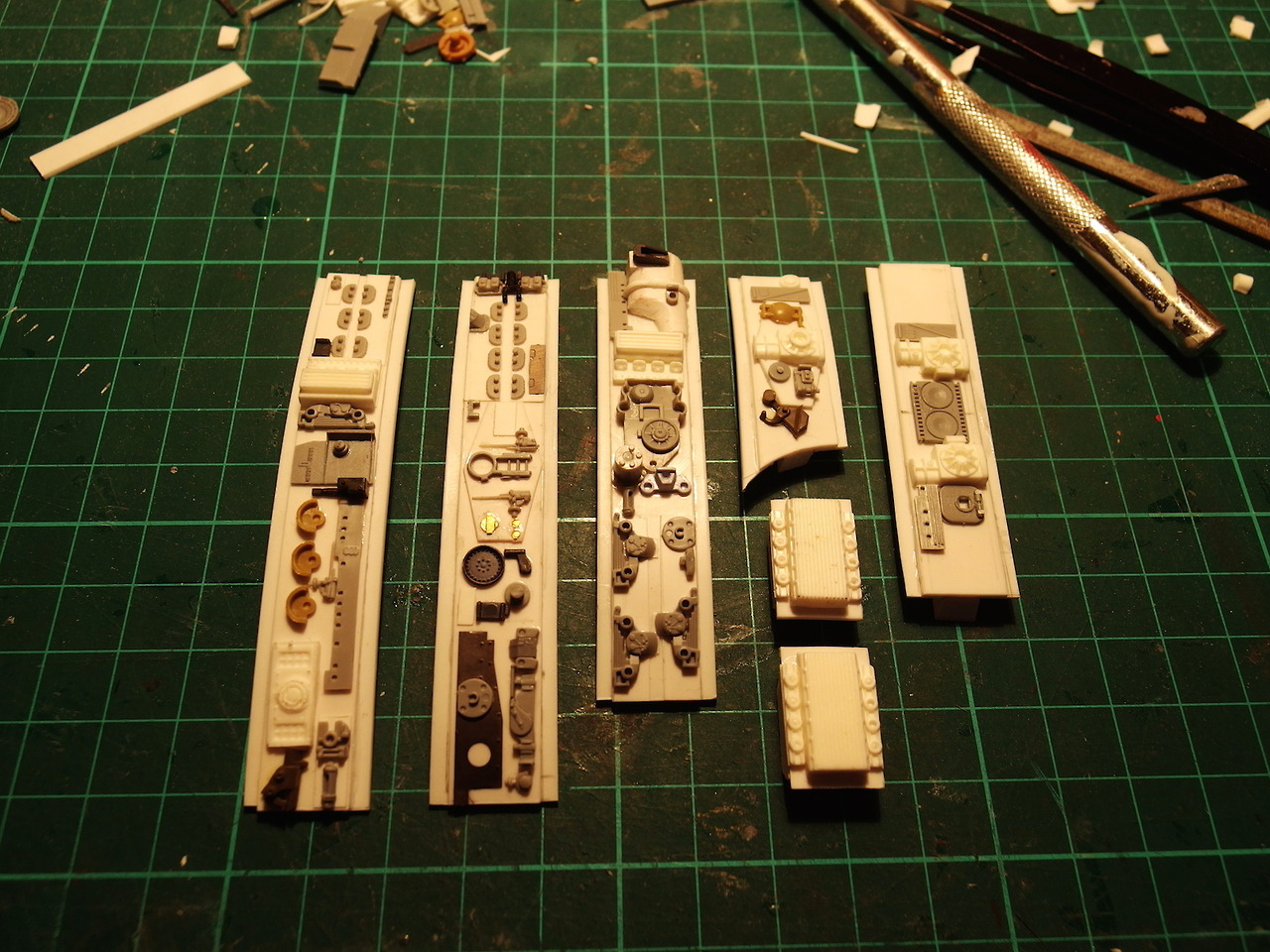

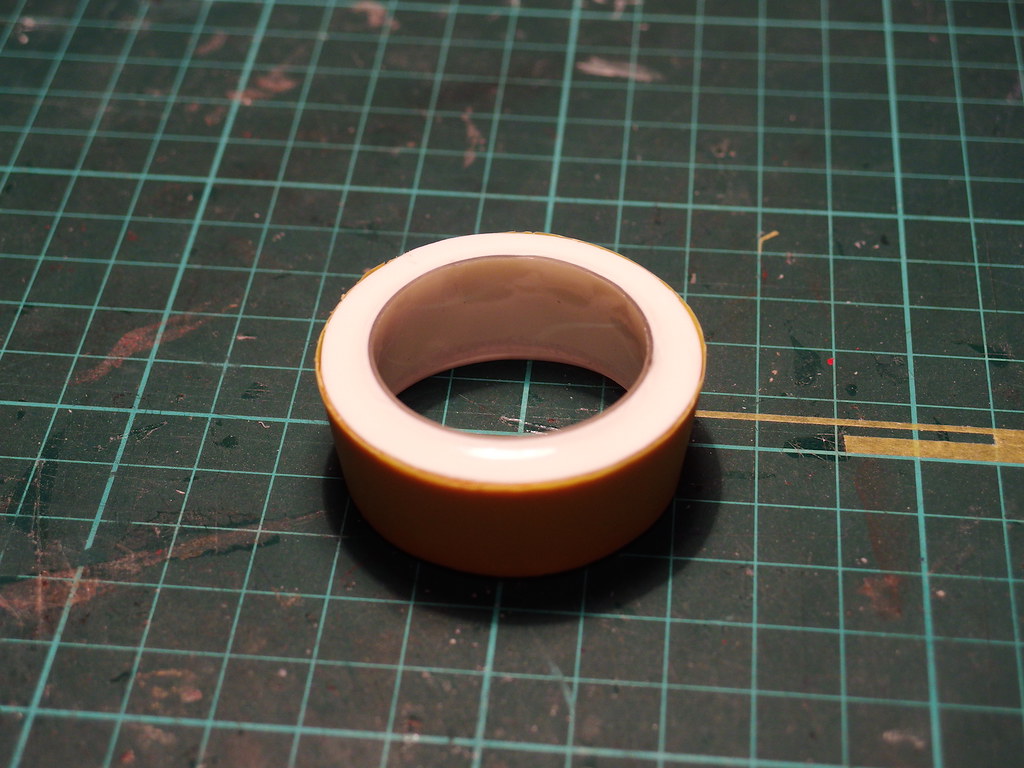

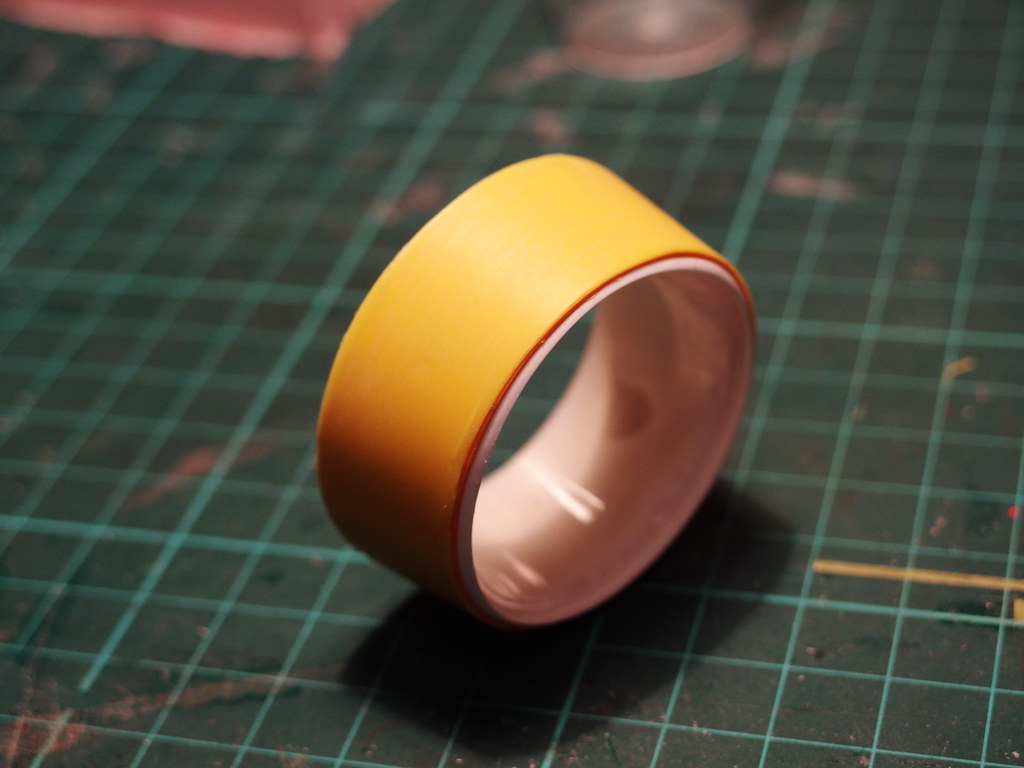

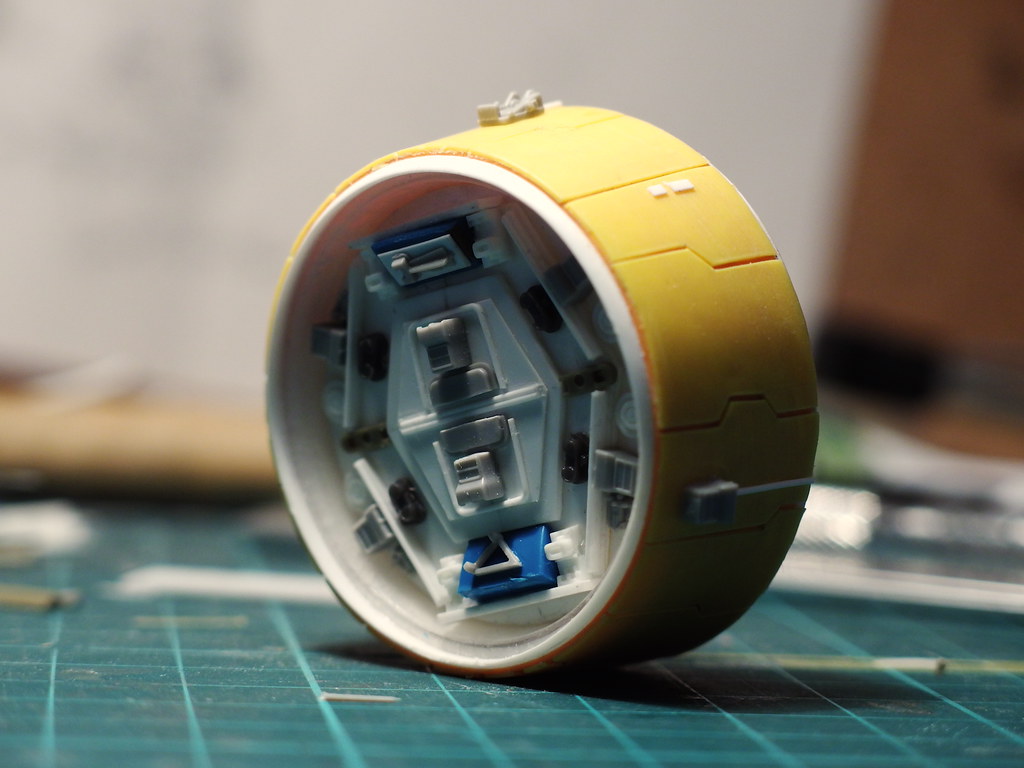

Today's work on the MPC Falcon upgrade kit, John very koindly made two vacuum forming bucks on his lathe yesterday and today we were pretty busy making a lot of vac pulls in different thicknesses. I also engineered the docking ring to be as easily mouldable and as easy to assemble as possible once it's in kit form......now I just need to mould and cast 20 of them!!

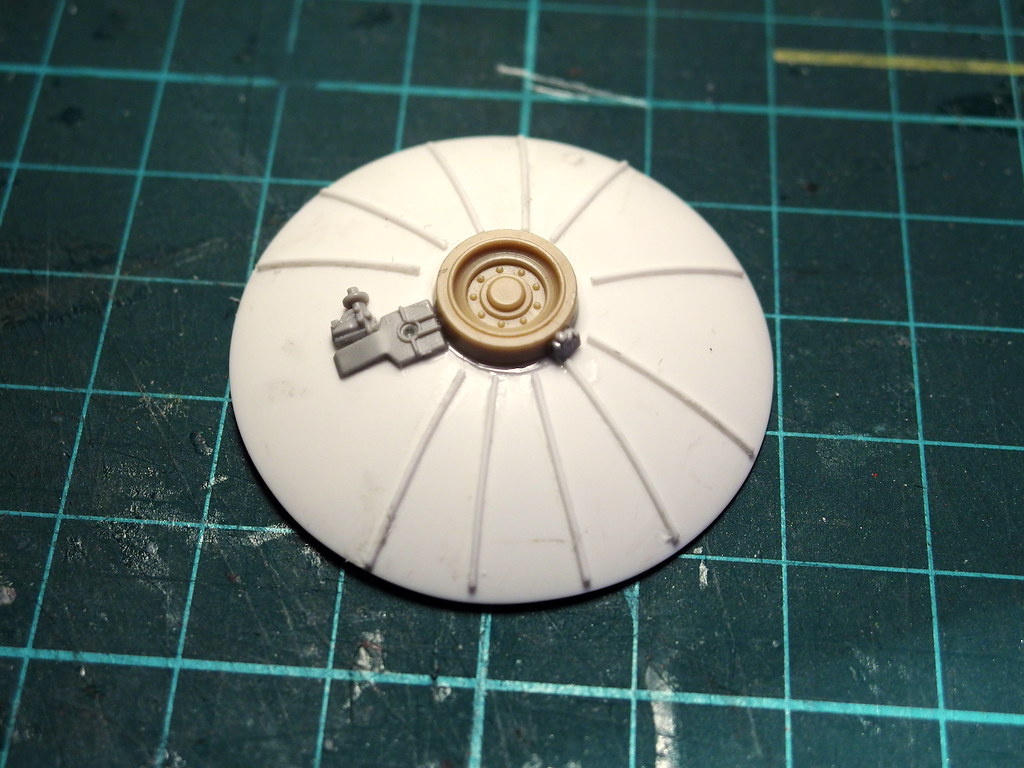

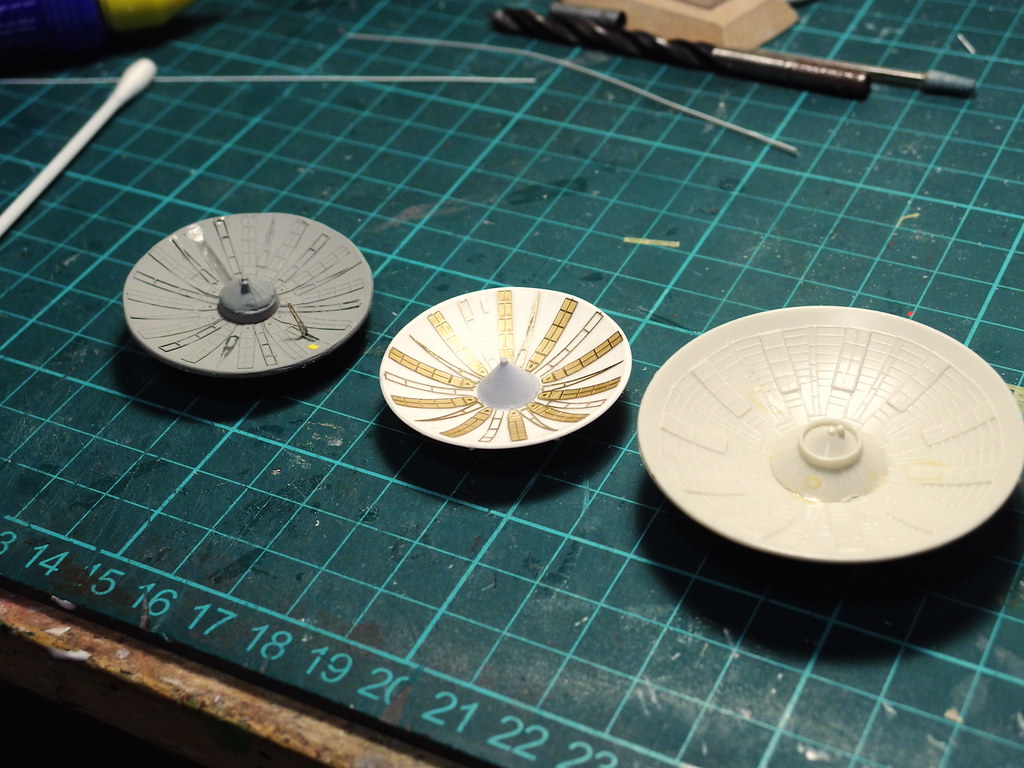

We started with a 1mm and 0.5mm set of pulls so I could emulate the lip and panelling

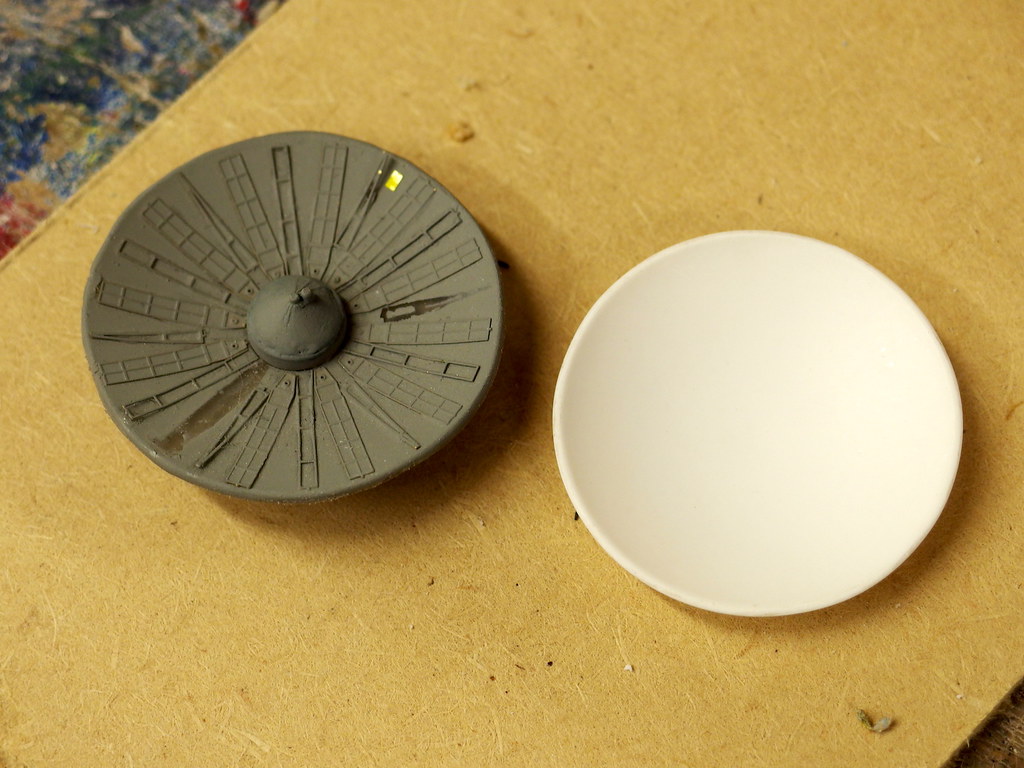

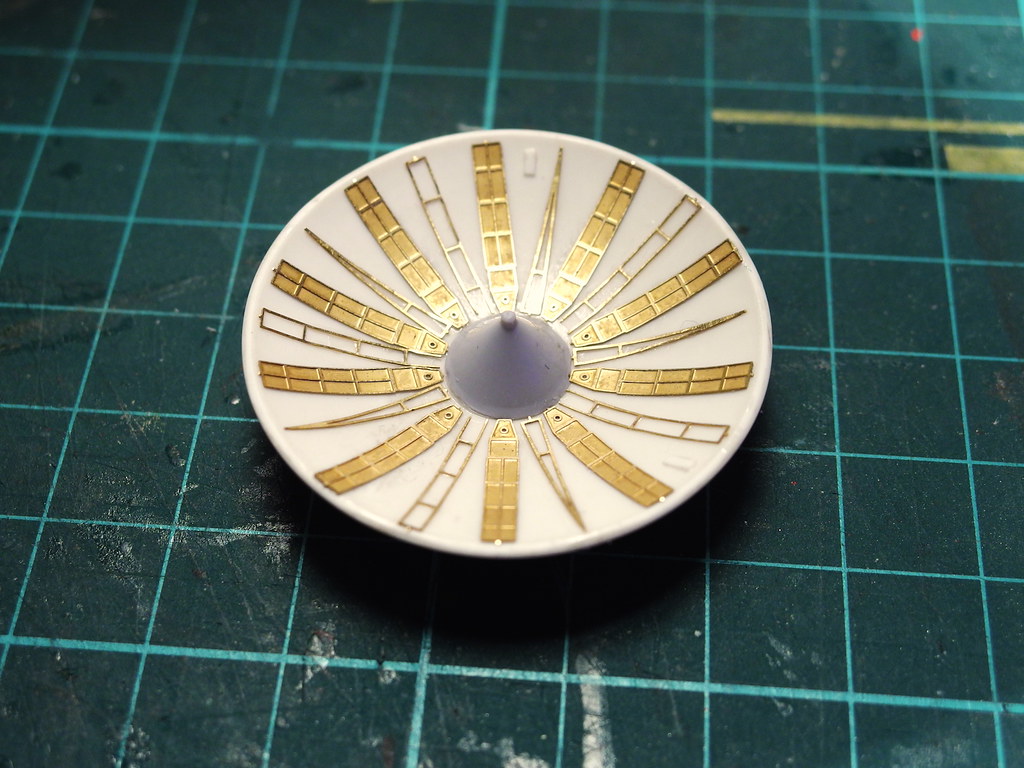

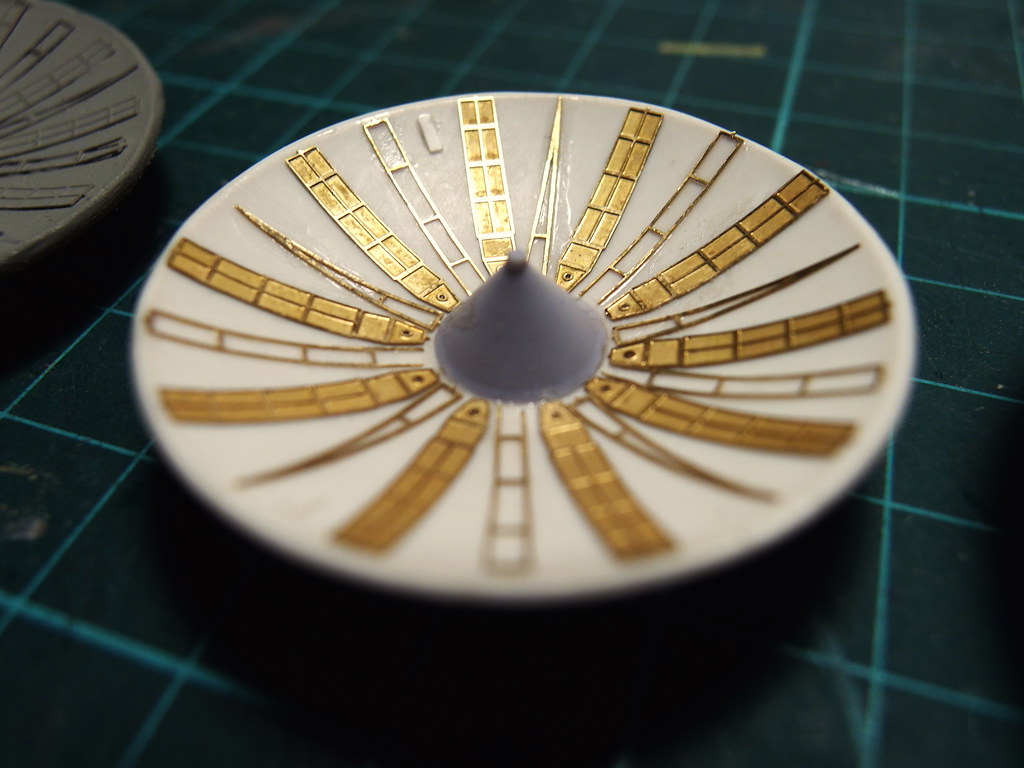

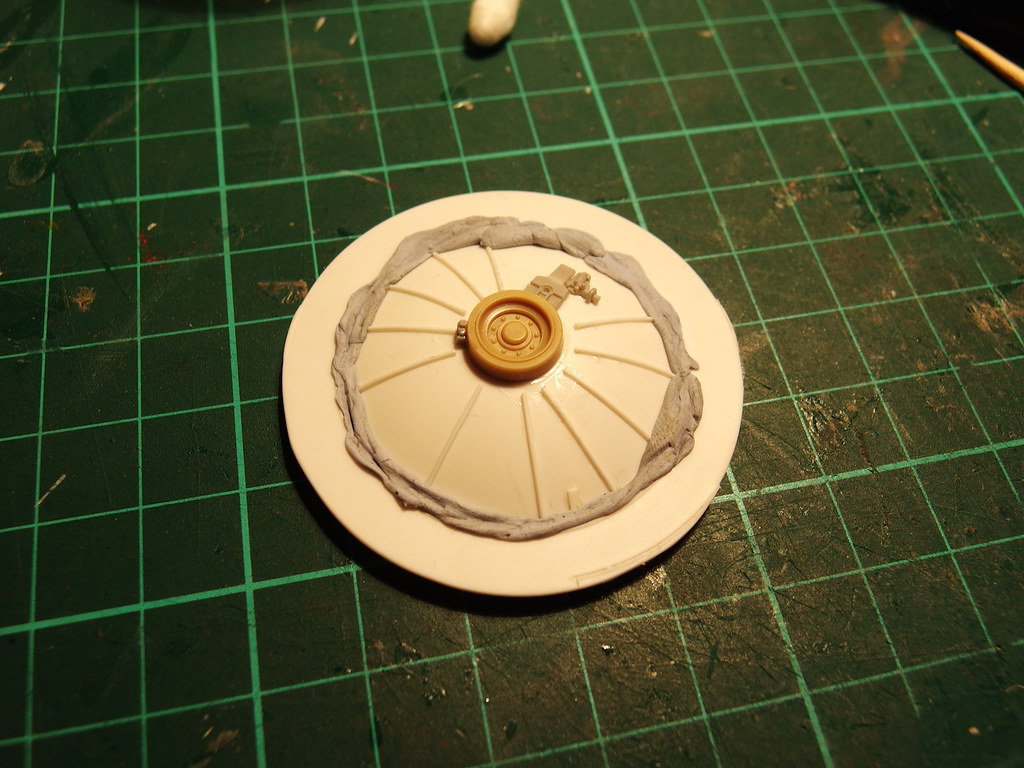

John also made a buck for a better radar dish, he finished this pull off with wet and dry abrasive paper and he really has done a superb job!! He's so skilled I'm lucky to have a friend like him. I'll use a part from the Airfix 1/144 space shuttle to make the center cone, and I'll use the remnants of my V1 photoetch kit to do the ANH style details before I mould it.

Yes you heard me, I'm doing 1/72 radar dish casts

(The first version I made about a year ago is on the left)

I made another pull using 0.30mm styrene to do the final segmented panelling

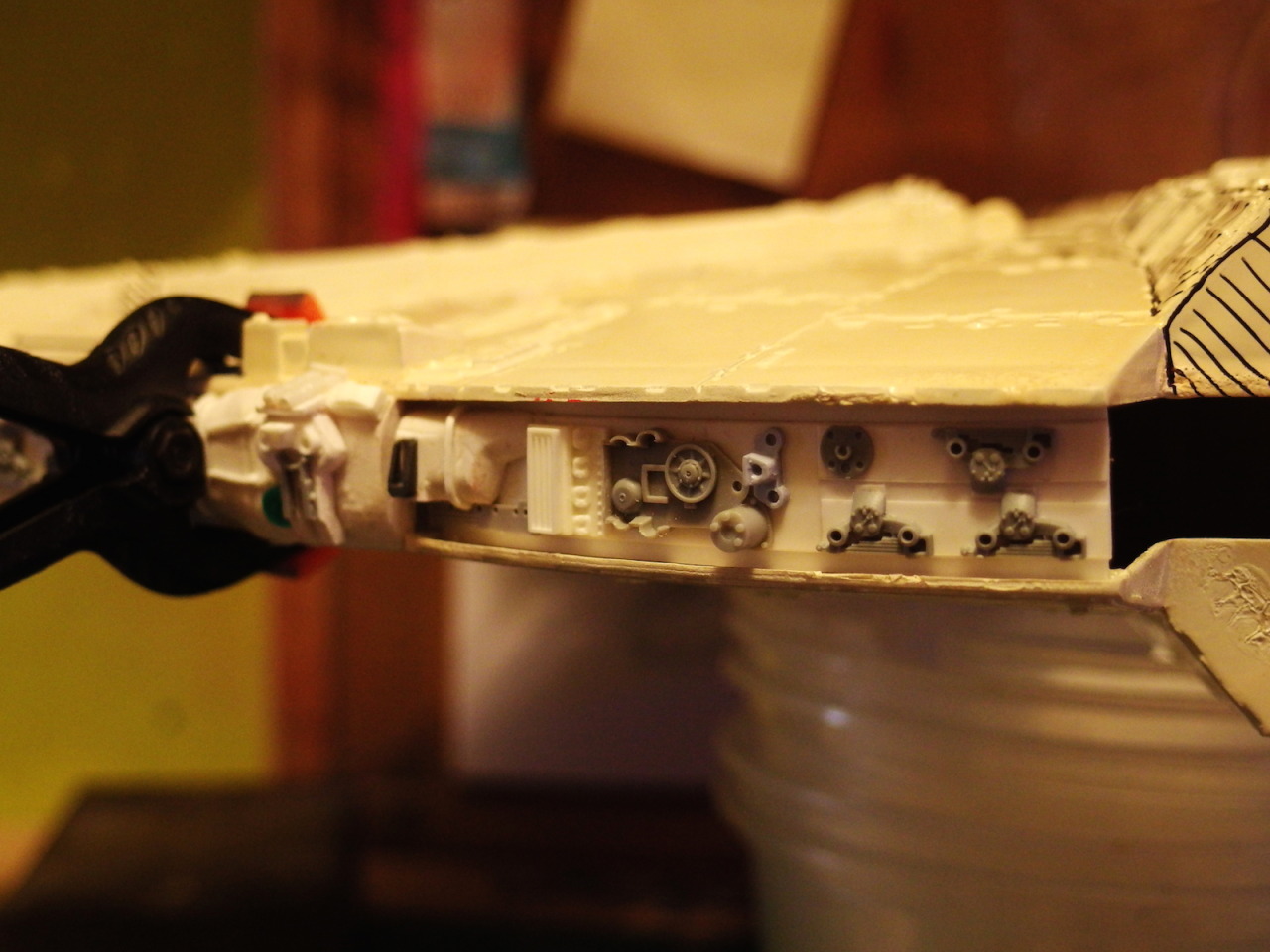

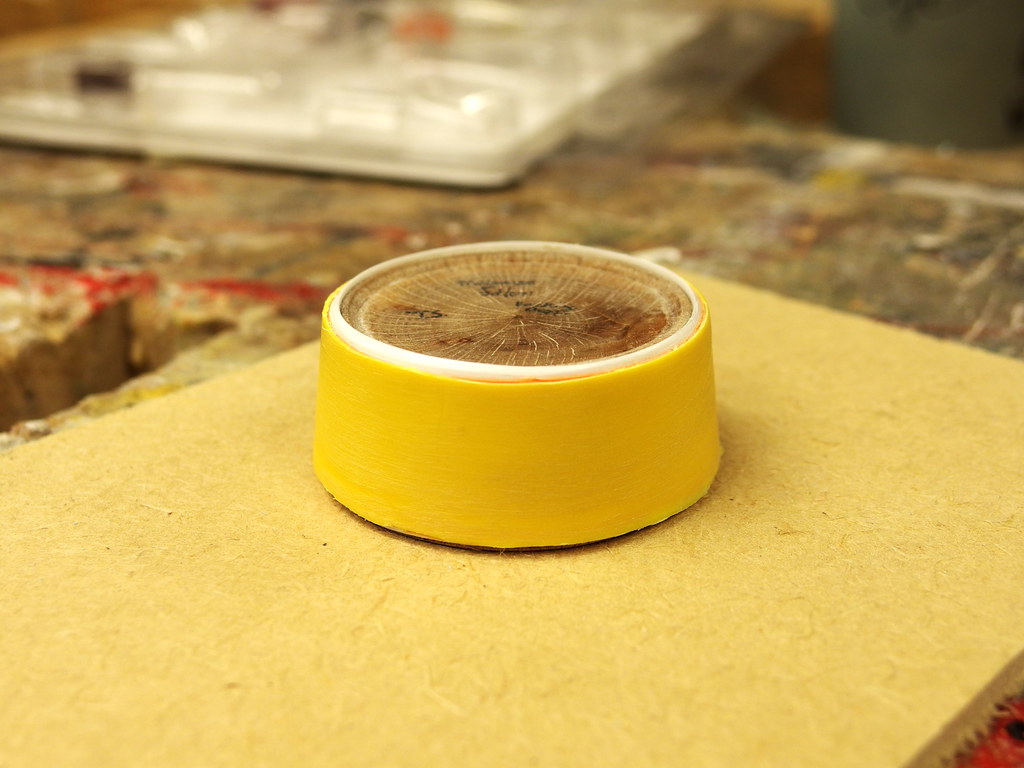

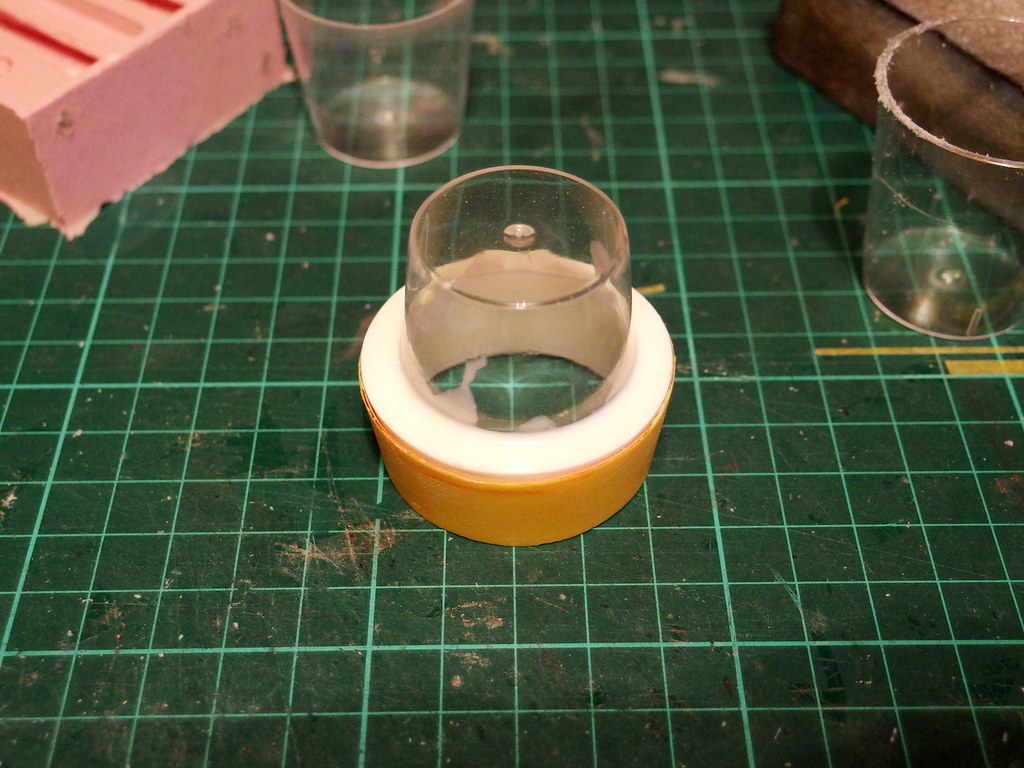

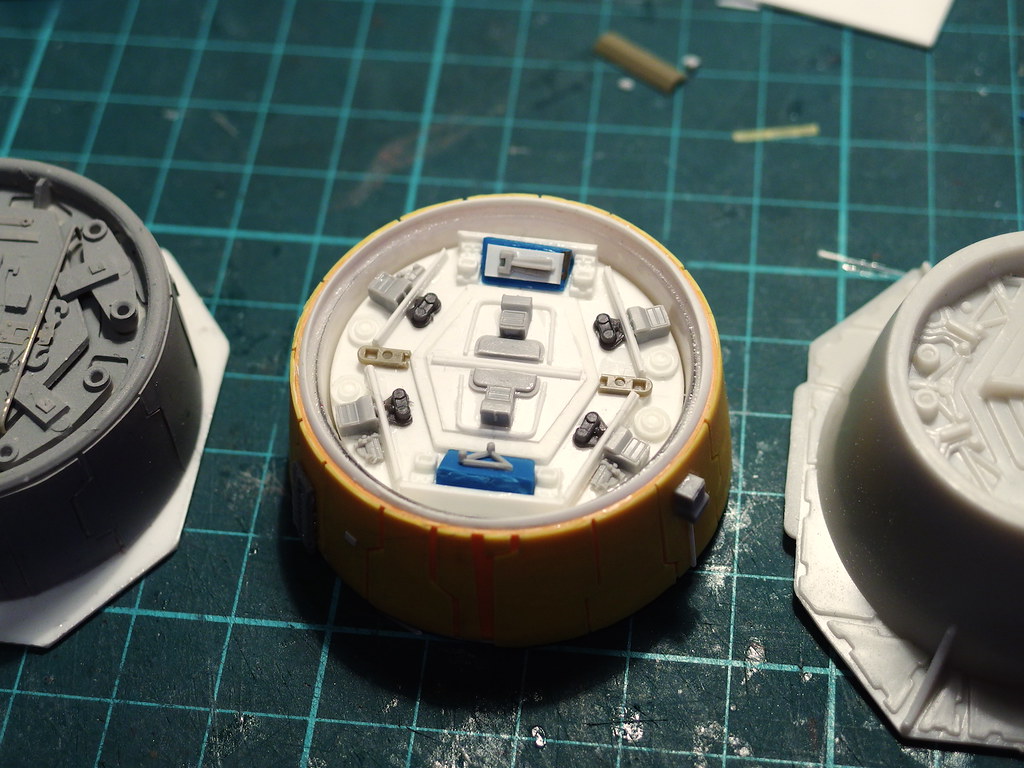

The next bit is kind of fiddly but mainly luck; I used a plastic shot glass turned upside down to make the inside of the docking ring.....I wanted to make all the parts for this kit in one part moulds because it's generally more reliable, so the profile of the docking ring is like a triangle now if you can see what I mean...Anyway I superglued the cup in and then filled the cavitiy with resin before cutting and sanding away the rest of the glass

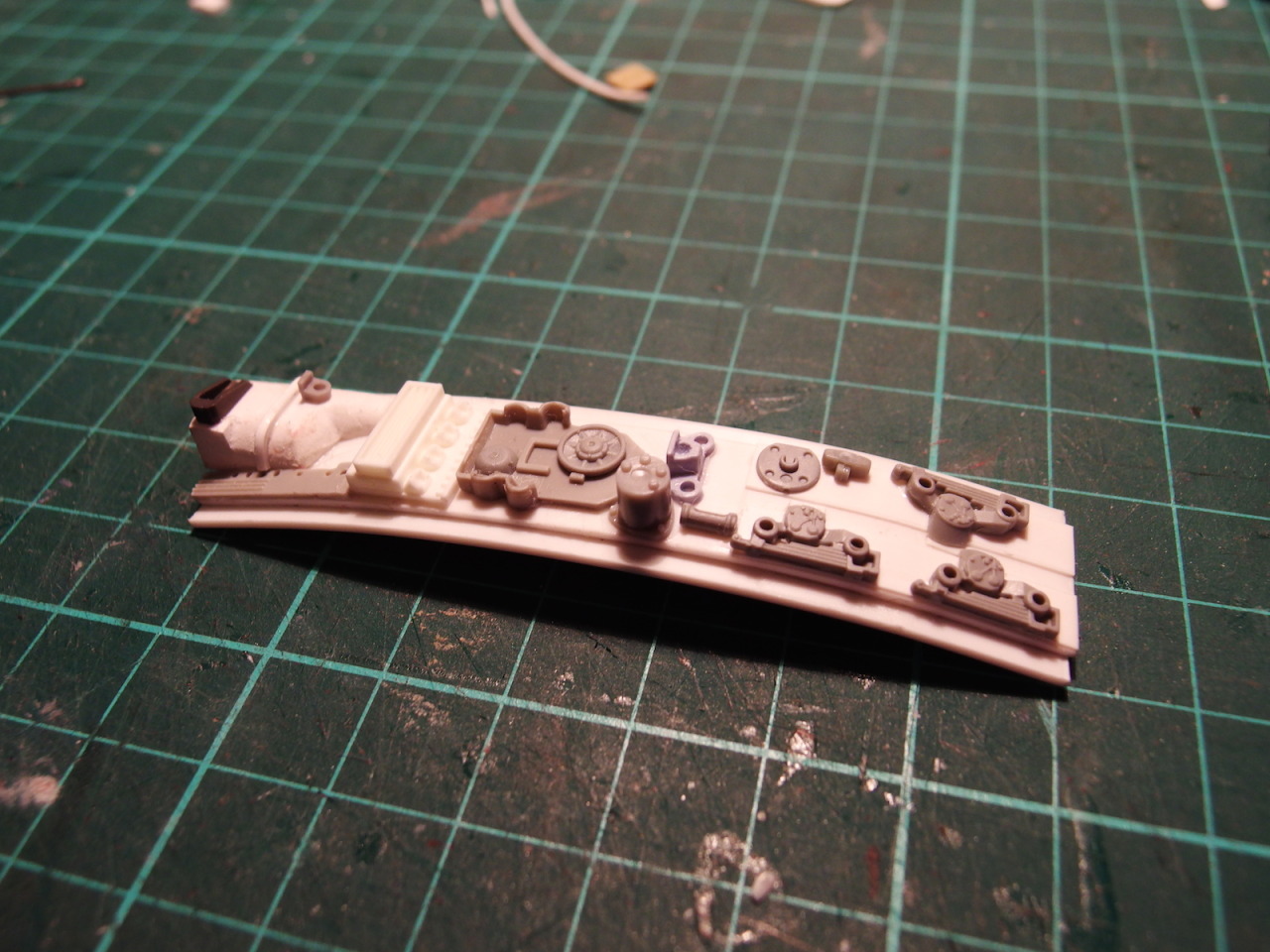

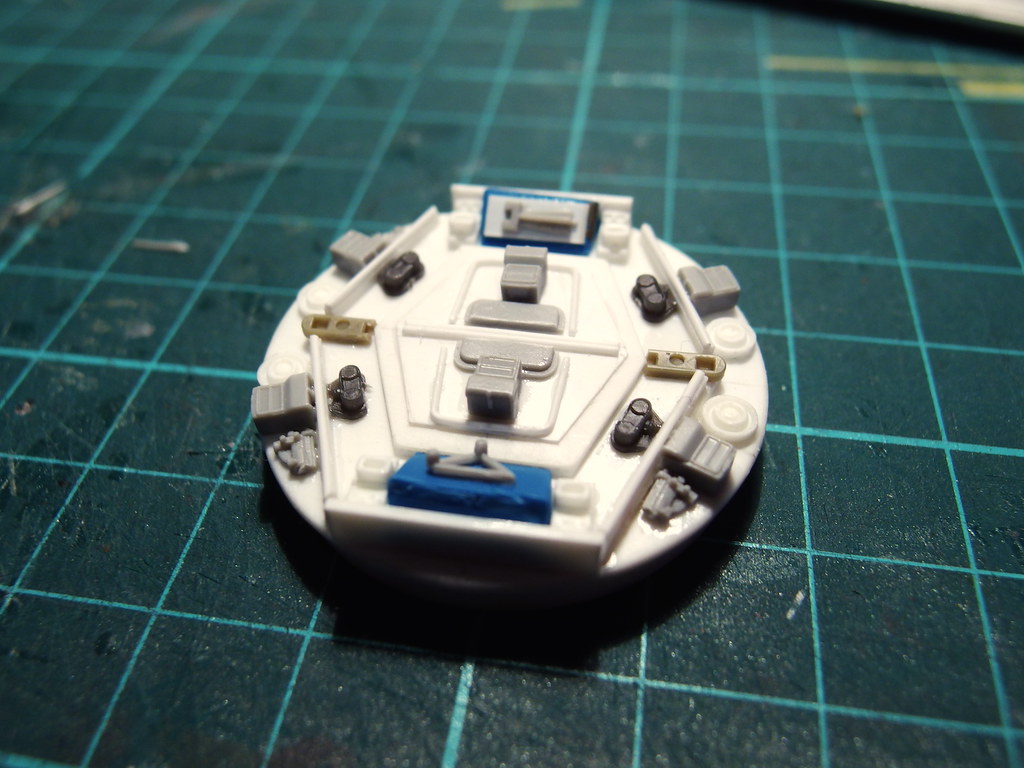

A fair amount of work later and I finished the panelling and details. Also, the detail plate is an insert which means that it's easy for me to cast and uses less resin than making the whole thing as one piece. Nice or what!!?

I'll start detailing the insert plate tomorrow hopefully, might be a little tricky to make it mould friendly with all those pipes, but hey.....I do love a challenge