hey guys,

It seems like the life-size Han in Carbonite is a "grail" prop for many of us.

There have been a few runs of the front panel with Han making the funny face. There have been runs of the side panels. But to my knowledge, we have limited access to a good source for the "box" that is so important for an accurate HIC.

One option is cutting one out yourself. But most of us have no tools (or no time) to do this properly. Even if you have the tools, you'll miss out on some of the accuracy the piece requires.

The best way to cut the box is with a CNC (Computer Numerical Control) router.

I picked up HIC plans from a gracious member here on the RPF that seem to be very accurate. I've sent these plans to TWO different CNC machine shops here in the USA inquiring about a "run" of these. It seems to be very doable, and not crazy expensive either.

Obviously, we all want this to be as screen accurate as possible.

I'm willing to do the legwork on these if I can get a little help from those that have done them in the past, or especially those that have used these plans.

1. Is it cool that I post the plans in this thread?

2. The box could be machined in 1/2" or 3/4" MDF board. I think 1/2" makes sense to cut down on weight?

3. After sending the plans to the CNC shops, they asked if it's available in "CAD." They said if it's not they can draw it up, but that will raise the price a bit.

4. Here is another comment, these guys are serious and accurate!...

"Also I see there are pockets that run at an angle in the depths Section A-A. So this part has to be tipped up at an angle so the machine can cut flat bottom pockets and the will be angled when complete. This will require a fixture of some kind to hold it at an angle. This will make machining more difficult."

So...that's the deal. I think if we can get together a decent number of guys interested it will help drive costs even lower.

I have all the same questions you do. How much is shipping? How do we assemble it? How do we patch seams? etc etc

The honest answer is...I don't know. I'm more than willing to do the first one for myself and be the guinea pig, with help from you guys. Then we could gauge interest after that...??

Bottom line. I'm here to get a HIC myself, not make a bunch of money on a "run." I'm still in the planning stages of this and need your help and advice. I'm going to set out to make as accurate a "box" as I can while still being practical.

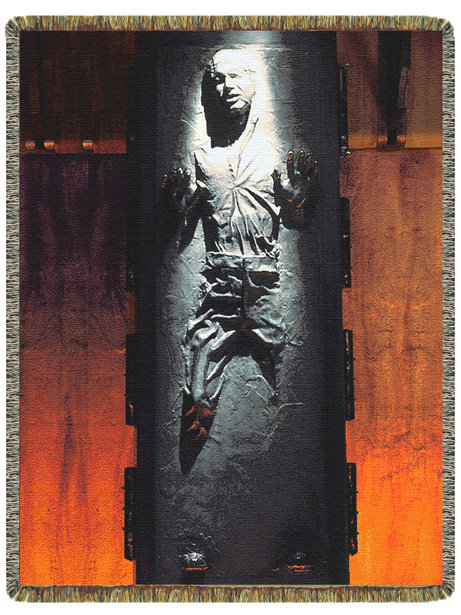

I've attached a pic of an HIC made by member "Vos" who has used these plans with success. (I hope that's OK) This is how good this thing can look! :love

I'd love to hear your feedback and suggestions, comments or concerns.

thanks!

brad

It seems like the life-size Han in Carbonite is a "grail" prop for many of us.

There have been a few runs of the front panel with Han making the funny face. There have been runs of the side panels. But to my knowledge, we have limited access to a good source for the "box" that is so important for an accurate HIC.

One option is cutting one out yourself. But most of us have no tools (or no time) to do this properly. Even if you have the tools, you'll miss out on some of the accuracy the piece requires.

The best way to cut the box is with a CNC (Computer Numerical Control) router.

I picked up HIC plans from a gracious member here on the RPF that seem to be very accurate. I've sent these plans to TWO different CNC machine shops here in the USA inquiring about a "run" of these. It seems to be very doable, and not crazy expensive either.

Obviously, we all want this to be as screen accurate as possible.

I'm willing to do the legwork on these if I can get a little help from those that have done them in the past, or especially those that have used these plans.

1. Is it cool that I post the plans in this thread?

2. The box could be machined in 1/2" or 3/4" MDF board. I think 1/2" makes sense to cut down on weight?

3. After sending the plans to the CNC shops, they asked if it's available in "CAD." They said if it's not they can draw it up, but that will raise the price a bit.

4. Here is another comment, these guys are serious and accurate!...

"Also I see there are pockets that run at an angle in the depths Section A-A. So this part has to be tipped up at an angle so the machine can cut flat bottom pockets and the will be angled when complete. This will require a fixture of some kind to hold it at an angle. This will make machining more difficult."

So...that's the deal. I think if we can get together a decent number of guys interested it will help drive costs even lower.

I have all the same questions you do. How much is shipping? How do we assemble it? How do we patch seams? etc etc

The honest answer is...I don't know. I'm more than willing to do the first one for myself and be the guinea pig, with help from you guys. Then we could gauge interest after that...??

Bottom line. I'm here to get a HIC myself, not make a bunch of money on a "run." I'm still in the planning stages of this and need your help and advice. I'm going to set out to make as accurate a "box" as I can while still being practical.

I've attached a pic of an HIC made by member "Vos" who has used these plans with success. (I hope that's OK) This is how good this thing can look! :love

I'd love to hear your feedback and suggestions, comments or concerns.

thanks!

brad

Last edited: