Hey everyone!

Inspired by Rogue One and the end scene I decided to take another look at my ANH Graflex and rebuild the chamber and electronics. I finished the original build last February. You can see it here: http://www.therpf.com/showthread.php?t=256361

The first one was created in high school with essentially a few files and a Dremel, and now that I have access to the correct tools I knew I could do so much better. So full of two viewings worth of inspiration, I set about finding some parts and starting the build. The idea behind this was to re-imagine the first crystal chamber I made taking cues from Slothfurnace, the original visual dictionary, and other saber smiths whose work I have enjoyed over the past years. Brad is a great guy and has always been forthcoming about how he does things and does a great job showing the steps he uses in his builds. I can't say my photography is anywhere near as good, but I hope you all enjoy seeing what I have done so far!

The first step was to get in the right mindset. I have found a certain amount of clarity in chaos recently, and with all of these parts laid out in front of me, I could begin to shape my ideas and begin to form the chamber in my minds eye. I took apart a few new (to me) old hard drives and organized parts.

I chose a large piece of aluminum pipe. I cut it to roughly twice the length I needed, to allow a better hold in the jaws of the lathe. Here I have faced the material and have started turning the diameter down to what I needed.

Here I've machined the channel where the recharge port will sit. I've also finished turning the piece to the correct outer diameter. I have also made a small channel on the inside of the mouth of the tube where the chamber will sit.

Using a bit of Dychem to allow me to see exactly where I was cutting I began to make a channel. I had to be incredibly careful to not cut too deeply. The wall thickness when I finished this step was scary.

I then drilled the hole for the recharge port and began to clean up the edges. Up to here the entire piece is still attached to the parent stock. It gave me something to grab with the vice on the mill.

Here you can see the battery can finished. The depression for the recharge port has been sand blasted to differentiate the textures. I drilled two holes for status LED's that may or may not actually show status. I haven't really figured that part out to be honest. You can also see the hard drive ring on top which fits in that small channel I machined. It is a very snug fit that I will secure with drilled pins later.

I chucked a small piece of delrin and created a multi step speaker holder that fits snuggly in the bottom of the can. I have considered shortening it, though the visual balance is nice.

And installed! The speaker is a TCSS 2W bass speaker. The speaker pressure fits into the holder, and the holder pressure fits into the battery can. I machined a step in the can to accommodate it also.

Now that the "boring" stuff was finished, I could start the stressful parts! I used the jump shear to cut a bunch of semi similarly sized pieces of brass. I then began to think more about what shape I wanted for the fins of the radiator.

Super glue was sent by the gods. I'm pretty convinces about that now. I was able to drill the holes for the master brass plate by attaching the chamber base plate to a piece of brass with super glue.

I then proceeded to machine these pieces en masse. I had some chipping in the top of the master plate on top, but that doesn't matter.

Using the advice of good friend I created a franken-jig to hold all the plates lined up while I machined the corners off. This was extremely satisfying and worked like a charm. The most hokey approaches to things can sometimes be the answer we're looking for!

At this point I stopped work for the day! The kicker on this project is that I was in the middle of finals. In a ditch effort to distract myself from writing papers, I decided to completely tear down this saber and rebuild it. Call me crazy, you're right. I spent about 12 hours working on the saber this day. I started with a sketch and that table of random parts, and by the end of the day had finished the rough assembly of the basic components. At the end of of the night I went home with what you see below. Rough but on its way.

I took a cue from the first chamber I made, and from the chamber I made for my buddy JaxAndTheMoon and used guitar ends for the spacers. Here you can see the spacers and fins right next to the original chamber. Like and idiot I disassembled the original one and destroyed it, mostly by accident. So there aren't any side by side comparison shots. This was all the next day by the way if anyone is keeping track.

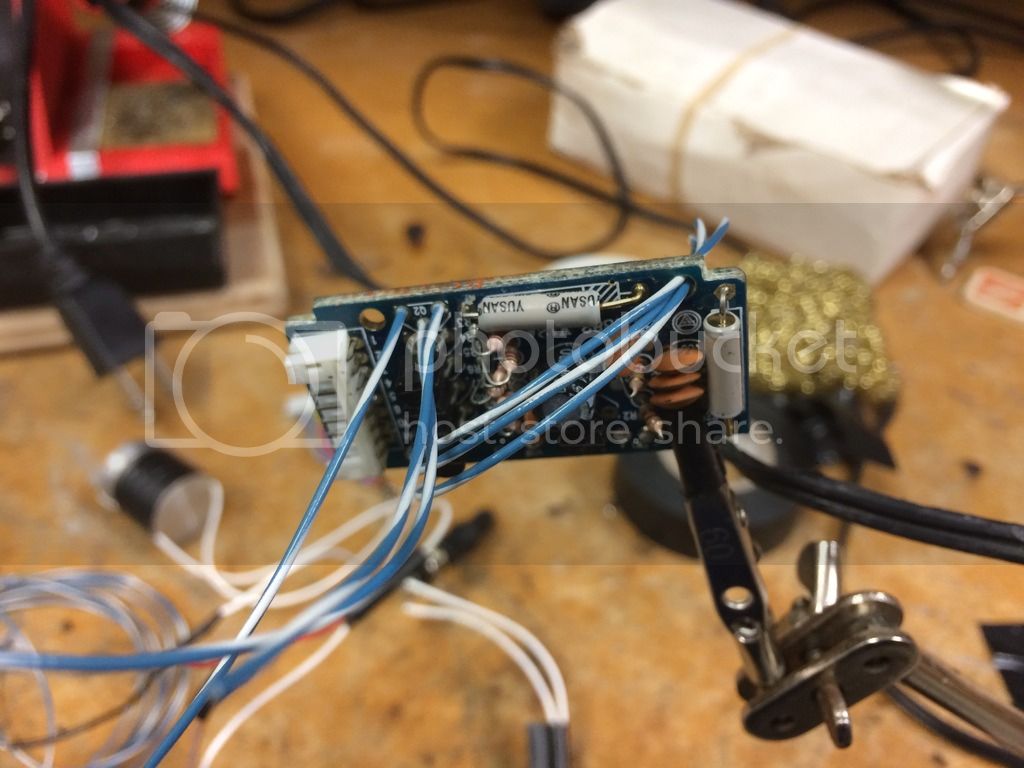

I have had a love affair with MR boards because they're the only ones I've ever used and are simple enough. They are also large however. And I prefer to use the space efficiently inside my sabers. These two things do not go together hand in hand, and I often have to do odd things to make it all work out. Here I've removed two of the transistors and soldered them out of the way so that the board and batteries can fit in the battery can. This is obnoxious and best avoided.

There we go! Now it fits.

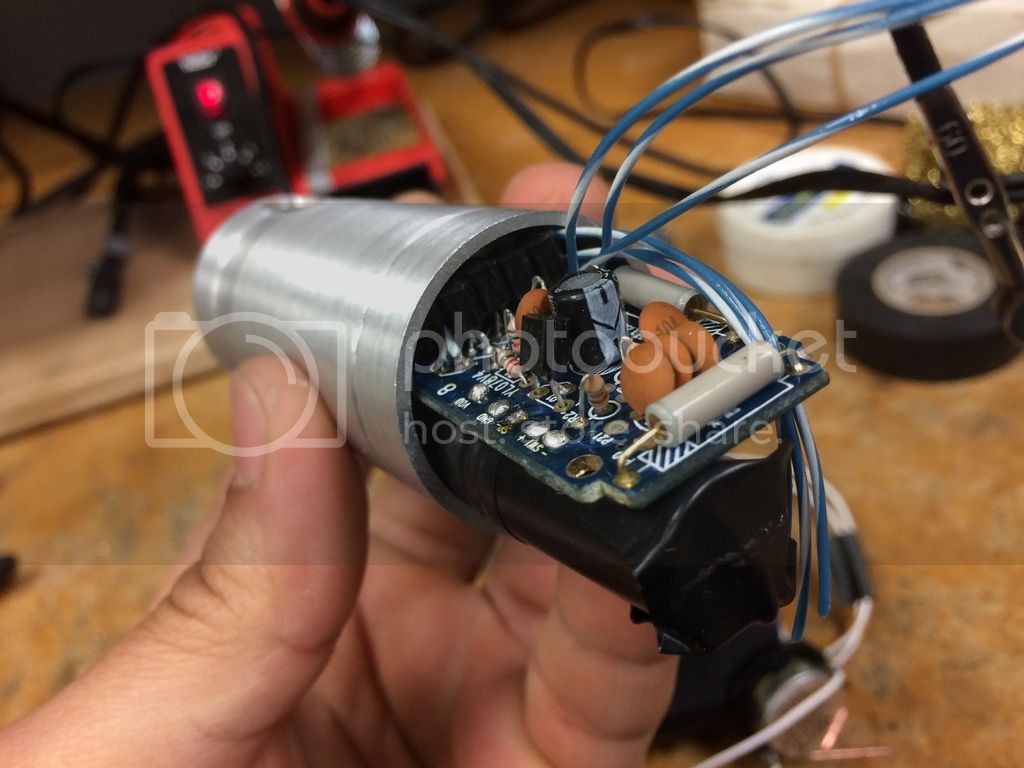

Here I'm starting to sort out where things need to go. Remember those two status LED's I was going to put in the battery can? Well at this stage I didn't either. That was 'fun' about ten minutes after this photo was taken.

But! It worked out okay. The two were first soldered to the first and last negative contact so that they lit up separately. It looked great and I loved the way it looked. Alas, I had to change it up when I joined all the negative leads to the main LED. I have some ideas about this though, and I think I can find a way around it that will allow them to work the way I intended originally. It will just take some fancy wiring and a bit of well-rested thinking.

I took a break from wiring and came back to the chamber. I've been building this whole saber incredibly quickly and one of the joys was being able to jump back and forth between the machining and fitting and finishing and wiring not just by choice, but because that was the next step that needed to be taken in order to continue work. This was part of the final fit of the chamber. I peened the rods over both of the end caps of the chamber in order to permanently bind it all together.

I spent a few anxious minutes with the mill again. I clamped the assembly as you see it in this photo in the mill and drilled three holes. There are three pins that hold the chamber to the battery canister. A few interesting things to note about this picture: the tiny nut that comes with the recharge port was machined down (a giant pain in the ass) to fit between the port and the walls of the hollow I machined for it, the two brass screws above anchor the chamber to the chassis, and the way I plan on finishing the saber will mean that I can take this chassis, disconnect it from the Graflexshop adapter, and attach this chamber to any other saber I have machined to the correct specifications.

This is the chamber as it sits now. I machined two crystal mounts with stepped holes that hold LED's at the correct distance from the crystals. The primary crystal and the secondary crystal are angled towards each other in such a way that they complete each other visually. I will get a better photo of this soon. There are some parts that are not 100% in alignment in the chamber, like the fins. This is mostly intentional. It wasn't a question of time, because the mill does whatever I control it to do, but a question of what I thought Anakin would have done. This saber exists as a record of his work, passed down eventually to Luke. Anakin was rash and hot headed, but ultimately a great tinkerer. He would have created a weapon that was elegant inside and out, but that under closer inspection would show a level of roughness that didn't affect function. This saber has been machined by hand on a multitude of machines, and as such is a union of machine and man, like Anakin himself. I used long and short Graflex pins from TCSS in the chamber. It is a nod to the provenance, but also a chamber I made for JaxAndTheMoon as a surprise about a year ago. You can barely see one of the metal conduits I am using to channel the wiring. I milled a slot in the chamber to accommodate them. The two crystals were a pair I got years and years ago, and the two screamed out to me when I began to put the chamber together at last. The brightest stars have hearts of Kyber, and this saber has two.

Remember when I mentioned that this was all done in a last minute and decidedly vain effort to avoid writing papers? Well it worked pretty well. I spent a total of two and a half working days on this saber before going back home for the holidays, and then I finished my paper in the wee hours of the morning before it was due. Jax surprised me by sending me a Nano Biscotte V3 as a wonderful Christmas gift, so when I return home I will redo the wiring with the board he gave me and hopefully finish up soon! I still have to finish milling a small channel in the connector between the blade socket and chamber, but that can wait till the return to school.

I hope you guys enjoy what I've done so far!

Inspired by Rogue One and the end scene I decided to take another look at my ANH Graflex and rebuild the chamber and electronics. I finished the original build last February. You can see it here: http://www.therpf.com/showthread.php?t=256361

The first one was created in high school with essentially a few files and a Dremel, and now that I have access to the correct tools I knew I could do so much better. So full of two viewings worth of inspiration, I set about finding some parts and starting the build. The idea behind this was to re-imagine the first crystal chamber I made taking cues from Slothfurnace, the original visual dictionary, and other saber smiths whose work I have enjoyed over the past years. Brad is a great guy and has always been forthcoming about how he does things and does a great job showing the steps he uses in his builds. I can't say my photography is anywhere near as good, but I hope you all enjoy seeing what I have done so far!

The first step was to get in the right mindset. I have found a certain amount of clarity in chaos recently, and with all of these parts laid out in front of me, I could begin to shape my ideas and begin to form the chamber in my minds eye. I took apart a few new (to me) old hard drives and organized parts.

I chose a large piece of aluminum pipe. I cut it to roughly twice the length I needed, to allow a better hold in the jaws of the lathe. Here I have faced the material and have started turning the diameter down to what I needed.

Here I've machined the channel where the recharge port will sit. I've also finished turning the piece to the correct outer diameter. I have also made a small channel on the inside of the mouth of the tube where the chamber will sit.

Using a bit of Dychem to allow me to see exactly where I was cutting I began to make a channel. I had to be incredibly careful to not cut too deeply. The wall thickness when I finished this step was scary.

I then drilled the hole for the recharge port and began to clean up the edges. Up to here the entire piece is still attached to the parent stock. It gave me something to grab with the vice on the mill.

Here you can see the battery can finished. The depression for the recharge port has been sand blasted to differentiate the textures. I drilled two holes for status LED's that may or may not actually show status. I haven't really figured that part out to be honest. You can also see the hard drive ring on top which fits in that small channel I machined. It is a very snug fit that I will secure with drilled pins later.

I chucked a small piece of delrin and created a multi step speaker holder that fits snuggly in the bottom of the can. I have considered shortening it, though the visual balance is nice.

And installed! The speaker is a TCSS 2W bass speaker. The speaker pressure fits into the holder, and the holder pressure fits into the battery can. I machined a step in the can to accommodate it also.

Now that the "boring" stuff was finished, I could start the stressful parts! I used the jump shear to cut a bunch of semi similarly sized pieces of brass. I then began to think more about what shape I wanted for the fins of the radiator.

Super glue was sent by the gods. I'm pretty convinces about that now. I was able to drill the holes for the master brass plate by attaching the chamber base plate to a piece of brass with super glue.

I then proceeded to machine these pieces en masse. I had some chipping in the top of the master plate on top, but that doesn't matter.

Using the advice of good friend I created a franken-jig to hold all the plates lined up while I machined the corners off. This was extremely satisfying and worked like a charm. The most hokey approaches to things can sometimes be the answer we're looking for!

At this point I stopped work for the day! The kicker on this project is that I was in the middle of finals. In a ditch effort to distract myself from writing papers, I decided to completely tear down this saber and rebuild it. Call me crazy, you're right. I spent about 12 hours working on the saber this day. I started with a sketch and that table of random parts, and by the end of the day had finished the rough assembly of the basic components. At the end of of the night I went home with what you see below. Rough but on its way.

I took a cue from the first chamber I made, and from the chamber I made for my buddy JaxAndTheMoon and used guitar ends for the spacers. Here you can see the spacers and fins right next to the original chamber. Like and idiot I disassembled the original one and destroyed it, mostly by accident. So there aren't any side by side comparison shots. This was all the next day by the way if anyone is keeping track.

I have had a love affair with MR boards because they're the only ones I've ever used and are simple enough. They are also large however. And I prefer to use the space efficiently inside my sabers. These two things do not go together hand in hand, and I often have to do odd things to make it all work out. Here I've removed two of the transistors and soldered them out of the way so that the board and batteries can fit in the battery can. This is obnoxious and best avoided.

There we go! Now it fits.

Here I'm starting to sort out where things need to go. Remember those two status LED's I was going to put in the battery can? Well at this stage I didn't either. That was 'fun' about ten minutes after this photo was taken.

But! It worked out okay. The two were first soldered to the first and last negative contact so that they lit up separately. It looked great and I loved the way it looked. Alas, I had to change it up when I joined all the negative leads to the main LED. I have some ideas about this though, and I think I can find a way around it that will allow them to work the way I intended originally. It will just take some fancy wiring and a bit of well-rested thinking.

I took a break from wiring and came back to the chamber. I've been building this whole saber incredibly quickly and one of the joys was being able to jump back and forth between the machining and fitting and finishing and wiring not just by choice, but because that was the next step that needed to be taken in order to continue work. This was part of the final fit of the chamber. I peened the rods over both of the end caps of the chamber in order to permanently bind it all together.

I spent a few anxious minutes with the mill again. I clamped the assembly as you see it in this photo in the mill and drilled three holes. There are three pins that hold the chamber to the battery canister. A few interesting things to note about this picture: the tiny nut that comes with the recharge port was machined down (a giant pain in the ass) to fit between the port and the walls of the hollow I machined for it, the two brass screws above anchor the chamber to the chassis, and the way I plan on finishing the saber will mean that I can take this chassis, disconnect it from the Graflexshop adapter, and attach this chamber to any other saber I have machined to the correct specifications.

This is the chamber as it sits now. I machined two crystal mounts with stepped holes that hold LED's at the correct distance from the crystals. The primary crystal and the secondary crystal are angled towards each other in such a way that they complete each other visually. I will get a better photo of this soon. There are some parts that are not 100% in alignment in the chamber, like the fins. This is mostly intentional. It wasn't a question of time, because the mill does whatever I control it to do, but a question of what I thought Anakin would have done. This saber exists as a record of his work, passed down eventually to Luke. Anakin was rash and hot headed, but ultimately a great tinkerer. He would have created a weapon that was elegant inside and out, but that under closer inspection would show a level of roughness that didn't affect function. This saber has been machined by hand on a multitude of machines, and as such is a union of machine and man, like Anakin himself. I used long and short Graflex pins from TCSS in the chamber. It is a nod to the provenance, but also a chamber I made for JaxAndTheMoon as a surprise about a year ago. You can barely see one of the metal conduits I am using to channel the wiring. I milled a slot in the chamber to accommodate them. The two crystals were a pair I got years and years ago, and the two screamed out to me when I began to put the chamber together at last. The brightest stars have hearts of Kyber, and this saber has two.

Remember when I mentioned that this was all done in a last minute and decidedly vain effort to avoid writing papers? Well it worked pretty well. I spent a total of two and a half working days on this saber before going back home for the holidays, and then I finished my paper in the wee hours of the morning before it was due. Jax surprised me by sending me a Nano Biscotte V3 as a wonderful Christmas gift, so when I return home I will redo the wiring with the board he gave me and hopefully finish up soon! I still have to finish milling a small channel in the connector between the blade socket and chamber, but that can wait till the return to school.

I hope you guys enjoy what I've done so far!