910dohead

New Member

Hello, RPF! We are a Ghostbusters cosplay group that formed just over a year ago called Southland Ghostbusters.

Besides doing events for charity, we've been hitting the convention scene in California pretty hard since forming. Recently, we've been invited to have our own fan table at the upcoming C4 Central Coast Comic Convention here in Southern California. The convention will run from September 12th thru the 14th in the beautiful city of Ventura. For more info & tickets, you can check out their site at C4 Central Coast Comic Con - C4.

Since this will be our first fan table at an event, we wanted to put something special together for our booth that you normally wouldn't see on display; a 1:1 screen accurate replica of the Ecto Containment Unit from the first film. We will also be having a special guest at our booth and we don't want to disappoint with our presentation. We are currently about a third of the way through with our build, so our first post will be a summary of our progress up until this point. If you are interested in catching up our progress in full, you can visit our build thread on Ghostbusters Fans: Containment Unit Discussion & Build - Community - Ghostbusters Fans Forum

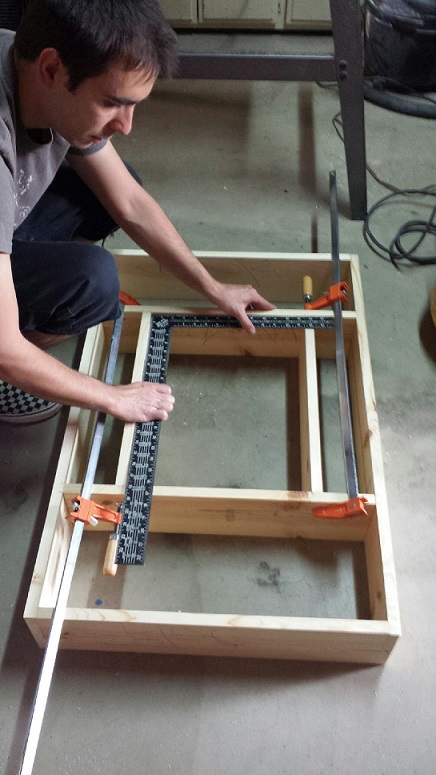

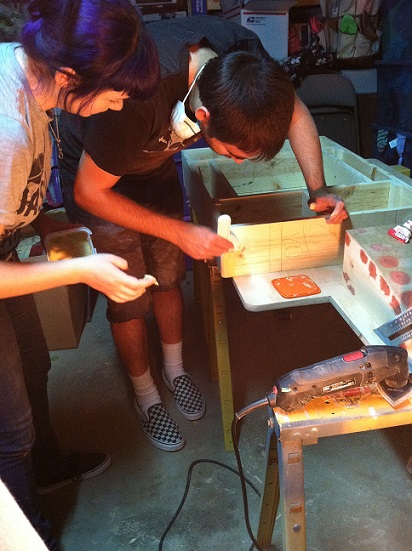

There have been a lot of people that have already built containment units of their own, so we had no problem finding plans online for the prop. We began by building the frame for the upper box portion.

Next we moved onto the lower portion of the frame.

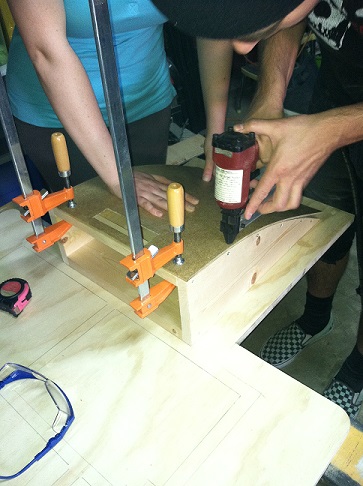

Added some more support beams to the frame and then moved onto the backboard.

At this point in the build, we weren't satisfied with the results we were getting from the plans we chose. Unfortunately, the dimensions were not as close to scale as we wanted so we decided to take a step back and figure out the scale. The frame looked about right, but the bottom half was undersized. This resulted in us having to rebuild a second bottom piece.

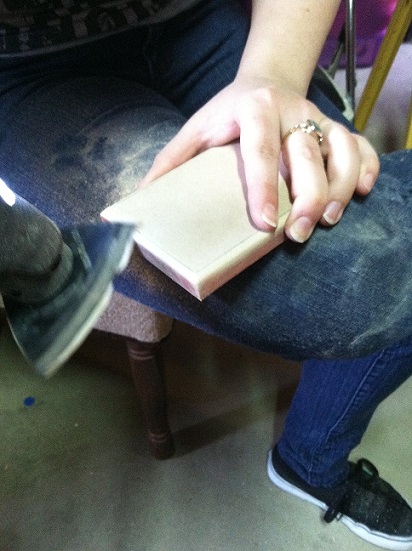

We were satisfied with the scale of the bottom piece at this point. This setback also had us cutting out a new backboard, which we were glad to have happened. The wood we cut out originally was going to need a lot of sanding. The new piece was an upgrade, so we saved ourselves from a few days of future sanding. Next we moved onto the cover for the bottom piece.

Then we moved onto the cover for the upper half of the frame.

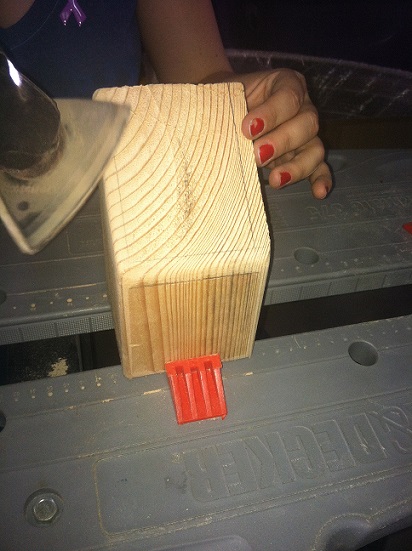

Next we moved onto screwing the bottom cover onto the frame and then using bondo to cover up the screws.

Then we cut out the door and the other faceplate pieces. Once the door was cut, we compared it to screen shots and realized it was undersized in the plans. This resulted in us having to move the inner support beams of the frame a few inches apart and recut the opening to the door.

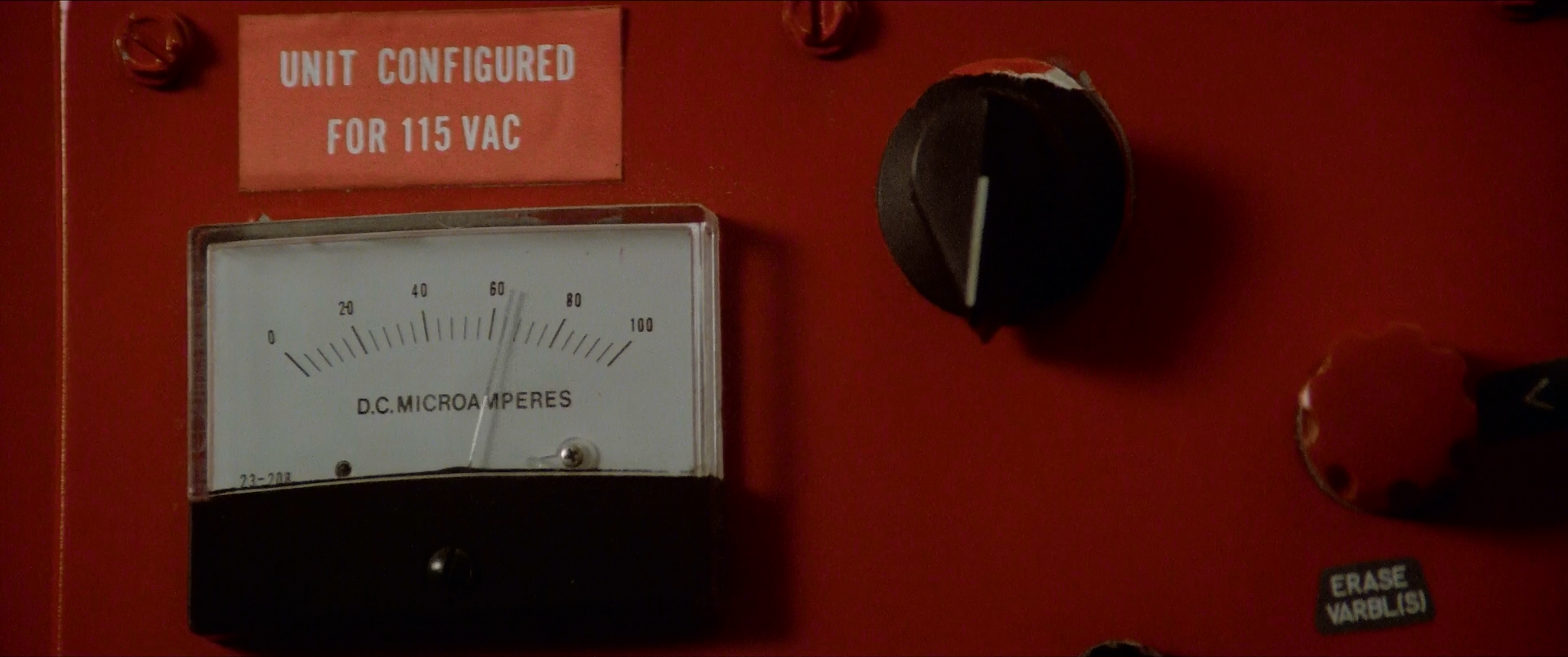

This hiccup had us reverting back to revising the plans and taking closer looks at screen shots. To make matters worse, we discovered something new in this screenshot here:

If you take a look at the lower half on the frame of the containment unit, you'll notice a small black and white rectangle. Well, that's always been previously referred to as a handle, but taking a closer look at it reveals it to be a manufacturers sticker of some sort. Since we're striving for accuracy, we had to go back and rebuild the piece since we had cut the handle into ours.

Here you start to see a happy containment unit:

Let's add a new cover to this piece and sand it down.

Now that we're back on track, we decided to get all of the smaller pieces going.

Here's the part to the right of the unit:

The ribbon cable stops that goes on at the upper left: (the legos are only being used for scale since we haven't received the real part yet.)

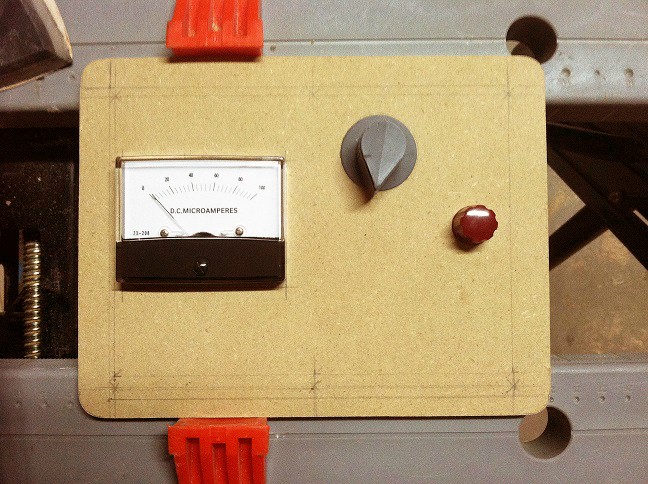

Then we drilled out the hole we needed to add the meter piece to the faceplate:

Now this leaves us at step in our progress which was rounding out the sides of the upper frame and sanding the sides.

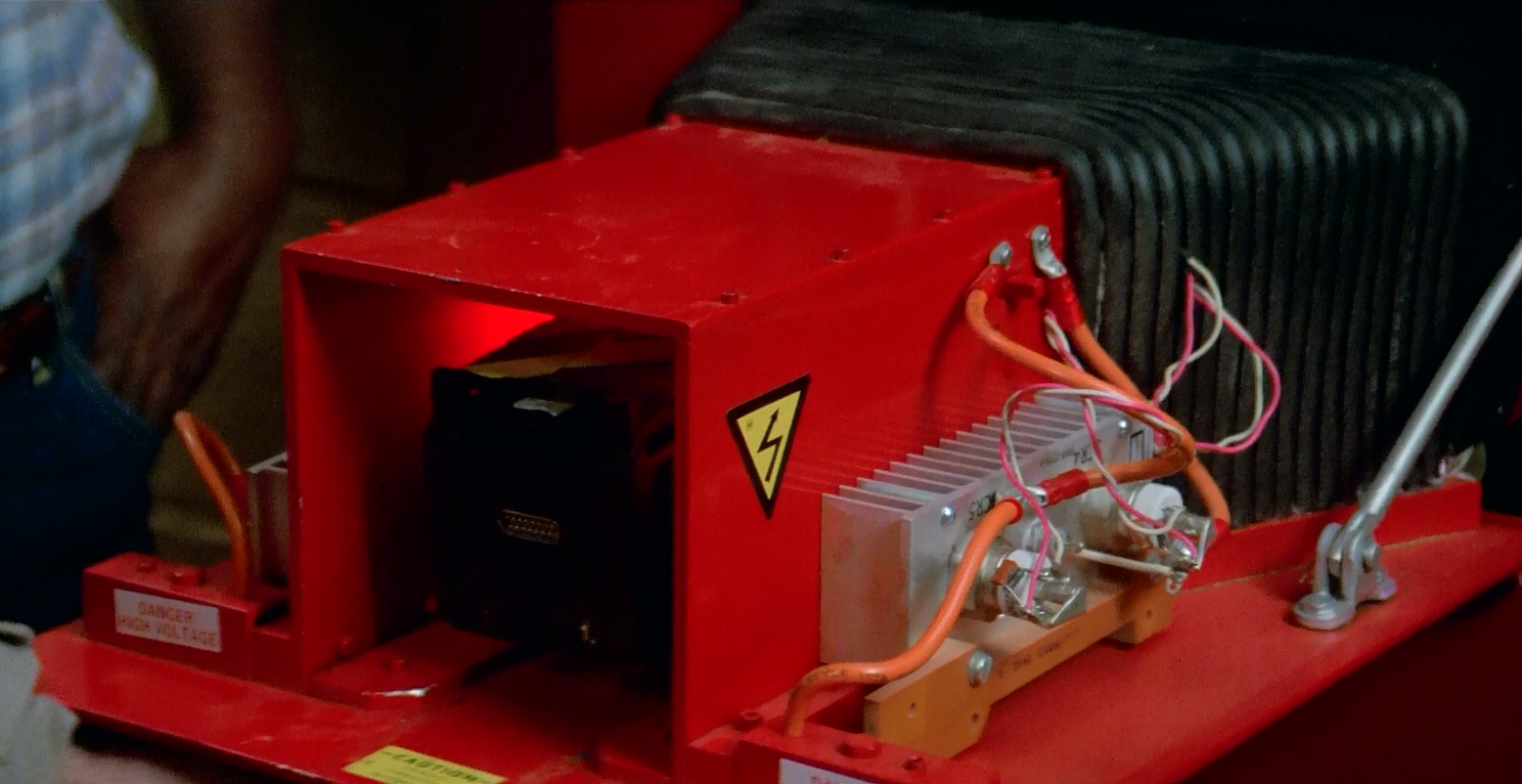

One thing that I will reveal on the rpf that I haven't done in our other thread is that we have researched and found all of the original parts (except two). We're not sure if this has ever been done before on a containment unit build. This may be a first? Anyways, the two parts we haven't been able to identify are the door handle (which we think might be an aircraft handle either used on door or an older jettison latch) and the black rubber looking piece inside the door around the trap housing (which we think is a leather camera bellows).

Feel free to chime in with your guesses as to what these parts might be. We found some close substitutes but no spot on matches. Also, we would like any input or critism on our build so far. Everything is up for discussion. We'll be sharing different things on each of our build threads to keep them both exciting. Stay Tuned!

Besides doing events for charity, we've been hitting the convention scene in California pretty hard since forming. Recently, we've been invited to have our own fan table at the upcoming C4 Central Coast Comic Convention here in Southern California. The convention will run from September 12th thru the 14th in the beautiful city of Ventura. For more info & tickets, you can check out their site at C4 Central Coast Comic Con - C4.

Since this will be our first fan table at an event, we wanted to put something special together for our booth that you normally wouldn't see on display; a 1:1 screen accurate replica of the Ecto Containment Unit from the first film. We will also be having a special guest at our booth and we don't want to disappoint with our presentation. We are currently about a third of the way through with our build, so our first post will be a summary of our progress up until this point. If you are interested in catching up our progress in full, you can visit our build thread on Ghostbusters Fans: Containment Unit Discussion & Build - Community - Ghostbusters Fans Forum

There have been a lot of people that have already built containment units of their own, so we had no problem finding plans online for the prop. We began by building the frame for the upper box portion.

Next we moved onto the lower portion of the frame.

Added some more support beams to the frame and then moved onto the backboard.

At this point in the build, we weren't satisfied with the results we were getting from the plans we chose. Unfortunately, the dimensions were not as close to scale as we wanted so we decided to take a step back and figure out the scale. The frame looked about right, but the bottom half was undersized. This resulted in us having to rebuild a second bottom piece.

We were satisfied with the scale of the bottom piece at this point. This setback also had us cutting out a new backboard, which we were glad to have happened. The wood we cut out originally was going to need a lot of sanding. The new piece was an upgrade, so we saved ourselves from a few days of future sanding. Next we moved onto the cover for the bottom piece.

Then we moved onto the cover for the upper half of the frame.

Next we moved onto screwing the bottom cover onto the frame and then using bondo to cover up the screws.

Then we cut out the door and the other faceplate pieces. Once the door was cut, we compared it to screen shots and realized it was undersized in the plans. This resulted in us having to move the inner support beams of the frame a few inches apart and recut the opening to the door.

This hiccup had us reverting back to revising the plans and taking closer looks at screen shots. To make matters worse, we discovered something new in this screenshot here:

If you take a look at the lower half on the frame of the containment unit, you'll notice a small black and white rectangle. Well, that's always been previously referred to as a handle, but taking a closer look at it reveals it to be a manufacturers sticker of some sort. Since we're striving for accuracy, we had to go back and rebuild the piece since we had cut the handle into ours.

Here you start to see a happy containment unit:

Let's add a new cover to this piece and sand it down.

Now that we're back on track, we decided to get all of the smaller pieces going.

Here's the part to the right of the unit:

The ribbon cable stops that goes on at the upper left: (the legos are only being used for scale since we haven't received the real part yet.)

Then we drilled out the hole we needed to add the meter piece to the faceplate:

Now this leaves us at step in our progress which was rounding out the sides of the upper frame and sanding the sides.

One thing that I will reveal on the rpf that I haven't done in our other thread is that we have researched and found all of the original parts (except two). We're not sure if this has ever been done before on a containment unit build. This may be a first? Anyways, the two parts we haven't been able to identify are the door handle (which we think might be an aircraft handle either used on door or an older jettison latch) and the black rubber looking piece inside the door around the trap housing (which we think is a leather camera bellows).

Feel free to chime in with your guesses as to what these parts might be. We found some close substitutes but no spot on matches. Also, we would like any input or critism on our build so far. Everything is up for discussion. We'll be sharing different things on each of our build threads to keep them both exciting. Stay Tuned!