Strikerkc

Sr Member

Hey all, after dragon con at the end of the month, I'm gonna get an early start on a costume for the following year, and it's time for a Vault Dweller "Veteran".

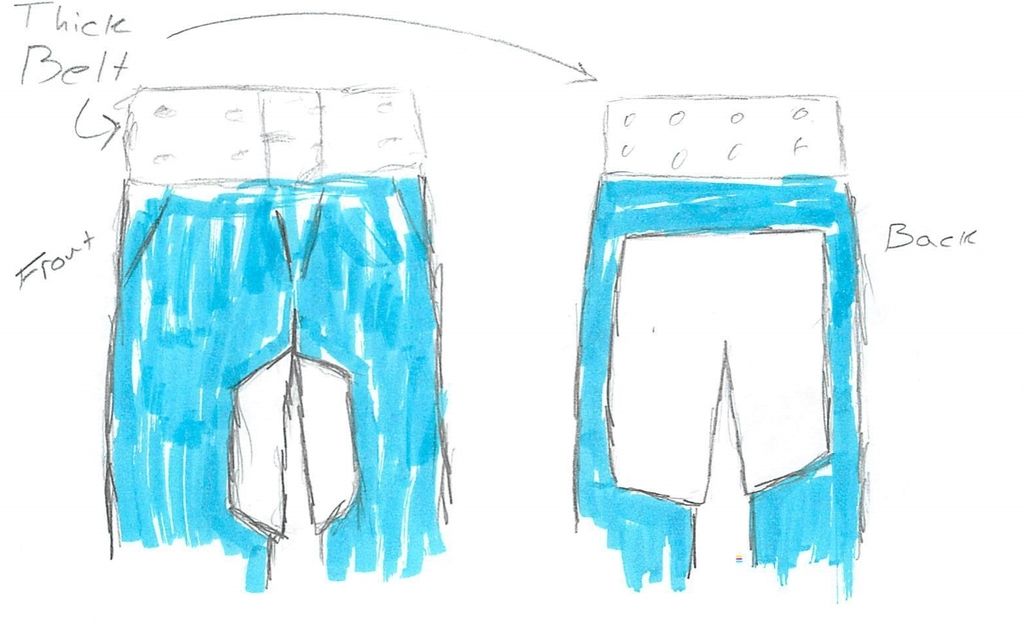

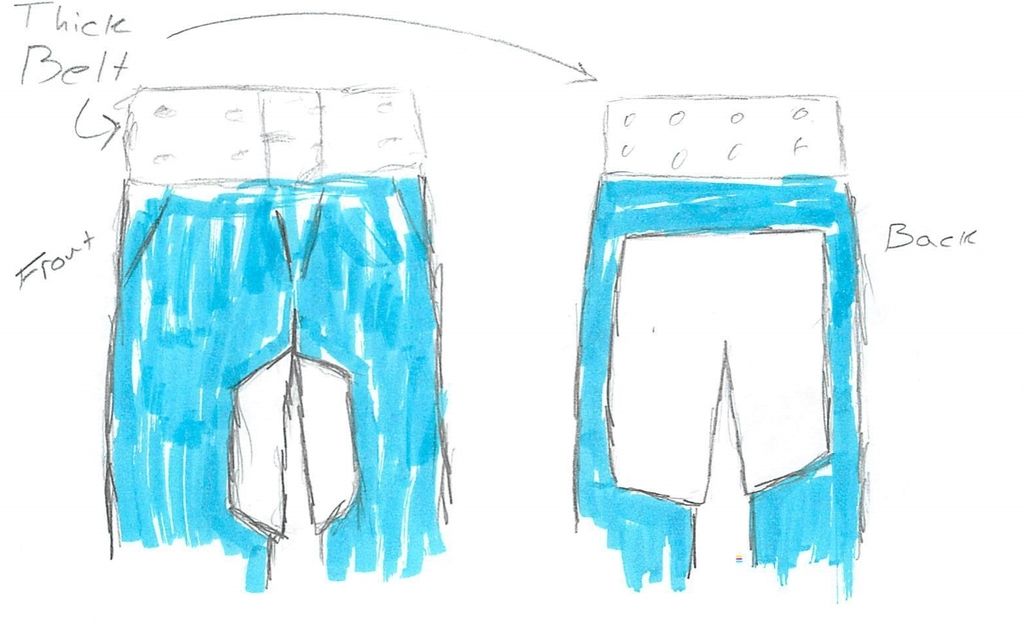

general idea is pictured below, will explain what's what after the horrible pictures.

BEHOLD MY ARTISTIC PROWESS!

So, the general idea, is that it'll be a very worn vault jump suit, where the "high wear" areas have been reinforced with some sort of leather type material; that's what the white spot on the pictures represent.

So, the general idea, is that it'll be a very worn vault jump suit, where the "high wear" areas have been reinforced with some sort of leather type material; that's what the white spot on the pictures represent.

On the upper part, it covers the top of the shoulders, the front of the chest (with a larger, possibly padded area where a riffle stock would rest while shooting), and the upper back, where cargo packs would rest.

On the lower legs, the seat and inner thighs will be reinforced with the same material, essentially anywhere he would ride a wasteland beast of burden, or where the pants might have worn through from long travels, wrapping around onto the front of the legs some.

What I need to figure out, is what material to use. for those added patch areas.

-Leather would be great, but I'm afraid it would be to thick to move in comfortably, and to thick to be able to add actual padding to the front right chest piece.

-Vinyl in a leather pattern would be thin enough, but I'm not sure it could be weathered well enough to not look like shiny fake leather vinyl

-One buddy suggested canvas, which I think will probably be the ticket, unless someone knows of a proper leather for accomplishing what I'm after.

So, if leather; what type/thickness?

If Vinyl; how do I weather it/make it worn looking?

If Canvas; similar question to leather, at what point does canvas stop being thin enough to add padding under in some places, and to difficult to sew?

Thank you very much in advance

-Ken/Strikerkc

general idea is pictured below, will explain what's what after the horrible pictures.

BEHOLD MY ARTISTIC PROWESS!

So, the general idea, is that it'll be a very worn vault jump suit, where the "high wear" areas have been reinforced with some sort of leather type material; that's what the white spot on the pictures represent.

So, the general idea, is that it'll be a very worn vault jump suit, where the "high wear" areas have been reinforced with some sort of leather type material; that's what the white spot on the pictures represent. On the upper part, it covers the top of the shoulders, the front of the chest (with a larger, possibly padded area where a riffle stock would rest while shooting), and the upper back, where cargo packs would rest.

On the lower legs, the seat and inner thighs will be reinforced with the same material, essentially anywhere he would ride a wasteland beast of burden, or where the pants might have worn through from long travels, wrapping around onto the front of the legs some.

What I need to figure out, is what material to use. for those added patch areas.

-Leather would be great, but I'm afraid it would be to thick to move in comfortably, and to thick to be able to add actual padding to the front right chest piece.

-Vinyl in a leather pattern would be thin enough, but I'm not sure it could be weathered well enough to not look like shiny fake leather vinyl

-One buddy suggested canvas, which I think will probably be the ticket, unless someone knows of a proper leather for accomplishing what I'm after.

So, if leather; what type/thickness?

If Vinyl; how do I weather it/make it worn looking?

If Canvas; similar question to leather, at what point does canvas stop being thin enough to add padding under in some places, and to difficult to sew?

Thank you very much in advance

-Ken/Strikerkc

Last edited: