You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ESB Bladed Stunt Graflex Lightsaber "The Core!"

- Thread starter thd9791

- Start date

Drew Baker

Sr Member

I also realized idk how they keep this core in place! ... Maybe glue?

All the gunk we see in the MoM Vader sync port makes me think there's glue or epoxy putty involved, but I don't know what would or wouldn't have been available at the time.

Mouse Vader

Sr Member

Maybe glue?

If this is subject to repeat impact I don't think glue, or even epoxy putty*, would stay the course - not with that shallow an insert & a long blade for leverage.

* milliput & P38 car body filler were def. available.

On this one there is definitely a screw at the top & something going on at the side (grub screw?). The metal disc looks more deeply seated than you have it . The black graflex bulb holder also seems absent.

Certainly from my research (ANH) screws seem the preferred method.

These are good observations.

I hadn't seen that hole on the side until now - going to dig more into that, it could very well be a grub screw

The center socket I thought was there because of the dark gray section with the Graflex pin hole facing us.

My socket seems to cause a more dramatic overhang in the port. The one here seems to only be a small amount, maybe that isn't the center piece of the socket....

I hadn't seen that hole on the side until now - going to dig more into that, it could very well be a grub screw

The center socket I thought was there because of the dark gray section with the Graflex pin hole facing us.

My socket seems to cause a more dramatic overhang in the port. The one here seems to only be a small amount, maybe that isn't the center piece of the socket....

There is a mark in the same spot here

Edit: I was able to get my upper core to sit lower, more accurate to the MoM shots. I can technically tap that Graflex screw in the socket if anyone knows the thread count? Also, my vote is for a grub screw on the side

Edit: I was able to get my upper core to sit lower, more accurate to the MoM shots. I can technically tap that Graflex screw in the socket if anyone knows the thread count? Also, my vote is for a grub screw on the side

Last edited:

Mouse Vader

Sr Member

with the Graflex pin hole facing us.

Haha I missed that one. For some reason that grey part (dust & muck?) was reading as the rear face of the front metal disc (with nothing further in the graflex tube). I also can't decide if the front disc is bulging the graflex tube slightly or if that 'line' is a reflection from the shroud (following the 'seam' in the hole between disc & bulbholder).

I wouldn't discount other grub screws either, most prob one on the opposite side to balance out stresses.

ROTJ Vader Pic Thread

Middle socket is definitely there.

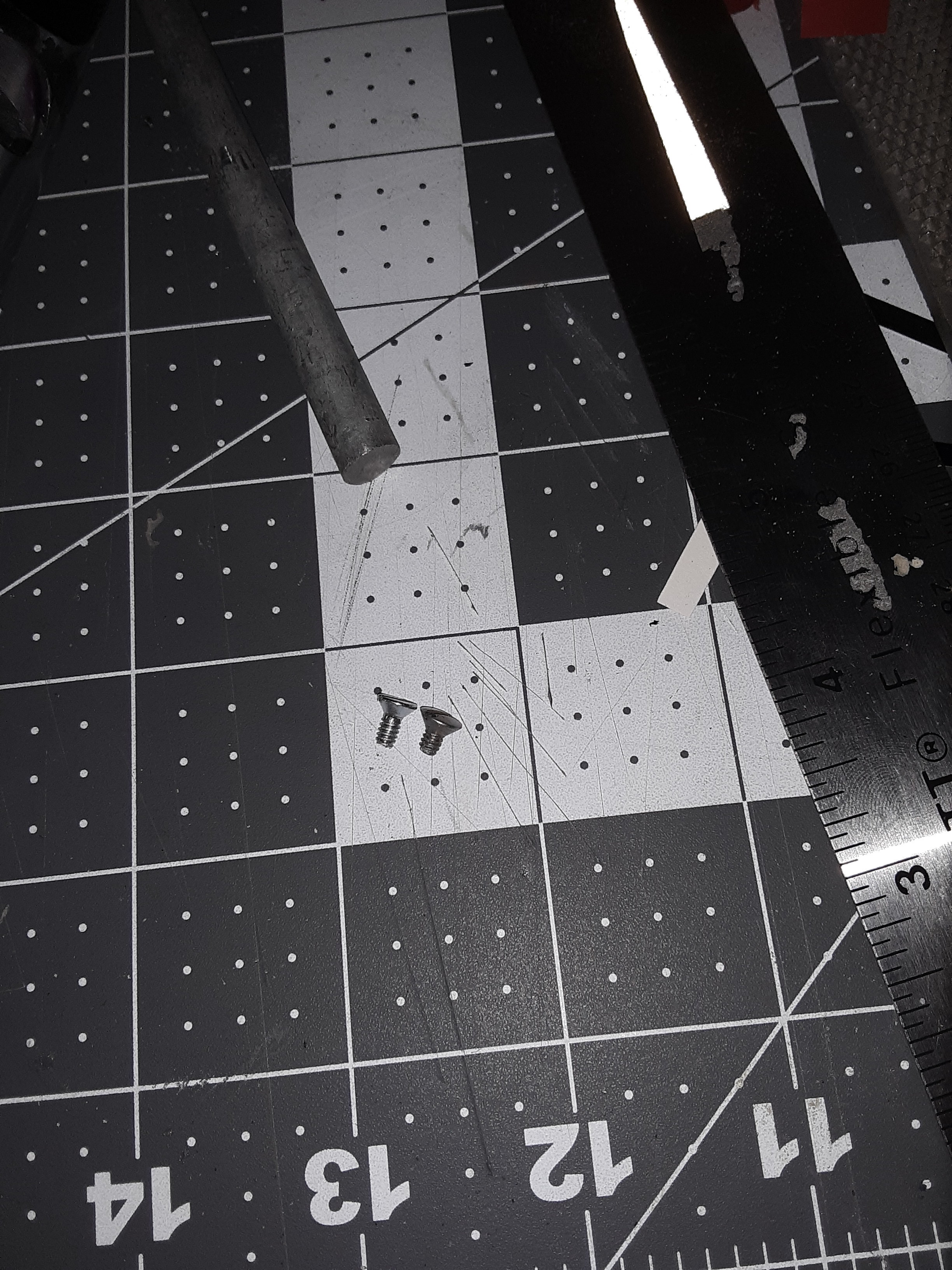

I got myself some 4-40 countersunk screws and some 6-32 grub screws to set the puck in with what we see

Middle socket is definitely there.

I got myself some 4-40 countersunk screws and some 6-32 grub screws to set the puck in with what we see

I successfully tapped/drilled the set screws we see. I follower Mouse Vader's advice and did another opposite grub screw because the puck wasn't really secure. I just only have one 4-40 grub screw (1/8" long!) And I need to find another

Pictured: only 2 of 3 holes I drilled. The other one is just on the other side

I swapped the graflex slotted screw for one with a flatter head from a hardware store. It was so nerve wracking drilling this one! I sanded the bottom of the plastic socket and sanded the core to get a little more space... sink the puck down a little further and make that hole happen.

I also, for good measure drilled, tapped and lubricated/cleaned out the holes I already made for the bolts and stuff. This was my first countersunk job and rather messy. I may have to drill out the threads in the control box and just use it as a spacer. I did tap the core, but the box and core are like a half thread off and I dint want to take any more material away. (There are 3 holes down there because my first one was a dud when trying to space the halves a part. The two on the outside line up)

How's this for a comparison photo?

Pictured: only 2 of 3 holes I drilled. The other one is just on the other side

I swapped the graflex slotted screw for one with a flatter head from a hardware store. It was so nerve wracking drilling this one! I sanded the bottom of the plastic socket and sanded the core to get a little more space... sink the puck down a little further and make that hole happen.

I also, for good measure drilled, tapped and lubricated/cleaned out the holes I already made for the bolts and stuff. This was my first countersunk job and rather messy. I may have to drill out the threads in the control box and just use it as a spacer. I did tap the core, but the box and core are like a half thread off and I dint want to take any more material away. (There are 3 holes down there because my first one was a dud when trying to space the halves a part. The two on the outside line up)

How's this for a comparison photo?

Mouse Vader

Sr Member

Looking pretty good. You certainly got the puck depth spot on. (like the term puck too, fits well). Tried fleabay for the grub screws ?

What's the original graflex screw like? I only have a repro to go on. The one in the pic of the original looks like a flat head (countersunk) the one you used looks more like a pan head.

What's the original graflex screw like? I only have a repro to go on. The one in the pic of the original looks like a flat head (countersunk) the one you used looks more like a pan head.

I can get like 100 of these on ebay it looks like, I might get an assorted pack and help future Tom.

I used 440 because the hole for the side screw seemed to be similar size to the graflex socket pin. (Mine are missing) turns out the graflex front screw is the same tap.

The graflex one is on the right, it's like an oval countersunk head that pokes up a little. I even have a dimple carved out of my shroud ring for it haha the one on the left I got from my local hardware store

I used 440 because the hole for the side screw seemed to be similar size to the graflex socket pin. (Mine are missing) turns out the graflex front screw is the same tap.

The graflex one is on the right, it's like an oval countersunk head that pokes up a little. I even have a dimple carved out of my shroud ring for it haha the one on the left I got from my local hardware store

Nice job with all this madness, Tom!

Yeah, the little slotted oval head screw is a 4-40.

The pins are smaller, though. I wanna say 1-72, but it's been a while since I checked. Maybe 2-56.

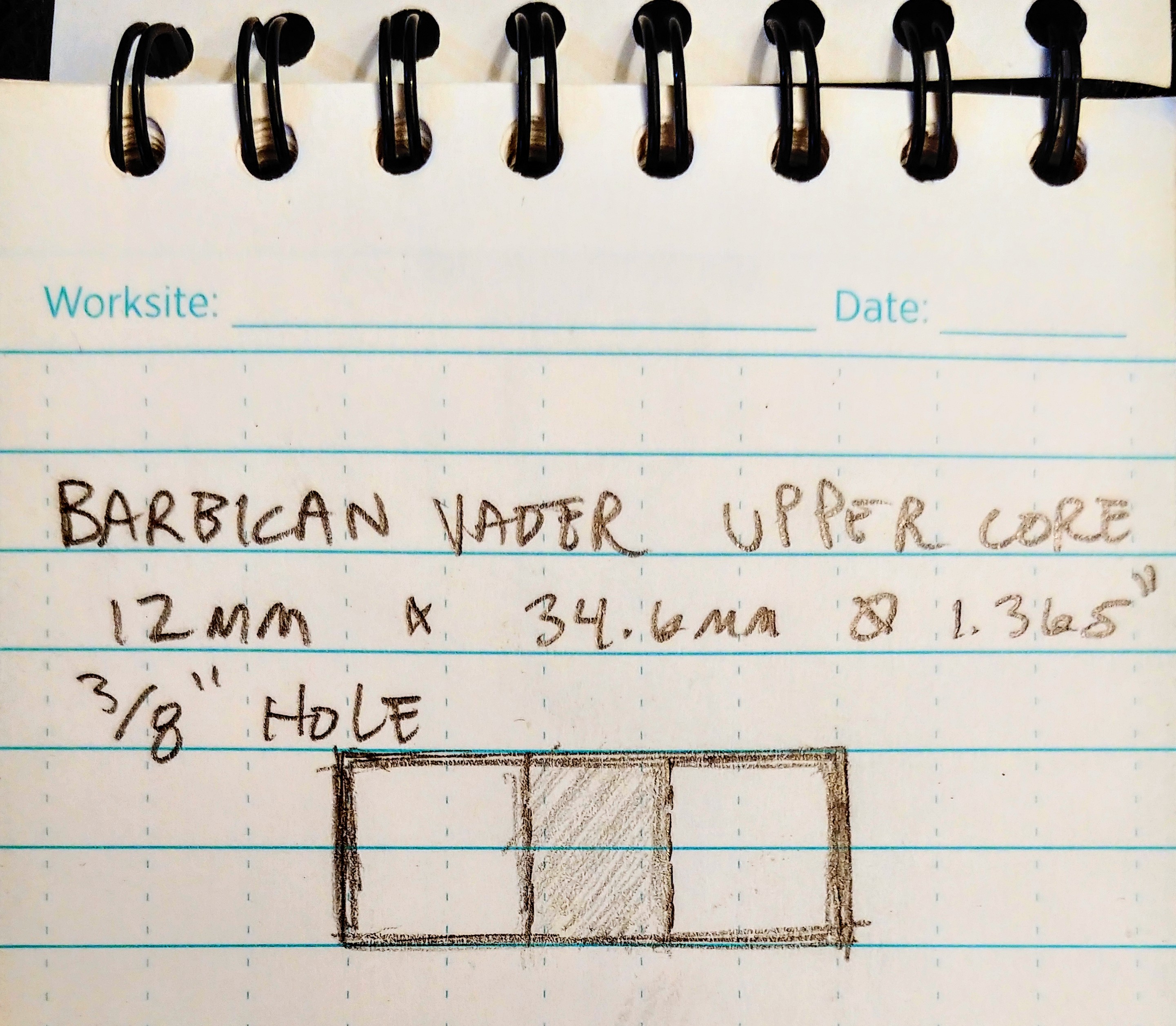

The puck you've made there is about what I was gonna make for my Barbican! I even did a little drawing the other day. Great minds!!

Also, check your PM's for core info!

Yeah, the little slotted oval head screw is a 4-40.

The pins are smaller, though. I wanna say 1-72, but it's been a while since I checked. Maybe 2-56.

The puck you've made there is about what I was gonna make for my Barbican! I even did a little drawing the other day. Great minds!!

Also, check your PM's for core info!

Last edited:

Some better sized shots to work from. Looks like they used the ESB Duelers in a photoshoot

Attachments

Propdude113

Active Member

Some better sized shots to work from. Looks like they used the ESB Duelers in a photoshoot

Never seen those photo shoot pics before

Propdude (mobile chrome app erroring and not letting me quote)

I do see those. Now, they do line up with pieces of the set behind them - so it could be a refraction light

But I do recognize different diameters at these "joints" almost as if either they are sections of reflective tape or sections of a fishing pole.

I could be wrong, but sectioned blades wouldn't flex the way they do or withstand sparring I'm guessing

I do see those. Now, they do line up with pieces of the set behind them - so it could be a refraction light

But I do recognize different diameters at these "joints" almost as if either they are sections of reflective tape or sections of a fishing pole.

I could be wrong, but sectioned blades wouldn't flex the way they do or withstand sparring I'm guessing

Propdude113

Active Member

Propdude (mobile chrome app erroring and not letting me quote)

I do see those. Now, they do line up with pieces of the set behind them - so it could be a refraction light

But I do recognize different diameters at these "joints" almost as if either they are sections of reflective tape or sections of a fishing pole.

I could be wrong, but sectioned blades wouldn't flex the way they do or withstand sparring I'm guessing

I do have a theory. What if the SOME of the blades themselves were straight, non tapered tubes. Reflective materials were applied in sections with the most being at the base of the blade with less going towards the tip giving the tapered look. A thinner blade wrapped would explain some of the crazy flex we see.

Okay gentleman I know I am not crazy! lol! Does anyone else see these "steps"..those obvious gaps in the blades??

This is just the high contrast of the lighting blowing out the blade in areas you can see it anywhere the dark areas of the set is behind the blades.

****, does bamboo flex like this?

I trained in martial arts with a bamboo staff, probably 3/4” 7/8th thick.. it was a long time ago. It was incredibly stiff no way that bow was bending

Propdude113

Active Member

This is just the high contrast of the lighting blowing out the blade in areas you can see it anywhere the dark areas of the set is behind the blades.

Ah gotcha

Similar threads

- Replies

- 2

- Views

- 431

- Replies

- 1

- Views

- 479

- Replies

- 34

- Views

- 3,543

- Replies

- 17

- Views

- 1,250