My nephew has an Ender 3 Pro 3D printer he is borrowing and he started having trouble with the filament feeding. I don't have any experience with 3D printers so I'm limited on what I can help with. He said it will print for maybe an hour and then it will stop and it looks like there is some kind of problem with the part that grips the filament and feeds it. He read up on it online and he replaced some M3 screw to a longer screw, which people advised and it helped, but the problem is still there. Anyone have experience with this printer that can help?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ender 3 Pro help

- Thread starter Sluis Van Shipyards

- Start date

TazMan2000

Master Member

I’m assuming your nephew has properly levelled the print surface.

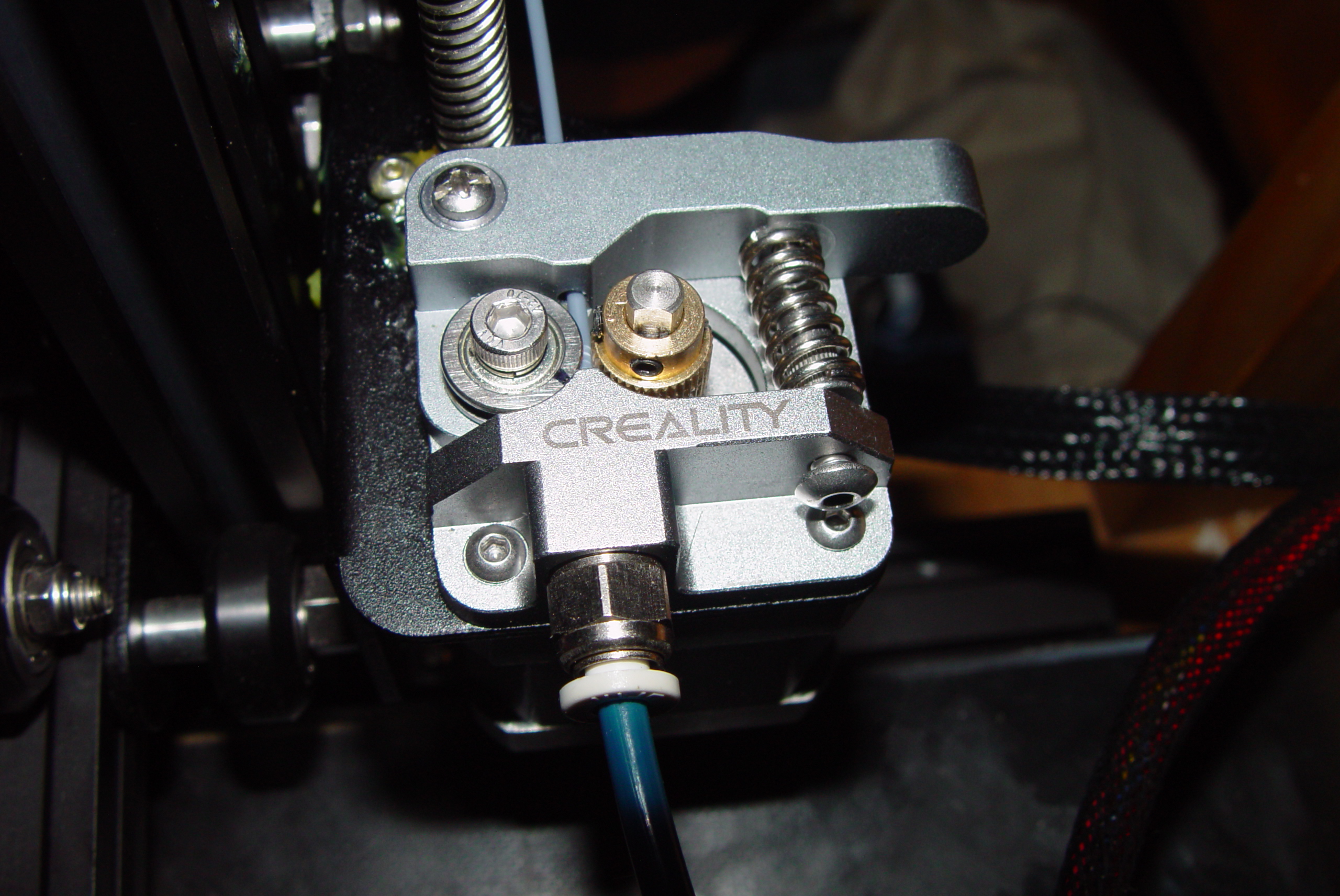

If you could send me a picture of the extruded mechanism I can probably suggest a better course of action, but without a picture, all I can suggest is to loosen off the part that grips the filament. Don’t lose the tiny set screws. Check for wear marks. You might be able to restore the teeth if you have a small and sharp file. Otherwise you could reposition the teeth to a section where it isn’t worn.

Older extruders have weak springs which don’t push the rollers against the filament enough causing slippage.

It could also be a plugged up nozzle which restricts the flow.

Worst case it could be a bad hot end, which I had recently. The temperature sensor could be misreading the hot end temp and not heating up the filament enough causing a blockage after a while.

TazMan2000

If you could send me a picture of the extruded mechanism I can probably suggest a better course of action, but without a picture, all I can suggest is to loosen off the part that grips the filament. Don’t lose the tiny set screws. Check for wear marks. You might be able to restore the teeth if you have a small and sharp file. Otherwise you could reposition the teeth to a section where it isn’t worn.

Older extruders have weak springs which don’t push the rollers against the filament enough causing slippage.

It could also be a plugged up nozzle which restricts the flow.

Worst case it could be a bad hot end, which I had recently. The temperature sensor could be misreading the hot end temp and not heating up the filament enough causing a blockage after a while.

TazMan2000

I'm pretty sure he leveled it because I do know you have to do that and I told him when he set it up. I cleaned out the nozzle because they were plugging up because of this problem. The screw he replaced is the Philips one. BTW, he's using PLA and everything online said to use acetone to soften it to clean the nozzle, but I used 100% acetone and it did nothing. I ended up using lacquer thinner. Is there anything that works better?

TazMan2000

Master Member

Acetone has little effect on most PLA recipes. Methylene Chloride may dissolve PLA, but the cost and difficulty in obtaining it makes replacing the nozzle a far easier and cheaper option. The extruder is a modern one. No issue with that. Did you check the brass piece for wear?

TazMan2000

TazMan2000

This is the first time I've looked at it. I was trying to let him see if he can figure it out. He's never had any interest with models or props until now so I am trying to let him do as much as possible. I'll check it out for wear when I'm over there tomorrow.

I checked the brass gear and it looks like it's in great shape.

TazMan2000

Master Member

So its probably either the nozzle or the hot end.

TazMan2000

TazMan2000

Another possibility with a Creality printer is that the PTFE tube has shifted creating a small gap between tube and hot end. This area can then clog. Google "Luke's Hot End Fix". It's a simple fix and most Creality owners do this as a preventative measure even if they're not experiencing problems currently. Worth a try.

propmaster2000

Sr Member

Did the printer come with the EXTRUDER and BOWDEN Tube pictured above?

Does he know if his friend was printing well after the change from the stock EXTRUDER and original Bowden tube?

This issue may just be a culmination of these changes and nozzle cleaning.

Have him run a standard manual PURGE of filament at about 210C, with the GANTRY raised off the table using the MOVE AXIS control - EXTRUDER - 1mm to see how the after market EXTRUDER functions.

Does he know if his friend was printing well after the change from the stock EXTRUDER and original Bowden tube?

This issue may just be a culmination of these changes and nozzle cleaning.

Have him run a standard manual PURGE of filament at about 210C, with the GANTRY raised off the table using the MOVE AXIS control - EXTRUDER - 1mm to see how the after market EXTRUDER functions.

Last edited:

Ok I'll have him check those suggestions out. Thanks guys!

Well they talked and they think it needs the extruder replaced. So we'll see. I'm trying to get him to problem solve and not just throw money at a problem, which doesn't always work. I'm actually proud he's taking an interest in some hobby because the most he's done before is build a LEGO kit as a kid, and those instances were rare. Usually I am called on to fix, build, repair, etc. whatever toy or item he has!

Iskelderon

Sr Member

Interesting! They actually introduced the all-metal extruder because the plastic components on the original Ender 3 had a habit of eventually splitting irreparably due to material fatigue.Well they talked and they think it needs the extruder replaced. So we'll see. I'm trying to get him to problem solve and not just throw money at a problem, which doesn't always work. I'm actually proud he's taking an interest in some hobby because the most he's done before is build a LEGO kit as a kid, and those instances were rare. Usually I am called on to fix, build, repair, etc. whatever toy or item he has!

JiminSTLouis

Sr Member

The hot end is clogged putting back pressure on the filament. The extruder can’t overcome the back pressure.

Replace the nozzle. I know you said you cleaned it, but they’re cheap.

Make sure the inside of the hot end is clean of any resin.

Replace the Bowden tube. Use a Capricorn tube. Make sure the end is cut square by using a tube cutter. Install the nozzle then turn it back 1/2 turn. Install the new tube tight against the nozzle. Re-tighten the nozzle to ensure a tight seal against the tube. DO THIS WHILE HOT. Be careful not to burn yourself.

Make sure a locking clip is installed in the fitting to make sure the tube doesn’t back out.

Replace the nozzle. I know you said you cleaned it, but they’re cheap.

Make sure the inside of the hot end is clean of any resin.

Replace the Bowden tube. Use a Capricorn tube. Make sure the end is cut square by using a tube cutter. Install the nozzle then turn it back 1/2 turn. Install the new tube tight against the nozzle. Re-tighten the nozzle to ensure a tight seal against the tube. DO THIS WHILE HOT. Be careful not to burn yourself.

Make sure a locking clip is installed in the fitting to make sure the tube doesn’t back out.

Ok so he replaced the hot end/nozzle and the extruder and it's still not working correctly. Now he thinks it might be something with humidity and the filament. He said because his room is near the shower, humidity is messing up the filament. I don't know how much humidity affects the filament. The house has AC running and a dehumidifier and I can't really imagine that much humidity is going into his room from someone taking a 10 min. shower. I could be wrong though. I told him to see if there's a default/factory setting and reset it and try that. He's 18 and thinks he's an expert on everything though, so he's convinced he knows...

propmaster2000

Sr Member

Can you post a few pictures of the printer from different angles and what again is it doing that needs fixing?Ok so he replaced the hot end/nozzle and the extruder and it's still not working correctly. Now he thinks it might be something with humidity and the filament. He said because his room is near the shower, humidity is messing up the filament. I don't know how much humidity affects the filament. The house has AC running and a dehumidifier and I can't really imagine that much humidity is going into his room from someone taking a 10 min. shower. I could be wrong though. I told him to see if there's a default/factory setting and reset it and try that. He's 18 and thinks he's an expert on everything though, so he's convinced he knows... View attachment 1496353

Thanks.

Last edited:

I can't get any pictures probably until this weekend when I'm over there. He just said it prints maybe half way then stops like the nozzle is clogged, but it isn't (new nozzle).

Similar threads

- Replies

- 0

- Views

- 91