You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dishonored 2 Elite Guard Uniform

- Thread starter TheSpaceMongol

- Start date

TheSpaceMongol

New Member

Thanks!

Time for some progress on other parts of the costume. Here's the initial fitting for the spats:

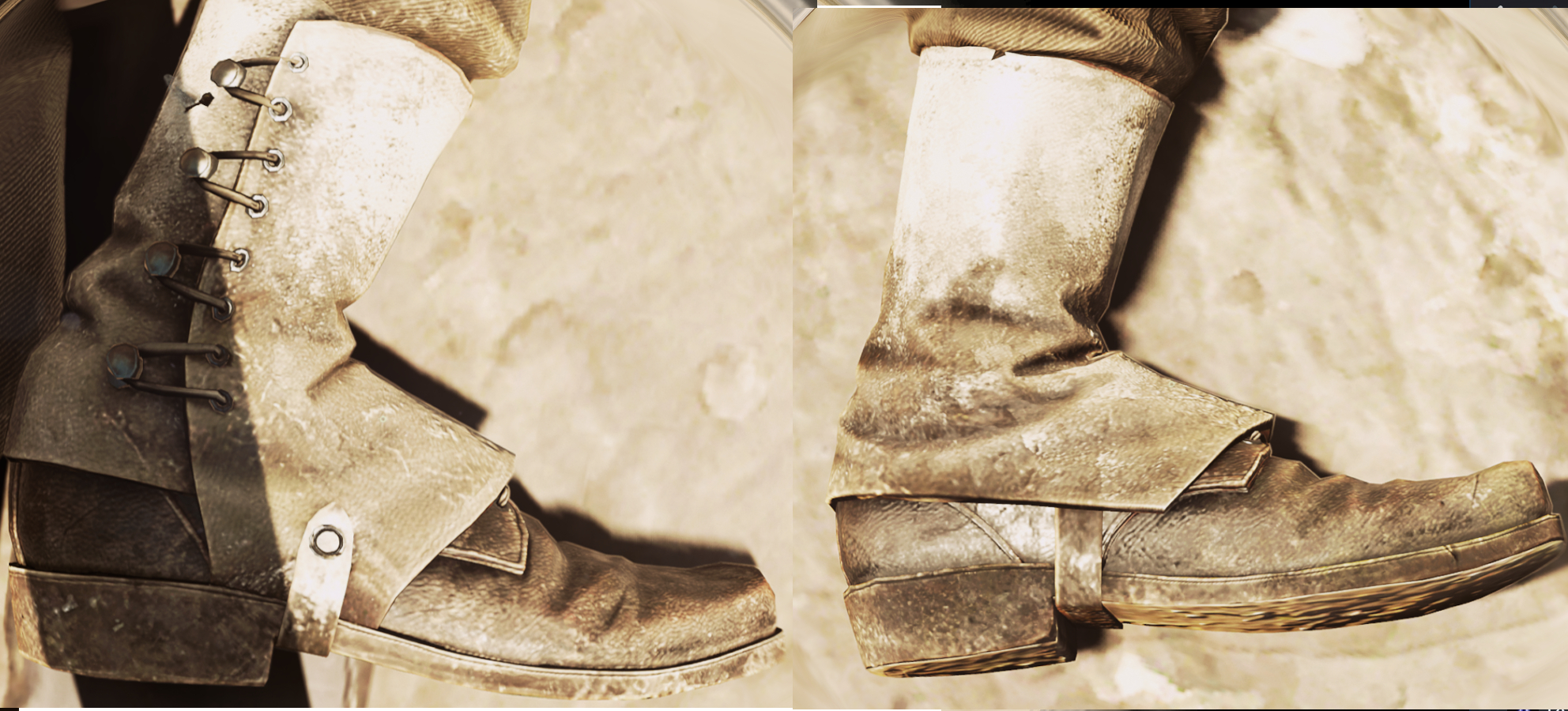

Let's check the in-game spats for comparison:

Basically, not great, not terrible. Disregarding the lack of wear and weathering on mine, there seems to be some differences in the general shape. Some excess lenght on a few edges that needs to be cut down and the front part of the spat looks like to be just a tiny bit too short on first glance. I've deemed this to not be such a big problem as I mainly tried to get a tight fit on this specific shoe which isn't perfectly similar to the one in-game. There was also the issue of material selection, as the game texture wasn't really clear enough to tell whether it was something like canvas or leather, so I opted for leather as I already had the white leather I bought for the belt and other items ready. This way the spats, belt, etc. will go nicely together even if it deviates from the original model. I'm fine with not being 100% accurate if a change makes sense.

There's also a notable difference in construction too, here's my spats laid out:

The ones in game don't have a seam in front, where as mine do. I tried to think of patterns that would let me have the front seamless but it's just not possible without some stretchy material, which leather(or canvas) is not. It would've just had a massive, ugly crease in front and not the small kind seen in-game. On a side note, all spats I saw on sale also have this seam.

I'll probably make some minor changes to them still, maybe water form the seams to make them straighter, cut the excess and do some weathering.

Edit: I test fitted the parts that I have on hand now. Shirt, pants, spats, shoes and helmet. Looks like a decent start in terms of the silhouette and pretty good concerning the jacket that I still have to make. I feared the waistline of the pants might be too low but looks like it'll work out.

Time for some progress on other parts of the costume. Here's the initial fitting for the spats:

Let's check the in-game spats for comparison:

Basically, not great, not terrible. Disregarding the lack of wear and weathering on mine, there seems to be some differences in the general shape. Some excess lenght on a few edges that needs to be cut down and the front part of the spat looks like to be just a tiny bit too short on first glance. I've deemed this to not be such a big problem as I mainly tried to get a tight fit on this specific shoe which isn't perfectly similar to the one in-game. There was also the issue of material selection, as the game texture wasn't really clear enough to tell whether it was something like canvas or leather, so I opted for leather as I already had the white leather I bought for the belt and other items ready. This way the spats, belt, etc. will go nicely together even if it deviates from the original model. I'm fine with not being 100% accurate if a change makes sense.

There's also a notable difference in construction too, here's my spats laid out:

The ones in game don't have a seam in front, where as mine do. I tried to think of patterns that would let me have the front seamless but it's just not possible without some stretchy material, which leather(or canvas) is not. It would've just had a massive, ugly crease in front and not the small kind seen in-game. On a side note, all spats I saw on sale also have this seam.

I'll probably make some minor changes to them still, maybe water form the seams to make them straighter, cut the excess and do some weathering.

Edit: I test fitted the parts that I have on hand now. Shirt, pants, spats, shoes and helmet. Looks like a decent start in terms of the silhouette and pretty good concerning the jacket that I still have to make. I feared the waistline of the pants might be too low but looks like it'll work out.

Last edited:

King Jacob

New Member

You already got the pose down  anyway, fantastic work. those are going to look great weathered.

anyway, fantastic work. those are going to look great weathered.

TheSpaceMongol

New Member

You already got the pose downanyway, fantastic work. those are going to look great weathered.

Thank you! Yes, I think they'll look quite decent after they've received some wear and dirt. Not exactly sure what to do to make the wear look natural but I'm considering just wearing them for a few hikes to the woods and putting the spats though a water treatment, then try cleaning them out afterwards as best I can. I wouldn't want to use paints or dyes for the leather as it might look a bit off with my skills.

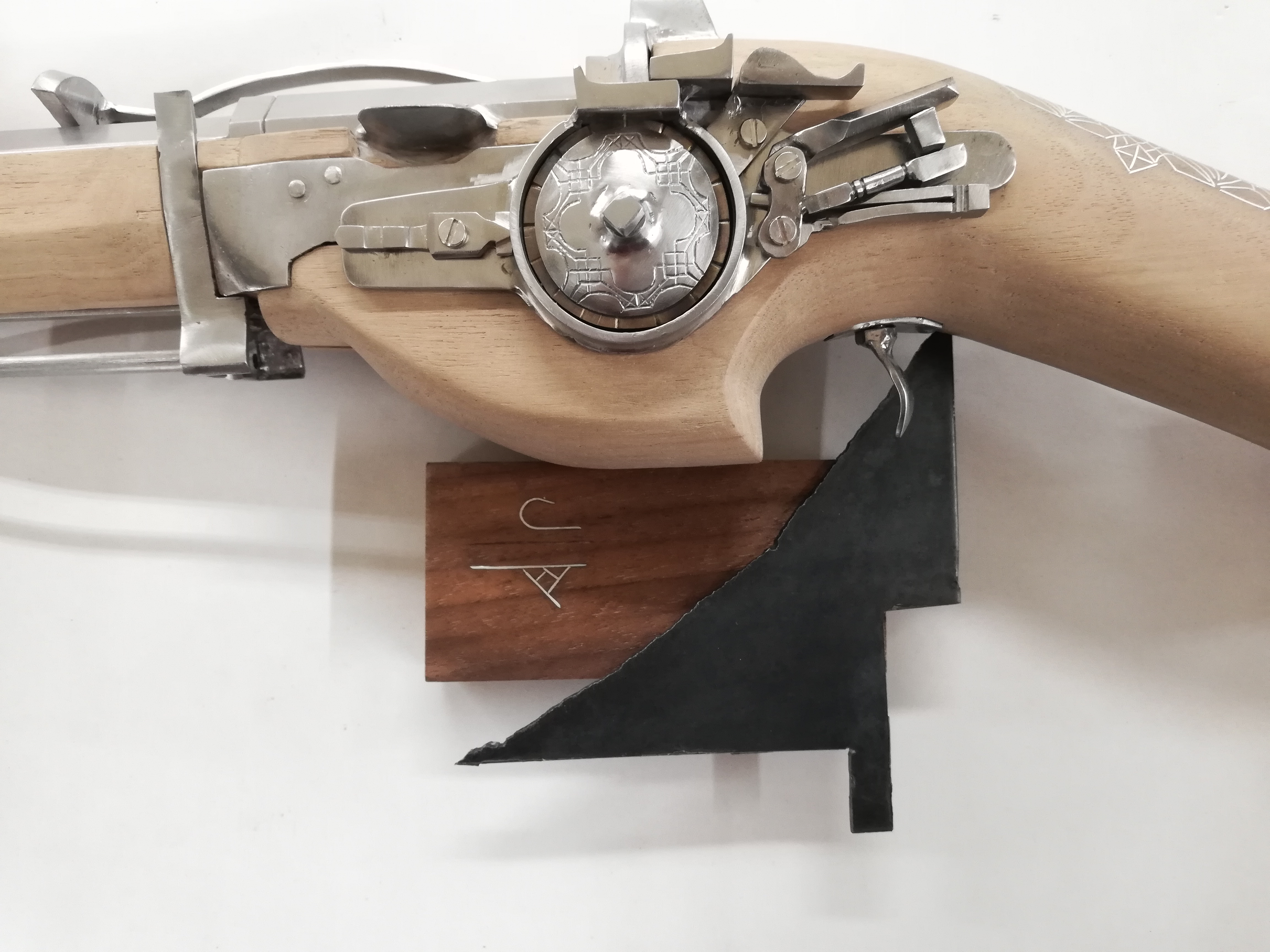

Some more progress with the gun:

A stressful part is now done as I've succesfully made the connecting rods that hold the side plates on the gun.

The end of the rods have an M3 threaded hole at the end where you can attach the other side plate.

It still requires fine tuning however. As you can see here, the side plates are not completely flush with the wood so they'll need some additional shaping yet.

All current parts assembled. Next up is the trigger and another connecting rod to fix the barrel in place.

TheSpaceMongol

New Member

So I managed to get the trigger done:

It also functions as a wingnut to hold the barrel in place via a connecting rod. I had to deviate from the in game look of the trigger slightly by making a custom washer to go under the trigger, but I tried my best to make it visually fit the gun:

I was also thinking about weathering the spats with Mig pigments generally used in modelling since they have a variety of colors. Only thing I'm unsure of whether they stick to the leather well enough or not, even if I am using a pigment fixer. If anyone has info on this, let me know.

It also functions as a wingnut to hold the barrel in place via a connecting rod. I had to deviate from the in game look of the trigger slightly by making a custom washer to go under the trigger, but I tried my best to make it visually fit the gun:

I was also thinking about weathering the spats with Mig pigments generally used in modelling since they have a variety of colors. Only thing I'm unsure of whether they stick to the leather well enough or not, even if I am using a pigment fixer. If anyone has info on this, let me know.

TheSpaceMongol

New Member

I've begun work on the silver wire inlay for the handle of the gun. I simply drew the patterns on the wood with a pencil to start off with:

The tools I'll use for the job: a tiny hammer, wire cutter, a custom widening tool made from a screwdriver, a scalpel, some tweezers and a file.

The process is as follows: first cut the line with the scalpel to prevent cracking of the grain when using the widening tool, depth of cut may vary occording to wire thickness:

Next use the custom tool to very gently widen the initial cut to fit the desired wire by pressing down into the cut, corner first with a rolling motion. This allows for slight corrections in direction if the tool isn't hitting the first cut properly.

Next flatten the wire on a suitable surface and roughen the flat sides of the wire with a file. This wire is 0,7mm thickness, flattened to about 0,5mm.

Cut a suitable lenght of wire, file the ends flat and fit it into the cut. It should fit somewhat snug and stand straight up in the groove much like a nail.

After all this, hammer the wire into the wood, all the while checking that there is no sideways fumbling or bending of the wire. Here's where I ended up after about three hours of work:

After the whole patterns is done, water should be applied lightly on the wood to swell it, gripping the wire tightly in the process. Applying some heat with a hairdryer to dry the wet surface will improve the end result too. Then just use fine sandpaper to make all the wires flush with the wood.

This really gives you all new appreciation for jewelers and other fine craftspeople. Inlay takes a LOT of concentration and time with not a much room for error.

The tools I'll use for the job: a tiny hammer, wire cutter, a custom widening tool made from a screwdriver, a scalpel, some tweezers and a file.

The process is as follows: first cut the line with the scalpel to prevent cracking of the grain when using the widening tool, depth of cut may vary occording to wire thickness:

Next use the custom tool to very gently widen the initial cut to fit the desired wire by pressing down into the cut, corner first with a rolling motion. This allows for slight corrections in direction if the tool isn't hitting the first cut properly.

Next flatten the wire on a suitable surface and roughen the flat sides of the wire with a file. This wire is 0,7mm thickness, flattened to about 0,5mm.

Cut a suitable lenght of wire, file the ends flat and fit it into the cut. It should fit somewhat snug and stand straight up in the groove much like a nail.

After all this, hammer the wire into the wood, all the while checking that there is no sideways fumbling or bending of the wire. Here's where I ended up after about three hours of work:

After the whole patterns is done, water should be applied lightly on the wood to swell it, gripping the wire tightly in the process. Applying some heat with a hairdryer to dry the wet surface will improve the end result too. Then just use fine sandpaper to make all the wires flush with the wood.

This really gives you all new appreciation for jewelers and other fine craftspeople. Inlay takes a LOT of concentration and time with not a much room for error.

King Jacob

New Member

Holy crap, you're doing real inlay! Respect.

I once tested a cheat inlay where you pack the channel with metal powder (I used brass) and saturate it with super glue, after which you can sand and polish to a decently convincing finish. I haven't actually applied it to a project though.

I once tested a cheat inlay where you pack the channel with metal powder (I used brass) and saturate it with super glue, after which you can sand and polish to a decently convincing finish. I haven't actually applied it to a project though.

TheSpaceMongol

New Member

Thanks Jacob! I hadn't considered or even heard about a method like that but it sounds like it could work just as well. I'm not sure how the superglue would affect to wood around it and what finish you could expect but there's certainly uses for it.

Took a while but I managed it:

I'd say it looks good enough from a distance, but when you view it closer up you can tell it wasn't made by a master craftsman:

Some lines aren't quite straight and there's wonky edges here and there not to mention the general asymmetry to the pattern... but that might just be me being too harsh about the standard of craftsmanship. Also, there's still the application of water and general clean up of the pattern to come which will make it look much cleaner yet. I can already see the finish line approaching for this piece of the costume so stay tuned!

Took a while but I managed it:

I'd say it looks good enough from a distance, but when you view it closer up you can tell it wasn't made by a master craftsman:

Some lines aren't quite straight and there's wonky edges here and there not to mention the general asymmetry to the pattern... but that might just be me being too harsh about the standard of craftsmanship. Also, there's still the application of water and general clean up of the pattern to come which will make it look much cleaner yet. I can already see the finish line approaching for this piece of the costume so stay tuned!

TheSpaceMongol

New Member

Well, its been a while since I made an update but I'm finally able to continue this after moving to a new apartment.

I finished smoothing the visible wood surfaces of the gun including the silver inlay and it turned out quite well in my opinion. I also refined the shape of the octagonal bulb on the end of the handle to be more symmetrical and angular, although there is still some work to do there.

There's some small decorative nails to add still as well as the band around the handle just in front of the bulb. I plan to use silver plate for that since it's easy to work with and doesn't degrade easily when handled. Not as easily as regular steel anyway. It also works well with the silver inlay. Here's a picture comparing my test pieces for the final surface finish of the wood and steel to the current unfinished look:

The scrap steel piece has been blued using a cold blueing agent and the wood has been stained using a special walnut gun stock color to bring out the natural wood grain better. It will also accentuate the silver inlay well and really make it pop. The color is pretty close to the in- game model too. For the final piece I will also apply triple layer of finishing oil(test piece only had one) with an antique wax layer on top to really make to surface well protected and smooth, just like any other walnut gun stock. The blued metal parts will be all polished with steel wool to different degrees of blueing to match the look of the respective parts of the in- game gun.

I finished smoothing the visible wood surfaces of the gun including the silver inlay and it turned out quite well in my opinion. I also refined the shape of the octagonal bulb on the end of the handle to be more symmetrical and angular, although there is still some work to do there.

There's some small decorative nails to add still as well as the band around the handle just in front of the bulb. I plan to use silver plate for that since it's easy to work with and doesn't degrade easily when handled. Not as easily as regular steel anyway. It also works well with the silver inlay. Here's a picture comparing my test pieces for the final surface finish of the wood and steel to the current unfinished look:

The scrap steel piece has been blued using a cold blueing agent and the wood has been stained using a special walnut gun stock color to bring out the natural wood grain better. It will also accentuate the silver inlay well and really make it pop. The color is pretty close to the in- game model too. For the final piece I will also apply triple layer of finishing oil(test piece only had one) with an antique wax layer on top to really make to surface well protected and smooth, just like any other walnut gun stock. The blued metal parts will be all polished with steel wool to different degrees of blueing to match the look of the respective parts of the in- game gun.

TheSpaceMongol

New Member

It has again been a while since the last update but better late than never!

At this point I'm done with the surface finish on the gun, just some cosmetic details to do before I move on to the jacket and belt. Even though it isn't fully finished, it looks pretty good in my opinion:

I ended up using a gun stock filler to smooth out the grain before applying the final wax coating and I have to say it works well! The surface is very smooth and the grain visible. At this point I made the last fine tuning to the shape of the stock and checked for any imperfections.

The cold blueing was successful as well. I used some fine steel wool to remove some of the blueing on the side plates and other varied parts that didn't have as dark of a color on the in-game model. The removal accentuated the patterns well on the side plate. The barrel and front plate fitting were left fully blued.

The silver inlay really pops from the dark walnut now. I had to make the decorative nails myself as I couldn't find suitable ones off the shelf.

I also made the silver band that will be fitted right in front of the bulb. The band had these grooves on it so I had to make a small punch tool to get them done. The silver still has the protective plastic Film on it here, that's why it looks blue.

A few extra shots as well:

Next time, the gun should be finished!

At this point I'm done with the surface finish on the gun, just some cosmetic details to do before I move on to the jacket and belt. Even though it isn't fully finished, it looks pretty good in my opinion:

I ended up using a gun stock filler to smooth out the grain before applying the final wax coating and I have to say it works well! The surface is very smooth and the grain visible. At this point I made the last fine tuning to the shape of the stock and checked for any imperfections.

The cold blueing was successful as well. I used some fine steel wool to remove some of the blueing on the side plates and other varied parts that didn't have as dark of a color on the in-game model. The removal accentuated the patterns well on the side plate. The barrel and front plate fitting were left fully blued.

The silver inlay really pops from the dark walnut now. I had to make the decorative nails myself as I couldn't find suitable ones off the shelf.

I also made the silver band that will be fitted right in front of the bulb. The band had these grooves on it so I had to make a small punch tool to get them done. The silver still has the protective plastic Film on it here, that's why it looks blue.

A few extra shots as well:

Next time, the gun should be finished!

TheSpaceMongol

New Member

The gun is done! Added the last silver decorations to it and permanently attached the steel band in the middle of the barrel as well as the trigger guard. I think the end result is pretty good.

Here are the silver fittings on the handle:

Another pic of the finished product:

One more:

Now that the gun is done I can move on to other pieces, possibly starting with a test version of the jacket to try to get the patterns figured out.

Here are the silver fittings on the handle:

Another pic of the finished product:

One more:

Now that the gun is done I can move on to other pieces, possibly starting with a test version of the jacket to try to get the patterns figured out.

Last edited:

Similar threads

- Replies

- 7

- Views

- 288