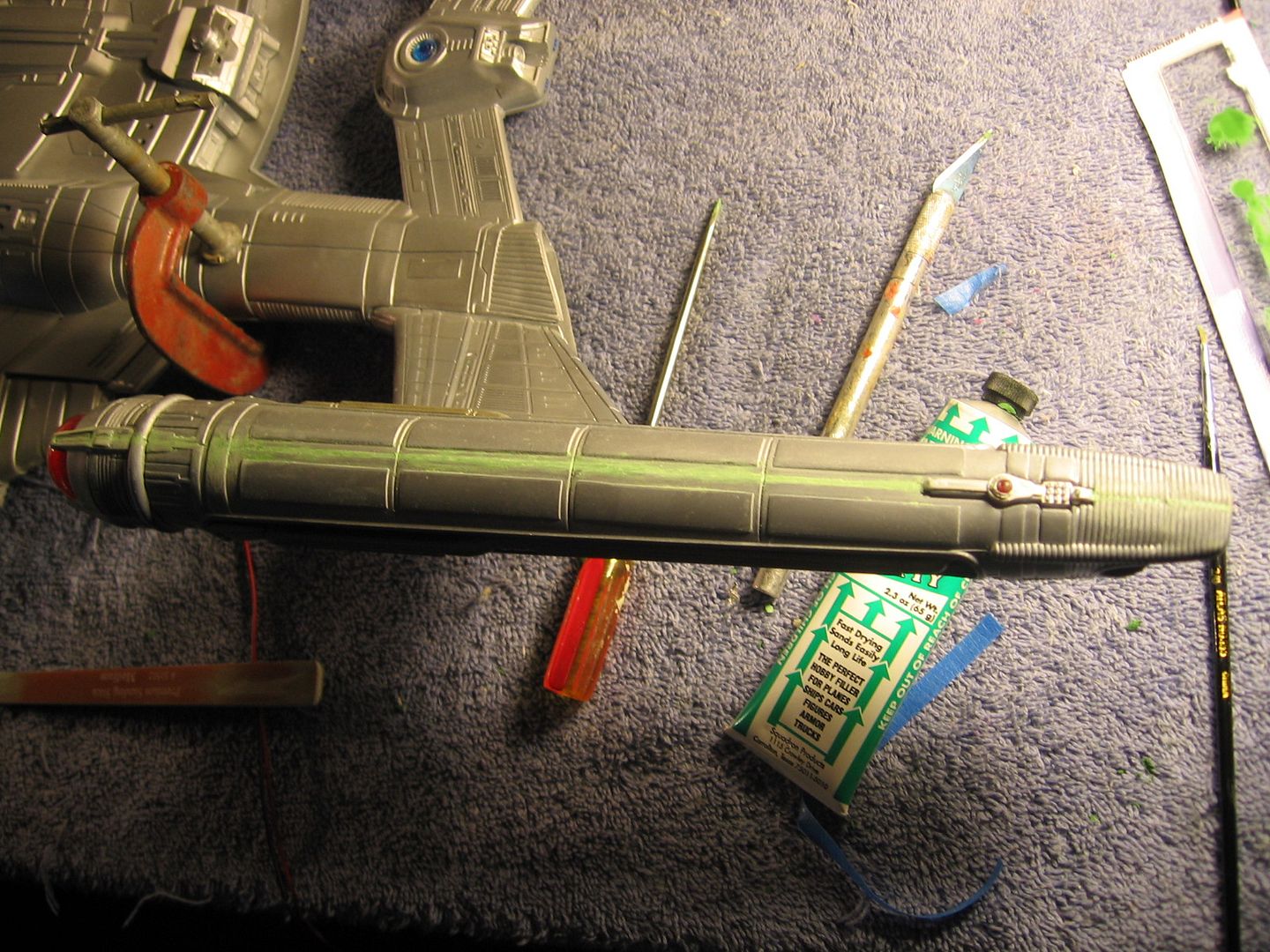

Three days of this. But the parts just drive me nuts how they fit together not to mention the light leaks as a result.

But it’s all fixed now and I’m touching up the paint as we speak.

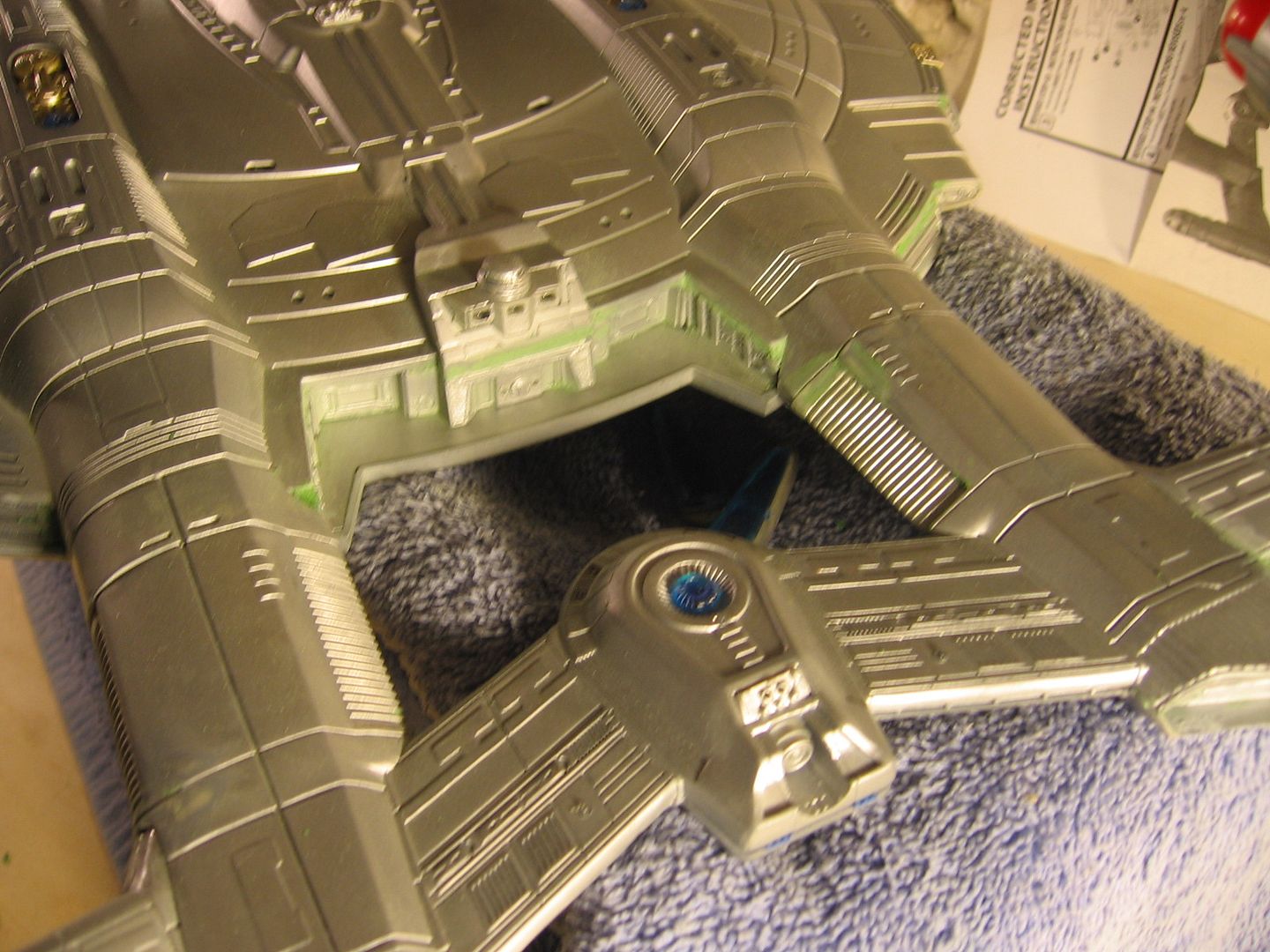

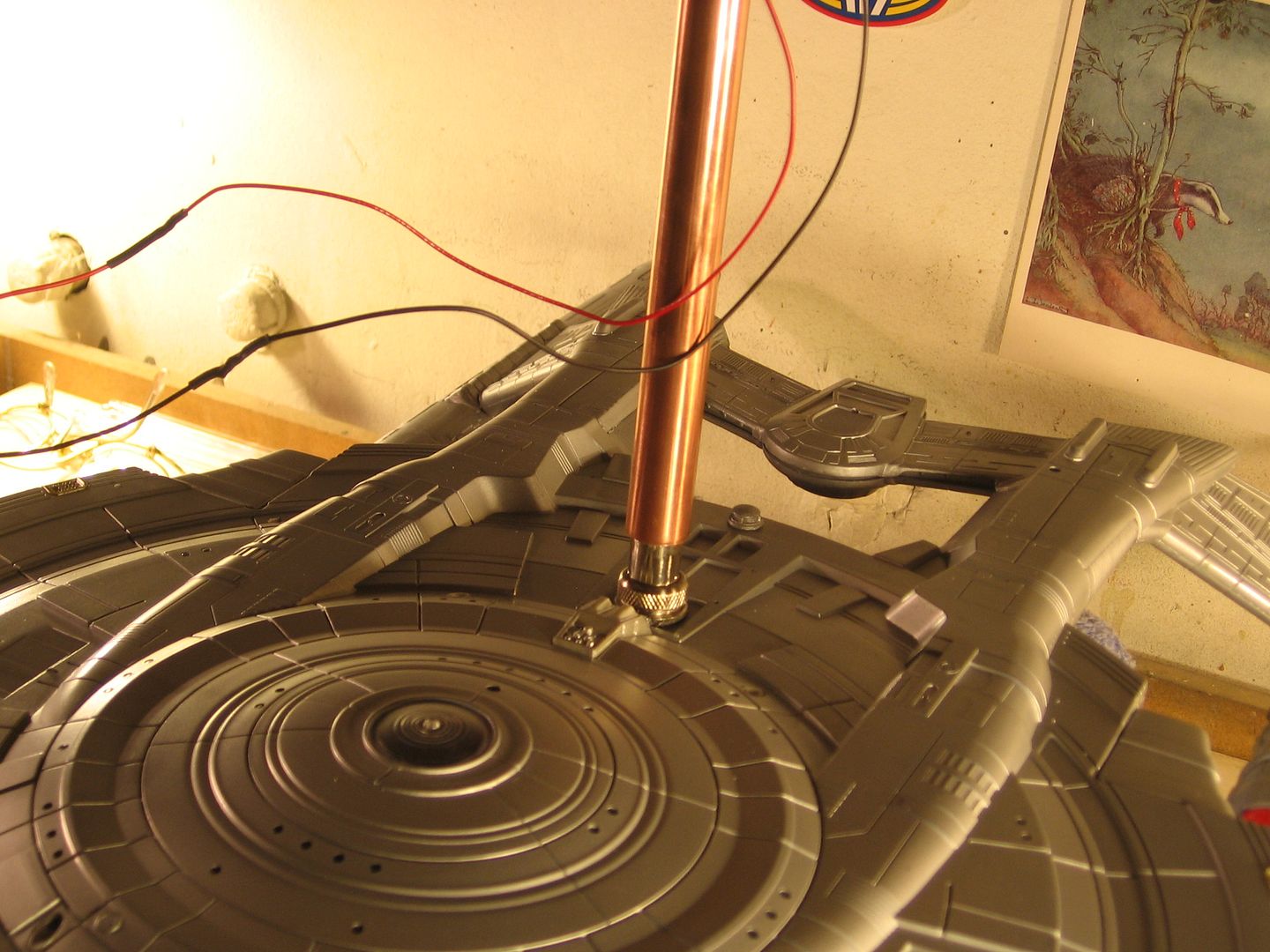

As you can see on the nacelles and other areas the seam lines don’t match when the two halves are properly put together. Not much one can do about that. I took the curse off the stepped areas with sanding and blended putty.

But all complaining aside in the end this is a nice solid model. Don’t let my griping stop you from building yours. Just do it and love it. To tell you the truth I can’t wait to start mine.

Thanks to Gary and Cultman TV I have the lighting and decals in the box with mine ready to go.

Steve

Yuck!

WTF? Panel lines don’t match.

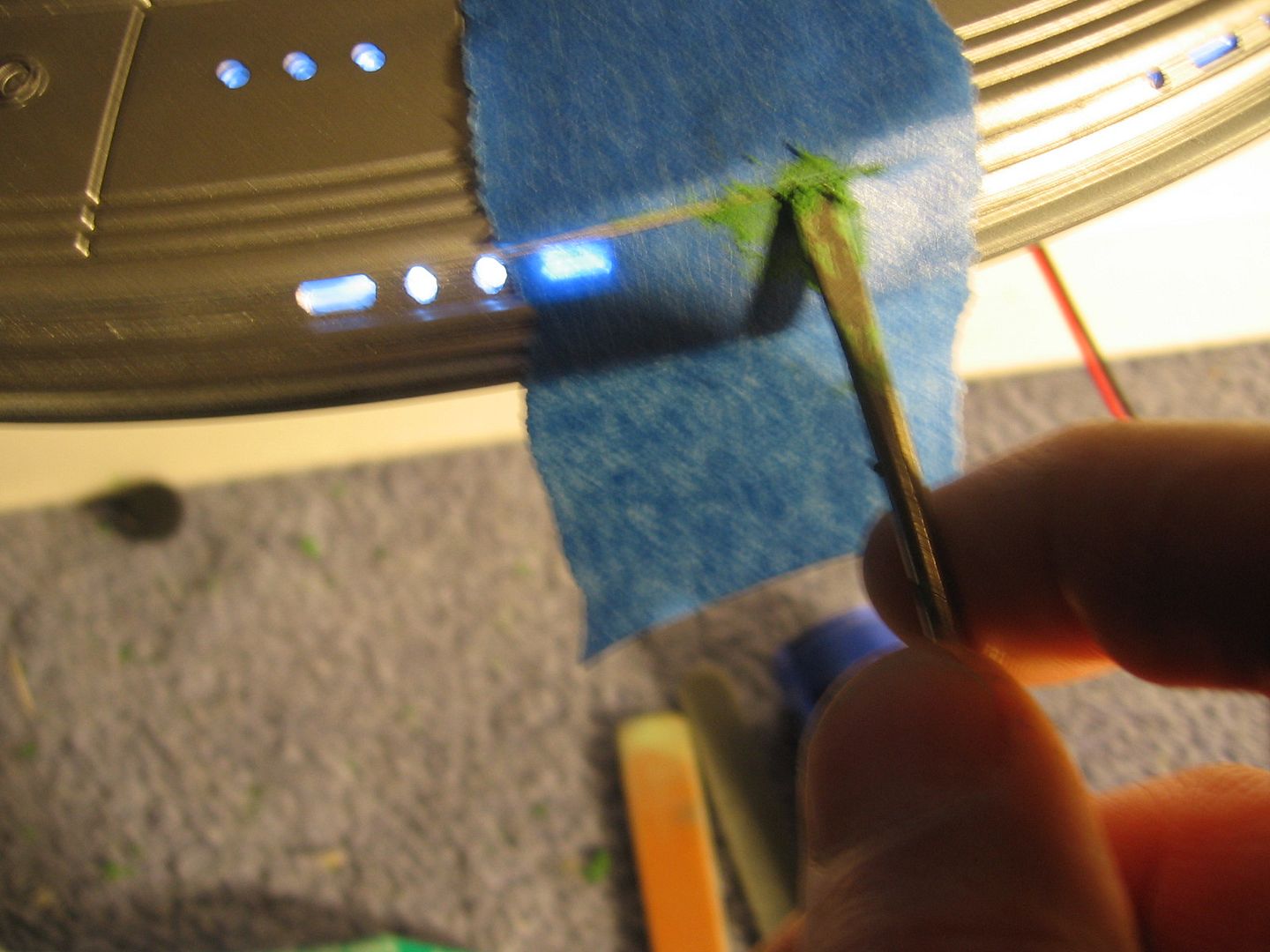

Plugin leaks. Tape keeps dummy fingers from getting it on the windows.

Sanding and sanding and sanding and sanding…

All the green is seam filling and light leak plugging up.

It’s almost done with seaming!

Wait a minute found another one!

These lines didn’t match either but were close enough to fix. However the step here if walked on would have tripped you down the stairs. Better now.

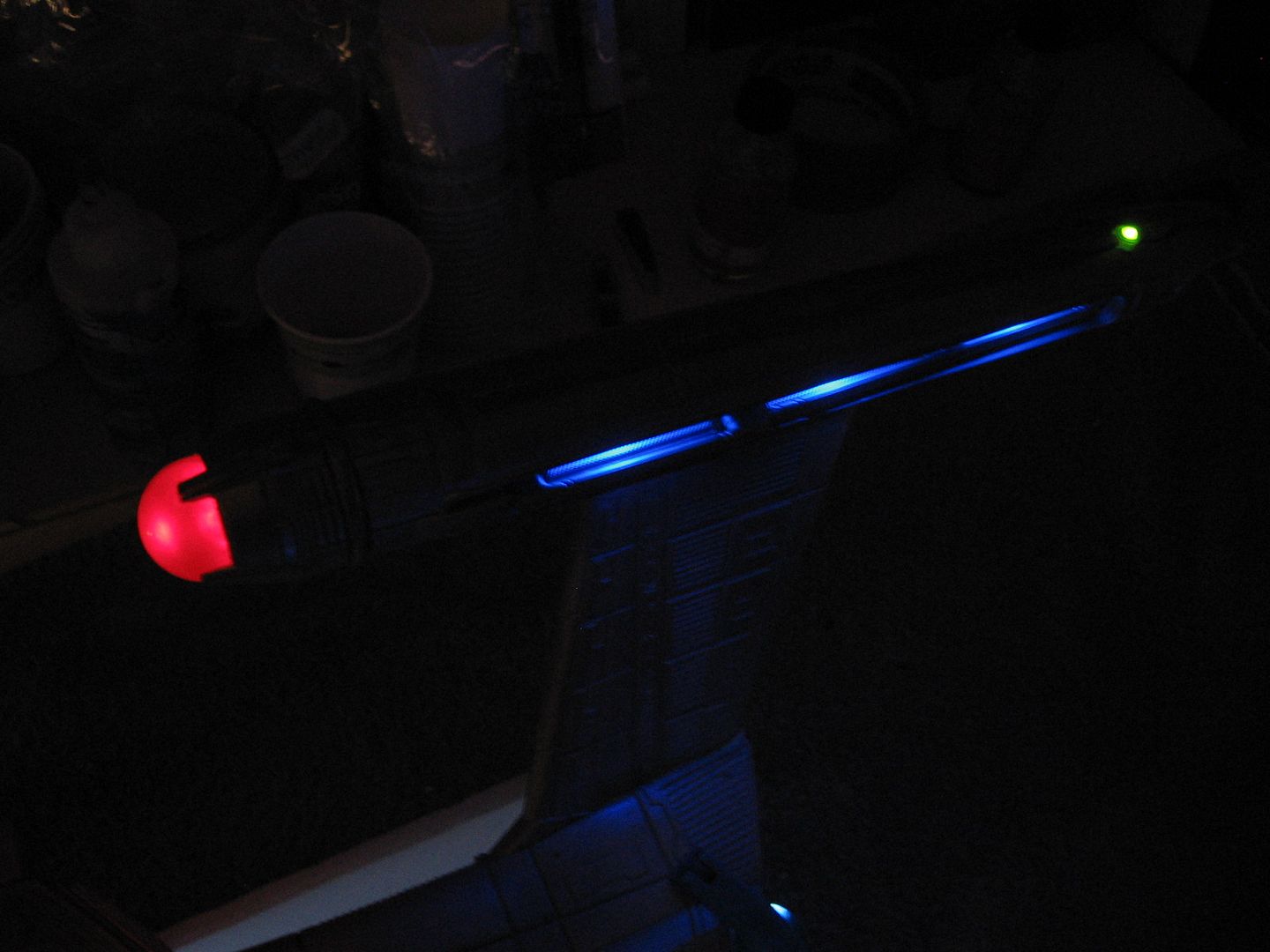

No light leaks.

With the lights on she’s still pretty bright.