I was just pointed to this thread. The build looks fantastic. As much time as you've spent applying them I spent 3x or more switching back and forth from Illustrator to the CGI scans.

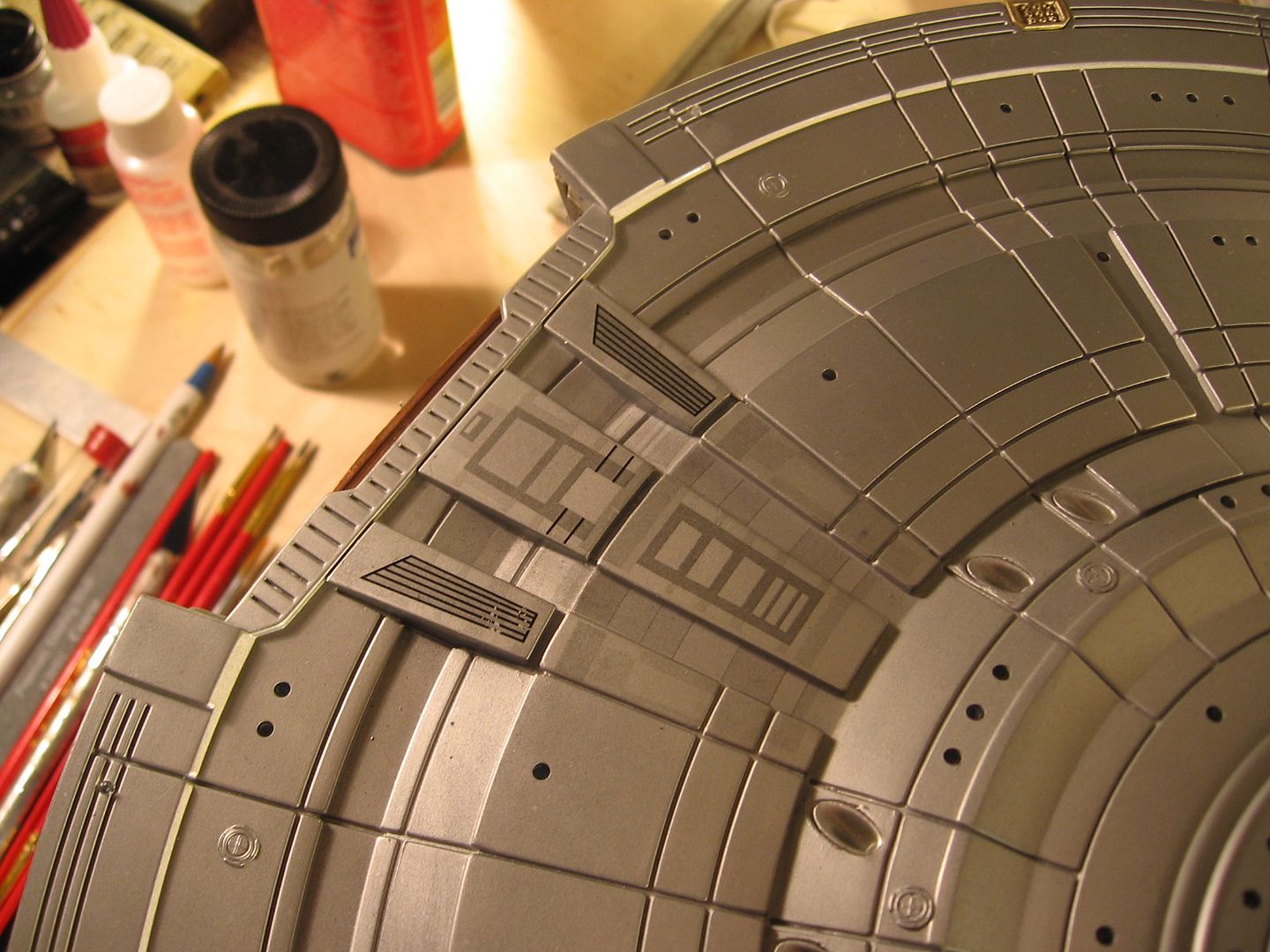

Yes, the decals are intended to be cut up into pretty much each individual section of paneling. Essentially where there is a scribe on the kit, you should probably reduce the decals to that section. At the time (years ago now) I thought it was best to keep general areas of the hull together to make them recognizable for where they went. Some people took that to mean they should be applied as one whole section which ends up having fit issues.

I use Testors Decal Bonder Spray to coat the decals. I found it to be the best coating for decals in general, its easy for me to apply in the paint booth compared to brushing on Microscale Liquid Decal Film which doesn't atomize in an airbrush well.

I have only seen a few of these put together, but I can say I made the decals for me first of all, because I loved most of the show, love the design Doug came up with and the metallic finish instead of the painted finish of the other ships of the line, and thats what kept me pushing through. The NX is the most complicated aztecing I've made simply because I was trying to be as accurate to the CGI as I could. The rest of the sets are about 75% what is visible in reference and 25% fabricated with the "feel" of what you can see in the other 75%.