mung

Sr Member

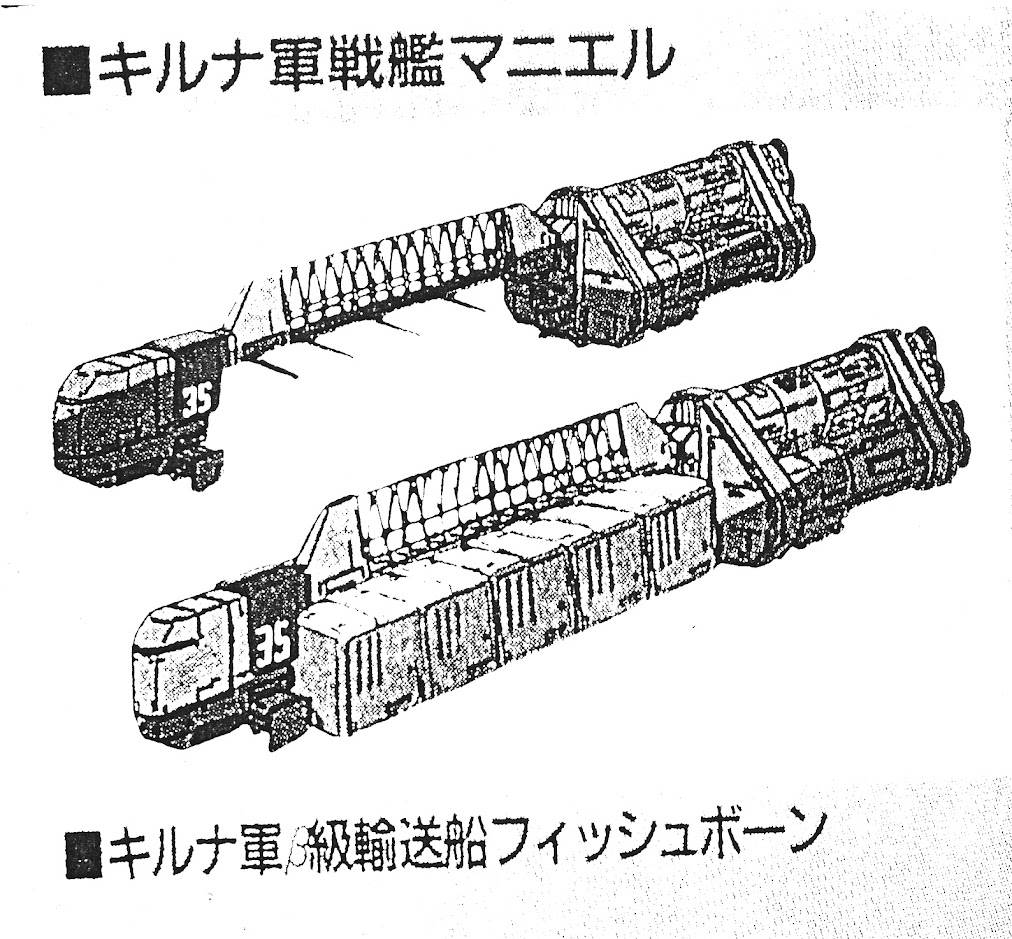

This project was started way back in 2016 and was inspired by a spaceship design I found in a Hobby Japan magazine .

A reader of my blog rcscifi.blogspot.com reminded me that it appeared back in the August 1991 issue which is when I made a blow up photocopy of the picture and filed it away in a display book for a future project. It believe it was designed for an anime featuring the Tomy Z-Knights range of toys.

I really liked the design of the container ship which is like a giant version of an Eagle transporter and wanted to make something like it.

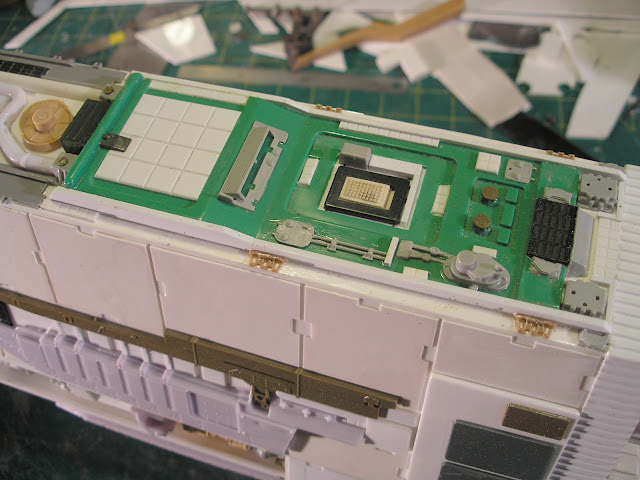

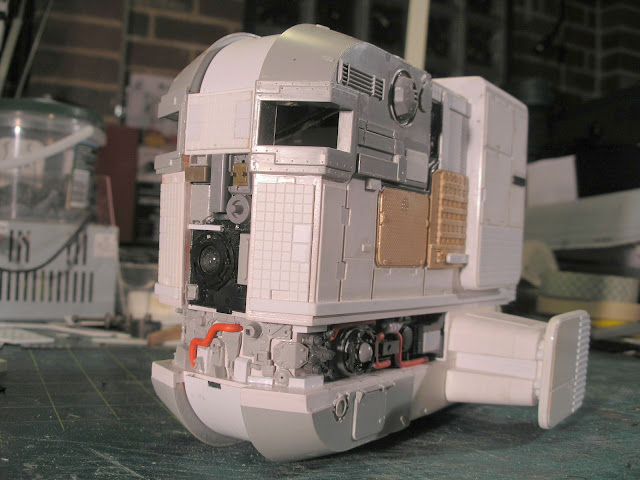

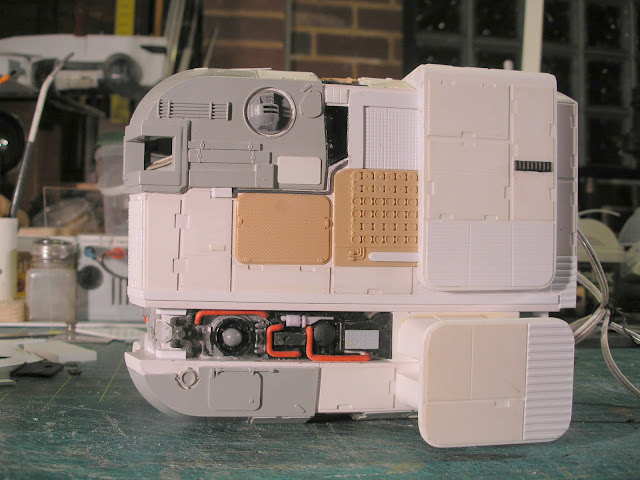

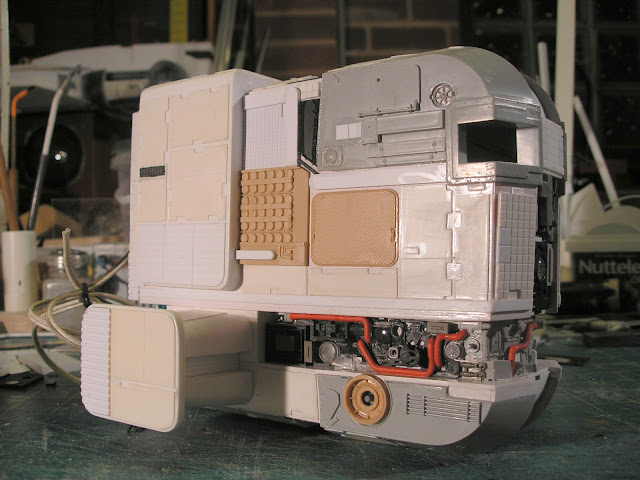

I happened to have a couple of turrets from two Italeri M108 kits which I always thought would make a good spaceship front when put together on their side.

So cutting these up and spacing the bits apart I could make something do the job intending on keeping the 1/35 scale.

Of course the size of the windows makes the scale much smaller than the sketch would suggest but as in my usual way I am making my own ship with that sketch as inspiration, which means I can do what I like and more importantly with what I have on hand.

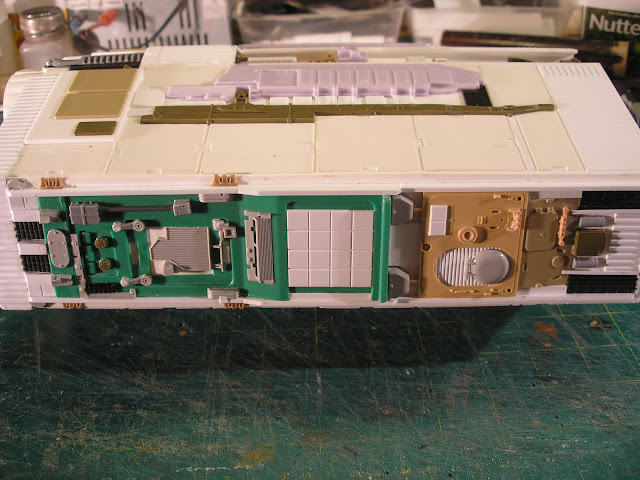

The project was all very experimental at this stage as I had no idea what I was going to use for the truss that connects the front to the engines and hold the containers in place.

I was also unsure exactly what I will use for the containers, though at this point I was considering plastic index card boxes.

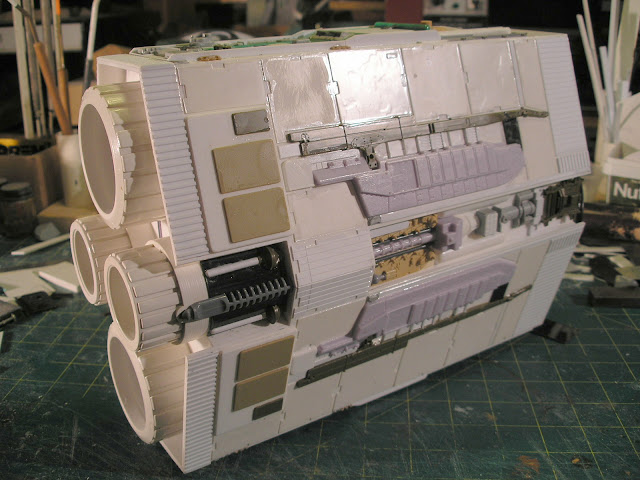

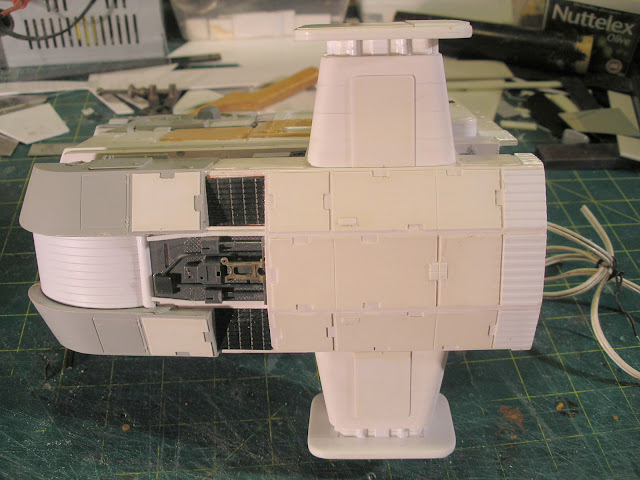

At the same time I started on an engine section which on a recent re-evaluation of the project I decided to rplaxce with a new structure. I found the original engine section just didn't sit well in proportion with the cockpit section so it has been abandoned but may re-appear on some future project. Below you can see that abandoned engine module which was close to completion.

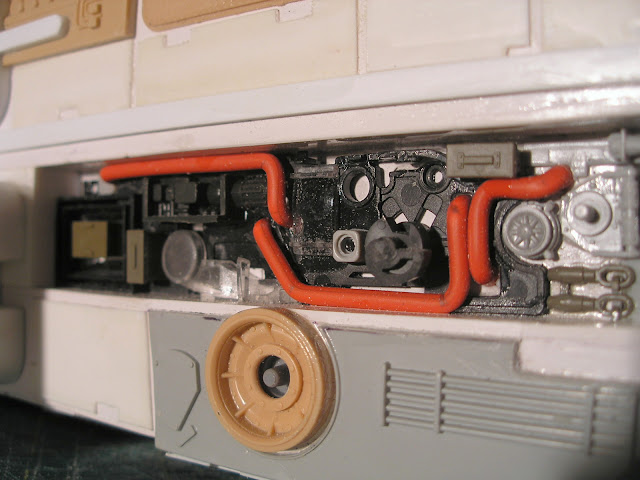

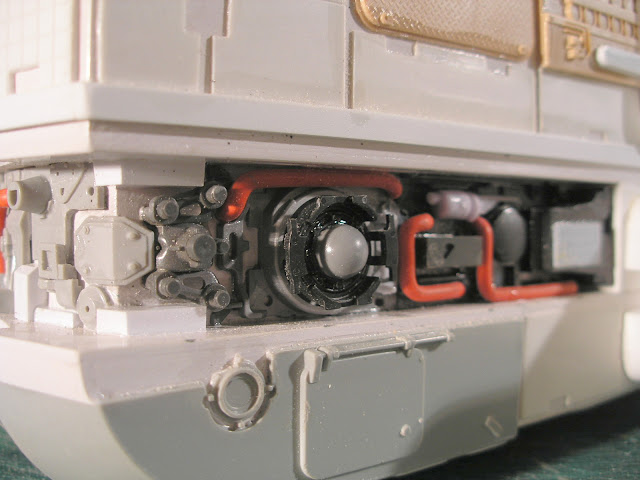

Some 10 months later in 2017 I did a bit more work on the project getting the engine section you can see above to that nearly complete state and also modifying the cockpit/bridge module by cutting it horizontally and making it taller, leaving space for a detail trench. This improved the proportions somewhat making it more like the inspiration design. I also completed the surface detailing phase.

The red pipes are some copper single core electrical wire and there is a number of bits from disposable cameras in the channel.

Around this time I was also was looking around for some container like shapes for the middle section and as it happened I found these Index card holders which were on clearance at my local Officeworks for $3.00 each.

I got 5 and they were pretty much just the right shape for hanging under the eventual truss work.

I guess nobody uses index cards any more with their function taken up by computer software, hence they were getting rid of the remaining stock cheap.

I was still looking around for some way to make the truss.

At the time I figured it will probably be brass silver soldered together and that I woukld have to make a jig to align all the pieces.

I also needed to find a cheap supply of brass tube the appropriate diameter.

Maybe a year later my local ALDI supermarket had one of their most bizarre special buys, 1 metre long 8mm diameter steel tube, four lengths to a packet.

I purchased all they had and all the other closest store had. Finally I had the material I thought would be suitable to make the truss.

Despite this fortuitous find the project lay dormant until now, 2021.

To be continued...

A reader of my blog rcscifi.blogspot.com reminded me that it appeared back in the August 1991 issue which is when I made a blow up photocopy of the picture and filed it away in a display book for a future project. It believe it was designed for an anime featuring the Tomy Z-Knights range of toys.

I really liked the design of the container ship which is like a giant version of an Eagle transporter and wanted to make something like it.

I happened to have a couple of turrets from two Italeri M108 kits which I always thought would make a good spaceship front when put together on their side.

So cutting these up and spacing the bits apart I could make something do the job intending on keeping the 1/35 scale.

Of course the size of the windows makes the scale much smaller than the sketch would suggest but as in my usual way I am making my own ship with that sketch as inspiration, which means I can do what I like and more importantly with what I have on hand.

The project was all very experimental at this stage as I had no idea what I was going to use for the truss that connects the front to the engines and hold the containers in place.

I was also unsure exactly what I will use for the containers, though at this point I was considering plastic index card boxes.

At the same time I started on an engine section which on a recent re-evaluation of the project I decided to rplaxce with a new structure. I found the original engine section just didn't sit well in proportion with the cockpit section so it has been abandoned but may re-appear on some future project. Below you can see that abandoned engine module which was close to completion.

Some 10 months later in 2017 I did a bit more work on the project getting the engine section you can see above to that nearly complete state and also modifying the cockpit/bridge module by cutting it horizontally and making it taller, leaving space for a detail trench. This improved the proportions somewhat making it more like the inspiration design. I also completed the surface detailing phase.

The red pipes are some copper single core electrical wire and there is a number of bits from disposable cameras in the channel.

Around this time I was also was looking around for some container like shapes for the middle section and as it happened I found these Index card holders which were on clearance at my local Officeworks for $3.00 each.

I got 5 and they were pretty much just the right shape for hanging under the eventual truss work.

I guess nobody uses index cards any more with their function taken up by computer software, hence they were getting rid of the remaining stock cheap.

I was still looking around for some way to make the truss.

At the time I figured it will probably be brass silver soldered together and that I woukld have to make a jig to align all the pieces.

I also needed to find a cheap supply of brass tube the appropriate diameter.

Maybe a year later my local ALDI supermarket had one of their most bizarre special buys, 1 metre long 8mm diameter steel tube, four lengths to a packet.

I purchased all they had and all the other closest store had. Finally I had the material I thought would be suitable to make the truss.

Despite this fortuitous find the project lay dormant until now, 2021.

To be continued...