-

Welcome to the Project Runs Forum!

This forum is intended for interest gauging and active runs. Due to the transient nature of this forum, please keep all research and ongoing discussion in one of our main forums so your information is not lost.

Only Premium Members can start a new run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Limited Run Cloud city blaster - Relby K23 - aluminium conversion kits! NOW LIVE!

Agreed! Fantastic work, really Fantastic work

Hello guys,

here is a little help to disassemble the Nemrod as requested.

as I said earlier, I want to keep this Nemrod as is so I can't disassemble it completely, so I'm going to do my best to explain with what I have.

This is my experience with only 2 Nemrods, I didn't have issues with those but I can't garranty that this is the right way to do it or that you will not have something happen on yours that didn't happen on mine.

first of all, work in an appropriate spot to do this. the back of the harpoon can be filled with more or less oil and it can drip on the spot you are using. this is just a friendly advice to avoid trouble with your wife

I know that this happens and still I got several spils today...

the oil can drip from both ends of that blue tube and it might also drip from the aluminium round part at the back of the pistol when disassembled, have paper towels at the ready

alright, here is our Nemrod:

first off, you need to unscrew counterclockwise the yellow cap at the end, this can normaly be done by hand:

here we go:

now, I'm not sure as I never had any issues myself, but I think that air needs to be released before removing the cylinder and I think , once again, that this is done with that screw at the end. turn it counterclockwise half a turn or something until you possibly hear a "psssch", then turn it back clockwise.

alright, now you can remove that back tube! so, for that purpose you need either a 17mm (I think from memory) wrench or an adjustable wrench like I used bellow, the trick is that the jaw has to be thin enough because the flat spots on the tube are pretty narrow.

once you have found the right tool, turn counter clockwise again until the part unscrews.

this end part is actually threaded into the inside tube, so when you start unscrewing, you'll see that the main blue tube becomes loose. you need to unscrew the back part completely, then just pull on the blue tube.

Carefull, this is where the oil will start dripping!

and here we go:

at this point, I can't show more on my Nemrod, but you have two solutions I would say.

- first one is to unscrew, if you can, the two screws on the white handle, you'll then have access to the thin rod that you can see above, it is attached to the trigger and you can remove it and pull it from the back.

- second solution that I never tried but I guess this would work fine, just cut everything from the back there without opening the pistol.

for my kit, you'll need to cut the thin blue tube at the back as close as possible to the back of the gun. I have put a little bit of room on my V8 aluminium part to accomodate for an imperfect cut though.

your harpoon ready to be converted will look like this:

last thing, the barrel tube needs to be clear to be able to put a threaded rod through it. In my case, I had one pistol with something stuck at the front end of the barrel and Kurtiboy had his stuck at the back end of the body of the pistol. I think this part bellow is supposed to be around the middle length of the back tube and should not normally get in the way, but it seems that sometimes it gets stuck somewhere else inside the barrel.

In my case, I took a long thin rod and a hammer and hammered it out without too much trouble.

alright, that's it. i hope this helps.

I would say proceed with caution if you have read somewhere that parts can fly off, but I really haven't experienced anything crazy in my case proceeding like I showed.

don't be discouraged by the long text, it's not a difficult conversion to do.

cheers

here is a little help to disassemble the Nemrod as requested.

as I said earlier, I want to keep this Nemrod as is so I can't disassemble it completely, so I'm going to do my best to explain with what I have.

This is my experience with only 2 Nemrods, I didn't have issues with those but I can't garranty that this is the right way to do it or that you will not have something happen on yours that didn't happen on mine.

first of all, work in an appropriate spot to do this. the back of the harpoon can be filled with more or less oil and it can drip on the spot you are using. this is just a friendly advice to avoid trouble with your wife

I know that this happens and still I got several spils today...

the oil can drip from both ends of that blue tube and it might also drip from the aluminium round part at the back of the pistol when disassembled, have paper towels at the ready

alright, here is our Nemrod:

first off, you need to unscrew counterclockwise the yellow cap at the end, this can normaly be done by hand:

here we go:

now, I'm not sure as I never had any issues myself, but I think that air needs to be released before removing the cylinder and I think , once again, that this is done with that screw at the end. turn it counterclockwise half a turn or something until you possibly hear a "psssch", then turn it back clockwise.

alright, now you can remove that back tube! so, for that purpose you need either a 17mm (I think from memory) wrench or an adjustable wrench like I used bellow, the trick is that the jaw has to be thin enough because the flat spots on the tube are pretty narrow.

once you have found the right tool, turn counter clockwise again until the part unscrews.

this end part is actually threaded into the inside tube, so when you start unscrewing, you'll see that the main blue tube becomes loose. you need to unscrew the back part completely, then just pull on the blue tube.

Carefull, this is where the oil will start dripping!

and here we go:

at this point, I can't show more on my Nemrod, but you have two solutions I would say.

- first one is to unscrew, if you can, the two screws on the white handle, you'll then have access to the thin rod that you can see above, it is attached to the trigger and you can remove it and pull it from the back.

- second solution that I never tried but I guess this would work fine, just cut everything from the back there without opening the pistol.

for my kit, you'll need to cut the thin blue tube at the back as close as possible to the back of the gun. I have put a little bit of room on my V8 aluminium part to accomodate for an imperfect cut though.

your harpoon ready to be converted will look like this:

last thing, the barrel tube needs to be clear to be able to put a threaded rod through it. In my case, I had one pistol with something stuck at the front end of the barrel and Kurtiboy had his stuck at the back end of the body of the pistol. I think this part bellow is supposed to be around the middle length of the back tube and should not normally get in the way, but it seems that sometimes it gets stuck somewhere else inside the barrel.

In my case, I took a long thin rod and a hammer and hammered it out without too much trouble.

alright, that's it. i hope this helps.

I would say proceed with caution if you have read somewhere that parts can fly off, but I really haven't experienced anything crazy in my case proceeding like I showed.

don't be discouraged by the long text, it's not a difficult conversion to do.

cheers

Hello guys,

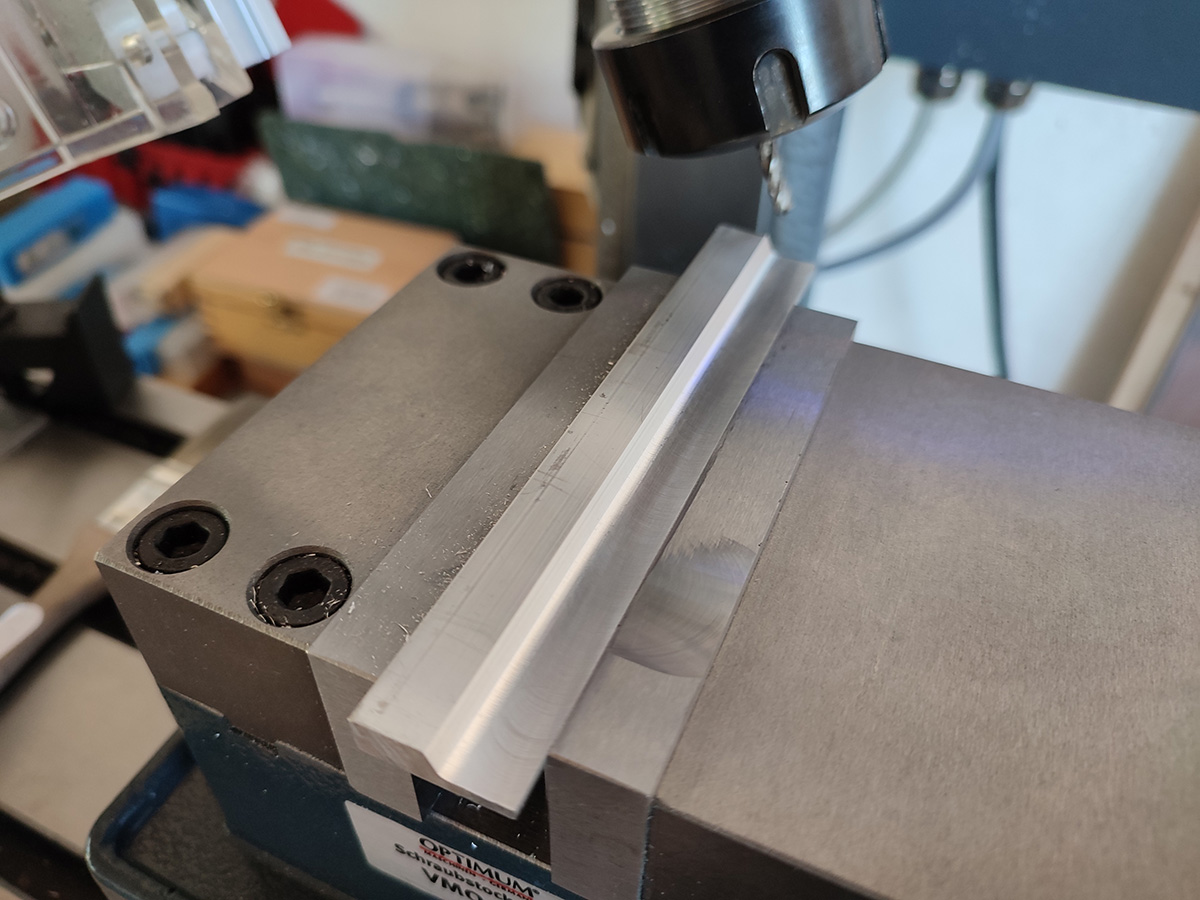

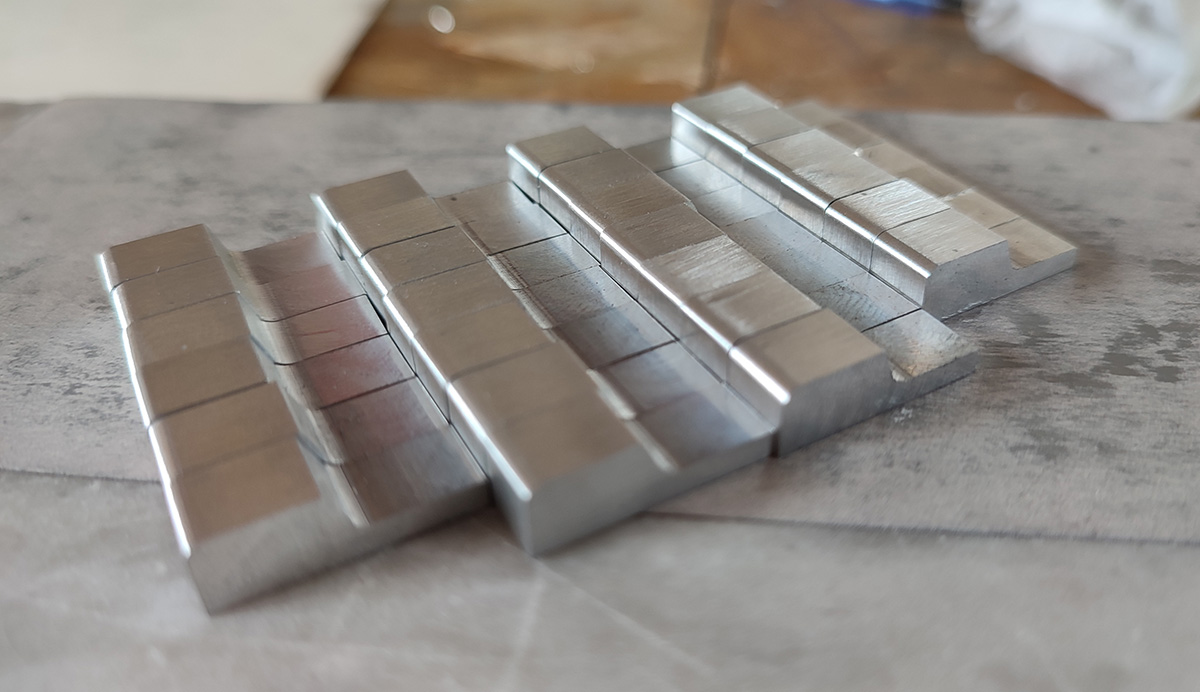

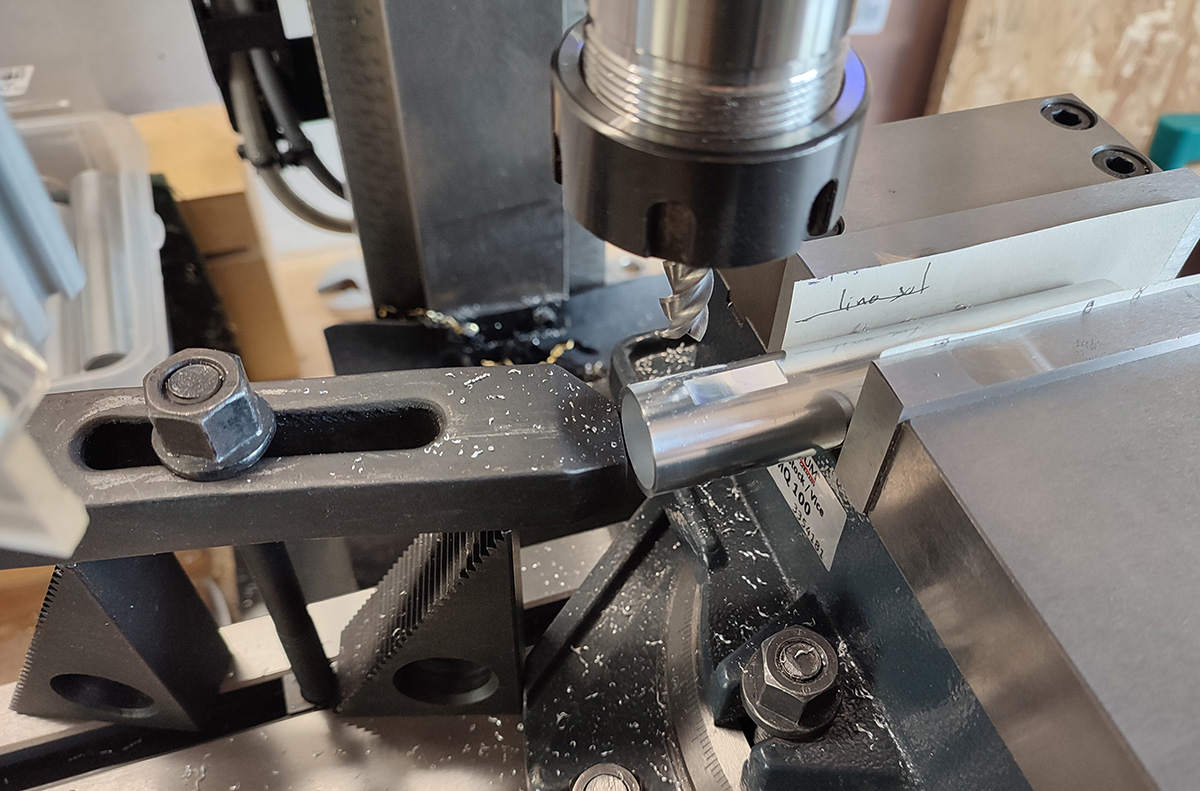

the sights are finished

to do those, I first milled long bars into the shape I wanted, then cut them in small pieces, then milled again the cut surfaces. I had to do 3 bars like that though as I didn't want the bars to be too much longer than my vice to avoid vibrations

here they all are!

I also received my metal order for the rest of the parts, additional death star camera kits as well as the next run (lightsaber)

cheers

the sights are finished

to do those, I first milled long bars into the shape I wanted, then cut them in small pieces, then milled again the cut surfaces. I had to do 3 bars like that though as I didn't want the bars to be too much longer than my vice to avoid vibrations

here they all are!

I also received my metal order for the rest of the parts, additional death star camera kits as well as the next run (lightsaber)

cheers

Nice David, happy that you got the Nemrod and welcome to that runPlease add me to the interest list.

if anyone else is hesitating and is interested by that blaster, I would recommend that you jump on this because the interest is now locked, we got 18 people on board and I decided to go with 26 kits, when they are gone, they are gone, those are very complex parts to make and I will be moving on to other exciting projects after this one

cheers

eethan you're awesome my friend thank you again for doing this!Nice David, happy that you got the Nemrod and welcome to that run

if anyone else is hesitating and is interested by that blaster, I would recommend that you jump on this because the interest is now locked, we got 18 people on board and I decided to go with 26 kits, when they are gone, they are gone, those are very complex parts to make and I will be moving on to other exciting projects after this one

cheers

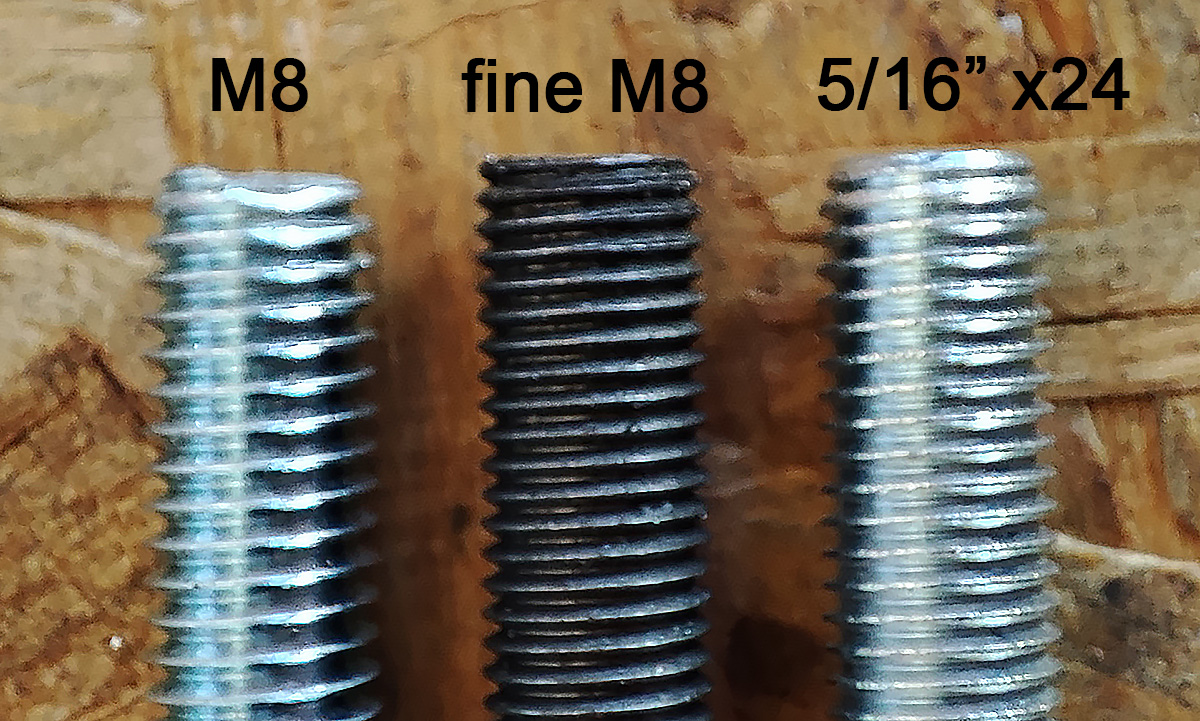

Alright, haven't been updating this run in a while, I have been struggling for almost a month with something very silly:

The threaded rod that we can see in the back.

A threaded rod is not something you normally lose time over, however, I started with a M8 rod and immediately knew that the pitch on it was too big and it didn't feel right to use that. This is where the delays started... it is not easy to find ANYTHING else than standard metric threaded rods in France.

I placed an order for MF8 rods (metric fine, 1mm pitch instead of 1.25mm). When I received it, I was very happy with the pitch, but it was raw steel, almost black... this was not going well at all with the aluminium and I didn't want to offer for sale something that would eventually rust...

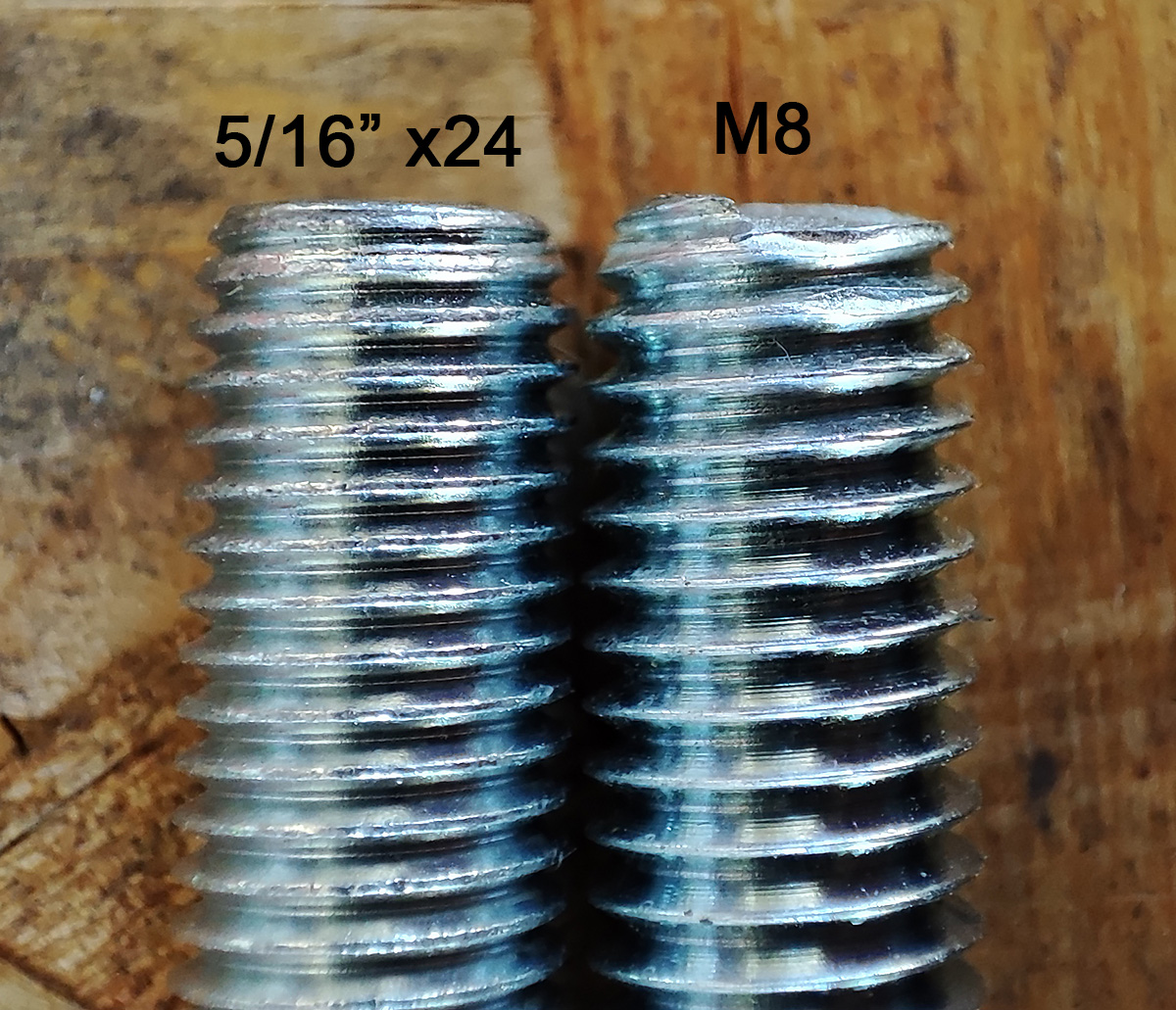

After this, I looked online for days and, in the end, I had two options, 5/16x24TPI stainless steel bars coming from the US for 15€ a bar and possibly some extra customs at arrival, or what I eventually went with, 5/16x24 bolts that I have to cut.

this was already starting to be silly, but, when the 5/16"x24TPI bolts finally arrived, they were partially threaded, despite not being described as so on the website!

ok, the thing was, I had to move forward. I ended up getting the bolts refunded but was able to keep them (small win, allowing me to spend a bit more time on the parts), and my seemingly complex solution at this point is to use a 12mmx2mm wall aluminium tube, cut the head of the bolt, slide it into the tube, drill a hole through all that and put a set screw to secure everything together. On both ends (in the end, I will spend around 5 minutes per rod, so the very low cost of that solution justifies the slight extra work, no worries!)

(in the end, I will spend around 5 minutes per rod, so the very low cost of that solution justifies the slight extra work, no worries!)

Well, for once, my wife was very supportive when I came to her with both my prototypes and showed her desperately how little difference there was, and she said, no, no, we can clearly see the difference!

alright!

more seriously, I really wasn't satisfied with a normal M8, and feel that this is much more screen-accurate and probably what they used, I just feel a bit silly that this whole run was delayed for this long over something so subtle! Anything for a screen-accurate prop!

this is very blurry, but this is to show the MF8 that I received at some point and was too dark to be used:

and here is an actual comparison between M8 and 5/16"x24:

M8 has a 1.25mm pitch, 24TPI equals to 1.05mm pitch, so the difference is very subtle, but still, i feel this is much better

alright, now this run is back on tracks and I actually have made quite a bit of progress today now that this is settled. threaded all the parts, cut and cleaned all the barrels. Still a lot of work to do and I also need to finish the Dome lights first, but this is moving forward

sorry for the long message, I have re-read it 5 times and reworked quite a bit, but I couldn't tell all the story with less words

cheers guys

The threaded rod that we can see in the back.

A threaded rod is not something you normally lose time over, however, I started with a M8 rod and immediately knew that the pitch on it was too big and it didn't feel right to use that. This is where the delays started... it is not easy to find ANYTHING else than standard metric threaded rods in France.

I placed an order for MF8 rods (metric fine, 1mm pitch instead of 1.25mm). When I received it, I was very happy with the pitch, but it was raw steel, almost black... this was not going well at all with the aluminium and I didn't want to offer for sale something that would eventually rust...

After this, I looked online for days and, in the end, I had two options, 5/16x24TPI stainless steel bars coming from the US for 15€ a bar and possibly some extra customs at arrival, or what I eventually went with, 5/16x24 bolts that I have to cut.

this was already starting to be silly, but, when the 5/16"x24TPI bolts finally arrived, they were partially threaded, despite not being described as so on the website!

ok, the thing was, I had to move forward. I ended up getting the bolts refunded but was able to keep them (small win, allowing me to spend a bit more time on the parts), and my seemingly complex solution at this point is to use a 12mmx2mm wall aluminium tube, cut the head of the bolt, slide it into the tube, drill a hole through all that and put a set screw to secure everything together. On both ends

Well, for once, my wife was very supportive when I came to her with both my prototypes and showed her desperately how little difference there was, and she said, no, no, we can clearly see the difference!

alright!

more seriously, I really wasn't satisfied with a normal M8, and feel that this is much more screen-accurate and probably what they used, I just feel a bit silly that this whole run was delayed for this long over something so subtle! Anything for a screen-accurate prop!

this is very blurry, but this is to show the MF8 that I received at some point and was too dark to be used:

and here is an actual comparison between M8 and 5/16"x24:

M8 has a 1.25mm pitch, 24TPI equals to 1.05mm pitch, so the difference is very subtle, but still, i feel this is much better

alright, now this run is back on tracks and I actually have made quite a bit of progress today now that this is settled. threaded all the parts, cut and cleaned all the barrels. Still a lot of work to do and I also need to finish the Dome lights first, but this is moving forward

sorry for the long message, I have re-read it 5 times and reworked quite a bit, but I couldn't tell all the story with less words

cheers guys

I'm still in! Worth the wait

hey there,

status update on this run, sorry, I'm working on other things so everything takes a bit of time!

- back V8 cone part: Done

- back washer: Done

- front sight: Done

- barrel tube: almost done, needs a bit of milling for the sights

- threaded rods: problems solved (see above), need to buy the aluminium tubes, but it won't take too long for that

- muzzles: WIP, see below

- gears: not started

alright, so, I did one more OP on the muzzles now that they are properly threaded in the back. They need 3 more OPs that will be done at the same time on each part now. lathing down all the valeys between the rings, drilling the front with a 8mm bit, then a very shallow 10mm "hole" with a flat end mill. Still quite a bit of work but each muzzle that I will work on from now on will be finished after I work on them

lastly, just re-read my first page, I'll edit it as the run is obviously delayed, the kits should be ready somewhere in September, not August, sorry!

cheers

status update on this run, sorry, I'm working on other things so everything takes a bit of time!

- back V8 cone part: Done

- back washer: Done

- front sight: Done

- barrel tube: almost done, needs a bit of milling for the sights

- threaded rods: problems solved (see above), need to buy the aluminium tubes, but it won't take too long for that

- muzzles: WIP, see below

- gears: not started

alright, so, I did one more OP on the muzzles now that they are properly threaded in the back. They need 3 more OPs that will be done at the same time on each part now. lathing down all the valeys between the rings, drilling the front with a 8mm bit, then a very shallow 10mm "hole" with a flat end mill. Still quite a bit of work but each muzzle that I will work on from now on will be finished after I work on them

lastly, just re-read my first page, I'll edit it as the run is obviously delayed, the kits should be ready somewhere in September, not August, sorry!

cheers

A bit more progress on that run

finished the barrels:

added an intermediate OP on the muzzles in the end, this should save some time removing material with my custom made rounded tool later on, hopefully:

- back V8 cone part: Done

- back washer: Done

- front sight: Done

- barrel tube: Done

- threaded rods: WIP

- muzzles: WIP

- gears: not started

cheers

finished the barrels:

added an intermediate OP on the muzzles in the end, this should save some time removing material with my custom made rounded tool later on, hopefully:

- back V8 cone part: Done

- back washer: Done

- front sight: Done

- barrel tube: Done

- threaded rods: WIP

- muzzles: WIP

- gears: not started

cheers

Similar threads

- Replies

- 61

- Views

- 2,548

Done / Completed

NERF SCOUT TROOPER BLASTER Conversion Kit by Astyanax & AnubisGuard

- Replies

- 14

- Views

- 821