Hi guys!

I've been working on my chappie head project and although I've been taking a lot of pictures, thought it would be good to document the process here and get help and feedback as I progress.

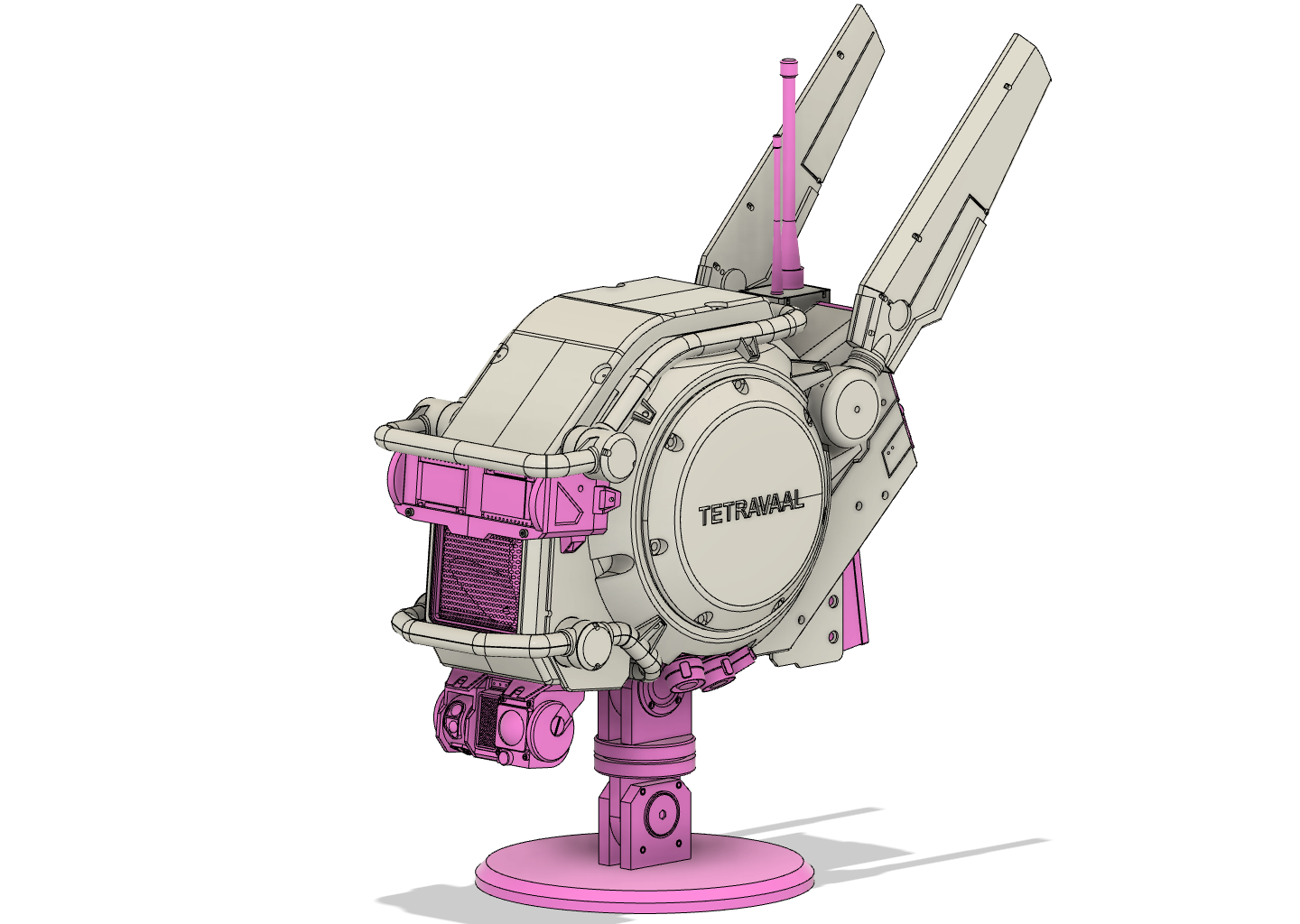

I got the original 3D files from RPF member Razmataz, and created/modified some new parts to be more screen accurate and also made a stand to display the head.

Here is the goal of this project:

Finished Result:

I will share my progress on the next couple posts!

I've been working on my chappie head project and although I've been taking a lot of pictures, thought it would be good to document the process here and get help and feedback as I progress.

I got the original 3D files from RPF member Razmataz, and created/modified some new parts to be more screen accurate and also made a stand to display the head.

Here is the goal of this project:

Finished Result:

I will share my progress on the next couple posts!

Last edited: