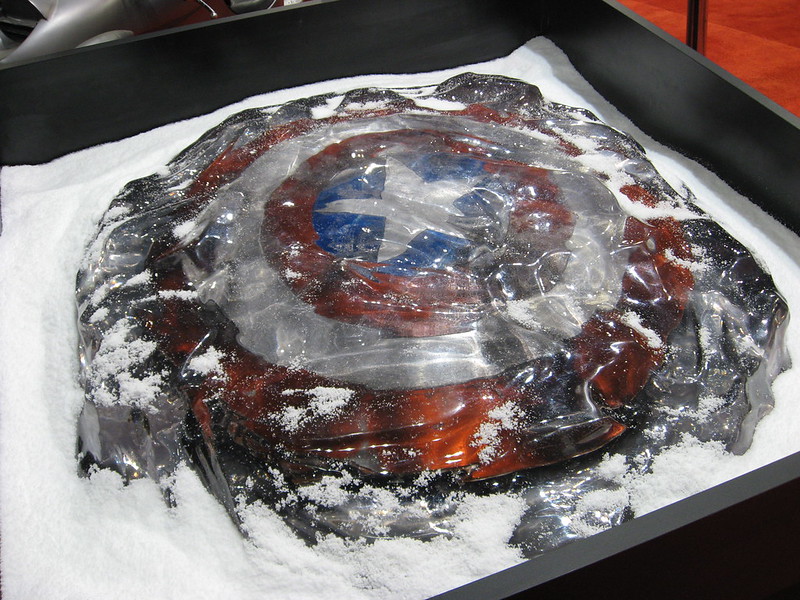

Has anyone thought about doing this? I did a quick search and didn't find anything on it.

The screen-used one sold for $20k at the Profiles Auction last weekend.

Profiles in History

How hard would this be to replicate?

I think this could make a really unique display piece! :cool

brad

The screen-used one sold for $20k at the Profiles Auction last weekend.

Profiles in History

How hard would this be to replicate?

I think this could make a really unique display piece! :cool

brad