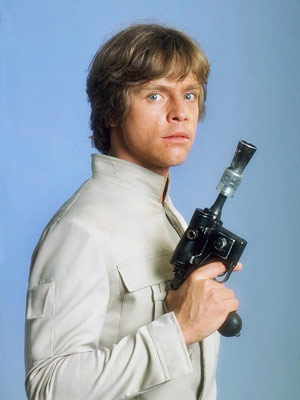

Thanks to some recently released photos (and the fact that I sold my original blaster to a local banker about 2 years ago  ), I've decided to build a Luke Skywalker Bespin blaster.

), I've decided to build a Luke Skywalker Bespin blaster.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build: Luke Skywalker Bespin Blaster

- Thread starter Corellianexports

- Start date

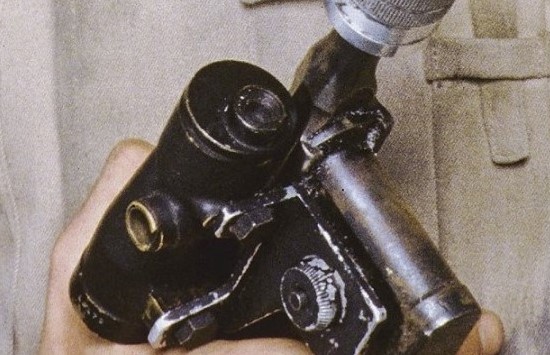

I'm starting with one of Bobadebt's, detailed Denix Mausers.

Instead of using the wood grips it came with, I'm opting for the original plastic grips with real Mauser grip hardware, since this is what was used on the original MGC from the film.

I still need to do some testing, but I'm thinking of using one of my own mounts. I'm not sure at this point if the Bobadebt mount is too short or not. It's only about a 1/16" or 1/8" difference. I'm fairly sure that the spacer has the correct thickness, so I'll probably use it instead of an off the shelf spacer. I like to think that the original prop guys used off the shelf items, but this might have been some thing machined if the knob was machined as well.

So at this point, I've taken apart the Mauser, wiped down all the parts, removed 1/2" off the end of the barrel and removed most of the pin at the back of the bolt. I used a belt sanded to remove a little material from the rear of the trigger stay; just enough to allow the hammer to hit the back of the bolt.

Then I sanded down the three main, metal parts and let them sit in soapy water over night.

I cleaned the parts with de-natured alcohol and then filled in the holes/Denix lettering with JBWeld. I've also glued down the site with JBWeld.

Instead of using the wood grips it came with, I'm opting for the original plastic grips with real Mauser grip hardware, since this is what was used on the original MGC from the film.

I still need to do some testing, but I'm thinking of using one of my own mounts. I'm not sure at this point if the Bobadebt mount is too short or not. It's only about a 1/16" or 1/8" difference. I'm fairly sure that the spacer has the correct thickness, so I'll probably use it instead of an off the shelf spacer. I like to think that the original prop guys used off the shelf items, but this might have been some thing machined if the knob was machined as well.

So at this point, I've taken apart the Mauser, wiped down all the parts, removed 1/2" off the end of the barrel and removed most of the pin at the back of the bolt. I used a belt sanded to remove a little material from the rear of the trigger stay; just enough to allow the hammer to hit the back of the bolt.

Then I sanded down the three main, metal parts and let them sit in soapy water over night.

I cleaned the parts with de-natured alcohol and then filled in the holes/Denix lettering with JBWeld. I've also glued down the site with JBWeld.

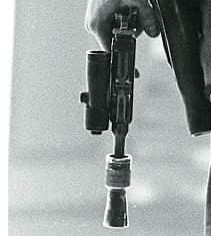

Great eye for detail, teecrooz.You can even make a post Vader fight blaster! It’s a resin stunt in a different configuration than the Bespin hero. Looks like the scope broke off after he dropped down from the fight.

I’m looking forward to seeing the progress on this build, Corellianexports. The Han ESB Hoth blaster gets a lot of attention, so it’s nice to see a Luke ESB Bespin blaster.

The prop in the photo above uses a MGC. I've heard that it is possible to fire blanks using a MGC so it's possible that was what was used for that quick scene with Vader. And if you watch one of the behind the scenes from the Blu-ray, you'll notice that the blaster prop used to "fly" into Vader's hand was actually made out of rubber. I'd like to see some close up photos of that version.nice, I love the Luke's Bespin blaster.

but wait, what? Luke's Bespin was based on an MGC? I thought they used live fire versions to shot at Vader and that they used both Han's and Luke's one after the other for that shot. What am I missing there?

It looks like the mount came off with the scope. I remember seeing an original stunt version in Sansweet's collection, but the mount and scope were intact. Very nice shot. Thanks.You can even make a post Vader fight blaster! It’s a resin stunt in a different configuration than the Bespin hero. Looks like the scope broke off after he dropped down from the fight.

Moving on with the build, I've sanded down the JB Weld areas:

One of the items I can't duplicate on a Denix are the etch marks around the magazine pin. Really wonderful work.

Unfortunately, the ESB blaster didn't have a flat magazine pin, like the one found on the Hero blaster, so typically remove these:

One of the items I can't duplicate on a Denix are the etch marks around the magazine pin. Really wonderful work.

Unfortunately, the ESB blaster didn't have a flat magazine pin, like the one found on the Hero blaster, so typically remove these:

I used a drill to remove the magazine pin and then replace it with the end of a rivet.

Here's a side by side with a MGC Mauser:

Another tid bit I discovered was the lanyard ring hole. The Denix is too large, so I used a belt sander to make it smaller.

Here's another side by side with a MGC:

And now on to the magazine plate. I've marked the area. This time, I'm going to try to machine around it.

Here's a side by side with a MGC Mauser:

Another tid bit I discovered was the lanyard ring hole. The Denix is too large, so I used a belt sander to make it smaller.

Here's another side by side with a MGC:

And now on to the magazine plate. I've marked the area. This time, I'm going to try to machine around it.

The upper received is done. Now on the small details on the sides of the sight hinge:

I start by using a sharp punch to make an indentation at the center of the brad:

Drill a very small hole (3/32") using a jewelers bit on both ends of the brad. Once completed, punch out the brad and then use a small counter sink on the sight hinge holes:

Then take the brad and machine both ends slightly, so they are the same diameter as the rolled pin in the MGC:

Because the holes and the brad from the Denix are larger than the ones on the MGC, it's easier to simply machine the brad. It is possible to fill in the holes with JBWeld and drill a smaller hole, but trying to tap in a rolled pin may not work, so this seems to be the best option.

The brad goes back and its done:

Up next, finishing off the upper receiver and moving on to the scope.

I start by using a sharp punch to make an indentation at the center of the brad:

Drill a very small hole (3/32") using a jewelers bit on both ends of the brad. Once completed, punch out the brad and then use a small counter sink on the sight hinge holes:

Then take the brad and machine both ends slightly, so they are the same diameter as the rolled pin in the MGC:

Because the holes and the brad from the Denix are larger than the ones on the MGC, it's easier to simply machine the brad. It is possible to fill in the holes with JBWeld and drill a smaller hole, but trying to tap in a rolled pin may not work, so this seems to be the best option.

The brad goes back and its done:

Up next, finishing off the upper receiver and moving on to the scope.

One small, modification to the upper receiver is the sight slide which should have a waffle pattern on it (MGC only) instead of just a bunch of vertical lines. The MGC manufacture probably used a special stamp made of up this waffle pattern.

To replicate the pattern, I simply use an artists saw from X-acto and re-cut the original lines and then add some horizontal lines with the same spacing:

The last modification is to add the small squares just in front of the sight hinge. I've marked them off with a sharpie:

To machine these, I use a tooth pick to keep the bolt in place, pulling it as far back as possible. The two indentations are right at the edge between the front of the hammer (once pulled back) and the bullet chamber. Once in the clamp, the pressure actually helps keep the hammer in place. The two indentations are fairly deep, but it is possible to do. The indentations are about 1/2" deep.

Once machined, I use a couple different square files to add the corners:

And the upper receiver is done! Up next, finishing off the scope.

To replicate the pattern, I simply use an artists saw from X-acto and re-cut the original lines and then add some horizontal lines with the same spacing:

The last modification is to add the small squares just in front of the sight hinge. I've marked them off with a sharpie:

To machine these, I use a tooth pick to keep the bolt in place, pulling it as far back as possible. The two indentations are right at the edge between the front of the hammer (once pulled back) and the bullet chamber. Once in the clamp, the pressure actually helps keep the hammer in place. The two indentations are fairly deep, but it is possible to do. The indentations are about 1/2" deep.

Once machined, I use a couple different square files to add the corners:

And the upper receiver is done! Up next, finishing off the scope.

For the scope, I'm using one of the - now rare and out of production - Thinkjedi scopes, which has been hollowed out.

I've cleaned it inside and out with denatured alcohol. I decided to add one of FieldMarshall's clear resin light port bulbs:

The plastic light bulb or port is too large for the scope, so I just machine it down a bit in my lathe. The trick with plastic is just to use a good amount of water to keep the part from melting:

I use a 1/4" drill bit to modify the brass light port to get a good fit.

And viola, it fits like a charm:

Next step is to prep the rest of the parts before applying the aluminum black. I use a cotton swab to apply the liquid on the inside of the scope. It's not needed on the inside of the light port:

After letting the scope dry over night, I hit it with a couple of coats of flat black and then satin black. I discovered recently that ACE hardware makes a very good "Preminum" satin black which isn't as glossy as some of the other satin black paints out there. It's much closer to the paint used on the original M19 scopes. Once dry, I use the white crayon method to add white to the lettering:

I noticed that the front lens was loose inside behind the front ring, so I used a little contact cement to keep it place. I let it set overnight before installing it back into the scope.

Up next, installing the mount, knob, flash hider and yet still more machining....ugh.

I've cleaned it inside and out with denatured alcohol. I decided to add one of FieldMarshall's clear resin light port bulbs:

The plastic light bulb or port is too large for the scope, so I just machine it down a bit in my lathe. The trick with plastic is just to use a good amount of water to keep the part from melting:

I use a 1/4" drill bit to modify the brass light port to get a good fit.

And viola, it fits like a charm:

Next step is to prep the rest of the parts before applying the aluminum black. I use a cotton swab to apply the liquid on the inside of the scope. It's not needed on the inside of the light port:

After letting the scope dry over night, I hit it with a couple of coats of flat black and then satin black. I discovered recently that ACE hardware makes a very good "Preminum" satin black which isn't as glossy as some of the other satin black paints out there. It's much closer to the paint used on the original M19 scopes. Once dry, I use the white crayon method to add white to the lettering:

I noticed that the front lens was loose inside behind the front ring, so I used a little contact cement to keep it place. I let it set overnight before installing it back into the scope.

Up next, installing the mount, knob, flash hider and yet still more machining....ugh.

So one thing I noticed, looking at a recent photo of the Luke Bespin Blaster is that the back of the scope or scope "foot" is that it doesn't line up with the edge of the mount. It's about 1/16" away from it.

So I widened the upper holes in the mount by 1/16" to get the scope placed back 1/16" from where it was.

Here's an example photo of the placement before the change:

And after:

It's a very subtle difference and since the holes were simply widened, the scope can always be moved forward if necessary.

Another subtle difference I noticed was that the aluminum spacer was too wide in comparison with a standard, vinyl spacer when I checked the set up against the reference photos, so I machined about 1/16" off the aluminum spacer. I was a little surprised because in one or two photos the mount does appear to be further away from the Mauser, but this is more than likely a play on shadows and distances.

And so on to attaching the mount...

I wasn't happy with the placement of the mount, so I filled the pre-drilled hole with JB Weld and moved the placement a little higher and to the left:

Since I'm using a very heavy, brass scope it's necessary to add one more bolt to keep the mount from rotating. My first thought was to use a brad or pin of some sort, but neither turned out to be stable enough.

With the mount in place with the knob, I marked the placement of the knob with a sharpie to give me an idea as to where the small bolt should go underneath the knob:

Placing the small bolt head against the mount for a "hidden" placement:

Marking the mount with a punch:

The mount was drilled and then the Mauser was marked and drilled, then tapped:

Counter sinking the mount for the second bolt:

The mount attaches nice and tight:

Up next, adding the left side details and prepping the grips. We're just about done.

So I widened the upper holes in the mount by 1/16" to get the scope placed back 1/16" from where it was.

Here's an example photo of the placement before the change:

And after:

It's a very subtle difference and since the holes were simply widened, the scope can always be moved forward if necessary.

Another subtle difference I noticed was that the aluminum spacer was too wide in comparison with a standard, vinyl spacer when I checked the set up against the reference photos, so I machined about 1/16" off the aluminum spacer. I was a little surprised because in one or two photos the mount does appear to be further away from the Mauser, but this is more than likely a play on shadows and distances.

And so on to attaching the mount...

I wasn't happy with the placement of the mount, so I filled the pre-drilled hole with JB Weld and moved the placement a little higher and to the left:

Since I'm using a very heavy, brass scope it's necessary to add one more bolt to keep the mount from rotating. My first thought was to use a brad or pin of some sort, but neither turned out to be stable enough.

With the mount in place with the knob, I marked the placement of the knob with a sharpie to give me an idea as to where the small bolt should go underneath the knob:

Placing the small bolt head against the mount for a "hidden" placement:

Marking the mount with a punch:

The mount was drilled and then the Mauser was marked and drilled, then tapped:

Counter sinking the mount for the second bolt:

The mount attaches nice and tight:

Up next, adding the left side details and prepping the grips. We're just about done.

Last edited:

On to attaching the left side details. As with all resin parts, these need to be washed in soap and water. I placed them using a reference of the left side of the stunt blaster since this is the best close up of the left side and both "c" clips can be seen:

The word "coil" faces the trigger area with "motor" facing the safety switch. With all the parts lined up, take each one off, one at time and lightly sand the back, then a little on the Mauser. Use a tiny drop of super glue and spread it on the piece with a tooth pick, then re-attach the parts.

The "c" clips are basically centered on the Mauser.

I leave it to dry over night. While waiting, we can move on to the grips.

I'm using some actual grip hardware (stainless steel) which can't be blackened with aluminum black so I simply painted it flat and the satin black:

To get the hardware to fit, I use a 7/32" drill bit to expand the holes in the Denix grips. I place a thick spacer (Han Hoth blaster) under each grip to avoid damaging the grips:

To keep the little parts centered, I use a different bolt to hold them in place and then tap with a hammer. I also use a wide punch to slowly tap them in place.

I use the MGC as a reference to make sure the parts go on the correct grips. It's easy at this point to get the parts mix matched. We want to make sure we don't put ROTJ blaster grips on an ESB blaster.

Up next, detailing the grip hardware and installing the flash hider.

The word "coil" faces the trigger area with "motor" facing the safety switch. With all the parts lined up, take each one off, one at time and lightly sand the back, then a little on the Mauser. Use a tiny drop of super glue and spread it on the piece with a tooth pick, then re-attach the parts.

The "c" clips are basically centered on the Mauser.

I leave it to dry over night. While waiting, we can move on to the grips.

I'm using some actual grip hardware (stainless steel) which can't be blackened with aluminum black so I simply painted it flat and the satin black:

To get the hardware to fit, I use a 7/32" drill bit to expand the holes in the Denix grips. I place a thick spacer (Han Hoth blaster) under each grip to avoid damaging the grips:

To keep the little parts centered, I use a different bolt to hold them in place and then tap with a hammer. I also use a wide punch to slowly tap them in place.

I use the MGC as a reference to make sure the parts go on the correct grips. It's easy at this point to get the parts mix matched. We want to make sure we don't put ROTJ blaster grips on an ESB blaster.

Up next, detailing the grip hardware and installing the flash hider.

Like every thing else, it's always a good idea to "test fit" everything before applying those final coats of paint.

In this case, the grip bolt was too long, so I had to chop it down a bit. One difference I noticed between my bolt and the MGC bolt is that it is rounded off and mine is flat:

So using a belt sander, I rounded off the end of my bolt and bingo:

It's a similar look to the magazine pin. For whatever reason, those MGC engineers seemed to like rounded off bolts.

However, the other side of the bolt needed to be completely flat and the original Mauser grip bolt had a rounded edge, so I machined it down a bit:

Flash Hider installation:

As you can see, the flash hider hole isn't lining up with the edge of the Mauser barrel:

To fix that, I turn the flash hider several times like a bolt, making an indentation on the barrel.

If you look carefully, you'll see a bright, line a little over an inch near the end of the barrel.

Using a sanding belt, I remove as much of the black paint as possible within a 2" area around the line:

If the flash hider doesn't fit properly, I repeat the process until it does:

So at this point, all the machining, test fitting, etc. is complete. Time to take the Mauser apart and clean it completely; inside and out with denatured alcohol using cotton swabs and a lint free cloth. Same deal with all the parts that need to be painted.

Up next, painting and final assembly....

In this case, the grip bolt was too long, so I had to chop it down a bit. One difference I noticed between my bolt and the MGC bolt is that it is rounded off and mine is flat:

So using a belt sander, I rounded off the end of my bolt and bingo:

It's a similar look to the magazine pin. For whatever reason, those MGC engineers seemed to like rounded off bolts.

However, the other side of the bolt needed to be completely flat and the original Mauser grip bolt had a rounded edge, so I machined it down a bit:

Flash Hider installation:

As you can see, the flash hider hole isn't lining up with the edge of the Mauser barrel:

To fix that, I turn the flash hider several times like a bolt, making an indentation on the barrel.

If you look carefully, you'll see a bright, line a little over an inch near the end of the barrel.

Using a sanding belt, I remove as much of the black paint as possible within a 2" area around the line:

If the flash hider doesn't fit properly, I repeat the process until it does:

So at this point, all the machining, test fitting, etc. is complete. Time to take the Mauser apart and clean it completely; inside and out with denatured alcohol using cotton swabs and a lint free cloth. Same deal with all the parts that need to be painted.

Up next, painting and final assembly....

Painting

I like to hang every thing from hangers:

To make the weathering easier, I attach a small piece of painters tape to the left side of the mount edge, near the hole for the scope "foot".

All the parts get hit with two coats of flat black primer and satin black. Before I start, I pull back the hammer on the Mauser and hang it from the grip area for the first coat of paint. Once dry, the hammer is gently unlocked and put back, then the Mauser is hung by the magazine/mount hole. The other parts are rotated 180 degrees. The mount is hung by different holes to make sure all areas get painted.

Once all the parts have dried, the grips are attached along with the mount. I use a little super glue to keep the small bolt in place:

Some JB weld is used to install the knob:

I remove the tape from the mount and sand a small area on the barrel with 220 grit sand paper. I then take the same paper, roll it up and spin it inside the muzzle to make sure that surface area is ready for the JB Weld that will keep it in place. I think one of the mistakes that most people make is not sanding down both areas where glue is applied:

The flash hider is installed and the scope is ready to be attached. A very tiny amount of contact cement is used to keep the light socket bulb in place. I used a cotton swab to help press the bulb into place:

I didn't bother to paint the steel bolts, so the scope is simply attached:

Just for grins, I thought it would be fun to take a photo of an "as built" version of the Luke Bespin blaster. Is this what it looked like when Luke acquired it, just before battling the empire on Hoth or was it just a mix match of parts taken from used blasters? We can only speculate.

Next up...…... weathering.

I like to hang every thing from hangers:

To make the weathering easier, I attach a small piece of painters tape to the left side of the mount edge, near the hole for the scope "foot".

All the parts get hit with two coats of flat black primer and satin black. Before I start, I pull back the hammer on the Mauser and hang it from the grip area for the first coat of paint. Once dry, the hammer is gently unlocked and put back, then the Mauser is hung by the magazine/mount hole. The other parts are rotated 180 degrees. The mount is hung by different holes to make sure all areas get painted.

Once all the parts have dried, the grips are attached along with the mount. I use a little super glue to keep the small bolt in place:

Some JB weld is used to install the knob:

I remove the tape from the mount and sand a small area on the barrel with 220 grit sand paper. I then take the same paper, roll it up and spin it inside the muzzle to make sure that surface area is ready for the JB Weld that will keep it in place. I think one of the mistakes that most people make is not sanding down both areas where glue is applied:

The flash hider is installed and the scope is ready to be attached. A very tiny amount of contact cement is used to keep the light socket bulb in place. I used a cotton swab to help press the bulb into place:

I didn't bother to paint the steel bolts, so the scope is simply attached:

Just for grins, I thought it would be fun to take a photo of an "as built" version of the Luke Bespin blaster. Is this what it looked like when Luke acquired it, just before battling the empire on Hoth or was it just a mix match of parts taken from used blasters? We can only speculate.

Next up...…... weathering.

Weathering

I start out with the mount, using one large and one small, standard X-acto knife to scratch off the paint:

Occasionally, I'll use some 220 grit sand paper on the edges of the Mauser and along the side of the scope:

This photo turned out handy for weathering the top of the blaster:

Up next, weathering the Flash Hider.

I start out with the mount, using one large and one small, standard X-acto knife to scratch off the paint:

Occasionally, I'll use some 220 grit sand paper on the edges of the Mauser and along the side of the scope:

This photo turned out handy for weathering the top of the blaster:

Up next, weathering the Flash Hider.

Last edited:

Flash Hider Weathering

For the flash hider, I used Aluminum Black and plenty of cotton swab sticks:

The odor from the liquid is extremely strong, so I used a full filter mask while applying the Aluminum black:

I used every view of the muzzle I had at my disposal going through about 5 applications:

There were a couple of areas that didn't need blackening, so I used 400 grit sand paper to remove tiny sections:

The drawback to using the sandpaper is that it does leave some scratches, so to lessen that, I used 1200 grit to lighten these up a bit. I let the muzzle dry for several hours before using a lint free cloth to polish it and clean the entire blaster in case there is any residue left over from the sanding:

For the flash hider, I used Aluminum Black and plenty of cotton swab sticks:

The odor from the liquid is extremely strong, so I used a full filter mask while applying the Aluminum black:

I used every view of the muzzle I had at my disposal going through about 5 applications:

There were a couple of areas that didn't need blackening, so I used 400 grit sand paper to remove tiny sections:

The drawback to using the sandpaper is that it does leave some scratches, so to lessen that, I used 1200 grit to lighten these up a bit. I let the muzzle dry for several hours before using a lint free cloth to polish it and clean the entire blaster in case there is any residue left over from the sanding:

Similar threads

- Replies

- 6

- Views

- 609

- Replies

- 2

- Views

- 553

- Replies

- 2

- Views

- 650