You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blank firing Blade Runner Blaster - Advice needed.

- Thread starter H0llyw00d

- Start date

that is one of the the best picture representation's of a replica prop builder.

Noeland

Master Member

I wanted to show you how hartford mounted the second trigger on their blasters, which was not based on a charter arms revolver. It was based on a smith and wesson revolver, which is not too far removed from the shape of the black firing gun you are using.

Attachments

H0llyw00d

Sr Member

I wanted to show you how hartford mounted the second trigger on their blasters, which was not based on a charter arms revolver. It was based on a smith and wesson revolver, which is not too far removed from the shape of the black firing gun you are using.

Awesome! Thanks Noeland! You mentioned that before but I couldn't find the pics. That's pretty much what I'm thinking I'll have to do.

H0llyw00d

Sr Member

Hells to the YEAH!!! Now I know what they mean by your ship coming in. Got the replacement trigger guard from Michele in Italy and the custom Sidkit barrel from Teddz in Greece. Three of the hardest hit countries (I'm in the US) by the Coronavirus and we're still plugging along being AWESEOME!!!:

I was glad I held off on altering the frame to accommodate the old trigger guard because the new one is a fraction of a millimetre longer.:

Still have to grind a solution though:

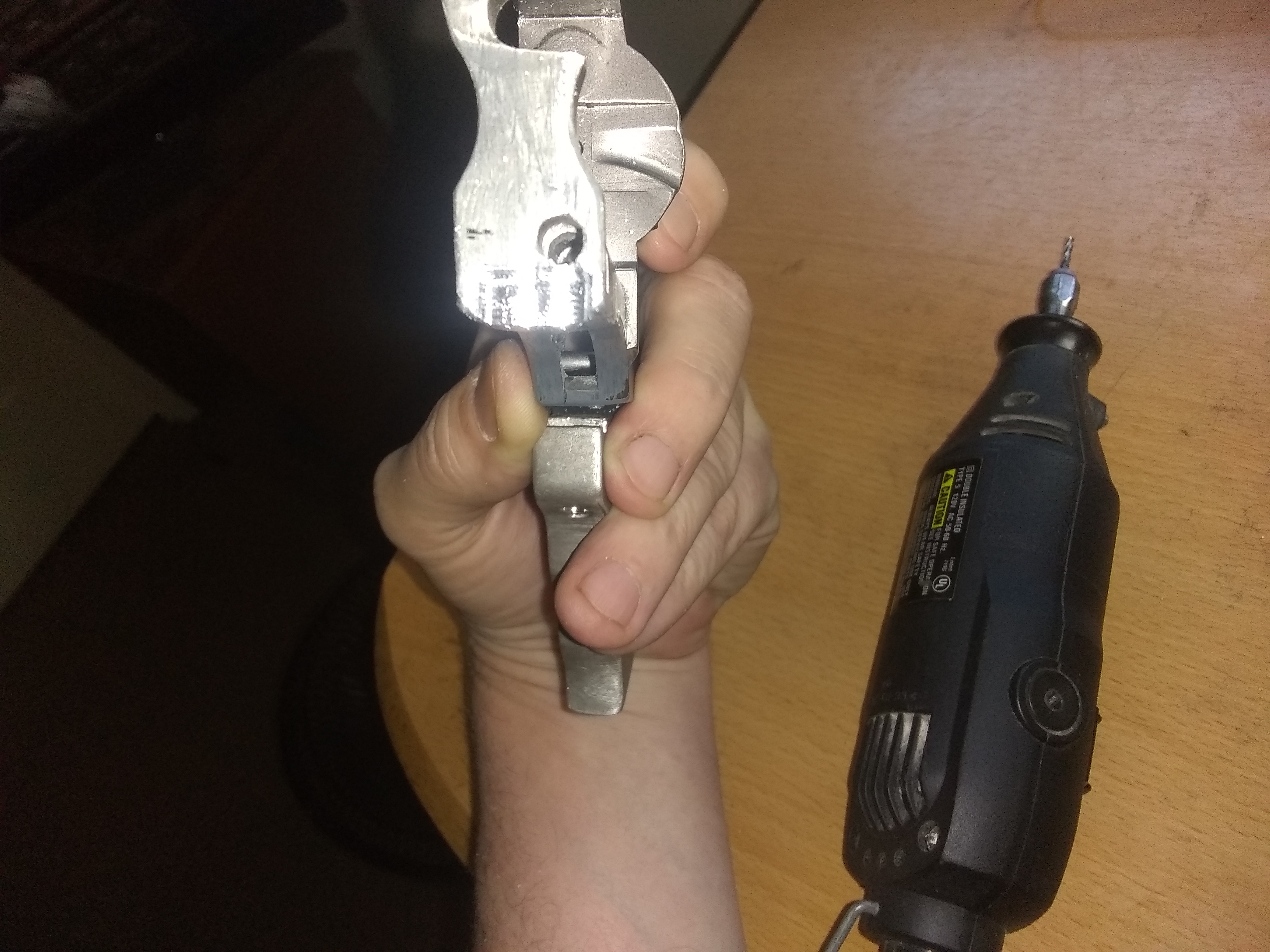

The trick to dremel whittling is to have a crap ton of bits:

Start with the stone wheel:

Then switch over to little metal shaping bits:

And, of course, it's all about not taking off too much. And since the new trigger guard isn't drilled out to fit the kit I can start with a fresh hole for the M3 screw to hold it in :

:

The barrel from Teddz is a beautiful piece:

And it is drilled through as promised:

The blank pistol comes with this flare launching adapter that screws in to the barrel:

If the barrel needs additional support beyond the friction fit/set screw combo I'm hoping for I can cut it down for an another point of contact:

I needed to grind down the pistol barrel base to fit the new barrel:

But slow and steady wins the race Now THAT is some progress:

Now THAT is some progress:

Now on to what I'm dreading... drilling and tapping without a press... ugh. And I hope I don't have to grind down the frame or cut the barrel to reduce the length.:

I was glad I held off on altering the frame to accommodate the old trigger guard because the new one is a fraction of a millimetre longer.:

Still have to grind a solution though:

The trick to dremel whittling is to have a crap ton of bits:

Start with the stone wheel:

Then switch over to little metal shaping bits:

And, of course, it's all about not taking off too much. And since the new trigger guard isn't drilled out to fit the kit I can start with a fresh hole for the M3 screw to hold it in

The barrel from Teddz is a beautiful piece:

And it is drilled through as promised:

The blank pistol comes with this flare launching adapter that screws in to the barrel:

If the barrel needs additional support beyond the friction fit/set screw combo I'm hoping for I can cut it down for an another point of contact:

I needed to grind down the pistol barrel base to fit the new barrel:

But slow and steady wins the race

Now on to what I'm dreading... drilling and tapping without a press... ugh. And I hope I don't have to grind down the frame or cut the barrel to reduce the length.:

Last edited:

I will be holding my breath for your drilling and tapping bud... finger's crossed

H0llyw00d

Sr Member

Got up today and realized that after all this time I'm married to this donor pistol and do not have the cajones to start drilling holes without a drill press. It seems Harbor freight has a base model for $70 so SOLD! I guess I get to learn something new... yay.

I still needed to cut down the swing out arm and ejector rod and cut notches in the side of the frame for the Steyr barrel to fit into:

It's time for choosing this donor for it's skinny swing out arm to produce dividends:

Easy peasy:

Now for the ejector rod. Blank ammo has a very short casing so you don't need much rod to get the job done:

Now for the notches you are going to want one of these bits. Don't know exactly what it is but it takes material off like it's a particularly hard chunk of Parmesan:

And there you have it:

Looking good:

Looking real good:

Oh YEAH, Baby!!!:

Tomorrow I'm off to Harbor Freight. We got some holes to drill and tap.

I still needed to cut down the swing out arm and ejector rod and cut notches in the side of the frame for the Steyr barrel to fit into:

It's time for choosing this donor for it's skinny swing out arm to produce dividends:

Easy peasy:

Now for the ejector rod. Blank ammo has a very short casing so you don't need much rod to get the job done:

Now for the notches you are going to want one of these bits. Don't know exactly what it is but it takes material off like it's a particularly hard chunk of Parmesan:

And there you have it:

Looking good:

Looking real good:

Oh YEAH, Baby!!!:

Tomorrow I'm off to Harbor Freight. We got some holes to drill and tap.

good luck with the drill press bud. more pictures ASAP!!

H0llyw00d

Sr Member

Thanks, Guys. Y'all are so awesome.  Thank you for the kind words.

Thank you for the kind words.

I did indeed get the $70 HF Drill Press. Pretty freakin' awesome for an entry model:

Before I could start drilling I needed to whip out the trusty bench grinder and grind down the squared off areas under the barrel to allow for the Steyer magazine to sit flush:

My first drill press experience was relatively good (custom Ted barrel set screw), until I went to tap the hole and the steel was so hard I snapped off my tap in the hole and had to drill a larger hole offset from the original and tap it. Ugh. Not pretty but gets the job done. I did indeed need to take off about 1/16" from the new barrel to get everything to line up so the grinder worked a double shift today:

I finally worked up enough courage and tackled the drilling and tapping on the donor frame:

SO glad I got the Drill Press. The odds of my being able to drill on those slim angled surfaces one-handed with any degree of accuracy is exactly zero. So that limits required power tool acquisition and use for this project so far to Bench Grinder, Drill Press and Dremel with a crap ton of bits. Not a serious cash layout thus far relative to the potential reward.

I can't believe that I haven't done a catastrophic screw up (Yet - knock on wood) or made a single mod to the kit (except for snapping the trigger guard. Tomorrow is the test fit and make requisite adjustments required. But I do feel like the opportunities for a build killer event are behind us and that makes me feel SO freakin' relieved!!!

Tomorrow it's test fit, adjust with spacers, refit the parts and zip it up. At that point it should be ready to do a video of a test fire.

That only leaves grinding down the gorgeous amber grips to fit the different grip width and configuration on the donor. I'm dreading that and could use any and all advice from the masters in that area. :/ And of course it will need the requisite painting, bluing, weathering as well as wiring up the LEDs and batteries.

We're getting there, brothers

I did indeed get the $70 HF Drill Press. Pretty freakin' awesome for an entry model:

Before I could start drilling I needed to whip out the trusty bench grinder and grind down the squared off areas under the barrel to allow for the Steyer magazine to sit flush:

My first drill press experience was relatively good (custom Ted barrel set screw), until I went to tap the hole and the steel was so hard I snapped off my tap in the hole and had to drill a larger hole offset from the original and tap it. Ugh. Not pretty but gets the job done. I did indeed need to take off about 1/16" from the new barrel to get everything to line up so the grinder worked a double shift today:

I finally worked up enough courage and tackled the drilling and tapping on the donor frame:

SO glad I got the Drill Press. The odds of my being able to drill on those slim angled surfaces one-handed with any degree of accuracy is exactly zero. So that limits required power tool acquisition and use for this project so far to Bench Grinder, Drill Press and Dremel with a crap ton of bits. Not a serious cash layout thus far relative to the potential reward.

I can't believe that I haven't done a catastrophic screw up (Yet - knock on wood) or made a single mod to the kit (except for snapping the trigger guard. Tomorrow is the test fit and make requisite adjustments required. But I do feel like the opportunities for a build killer event are behind us and that makes me feel SO freakin' relieved!!!

Tomorrow it's test fit, adjust with spacers, refit the parts and zip it up. At that point it should be ready to do a video of a test fire.

That only leaves grinding down the gorgeous amber grips to fit the different grip width and configuration on the donor. I'm dreading that and could use any and all advice from the masters in that area. :/ And of course it will need the requisite painting, bluing, weathering as well as wiring up the LEDs and batteries.

We're getting there, brothers

Attachments

Last edited:

man your making me "giddy" and all i am doing is looking at pictures and reading along...

Similar threads

- Replies

- 18

- Views

- 1,223

- Replies

- 2

- Views

- 684

- Replies

- 5

- Views

- 942