Archive&Future

Sr Member

Hello again to all you modellers here on the RPF!

I've been absent from the forum for several months due to the usual combination of work and personal life, however with the winter coming I will be focusing once again on HH Miniatures.

The MPC Millennium Falcon upgrade kits are being entirely re-moulded as the existing moulds are now falling apart, once that's done they will be back in full production again on a more consistent basis. More excitingly though, I'm not working on a new kit which this thread is for.

My full time job is as a teacher and technician for the Design & Technology department at a local high-school.

I run an after school club, and across May and June we built a 1/34th scale model of Saturn V, as you can see here. Once it was completed, I thought "What this really needs is a scale Lunar Module next to it somewhere", but my searches for an off-the-shelf kit turned up a blank.

So it appears there is a gap in the market for a Lunar Module kit any larger than 1/48th scale!

Since 1/34th is an unusual scale, I realised that producing the LM in that scale would be less desirable than 1/32nd which is a far more popular scale and close enough for the display purposes at my school.

(Silver paint and decals were added after this photograph)

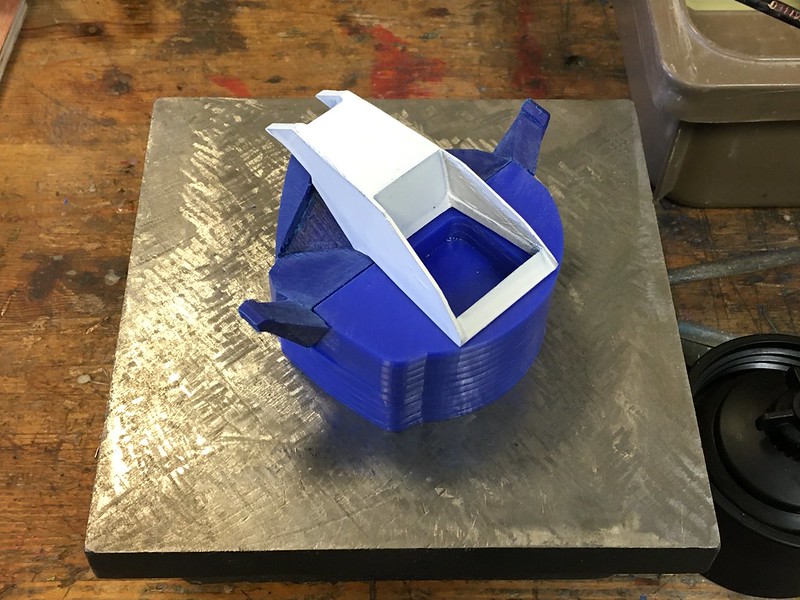

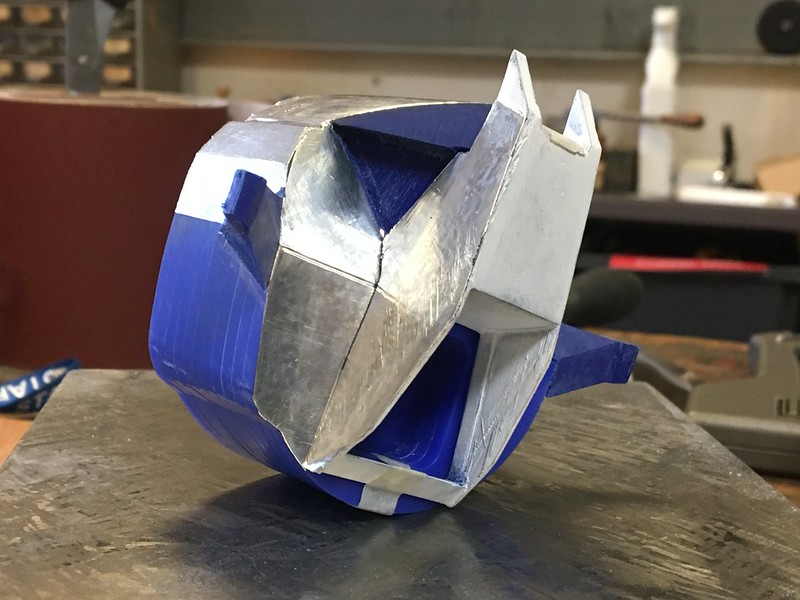

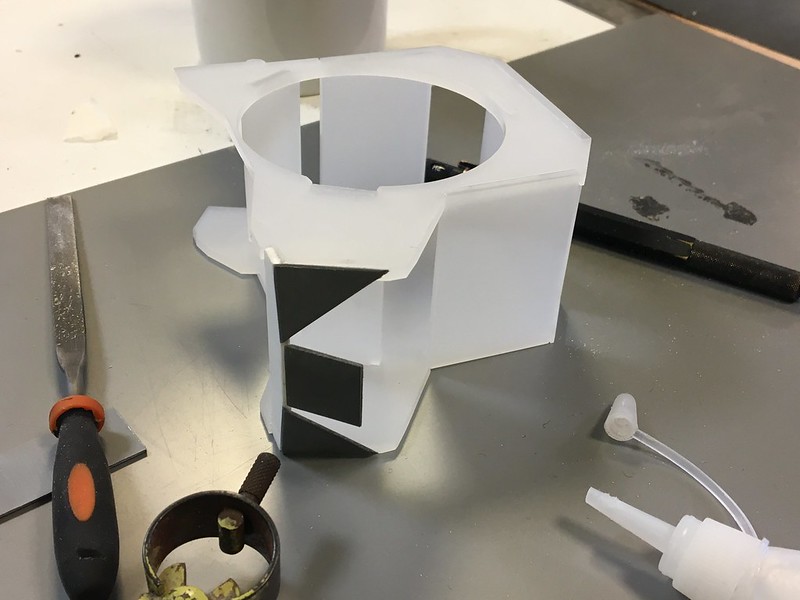

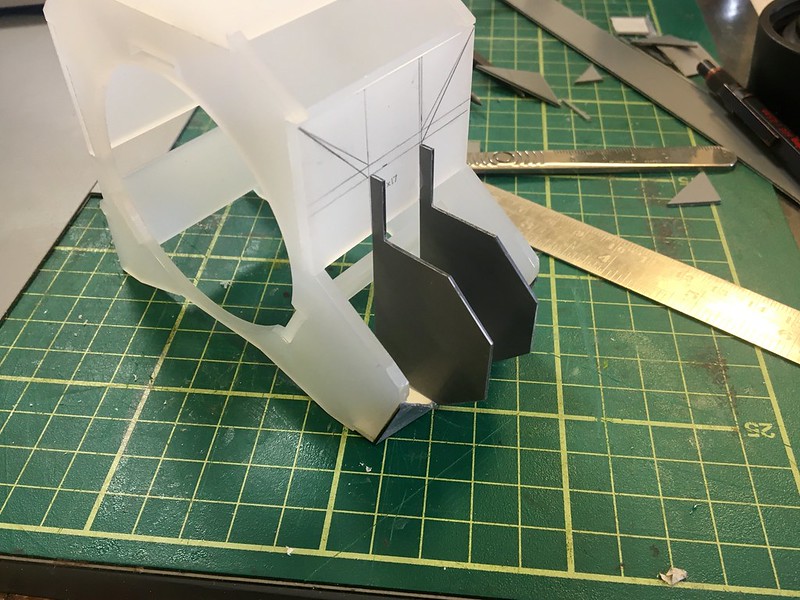

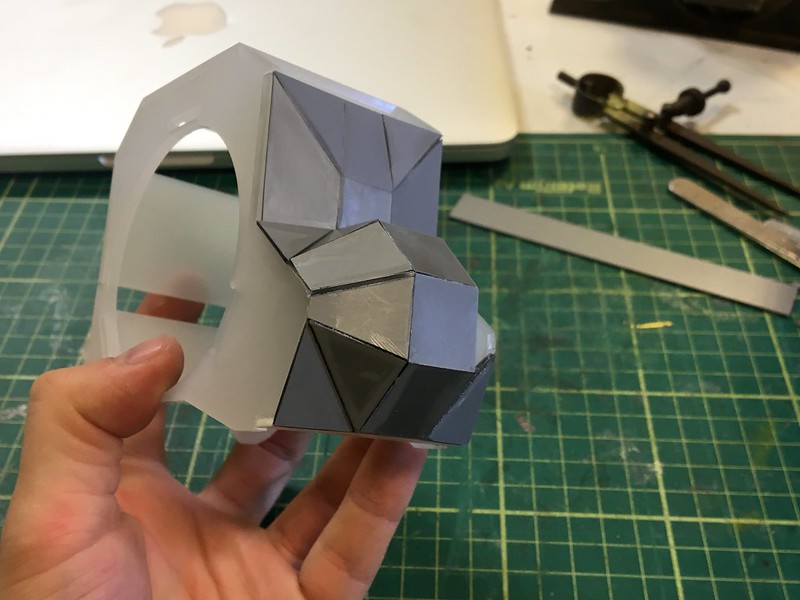

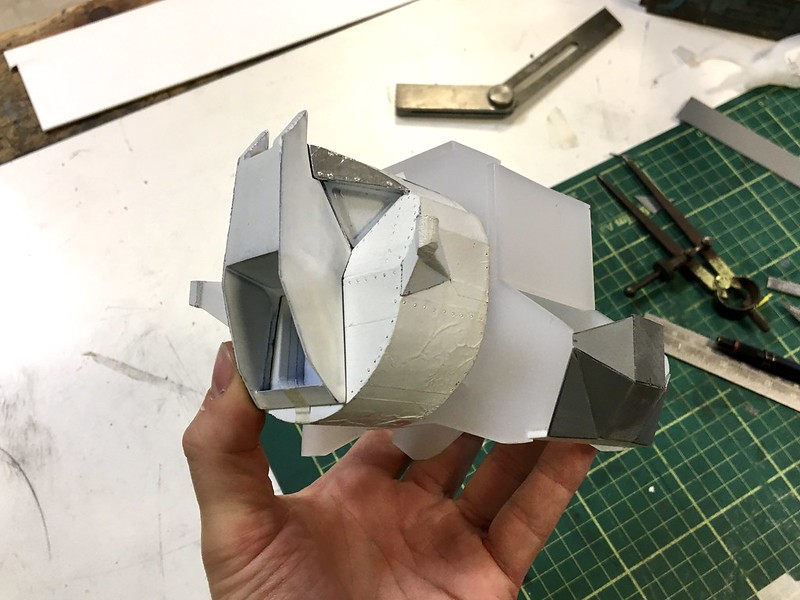

I began by designing the majority of the LM on Sketchup, then splitting the components up into what I could hand make, what I could laser cut, and what I needed to 3D print. We recently purchased three Da Vinci Nano printers for the department, and they are surprisingly great for the money.

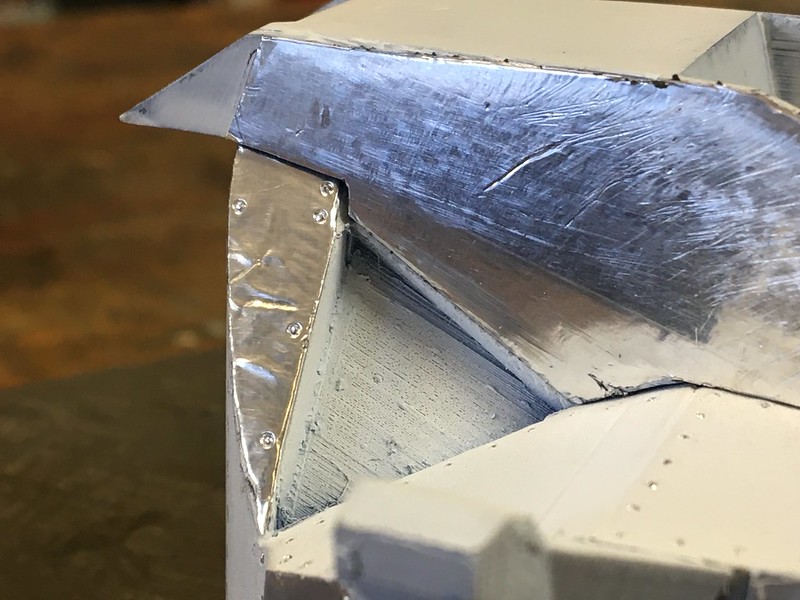

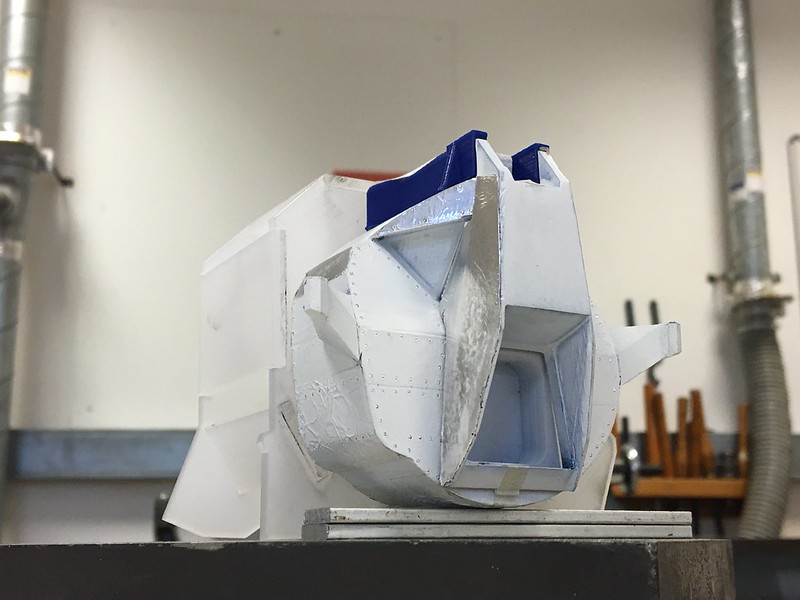

To mimic the stressed metal texture, all the surfaces will be covered in aluminium tape. This is also soft enough to press 'rivets' into using the end of a mechanical pencil.

The grey panelling is styrene cut by hand and then chamfered on a flat piece of 1000 grit abrasive before being glued together in-situ.

I intend to offer an interior version and a no interior version, the idea being that for modellers who are not interested in recreating the inside of the LM they will be able to purchase a version at a cheaper price point.

I am already in the process of designing the photo-etch which each kit will need, along with the graphics and instructions.

A disclaimer: While I'm making this model at school using school facilities, it is not during my contracted hours and not using materials that are dedicated to students. This is entirely during my break times and after work. My head of department is well aware and is happy with what I am doing!

I've been absent from the forum for several months due to the usual combination of work and personal life, however with the winter coming I will be focusing once again on HH Miniatures.

The MPC Millennium Falcon upgrade kits are being entirely re-moulded as the existing moulds are now falling apart, once that's done they will be back in full production again on a more consistent basis. More excitingly though, I'm not working on a new kit which this thread is for.

My full time job is as a teacher and technician for the Design & Technology department at a local high-school.

I run an after school club, and across May and June we built a 1/34th scale model of Saturn V, as you can see here. Once it was completed, I thought "What this really needs is a scale Lunar Module next to it somewhere", but my searches for an off-the-shelf kit turned up a blank.

So it appears there is a gap in the market for a Lunar Module kit any larger than 1/48th scale!

Since 1/34th is an unusual scale, I realised that producing the LM in that scale would be less desirable than 1/32nd which is a far more popular scale and close enough for the display purposes at my school.

(Silver paint and decals were added after this photograph)

I began by designing the majority of the LM on Sketchup, then splitting the components up into what I could hand make, what I could laser cut, and what I needed to 3D print. We recently purchased three Da Vinci Nano printers for the department, and they are surprisingly great for the money.

To mimic the stressed metal texture, all the surfaces will be covered in aluminium tape. This is also soft enough to press 'rivets' into using the end of a mechanical pencil.

The grey panelling is styrene cut by hand and then chamfered on a flat piece of 1000 grit abrasive before being glued together in-situ.

I intend to offer an interior version and a no interior version, the idea being that for modellers who are not interested in recreating the inside of the LM they will be able to purchase a version at a cheaper price point.

I am already in the process of designing the photo-etch which each kit will need, along with the graphics and instructions.

A disclaimer: While I'm making this model at school using school facilities, it is not during my contracted hours and not using materials that are dedicated to students. This is entirely during my break times and after work. My head of department is well aware and is happy with what I am doing!