Quick parts list for emitter and blade pixel setup:

Option 1 (KR connectors):

- Connector set: KR NeoPixel LED Strip Rotary PCB Connector Set - The Saber Armory

- Data line resistor for blade-side PCB: 330ohm 0603 SMD Resistor - The Saber Armory

- Pogo holder set for blade and hilt (because of the pin positions. You will not use the hilt-side pin cover: MK1 (TCSS Blade) Neopixel Adapter by wolf69 on Shapeways

LED cup should be trimmed to 8mm inside depth for this set of connectors

Option 2 TCSS connectors:

- Connector set: Pre-Soldered NeoPixel PCB connector and 7 pin set

- Data line resistor: 330 ohm SMD 0603 resistor

- Pogo holder set for blade and hilt MK1 (TCSS Blade) Neopixel Adapter by wolf69 on Shapeways

Once again, led cup to be trimmed to 8mm inside depth.

Option 3 Shtok connectors:

- Connector set: (individually sold)

-- Hilt: Hilt SIde NPXL NeoPixel LED Connector (select short pin option)

-- Blade: ShtokCustomWorx NPXL NeoPixel LED Connector Pcb Blade Side (select V2 w/o LEDs)

- Data line resistor: (pick one up from either KR or TCSS above. 0603 330 ohm 1/8w)

- Holders:

-- Hilt: LP HILT NPXL Pogo Connector Holder by ShtokyD on Shapeways (select size to match the ID of the cup)

-- Blade: BLADE NPXL Pogo Connector Holder THIN-NECK V2 by ShtokyD on Shapeways

I believe you want inside depth of the cup to be trimmed to 6mm but I am not positive as I have not installed any of my Shtok connectors yet. I would seat them and then mark off where it should be trimmed to So the lip of the cup is flush to the wall of the holder.

Hope this helps Halliwax. Happy to answer any other questions.

also note, there are other ways to connect pixel using things like 1/4 or even 1/8 headphone jacks, aviation/XLR type connectors and such, but the above represents the most user friendly setups.

EDIT:

So how this breaks down on the hilt side (using my Mk1 pics but general construction is the same) once the cup is trimmed and the holders are procured (pics using the TCSS connector option above).

you will have two pads for negative, two for positive and one for data. Now you generally can use a single larger gauge (20-22 AWG) or a couple smaller gauge (24-26 AWG) wires for the current load. (I tend to favor two 24 AWG PTFE wire for 2-strip blades and two 22 AWG for 3+ strip blades). You only need a 30 AWG or so for the data line.

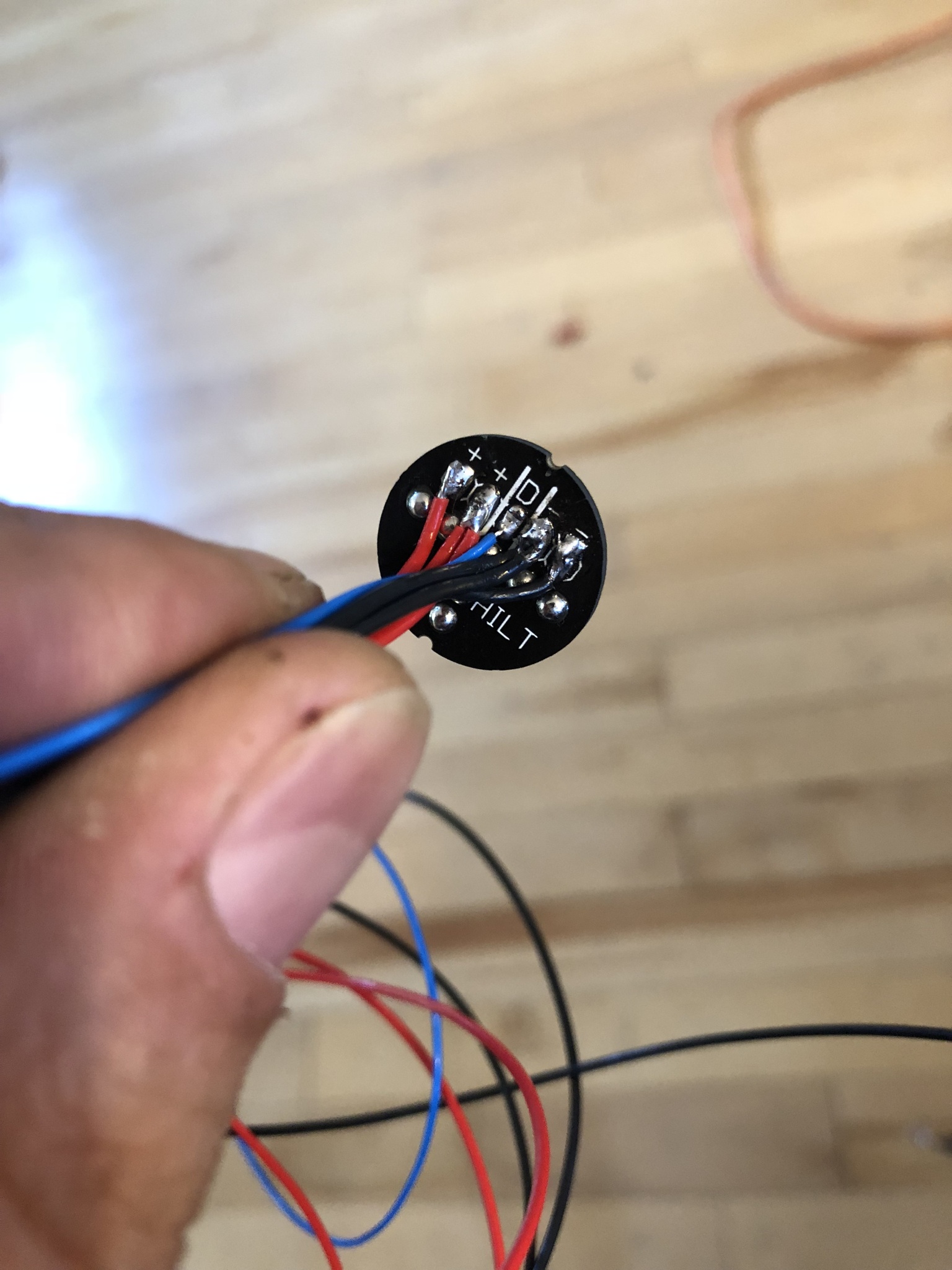

when soldered to the hilt-side PCB it will look like this:

Then you seat that inside the holder:

Then seat that into the trimmed cup and put the cover on it:

Now you run wires down through the neck and viola. (You get the idea from here).

now for BLADE side you want to add the data line 0603 resistor on the appropriate spot on the board (this will vary based on which option you chose, but all three vendors usually have instructions for this.

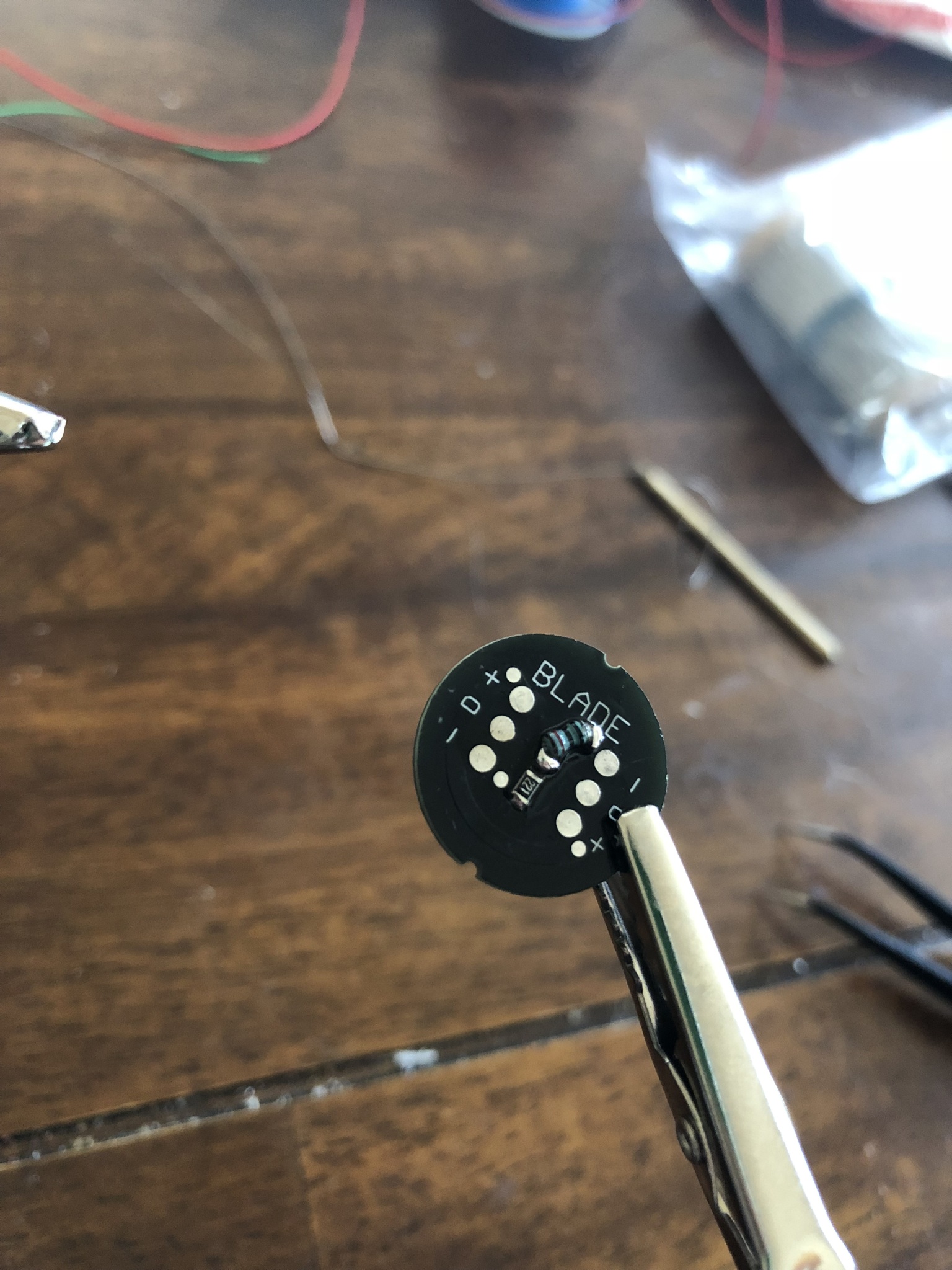

here is what it looks like on the TCSS blade-side PCB:

(note the 0603 SMD resistor center-bottom. Disregard the axial resistor here; that is a Proffieboard thing to handle its "blade ID" feature.)

now you will fit that INSIDE the blade tube using the blade side holder:

Now note: this means you CANNOT just buy a flush ended blade. It has to be a RECESSED pcb. So either you need to make your own blade, or have someone make it custom to your hilt.

I tend to "standardize" all my cups for all of my thin neck sabers to use the same dimensions of cups so I can reuse blades between all of my thin neck sabers (Roman MK1, Lukyanov Creepy Uncle, Roman Balance v4, and Solo's Hold V2).

but there you go!

Option 1 (KR connectors):

- Connector set: KR NeoPixel LED Strip Rotary PCB Connector Set - The Saber Armory

- Data line resistor for blade-side PCB: 330ohm 0603 SMD Resistor - The Saber Armory

- Pogo holder set for blade and hilt (because of the pin positions. You will not use the hilt-side pin cover: MK1 (TCSS Blade) Neopixel Adapter by wolf69 on Shapeways

LED cup should be trimmed to 8mm inside depth for this set of connectors

Option 2 TCSS connectors:

- Connector set: Pre-Soldered NeoPixel PCB connector and 7 pin set

- Data line resistor: 330 ohm SMD 0603 resistor

- Pogo holder set for blade and hilt MK1 (TCSS Blade) Neopixel Adapter by wolf69 on Shapeways

Once again, led cup to be trimmed to 8mm inside depth.

Option 3 Shtok connectors:

- Connector set: (individually sold)

-- Hilt: Hilt SIde NPXL NeoPixel LED Connector (select short pin option)

-- Blade: ShtokCustomWorx NPXL NeoPixel LED Connector Pcb Blade Side (select V2 w/o LEDs)

- Data line resistor: (pick one up from either KR or TCSS above. 0603 330 ohm 1/8w)

- Holders:

-- Hilt: LP HILT NPXL Pogo Connector Holder by ShtokyD on Shapeways (select size to match the ID of the cup)

-- Blade: BLADE NPXL Pogo Connector Holder THIN-NECK V2 by ShtokyD on Shapeways

I believe you want inside depth of the cup to be trimmed to 6mm but I am not positive as I have not installed any of my Shtok connectors yet. I would seat them and then mark off where it should be trimmed to So the lip of the cup is flush to the wall of the holder.

Hope this helps Halliwax. Happy to answer any other questions.

also note, there are other ways to connect pixel using things like 1/4 or even 1/8 headphone jacks, aviation/XLR type connectors and such, but the above represents the most user friendly setups.

EDIT:

So how this breaks down on the hilt side (using my Mk1 pics but general construction is the same) once the cup is trimmed and the holders are procured (pics using the TCSS connector option above).

you will have two pads for negative, two for positive and one for data. Now you generally can use a single larger gauge (20-22 AWG) or a couple smaller gauge (24-26 AWG) wires for the current load. (I tend to favor two 24 AWG PTFE wire for 2-strip blades and two 22 AWG for 3+ strip blades). You only need a 30 AWG or so for the data line.

when soldered to the hilt-side PCB it will look like this:

Then you seat that inside the holder:

Then seat that into the trimmed cup and put the cover on it:

Now you run wires down through the neck and viola. (You get the idea from here).

now for BLADE side you want to add the data line 0603 resistor on the appropriate spot on the board (this will vary based on which option you chose, but all three vendors usually have instructions for this.

here is what it looks like on the TCSS blade-side PCB:

(note the 0603 SMD resistor center-bottom. Disregard the axial resistor here; that is a Proffieboard thing to handle its "blade ID" feature.)

now you will fit that INSIDE the blade tube using the blade side holder:

Now note: this means you CANNOT just buy a flush ended blade. It has to be a RECESSED pcb. So either you need to make your own blade, or have someone make it custom to your hilt.

I tend to "standardize" all my cups for all of my thin neck sabers to use the same dimensions of cups so I can reuse blades between all of my thin neck sabers (Roman MK1, Lukyanov Creepy Uncle, Roman Balance v4, and Solo's Hold V2).

but there you go!

Last edited: