I would like to dedicate this build to my friend, colleague and fellow R2D2 cohort, Grant Imahara. His unexpected passing really sucked the wind out of my sails on posting this. Grant, Fon Davis, Billy Brooks and I were racing to finish our R2s this year – And we made it!

We just thought we’d have more time to share them in the end.

Here’s to his memory….

Doo-deedle-dooooo, Doodle-ee-deedle-ee-doo….

So there we were - kids who had grown up on the original films, now employed at ILM, working on the things we had only dreamed of when we were growing up.

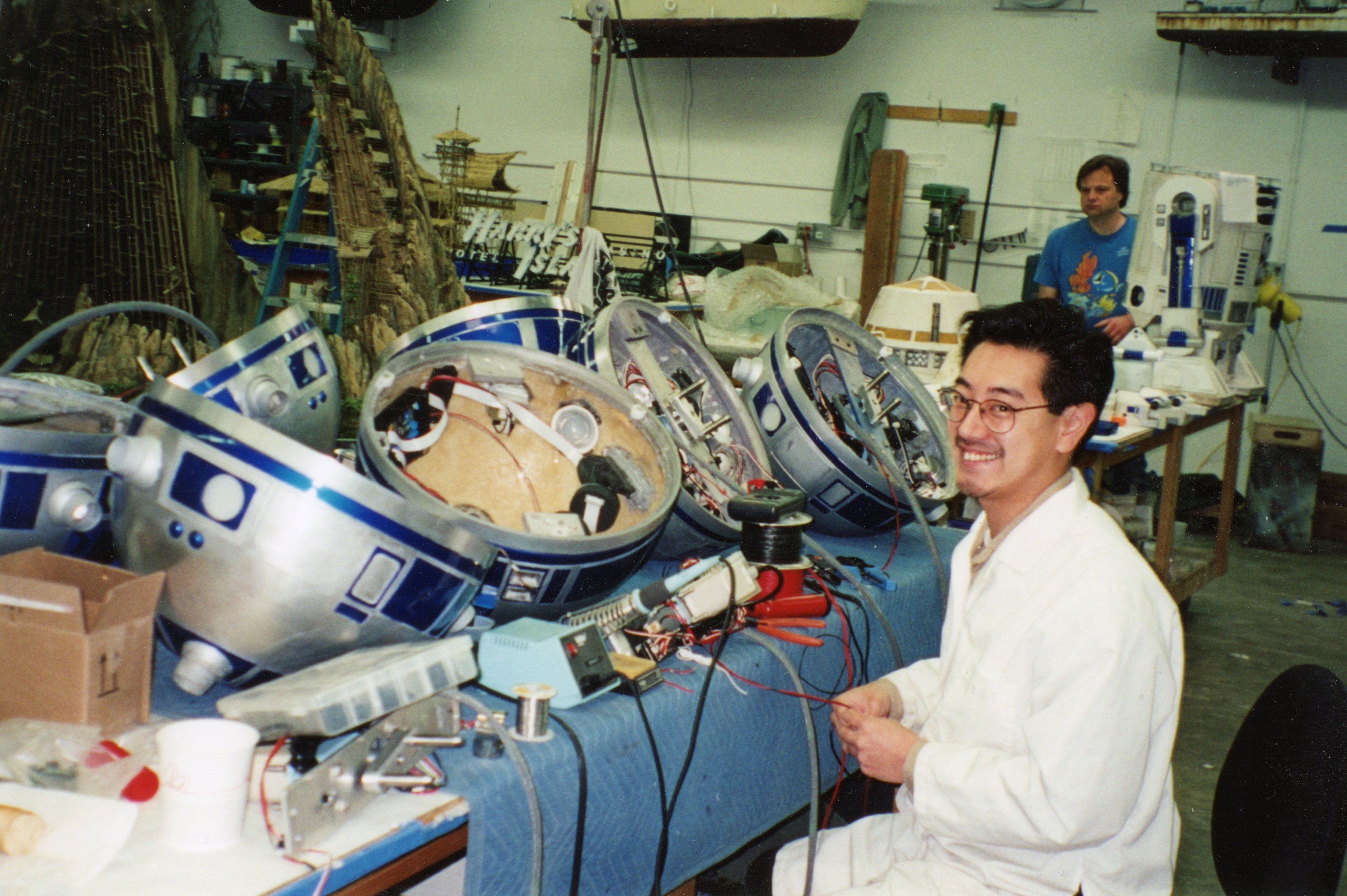

We were making new worlds, vehicles, robots and characters for Star Wars, as well as repairing some original props to be used in the new films. In fact, all of the original R2 units had been brought down from the Skywalker Ranch archives, and were currently in the model shop being completely gone through and refurbished.

We were getting to work on the objects that had inspired us to do exactly what we were doing – something we’d never thought would really happen!

Thrilled! Giddy even!

…. And then, someone shared a thought…

I forget who dared to say it first, (because each of us was nervous that if we admitted too much of our nerd-dom, it might lead to teasing) but someone finally said “It’s kind of a bummer that we are working on the real R2-D2s; the thing that we desired the most as kids, but we can’t have him.” (Taking original parts or castings was considered grounds for firing.)

“Yeah, I wish I could have one too!”

“Me too”

This group was made up of folks like John Goodson, Fon Davis, Adam Savage, Grant Imahara, Don Bies, Mark Buck, Billy Brooks, John Eblan and myself (John Duncan).

We looked around and said -

“Well……. We’re all pretty good at making stuff.”

“ … and we have the original parts right here to take accurate measurements from…”

“… and there aren’t any rules about us making our own patterns and molding those….”

blink, blink….

“Alright, whose in?”

And so began a project that has stretched over the last 20 years or so.

Here are some of the archive R2s during the refurbishment.

...and my buddy Grant!

We just thought we’d have more time to share them in the end.

Here’s to his memory….

Doo-deedle-dooooo, Doodle-ee-deedle-ee-doo….

So there we were - kids who had grown up on the original films, now employed at ILM, working on the things we had only dreamed of when we were growing up.

We were making new worlds, vehicles, robots and characters for Star Wars, as well as repairing some original props to be used in the new films. In fact, all of the original R2 units had been brought down from the Skywalker Ranch archives, and were currently in the model shop being completely gone through and refurbished.

We were getting to work on the objects that had inspired us to do exactly what we were doing – something we’d never thought would really happen!

Thrilled! Giddy even!

…. And then, someone shared a thought…

I forget who dared to say it first, (because each of us was nervous that if we admitted too much of our nerd-dom, it might lead to teasing) but someone finally said “It’s kind of a bummer that we are working on the real R2-D2s; the thing that we desired the most as kids, but we can’t have him.” (Taking original parts or castings was considered grounds for firing.)

“Yeah, I wish I could have one too!”

“Me too”

This group was made up of folks like John Goodson, Fon Davis, Adam Savage, Grant Imahara, Don Bies, Mark Buck, Billy Brooks, John Eblan and myself (John Duncan).

We looked around and said -

“Well……. We’re all pretty good at making stuff.”

“ … and we have the original parts right here to take accurate measurements from…”

“… and there aren’t any rules about us making our own patterns and molding those….”

blink, blink….

“Alright, whose in?”

And so began a project that has stretched over the last 20 years or so.

Here are some of the archive R2s during the refurbishment.

...and my buddy Grant!