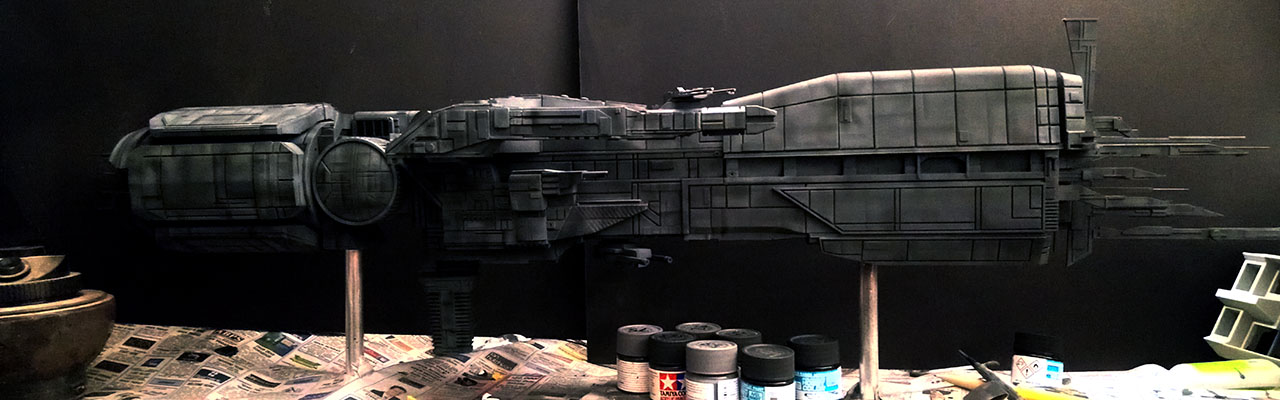

It is remarkably difficult to take a pic of a ship that is shaded in light grey, medium grey, dark grey, neutral grey, german grey, sky grey, ijn grey, nato black, rubschwarz, tire black, oil black, and who knows how many variations thereof...

I painted over the SULACO logo, it was too big, and i couldnt do the "USS" part small and neat enough. So i've ordered some printer decal sheet so i can print it and do it as a decal. Once thats on and ive blended it in, i think it'll be finished. Then i'll try and get some good photos under good light. In the meantime, these are pretty close, though dont quite show the shading as well as they should.

I painted over the SULACO logo, it was too big, and i couldnt do the "USS" part small and neat enough. So i've ordered some printer decal sheet so i can print it and do it as a decal. Once thats on and ive blended it in, i think it'll be finished. Then i'll try and get some good photos under good light. In the meantime, these are pretty close, though dont quite show the shading as well as they should.