You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printers..Which to buy?

- Thread starter yoopees

- Start date

Fetasigma1977

New Member

That would depend on your budget and if you are just going to be doing hobby stuff for yourself or for others as well,

And how big a build platform you want to have or how much you are willing to cut and Assemble pieces

Sent from my iPhone using Tapatalk

And how big a build platform you want to have or how much you are willing to cut and Assemble pieces

Sent from my iPhone using Tapatalk

Hero of Justice

Active Member

All credits for this information goes to http://www.pcmag.com/article2/0,2817,2470311,00.asp

(The first step is to understand the different types of 3D printers that are available and how they work. Fused Filament Fabrication (FFF) printers use melted filament (usually plastic) that's stacked layer upon layer. These are the most common 3D printers and range from $300-$5,000. Selective Layer Sintering (SLS) printers are the most expensive, costing upwards of $30,000. The GeekFabLab designers demonstrated printing cosplay gear using printers from LulzBot. The company makes two FFF printers—one sells for $1595, the other for $2194.)

(The first step is to understand the different types of 3D printers that are available and how they work. Fused Filament Fabrication (FFF) printers use melted filament (usually plastic) that's stacked layer upon layer. These are the most common 3D printers and range from $300-$5,000. Selective Layer Sintering (SLS) printers are the most expensive, costing upwards of $30,000. The GeekFabLab designers demonstrated printing cosplay gear using printers from LulzBot. The company makes two FFF printers—one sells for $1595, the other for $2194.)

swhite228

Well-Known Member

We just got a small M3D and a larger Flashforge Creator Pro for a company a friend and I have along with a Matter and Form 3D scanner..

The M3D was $399 with the Flashforge Creator Pro coming in at around $1200. Both are working well for what they were purchased for, but I wouldn't say they are interchangeable.

We did a fair amount of research before we made the purchases including playing with a $250k setup that my dentist purchased for his office (a SLS system with scanner), we also talked to teachers who use them in their classes ( that alone killed off the Makerbot printers)

Be prepared to spend a lot of time setting up the printer, and be ready to curse the software that comes with it, or check out 3Dhubs.com to find someone who does printing in your area who has already done the learning.

We are happy with the printers we got and if things workout the way we hope will be adding a Form1 printer to the mix early next year.

The M3D was $399 with the Flashforge Creator Pro coming in at around $1200. Both are working well for what they were purchased for, but I wouldn't say they are interchangeable.

We did a fair amount of research before we made the purchases including playing with a $250k setup that my dentist purchased for his office (a SLS system with scanner), we also talked to teachers who use them in their classes ( that alone killed off the Makerbot printers)

Be prepared to spend a lot of time setting up the printer, and be ready to curse the software that comes with it, or check out 3Dhubs.com to find someone who does printing in your area who has already done the learning.

We are happy with the printers we got and if things workout the way we hope will be adding a Form1 printer to the mix early next year.

Firefox3D

Well-Known Member

If you need a large build area, which you will for armour the Lulzbot Taz 5 is about the best "value" I can see, but still $2200.

If I had not bought a RepRapPro Ormerod kit I might have well bought one even though it is about 4 times the cost of the kit printer in the UK.

As the previous posted said, be prepared to spend a fair amount of time setting up - tuning - swearing not necessarily in that order

Filament type, make and colour influence how things print. Optimising the slicing software another hurdle, the good side of an open source printer like the RepRapPro is there is a lot of info out there on forums, with guys who have been there done that for just about everything, helped me considerably.

If I had not bought a RepRapPro Ormerod kit I might have well bought one even though it is about 4 times the cost of the kit printer in the UK.

As the previous posted said, be prepared to spend a fair amount of time setting up - tuning - swearing not necessarily in that order

Filament type, make and colour influence how things print. Optimising the slicing software another hurdle, the good side of an open source printer like the RepRapPro is there is a lot of info out there on forums, with guys who have been there done that for just about everything, helped me considerably.

darthviper107

Sr Member

Ultimaker 2 is a very good printer, and the have a larger volume one available also. Though it's more expensive--$3,000+

Don't get Makerbot, in general their printers have just been OK but not great, but their current line is crap

Don't get Makerbot, in general their printers have just been OK but not great, but their current line is crap

Ultimaker 2 is a very good printer, and the have a larger volume one available also. Though it's more expensive--$3,000+

Don't get Makerbot, in general their printers have just been OK but not great, but their current line is crap

I agree stay away from the new makerbots I waisted months with one . I have Ulitimaker 2 now and its wonderful.

swhite228

Well-Known Member

I would argue that hobby 3D is past the dot matrix stage and is into the late inkjet stage.I've been poking my head into the market every 6 months or so but for me the quality doesn't justify the price yet (my interest is in printing smaller, highly detailed pieces). I still feel like we're in the dot matrix days and I'm content to wait for a bit.

In 3D printing you will find that there are great deals with some printers, and others are ripoffs. The days of the build it yourself are fading and the quality of the prints has gone way up as the cost has come way down.

You are not going to get injected molded quality unless you're willing to lay out some heavy cash, but you will get parts that could never be molded which is a very nice trade off. As I said before there is a learning curve to these printers and with that knowledge is the ability to fabricate high quality parts that require little if any cleaning

One of the new things we've been trying out is Acetone Vapor Baths for our printed ABS parts, It's quick and the Acetone vapors polish and strenghens the printed parts . In a nut shell it melts the outside layer of plastic enough the printed layers flow together removing a lot of the print layer ridges, and leaving a smooth gloss surface, That layer of merged plastic gives the part added strength and helps stop the parts from splitting at a layer.

swhite228

Well-Known Member

Don't get Makerbot, in general their printers have just been OK but not great, but their current line is crap

To quote a teacher friend from Australia" We've only got 1 of 10 Makerbots running the others are used for displays in the local town. The printer was ok but the print nozzle will become detached the second you stop paying attention to the printer leaving you with a large mound of melted plastic goo."

TZY

Well-Known Member

Hi ,

Thought I might add my 2 cents worth here . Ive been involved with 3D printing for the past 10 years and we are on the cusp of some major breakthroughs in the next year or 2 .

I have been using the Form +1 printer for the past 2 years with great success. It cost about $3300 and I went into a partnership to get it... Its paid for itself many times over. Thats not to say that the original Form printer before the +1 didnt have its issues and we have sent it back more than once to be replaced ...but the service from the Form guys was magnificent and I believe they now have a product that truly delivers hi quality resolution prints .These prints were used as masters , molded and cast. This will help you pay for the machine if you want to make you investment pay for itself . Not to mention just making and selling parts straight from the printer. Check it out on line under Formlabs.. this is just 1 link

http://www.computerworld.com/articl...3d-printer-offers-mind-blowing-precision.html

Take a look at what might be the next big leap in printing..... google Carbon 3D

Hope this helps

Thought I might add my 2 cents worth here . Ive been involved with 3D printing for the past 10 years and we are on the cusp of some major breakthroughs in the next year or 2 .

I have been using the Form +1 printer for the past 2 years with great success. It cost about $3300 and I went into a partnership to get it... Its paid for itself many times over. Thats not to say that the original Form printer before the +1 didnt have its issues and we have sent it back more than once to be replaced ...but the service from the Form guys was magnificent and I believe they now have a product that truly delivers hi quality resolution prints .These prints were used as masters , molded and cast. This will help you pay for the machine if you want to make you investment pay for itself . Not to mention just making and selling parts straight from the printer. Check it out on line under Formlabs.. this is just 1 link

http://www.computerworld.com/articl...3d-printer-offers-mind-blowing-precision.html

Take a look at what might be the next big leap in printing..... google Carbon 3D

Hope this helps

darthviper107

Sr Member

Yep, that's going to be a big improvement for SLA printers, that's probably the only issue with the Form1---the separation process between each layer means you've got some design/orientation requirements, without having to deal with that it would mean there's very little issues with SLA

TZY

Well-Known Member

Theres another point I forgot to bring up .. The Form comes with great software that allows you to orientate the build and high lightens areas that need more support, or you can let the software self orientate the model for best placement of support and also allows you to edit supports by adding or removing them. The software is a free download from their site and you might want to give it a try. The layer thickness for the Form runs .01 .05 .025... The .025 is great for the hi detail parts

Also don't forget additional saving can be made by hollowing the part and leaving ports for the resin to drain out while building . This can save you over 50% of material at times . That can be said of all 3D printers.

Now going back to your original post...I just noticed you wanted to do helmets and armour...dooohh. If your doing 1:1 scale you might think of trying a 5 axis mill . Now im not saying you buy one ...but there a a few out that do great work for a fair price . You could use the Ren shape material and have shaped out of that then you could have it epoxied and finished that way or use it as a master to cast. Let me know ...I could point you towards one . You will need a 3D file of your project.

Hope this helps

Also don't forget additional saving can be made by hollowing the part and leaving ports for the resin to drain out while building . This can save you over 50% of material at times . That can be said of all 3D printers.

Now going back to your original post...I just noticed you wanted to do helmets and armour...dooohh. If your doing 1:1 scale you might think of trying a 5 axis mill . Now im not saying you buy one ...but there a a few out that do great work for a fair price . You could use the Ren shape material and have shaped out of that then you could have it epoxied and finished that way or use it as a master to cast. Let me know ...I could point you towards one . You will need a 3D file of your project.

Hope this helps

I want to drag this topic back to the top. I'm seriously considering purchasing a 3d printer in the $1000-$1500 range, maybe a bit more depending on the difference in price to what you get. $2000 tops. I've never used one before, and never worked with the software. It's completely chinese to me. In the past, ive self taught everything from airbrushing to mold making to vac forming. This is the next shop purchase. Im looking for feedback from people who have owned or worked with any printer they recommend (or condemn). Primarily looking for a good balance of print size, print quality, and price. Obviously anything user friendly is a bonus. Any info would be great. I'm not looking for links to review sites. Thanks in advance!

I've been here shooting out load my love for Ulitmaker 2 ( and I still say its a fantastic machine ) but I'm working on a new production and apart from the 5 Ultimakers the guy who runs them has just got aZortrax M200 3D Printer[/h]and the prints he's getting of it are jaw droopingly amazing . it has its draw backs as it only uses its own filament and only ABS but if I had to choose again id be very interested in this machine and its cheeper than an ultimaker.

but I'm still loving what I can get out of my U2

good luck with your search

but I'm still loving what I can get out of my U2

good luck with your search

Fetasigma1977

New Member

I will throw my 2 cents in, I have a hacked davinci 1.0a and for the price it is pretty hard to beat once it is dialed in and hacked so it can use outside filament. For a little over 500 bucks you get a machine that can print Pla and abs with decent resolution and has a very nicely sized print area. I would personally go this route until you are sure that you like 3d printing

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I've been here shooting out load my love for Ulitmaker 2 ( and I still say its a fantastic machine ) but I'm working on a new production and apart from the 5 Ultimakers the guy who runs them has just got aZortrax M200 3D Printer[/h]and the prints he's getting of it are jaw droopingly amazing . it has its draw backs as it only uses its own filament and only ABS but if I had to choose again id be very interested in this machine and its cheeper than an ultimaker.

but I'm still loving what I can get out of my U2

good luck with your search

I will throw my 2 cents in, I have a hacked davinci 1.0a and for the price it is pretty hard to beat once it is dialed in and hacked so it can use outside filament. For a little over 500 bucks you get a machine that can print Pla and abs with decent resolution and has a very nicely sized print area. I would personally go this route until you are sure that you like 3d printing

Sent from my iPhone using Tapatalk

These are exaxtly the kind reviews of reviews I'm looking for. If anyone else has anything to add I want to hear it! If anyone agrees or disagrees with the assessments given I also want to hear thise as well. Thanks @Filmzy & Fetasigma1977

Last edited by a moderator:

Fetasigma1977

New Member

I could even post some pics of prints if you like?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I could even post some pics of prints if you like?

Sent from my iPhone using Tapatalk

I wouldnt know a good print from an average print at this point, but if youve got a good print, it'll give me something to base from.

Fetasigma1977

New Member

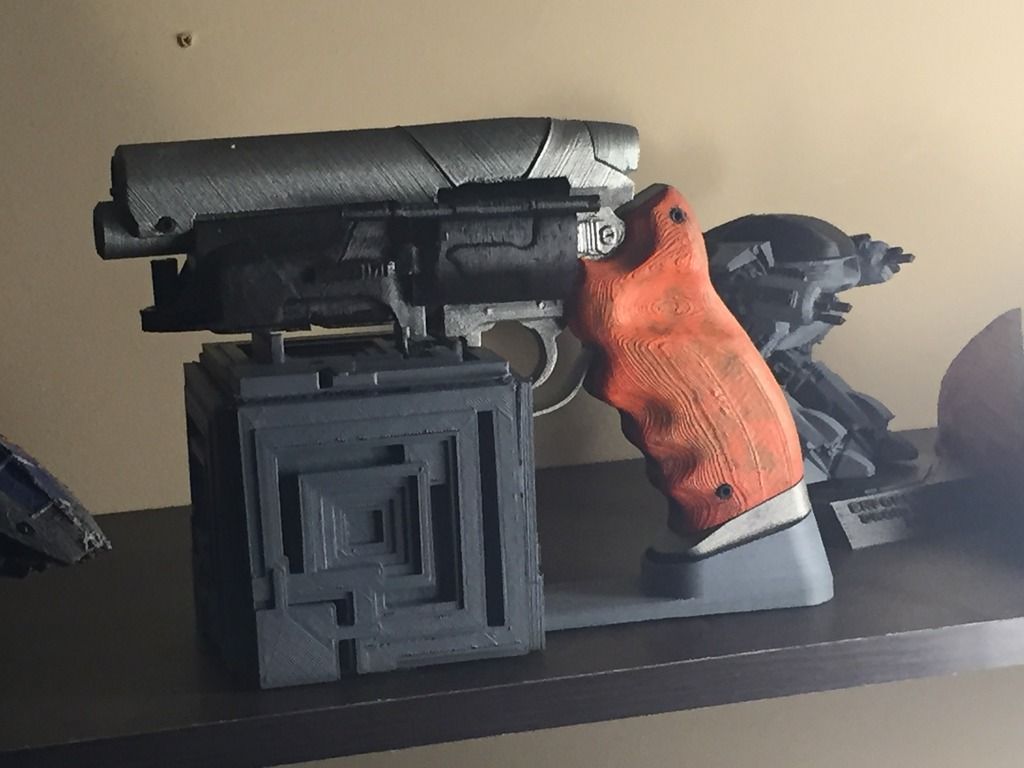

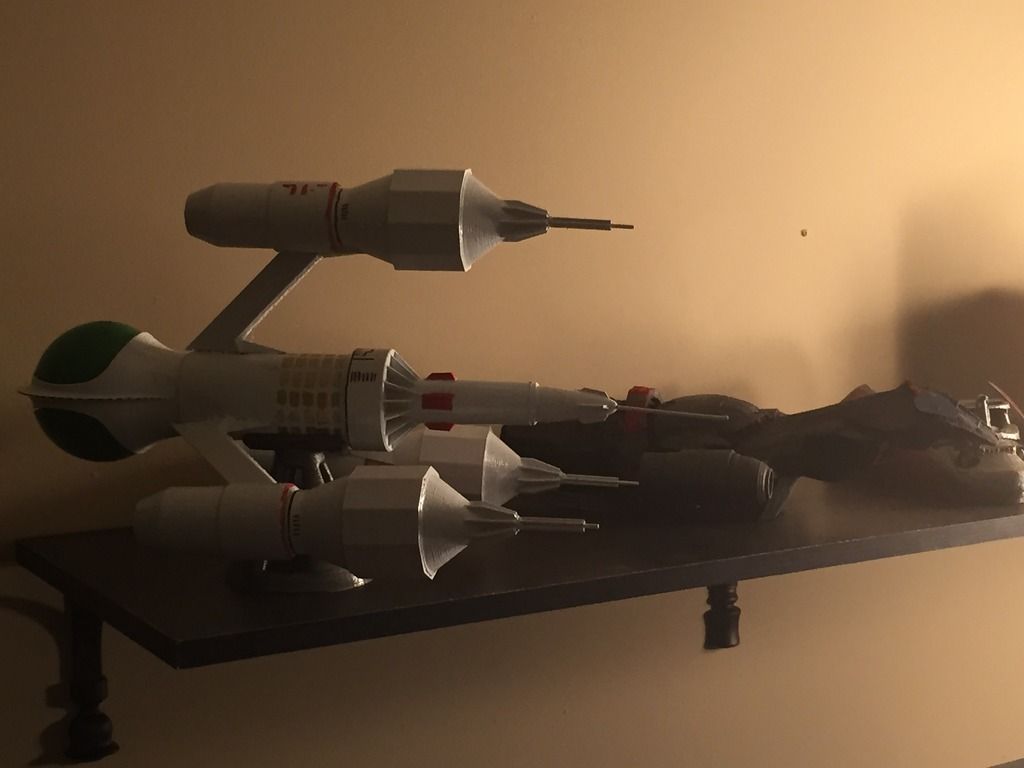

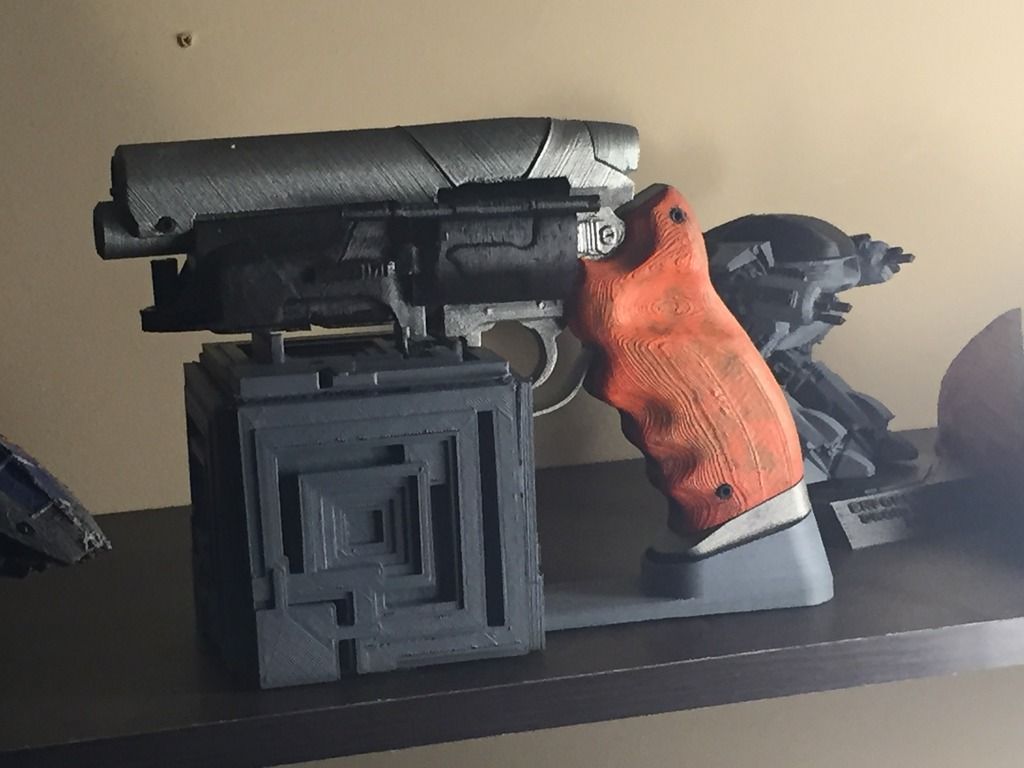

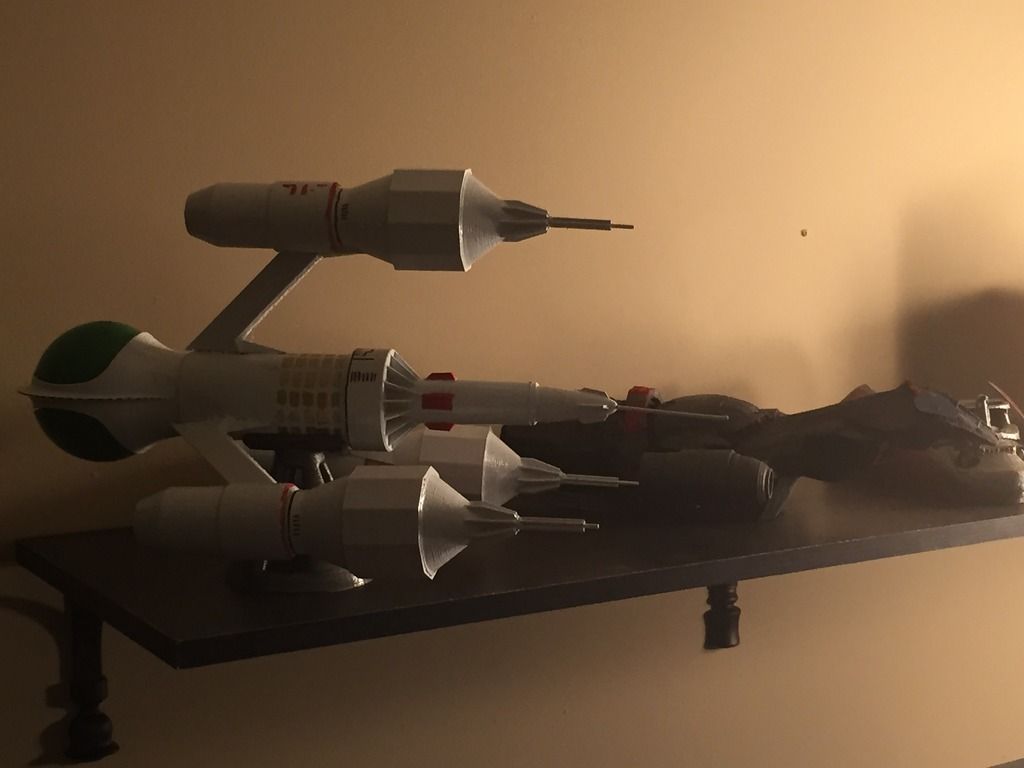

Well I can give you an idea of what is possible with the cheap end anyway. All prints will need some finishing but here are some pics to show you what is possible. I started from not knowing anything about 3d printing and now print something almost everyday, and even do some of my own modeling.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Similar threads

- Replies

- 16

- Views

- 411

- Replies

- 16

- Views

- 1,128

- Replies

- 4

- Views

- 845