You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

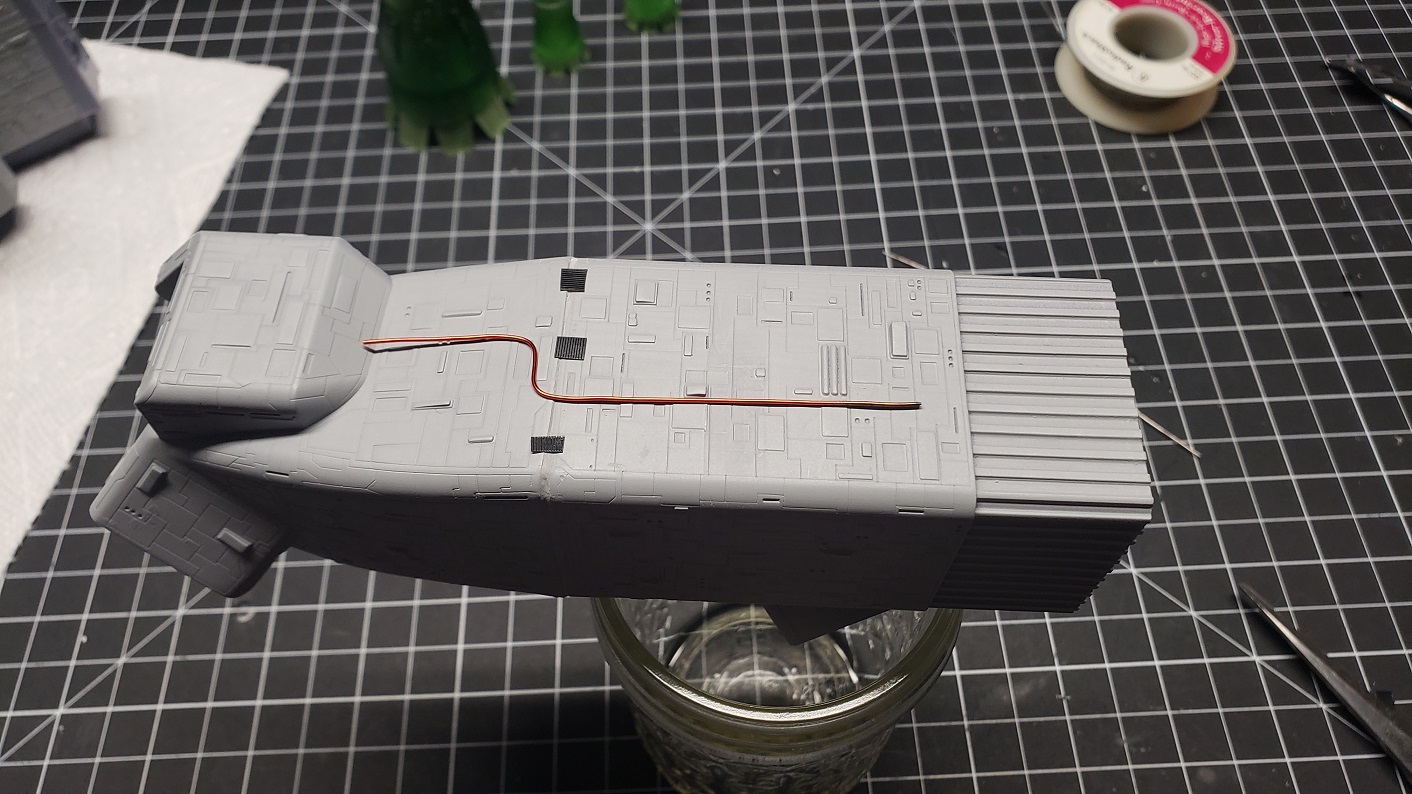

1:800 Scale Resin Printed USCSS Nostromo (WIP)

- Thread starter skahtul

- Start date

Bjorn

Sr Member

I'm just a noob when it comes to printing but these pieces seem pretty chunky.

Is it possible for you to hollow out the files. You possibly already know this but I would have thought that with the parts being so large and solid, you are getting a lot of shrinkage in every direction as the resin continues to cure. Parts of this size may need to be hollowed out more so they don't warp as much.

I understand that may be difficult to do, but modding the supports may, or may not remedy or address the underlying issue? - Just speculating here!

As you are no doubt aware, FDM printing probably gets around that issue with a fill matrix rather than solid material. I wonder if the files were designed or intended for FDM as opposed to SLA?

Either way, your prints look really beautiful!

Such an awesome model subject. I look forward to seeing you progress as it comes together!

Is it possible for you to hollow out the files. You possibly already know this but I would have thought that with the parts being so large and solid, you are getting a lot of shrinkage in every direction as the resin continues to cure. Parts of this size may need to be hollowed out more so they don't warp as much.

I understand that may be difficult to do, but modding the supports may, or may not remedy or address the underlying issue? - Just speculating here!

As you are no doubt aware, FDM printing probably gets around that issue with a fill matrix rather than solid material. I wonder if the files were designed or intended for FDM as opposed to SLA?

Either way, your prints look really beautiful!

Such an awesome model subject. I look forward to seeing you progress as it comes together!

Bjorn All good points, thanks for the input!

Yeah, these are for the SLA files, the FDM ones are 3x the size as the scale for those is huge. I have been hollowing all the parts and they are not as solid as they look. They are heavily drilled out (even before hollowing) for wiring tunnels and LEDs. I have also learned to 'drill' them out in order to get the resin cleaned out from the inside.

Now that I have the orientation down, I have been getting great prints with zero warping which is great. I hope to have a bunch of stuff printed for this during the weekend and get this thing glued together.

Yeah, these are for the SLA files, the FDM ones are 3x the size as the scale for those is huge. I have been hollowing all the parts and they are not as solid as they look. They are heavily drilled out (even before hollowing) for wiring tunnels and LEDs. I have also learned to 'drill' them out in order to get the resin cleaned out from the inside.

Now that I have the orientation down, I have been getting great prints with zero warping which is great. I hope to have a bunch of stuff printed for this during the weekend and get this thing glued together.

Bjorn

Sr Member

Awesome, please to hear that your getting better results.

Come to think of it, I have recently had trouble with thin parts warping also, so I can imagine that orientation is a bigger factor than I had previously considered.

And I'm guessing that resin properties may also be a factor? I'm yet to really play with orientation and different resins.

Come to think of it, I have recently had trouble with thin parts warping also, so I can imagine that orientation is a bigger factor than I had previously considered.

And I'm guessing that resin properties may also be a factor? I'm yet to really play with orientation and different resins.

Awesome, please to hear that your getting better results.

Come to think of it, I have recently had trouble with thin parts warping also, so I can imagine that orientation is a bigger factor than I had previously considered.

And I'm guessing that resin properties may also be a factor? I'm yet to really play with orientation and different resins.

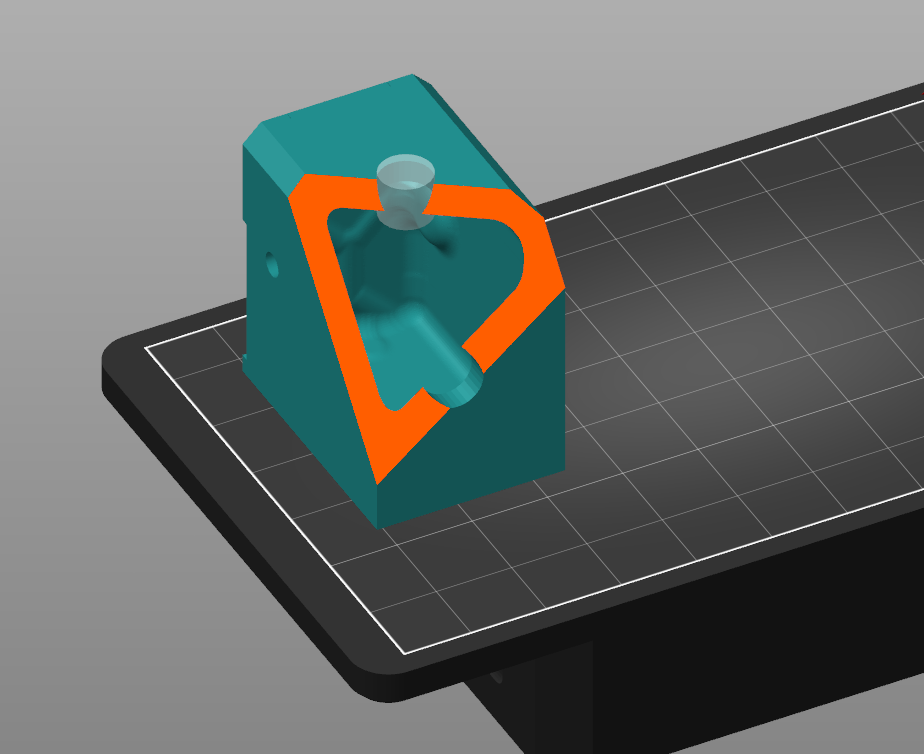

When I print really odd-shaped things like my Nazgul I find that orientation does not 'seem' to matter as much. But, as some have suggested these square parts can be odd. I find that tilting them back at a direct 45 degrees and then rotating the object seems to work really well. This orients the part so that the corner is that part pointing at the bed. I have only used one brand/type of resin so far. I have some other now that I will be testing out.

Good luck!

-Eric

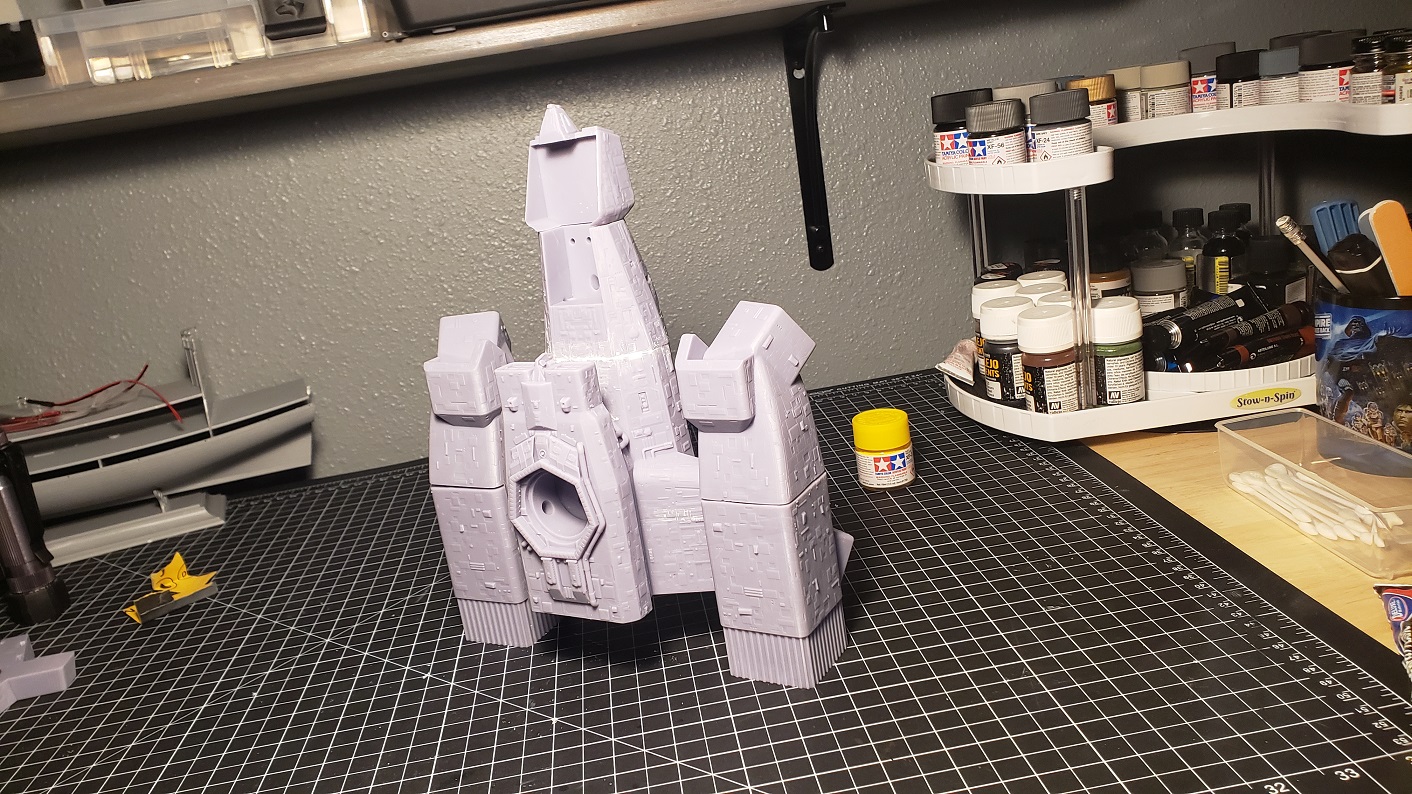

It's finally coming together. Even at 1:800 this is a pretty big kit and the detail is amazing. The warping of the early prints will be testing my putty skills for sure! I am under no illusions that this will be perfect but hopefully, it will still look pretty good! I am sure I will re-attempt this again in the near future once my printing skills are up to snuff.

I will also take a page from SB and combine some of these parts, it's sliced up way too much and would come to gether much better if some items were stiched together.

I will also take a page from SB and combine some of these parts, it's sliced up way too much and would come to gether much better if some items were stiched together.

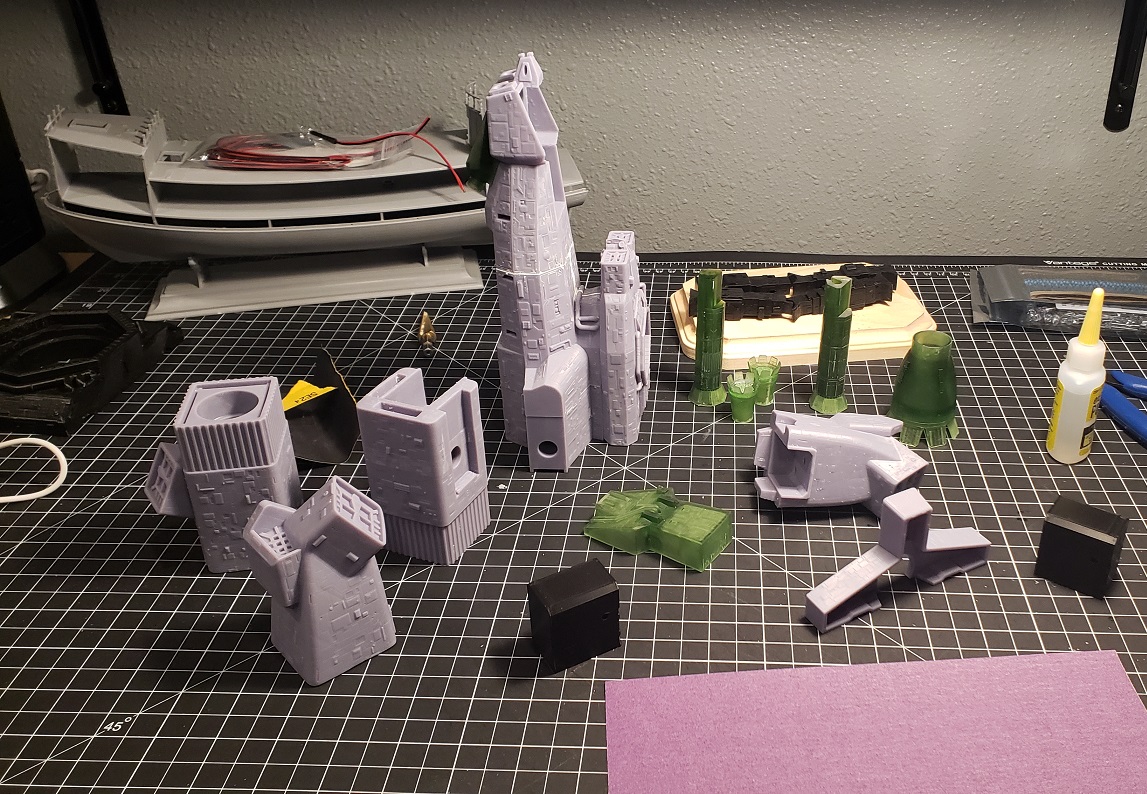

Testing out some parts with clear resins. They are nice to work with in some ways and a bit of a pain in others. It's nice that you can see into the reservoir for any pieces and they cure really well. The only issue is that since they are clear, it's hard to see some of the detail until you prime the parts...

Hunk a Junk

Sr Member

A Nostromo is on my list. Where did you get the file?

A Nostromo is on my list. Where did you get the file?

On the Gambody site, they have a bunch of alien files.

Almost all the major parts are printed, I am just working on a few smaller parts and the left and right rear thrusters.

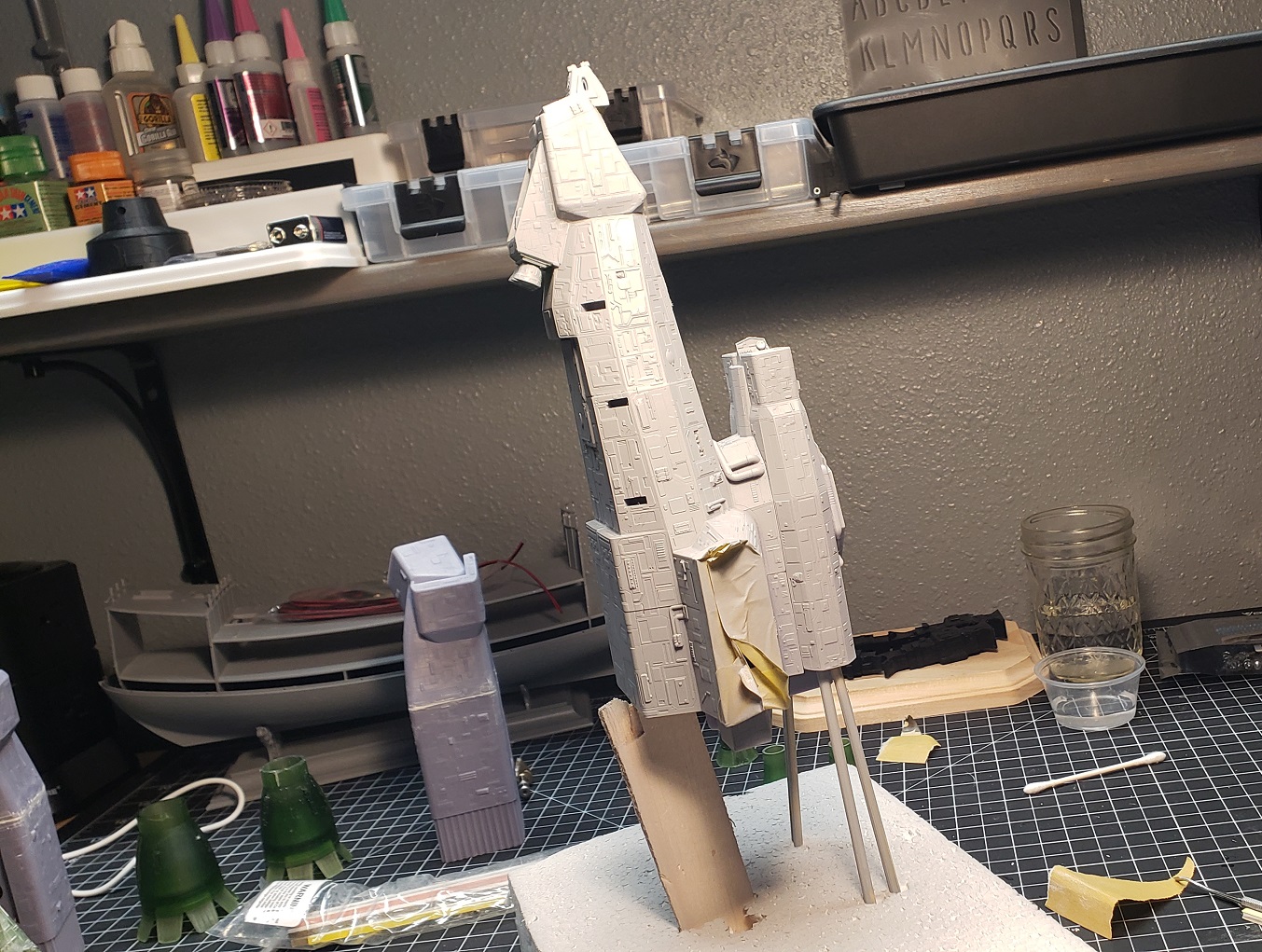

Nothing like a coat of primer to show how bad your putty job is

There is still some more work to do on the joints with filler putty. There is no way I can get the bottom to look as great as I would like, but you will almost never see it so I am not that worried.

Nothing like a coat of primer to show how bad your putty job is

There is still some more work to do on the joints with filler putty. There is no way I can get the bottom to look as great as I would like, but you will almost never see it so I am not that worried.

The large thrusters and the center engine pictured here. Once I have the two larger side engines printed I can really start getting this all put together. If anyone has any advice on hiding the seams I am all ears! I have always been able to figure out how to fill seam lines when the parts are smooth, it's not that hard.

Some of these will never look awesome as the resin cured at different rates and thus the parts don't match up perfectly. However, I am sure there are some ways to make these look better.

Some of these will never look awesome as the resin cured at different rates and thus the parts don't match up perfectly. However, I am sure there are some ways to make these look better.

Even though I think the real answer is to mesh these parts together and re-print, maybe at even a bit larger scale, I may be able to hide some of the crimes with wire and thin pieces of styrene or in this case leftover 3D print brim... The model is missing piping on the top and along the sides in several spots.

Here is a really rough idea of what it could look like:

Here is a really rough idea of what it could look like:

This is going great! I am still very impressed by the lack of print lines. Using greeblies to hide joints makes a lot of sense. The clear resin looks amazing. There are probably other great ways to use it.

Thanks!

Similar threads

- Replies

- 35

- Views

- 3,702

- Replies

- 11

- Views

- 1,072