This is my first large scale project with my new Mars resin printer. The prints are amazing and the apparent lack of layer lines is pretty awesome. So far, in my experience, the work is not really more or less than my PLA projects, and there is a lot I don't really like about the resin, even for a medium-sized project such as this. That may change with time but for now, I really like the structural integrity and ease of assembly of my PLA prints.

Anyway, here is my first attempt at a medium scale print/project. And my hat off to the author of the files, as you will see there is a ton of thought that has gone into the assembly and lighting options and the overall construction of the kit.

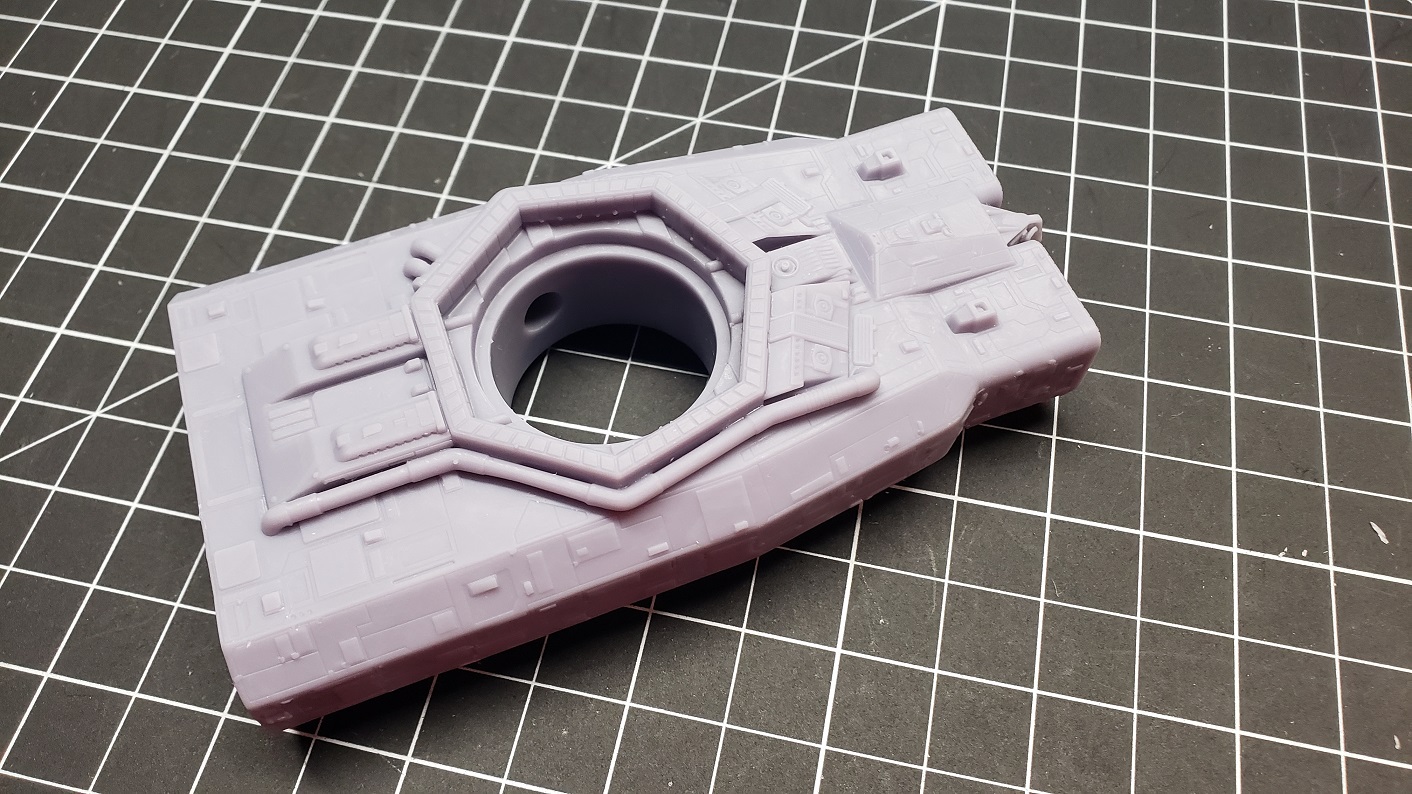

But, the amount of detail is undeniable, this little printer can print small and complex models without breaking a sweat and it really is amazing. It's also so fast, the print below would have taken days instead of hours.

Anyway, here is my first attempt at a medium scale print/project. And my hat off to the author of the files, as you will see there is a ton of thought that has gone into the assembly and lighting options and the overall construction of the kit.

But, the amount of detail is undeniable, this little printer can print small and complex models without breaking a sweat and it really is amazing. It's also so fast, the print below would have taken days instead of hours.