Archive&Future

Sr Member

It's been a little while since I kept you all updated, I've been so busy with the kits and college, but I'm ready to start showing a commission I'm working on for an excellent client.

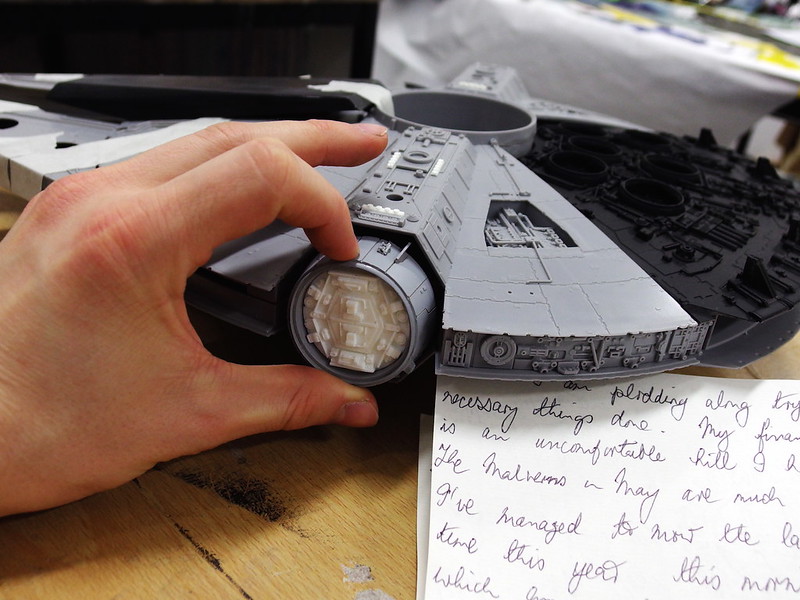

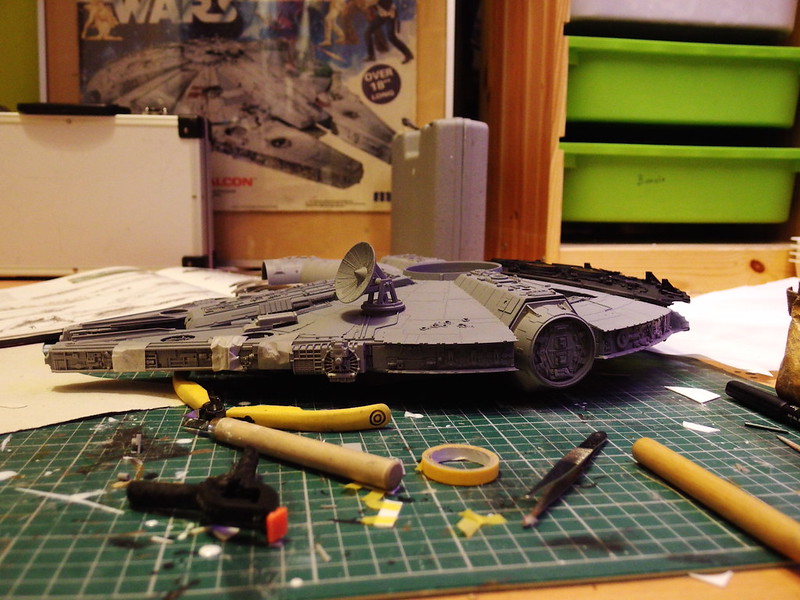

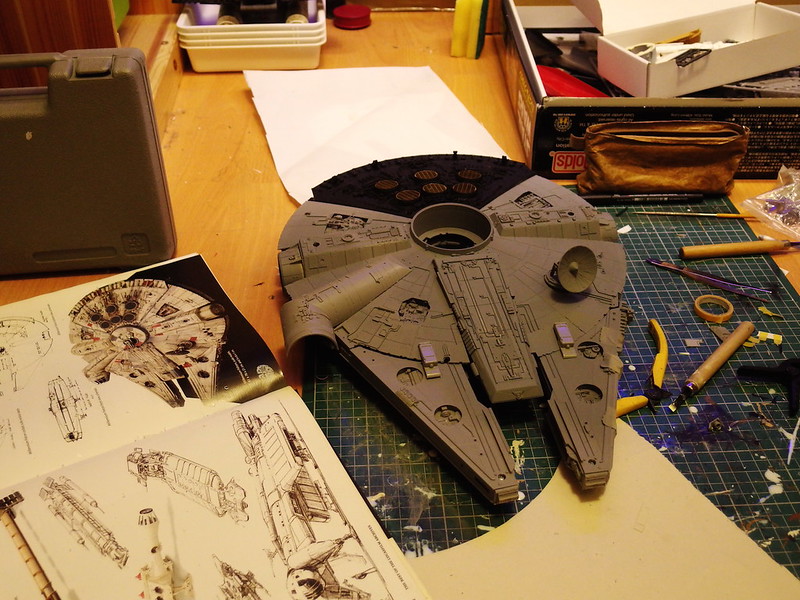

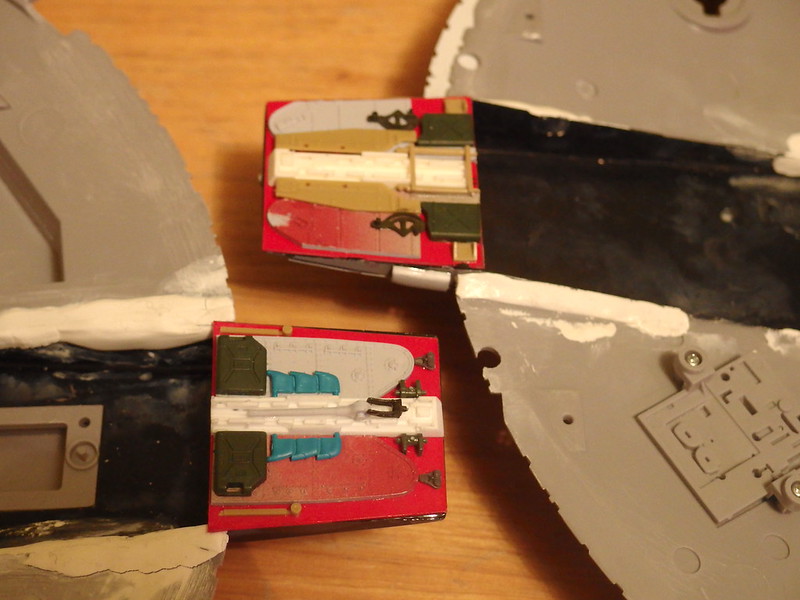

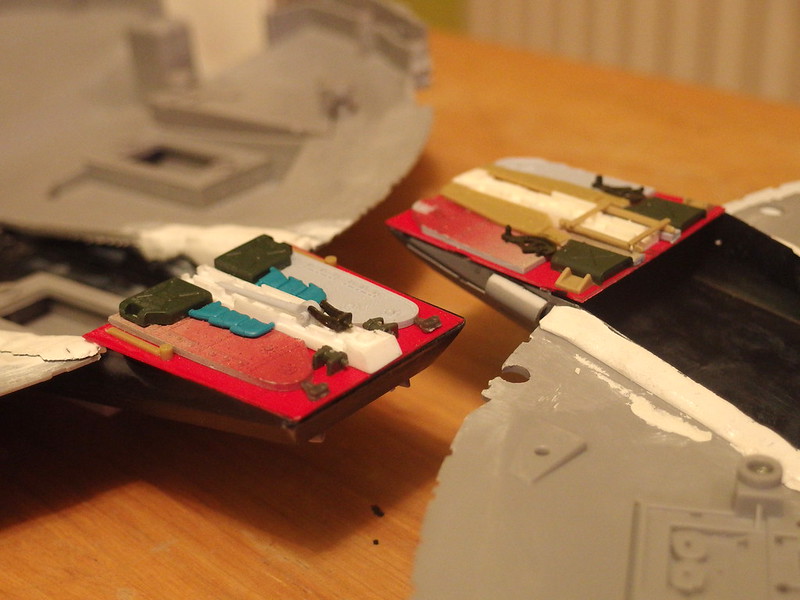

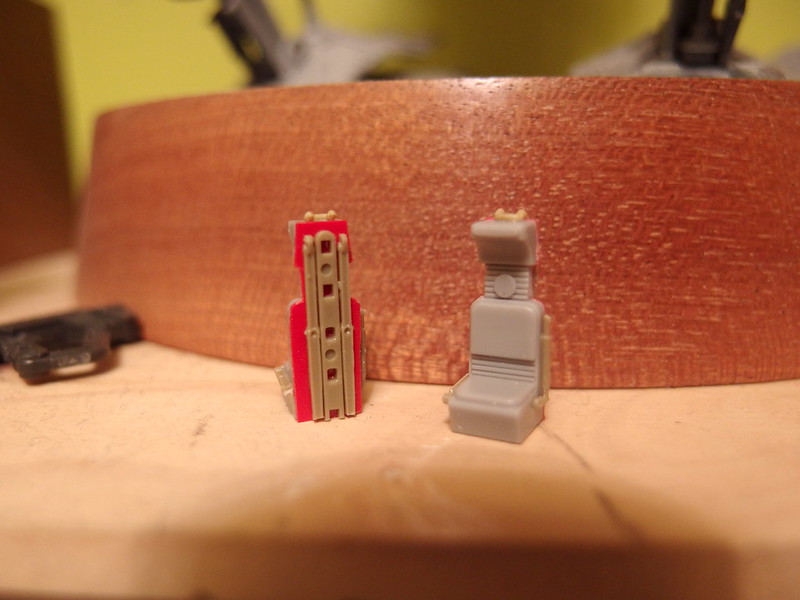

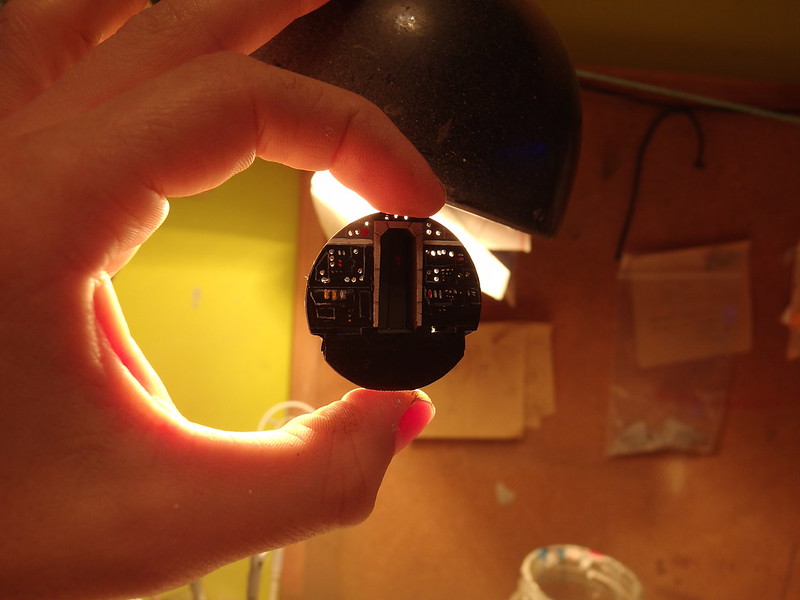

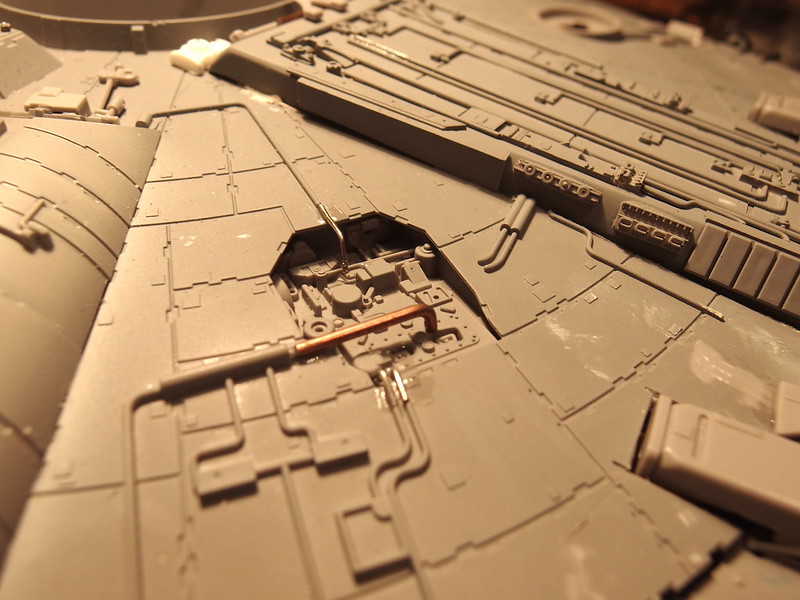

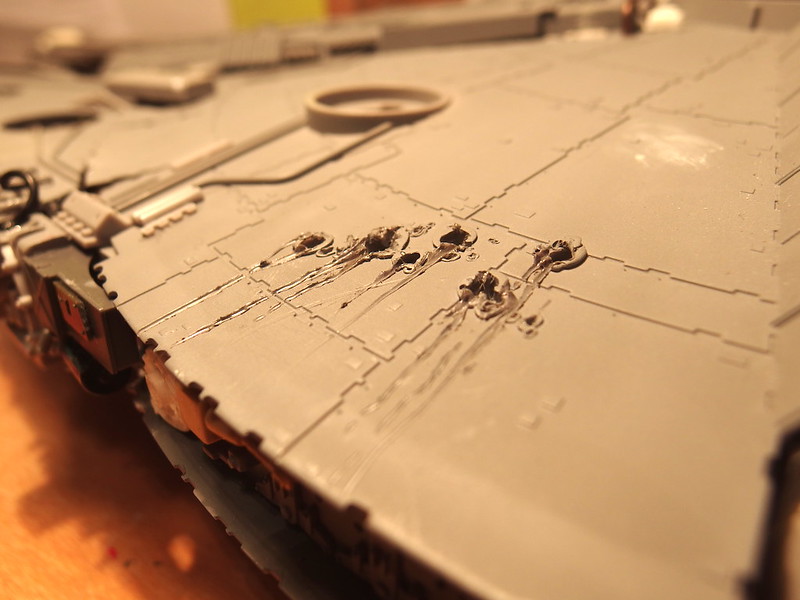

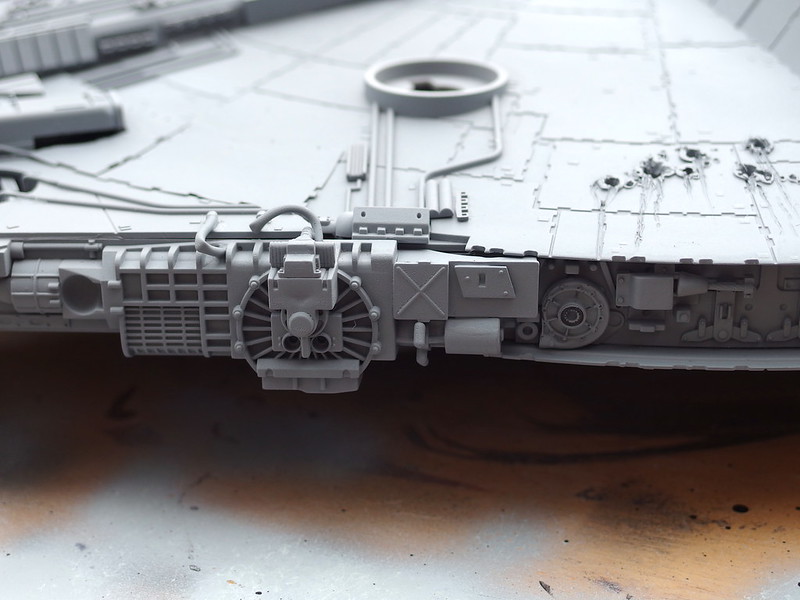

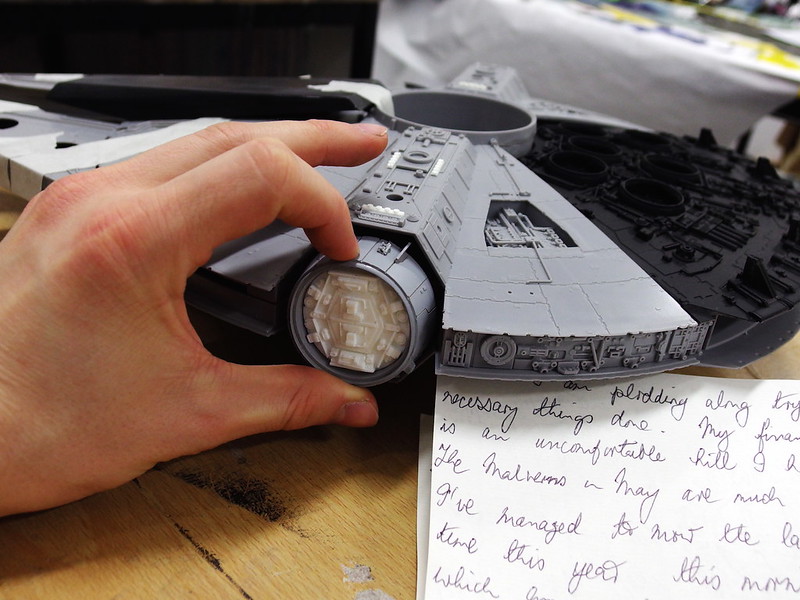

This is the 1/72nd Finemolds Millennium Falcon which is a really incredible kit (900 parts!!) but we decided to correct as much as possible and accurize it to the filming model. So far John and I have created a new jawbox, and today I laser-cut a specially designed MDF frame structure for the correct mandibles to be set into (I forgot to take any photos of it oh dear)

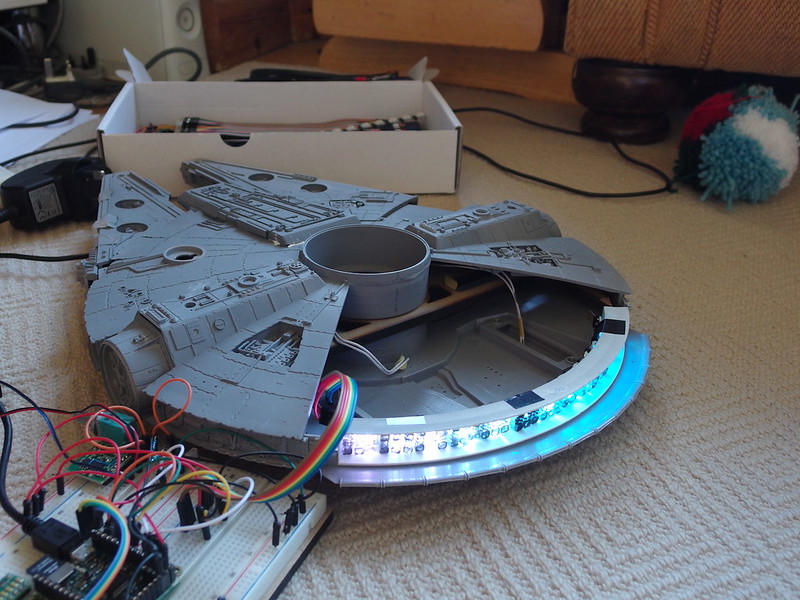

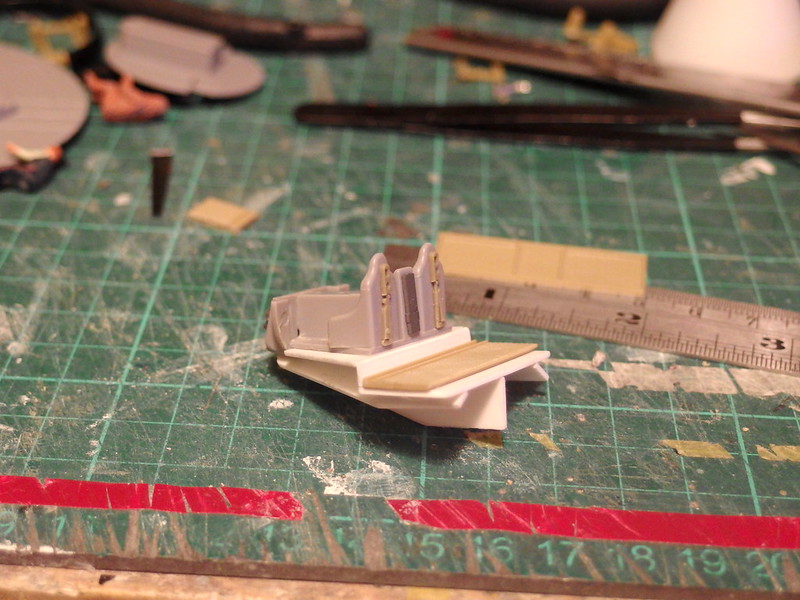

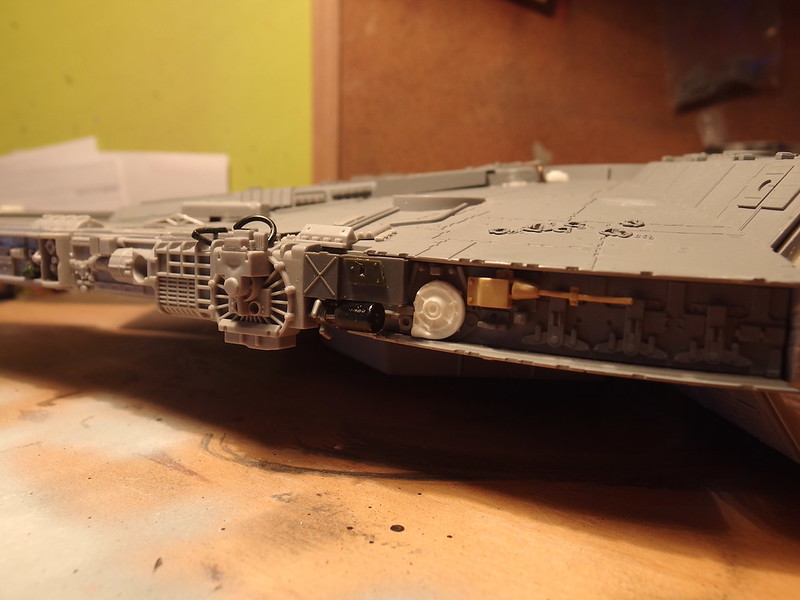

The rear engine deck has been cut out, and will be re-attached with a magnetic frame so that all the electronics can be easily accessed

This is the 1/72nd Finemolds Millennium Falcon which is a really incredible kit (900 parts!!) but we decided to correct as much as possible and accurize it to the filming model. So far John and I have created a new jawbox, and today I laser-cut a specially designed MDF frame structure for the correct mandibles to be set into (I forgot to take any photos of it oh dear)

The rear engine deck has been cut out, and will be re-attached with a magnetic frame so that all the electronics can be easily accessed