JNordgren42

Sr Member

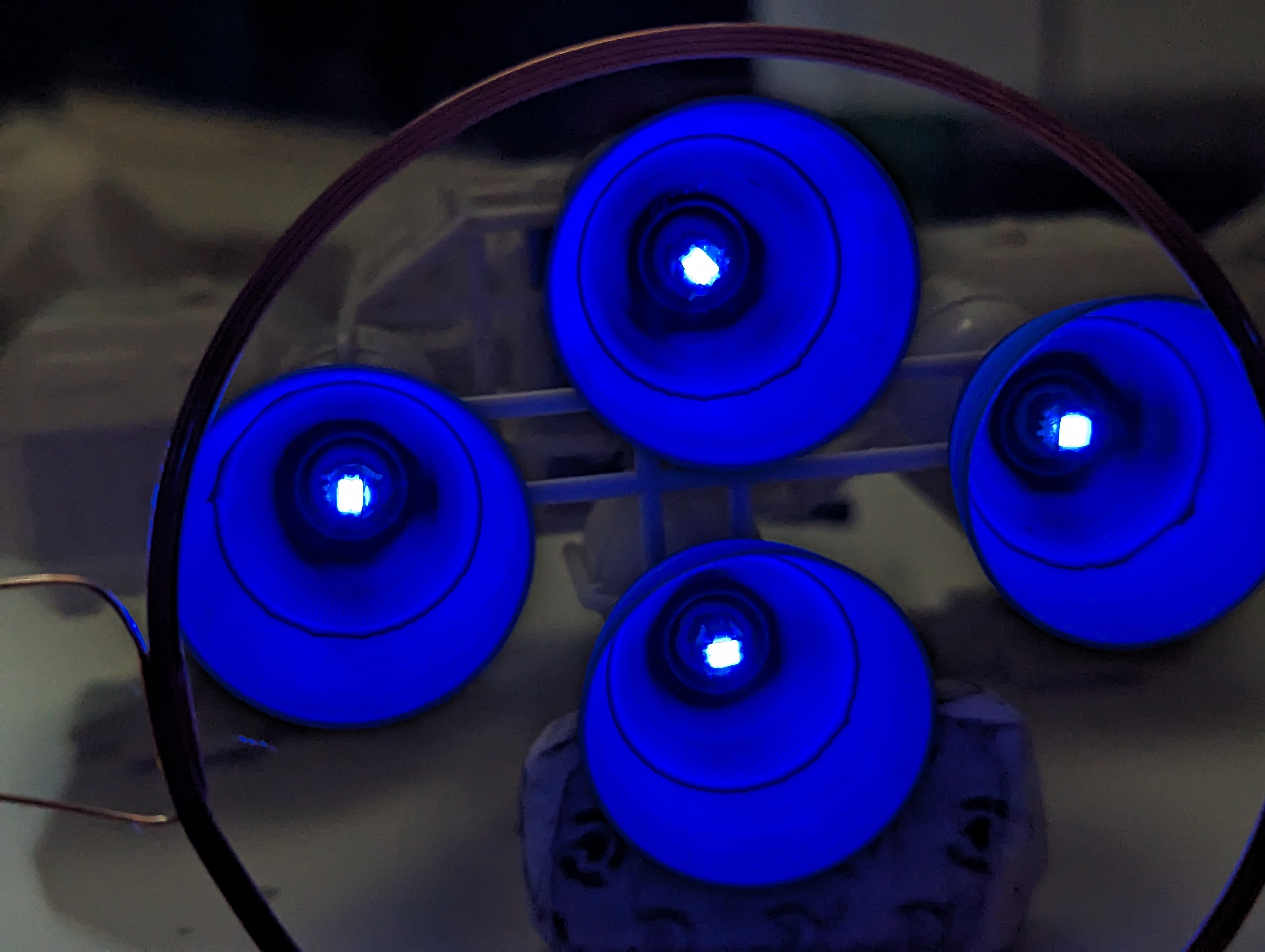

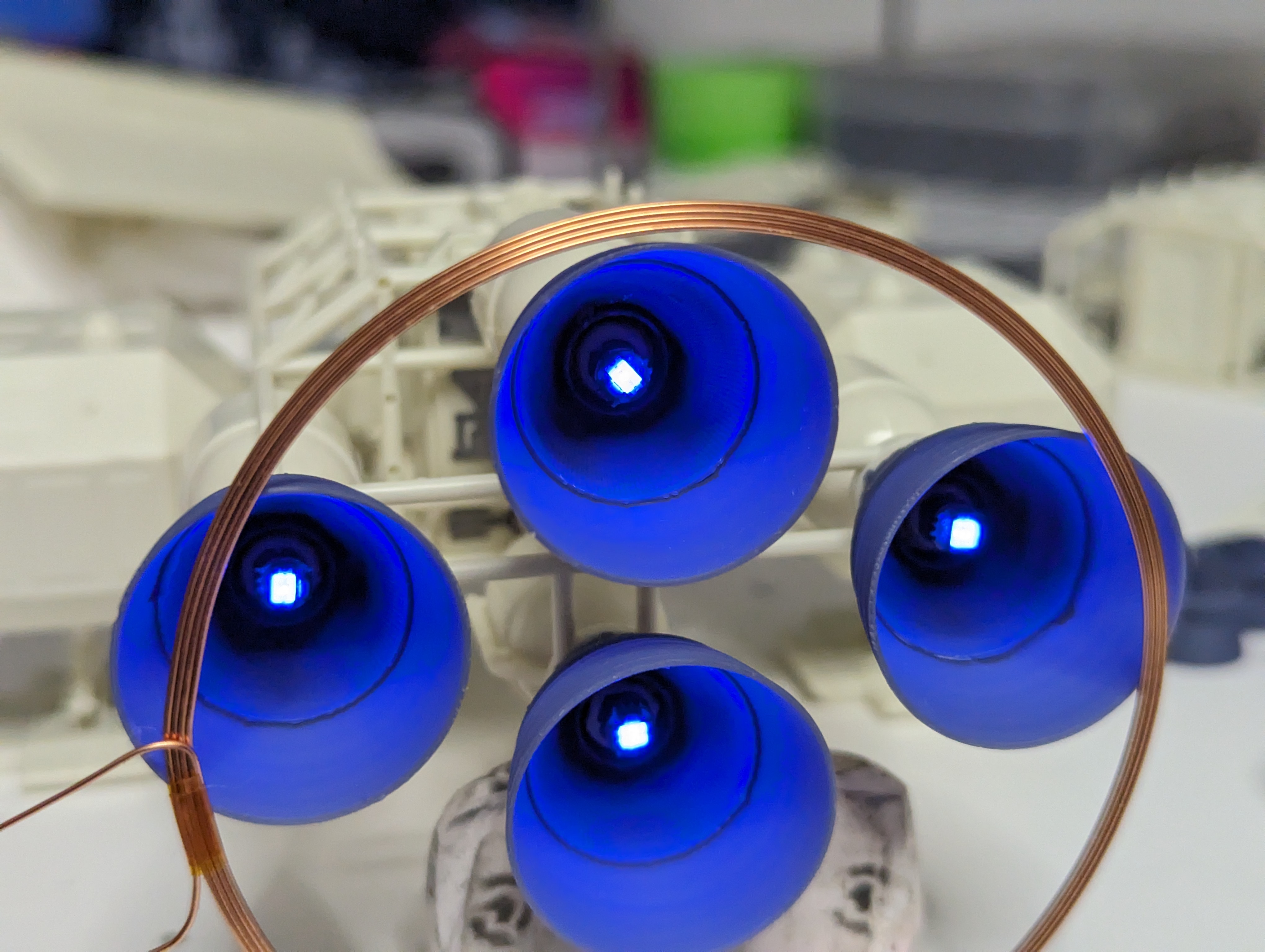

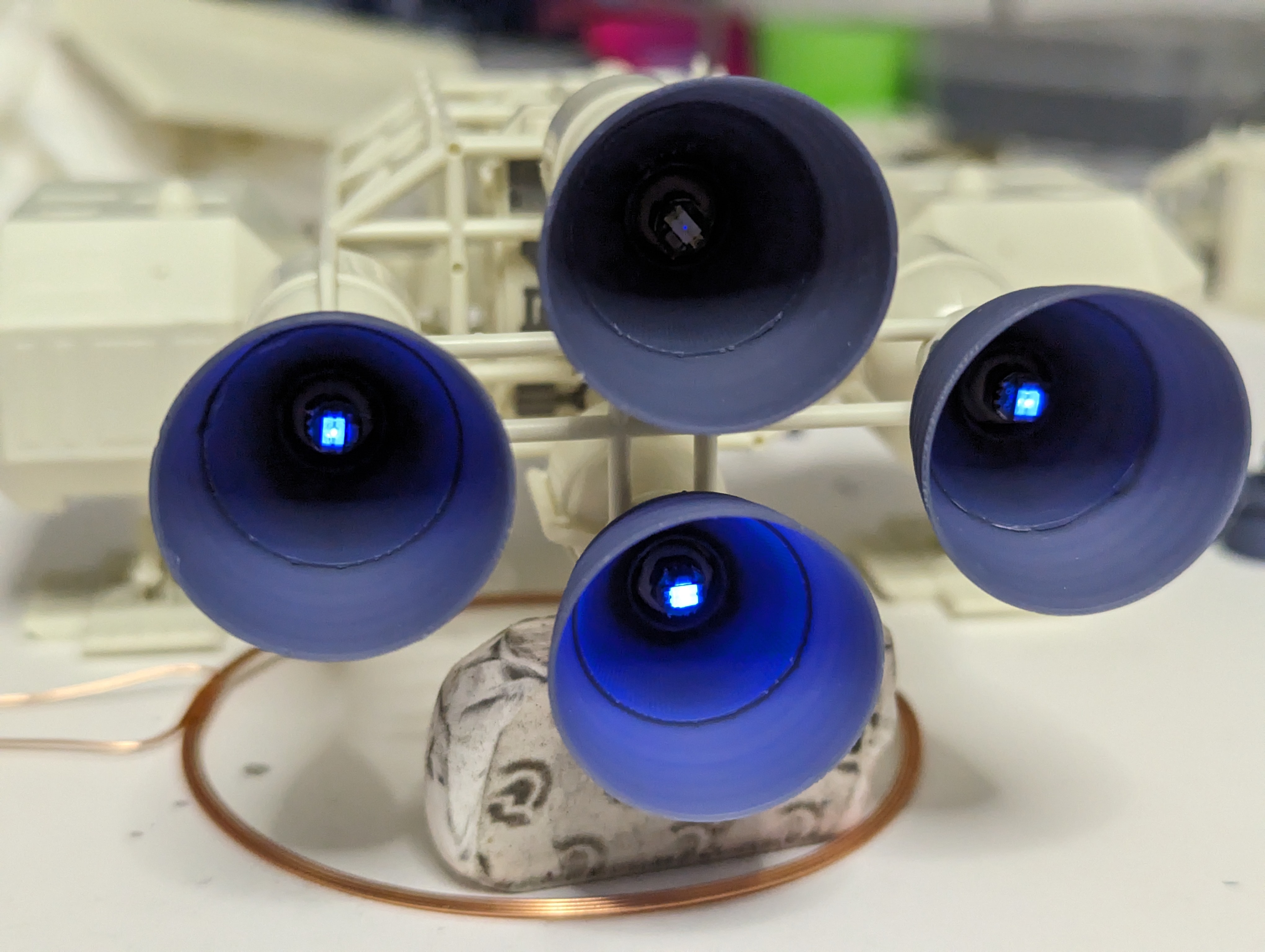

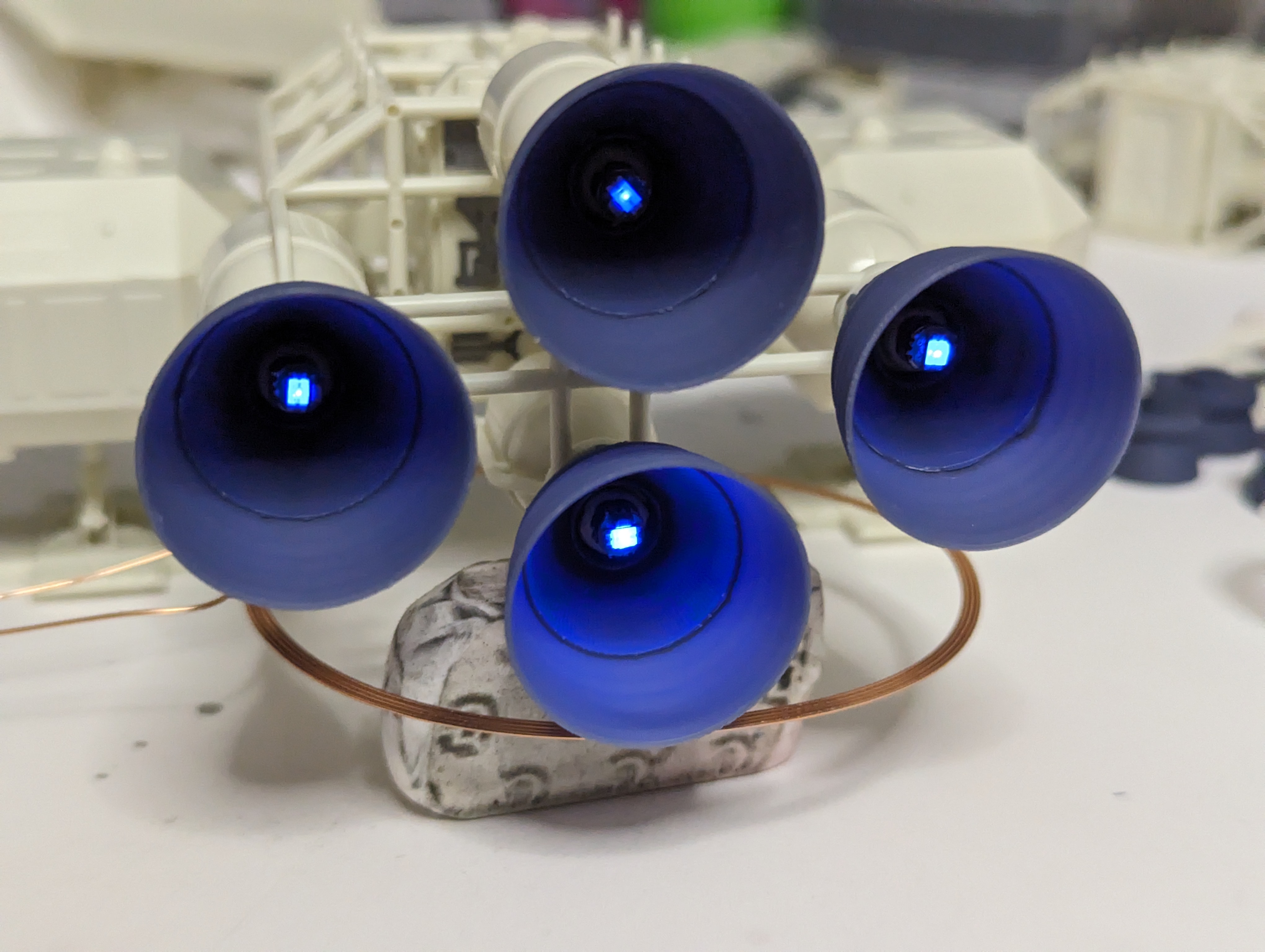

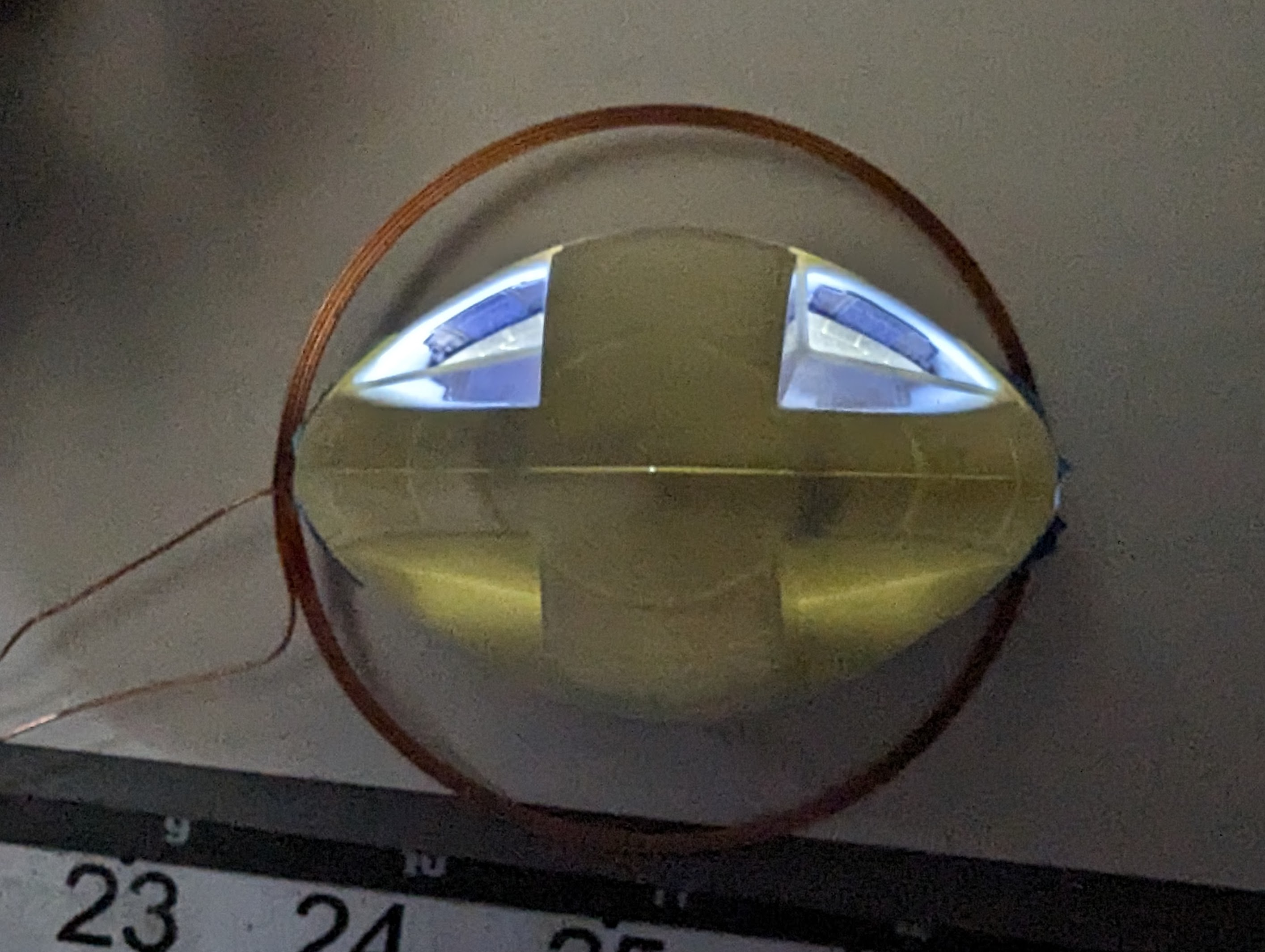

My test lighting arrived today and I think they will work. They're not the brightest and I'll definitely need a larger/more powerful induction coil(s), but as a proof of concept I'm happy. The brightness of the LEDs is highly dependent on exactly where they are in the induction field and I'm hoping a better quality coil and using more than one will help. I've attached some pictures of tests, the lights are just stuck in place with Blu Tak without any light blocking or diffusers. I've also got room in some areas for bigger LED units.

Video

Best brightness with the coil as close as possible to all four engine lights. This should be better with a bigger coil.

Uneven brightness with the coil under the engines. Hopefully it improves with a bigger coil.

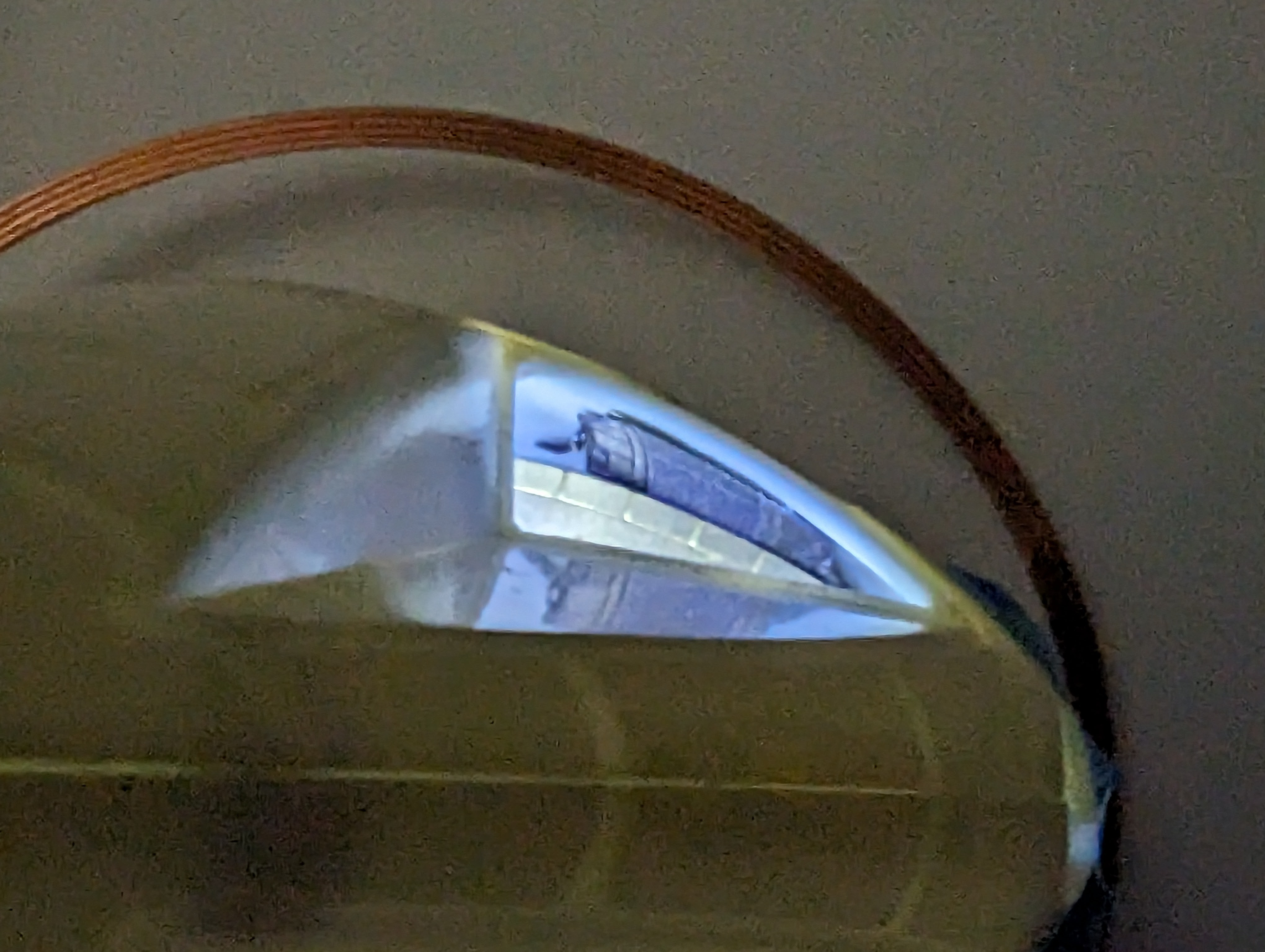

Cockpit test. This is with 4 white LEDs just forward of the windows, pointing at the back wall and ceiling. Again, need bigger coil.

Video

Best brightness with the coil as close as possible to all four engine lights. This should be better with a bigger coil.

Uneven brightness with the coil under the engines. Hopefully it improves with a bigger coil.

Cockpit test. This is with 4 white LEDs just forward of the windows, pointing at the back wall and ceiling. Again, need bigger coil.