You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/2256 Tantive IV

- Thread starter darthviper107

- Start date

darthviper107

Sr Member

To bring the price up to $25, how about adding the LEDs, fibre optics and wires required to light the model ?

Just a thought.

Shapeways doesn't sell that stuff, they just do a print, so it would have to be something that gets printed.

Anyways, when I submitted the order for printing it didn't ask me to add anything more, so maybe they changed their rules, used to be that shipping was included in the price too, but now it costs extra.

darthviper107

Sr Member

Do they give you a turn around time frame? Like, how long it will take for them to print it and get it back to you?

Originally they said they try to get it to you within 10 work days, but the last time I got something printed they were behind and it took like a month and a half.

They're supposed to be more on top of things now so hopefully it won't take that long. Original estimate was before the 28th

Troy Downen

Well-Known Member

Hey, this looks great! I'm anxious to see how the printed model turns out. A tip on the lights: run the fiber optic strands from the engines, bridge, etc down the mounting rod into the base and locate your LED in the base along with any necessary resistors and your power supply. That way you don't have to dink around inside the model hooking up wires to an LED and aligning your fiber strands to face the LED properly, plus any heat shed by the resistor is confined to the base and does not build up in the model.

darthviper107

Sr Member

Hey, this looks great! I'm anxious to see how the printed model turns out. A tip on the lights: run the fiber optic strands from the engines, bridge, etc down the mounting rod into the base and locate your LED in the base along with any necessary resistors and your power supply. That way you don't have to dink around inside the model hooking up wires to an LED and aligning your fiber strands to face the LED properly, plus any heat shed by the resistor is confined to the base and does not build up in the model.

Yeah, that's possible I think, although with the LED's in the model you could have a smaller base that just fits the battery. And you could still put the resistors in the base if you have the LED's in the model.

I was actually maybe thinking of doing a larger base, with maybe a white lit surface on the top. I'll have to figure out what I'm going to do since I'll have to build it out of styrene since even the small base design that I had was too expensive for printing (it brought the whole cost up to $80)

darthviper107

Sr Member

Got the print today--I think the fiber optics will work, but there's support material inside the holes so it's going to take some work to clean it out. I'm also wondering if it will even fit the LED.

Other issue is that they printed the wrong file for me, I was trying to get the one with the hole in the bottom and the hollow rod for the stand, but they printed the other one. Also, half the gun barrels were broken, they had wrapped the piece in tissue paper or something, I guess they thought that was a good idea, but it didn't work.

I've just got to finish cleaning it and then I'll do a layer of primer for pictures so that the detail can show up better, otherwise it's hard to see in the frosted material

Other issue is that they printed the wrong file for me, I was trying to get the one with the hole in the bottom and the hollow rod for the stand, but they printed the other one. Also, half the gun barrels were broken, they had wrapped the piece in tissue paper or something, I guess they thought that was a good idea, but it didn't work.

I've just got to finish cleaning it and then I'll do a layer of primer for pictures so that the detail can show up better, otherwise it's hard to see in the frosted material

darthviper107

Sr Member

Here's the pictures:

Here you can see the really small detail:

Too bad there's so much random roughness over it. There's patches where it's completely smooth and perfect, then there's areas that have a sort of white rough texture.

A bit of sanding and scrapping can make it a bit better, it looks better in person rather than these pictures. My only issue that can't be fixed is a sort of rippled pattern across the piece, I don't know why it's there and since it's over everything I can't get rid of it.

As for lighting--there's support material (like a gel) still in the holes for the engine, I was able to fit a 0.75mm fiber optic through all the holes, but I don't think it would be able to fit them all coming out of the engine part together, I would think it would be fine with 0.5mm fiber optic though.

I'll do a test with the lighting at some point and post the results. And also to add--the guns all broke off, half during shipping, and I accidentally broke the rest off as I was cleaning it. Using a toothbrush is too harsh. Since they did my order wrong I'm guessing they'll print a replacement, so I hope that the guns arrive OK on that one and I'll clean it using an airbrush rather than a toothbrush, then it should be fine and not break.

I think if they tape the piece to some cardboard and then bend the cardboard around the part and tape it closed, that will allow the guns not to be touching anything and they wouldn't have a chance to break. Hopefully they will accept that as a suggestion.

Here you can see the really small detail:

Too bad there's so much random roughness over it. There's patches where it's completely smooth and perfect, then there's areas that have a sort of white rough texture.

A bit of sanding and scrapping can make it a bit better, it looks better in person rather than these pictures. My only issue that can't be fixed is a sort of rippled pattern across the piece, I don't know why it's there and since it's over everything I can't get rid of it.

As for lighting--there's support material (like a gel) still in the holes for the engine, I was able to fit a 0.75mm fiber optic through all the holes, but I don't think it would be able to fit them all coming out of the engine part together, I would think it would be fine with 0.5mm fiber optic though.

I'll do a test with the lighting at some point and post the results. And also to add--the guns all broke off, half during shipping, and I accidentally broke the rest off as I was cleaning it. Using a toothbrush is too harsh. Since they did my order wrong I'm guessing they'll print a replacement, so I hope that the guns arrive OK on that one and I'll clean it using an airbrush rather than a toothbrush, then it should be fine and not break.

I think if they tape the piece to some cardboard and then bend the cardboard around the part and tape it closed, that will allow the guns not to be touching anything and they wouldn't have a chance to break. Hopefully they will accept that as a suggestion.

That looks every bit as good as my Ani 1/2256 Tantive. The guns can easily be replalced with stretched sprue. That is what I used to make mine. I think I will definately have to order one of these. How do I do that though? Go to the website, find the Tantive and click on the order button?

Troy Downen

Well-Known Member

Not bad! Yes, I see the "ripple" pattern across the model from the printing process. Not much you can do about that in this scale tho. 0.75mm fiber strand is pretty thick stuff for this scale. I would recommend the 0.50mm for the engines instead. You'll still get a good, bright light out of them if you're using a 6000mcd LED or so. Like I mentioned before, put the LED in the base and run your strands up the display stand. A model this size really doesn't give you sufficient room to bury the LED in the model. Plus you may have light leakage problems through the thin walls of the model.

But this is a great look at what can be done with these solid model prototyping tools. I am so glad that you've chosen to share this with us!

But this is a great look at what can be done with these solid model prototyping tools. I am so glad that you've chosen to share this with us!

darthviper107

Sr Member

Not bad! Yes, I see the "ripple" pattern across the model from the printing process. Not much you can do about that in this scale tho. 0.75mm fiber strand is pretty thick stuff for this scale. I would recommend the 0.50mm for the engines instead. You'll still get a good, bright light out of them if you're using a 6000mcd LED or so. Like I mentioned before, put the LED in the base and run your strands up the display stand. A model this size really doesn't give you sufficient room to bury the LED in the model. Plus you may have light leakage problems through the thin walls of the model.

But this is a great look at what can be done with these solid model prototyping tools. I am so glad that you've chosen to share this with us!

I think that's what I'm going to do, there's enough room for the LED's, but not enough room for the one for the back to fit in the space between the back piece and the hole that the wires have to go through.

Shouldn't be any light leaks if I do a coat of black.

Just wait a bit before ordering--I'm checking with the replacement and I'm hoping they will take my suggestion for packaging (to make sure the guns don't break). I'm suggesting they tape the piece to a piece of cardboard and then fold the cardboard over it so that it's not touching anything and the small pieces won't break from being crushed.

darthviper107

Sr Member

Getting my replacement made, hopefully it will be correct.

Some news on the print artifacts, they said that's something that can't be avoided at the moment, maybe in the future they can fix it. I'm working on the first print to try and smooth some of the areas out and we'll see how it turns out.

In the meantime, here is the link to order:

Blockade Runner Fixed by darthviper107 on Shapeways

I did make a few changes from before, making a few cylinders smoother and the guns a little bigger, hopefully they won't break, but for those that order, be prepared that the guns might be broken when it arrives. If that's the case, contact Shapeways.

Some news on the print artifacts, they said that's something that can't be avoided at the moment, maybe in the future they can fix it. I'm working on the first print to try and smooth some of the areas out and we'll see how it turns out.

In the meantime, here is the link to order:

Blockade Runner Fixed by darthviper107 on Shapeways

I did make a few changes from before, making a few cylinders smoother and the guns a little bigger, hopefully they won't break, but for those that order, be prepared that the guns might be broken when it arrives. If that's the case, contact Shapeways.

Troy Downen

Well-Known Member

I've been looking at the Shapeways site (my first time there). What material did you have this printed with?

darthviper107

Sr Member

This is the Frosted Ultra Detail

Has to be that material for the minimum thickness (0.3mm). It can do very good and sharp detail, but there will be some artifacts on the print.

The best quality will come from the more professional places, but they are much more expensive and take longer.

Has to be that material for the minimum thickness (0.3mm). It can do very good and sharp detail, but there will be some artifacts on the print.

The best quality will come from the more professional places, but they are much more expensive and take longer.

darthviper107

Sr Member

It's plastic, pretty hard. It's not uniformly hard though. I was drilling the hole in the bottom and at first it didn't do much, but after a bit it went through.

The best quality will come from the more professional places, but they are much more expensive and take longer.

not really. shapeways sends your order to the "professional places" along with lots of orders they take in. they aren't really a printing company themselves.

darthviper107

Sr Member

Their process is setup to make things as fast as possible and as cheap as possible which is why there's quality issues. When people work with the places like Modeler or Ownage and stuff like that you can be sure there won't be these issues, but for something that cost like $5 at Shapeways you could end up paying $80 for

BTW on the guns--I'm finding I can replace them using a bit of fiber optic, minimum thickness on the print is 0.3mm and I've got fiber optic that's 0.25 so it's very close. A bit difficult to glue on but it works.

BTW on the guns--I'm finding I can replace them using a bit of fiber optic, minimum thickness on the print is 0.3mm and I've got fiber optic that's 0.25 so it's very close. A bit difficult to glue on but it works.

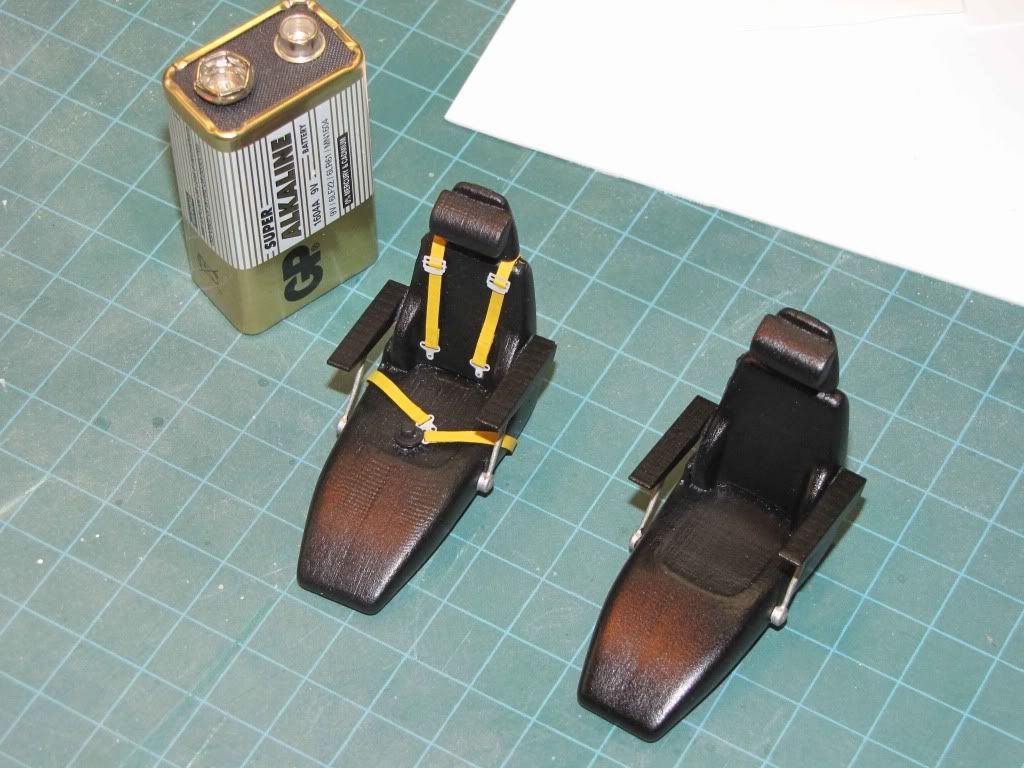

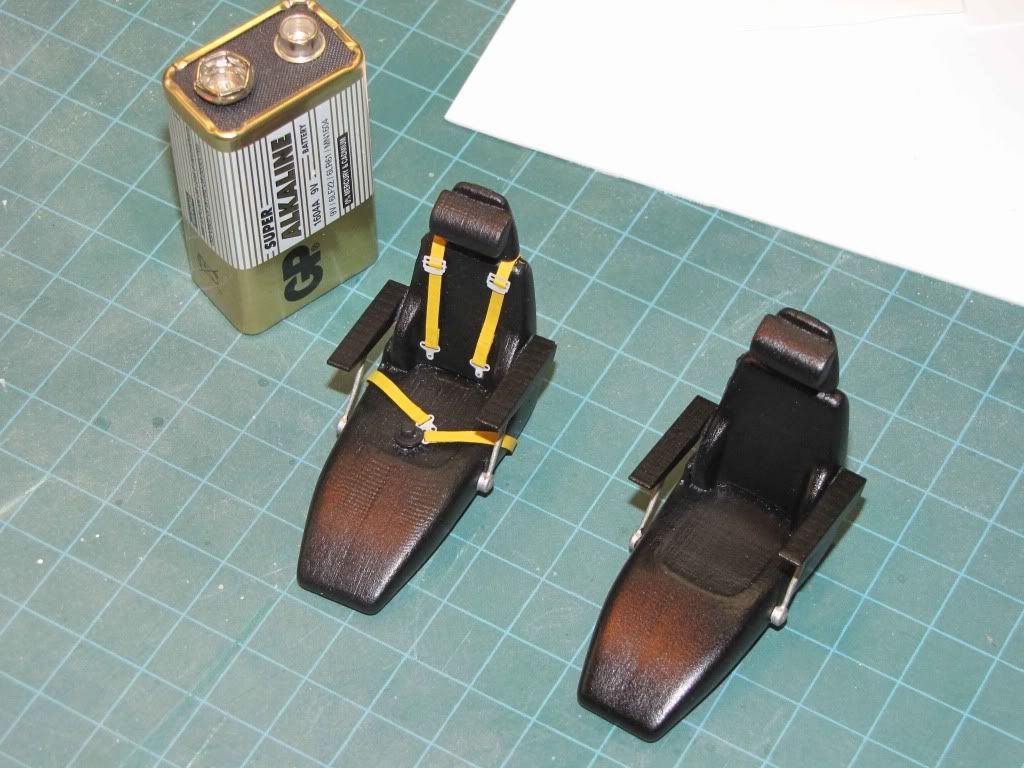

Here is an example of what Modeler had done for me. $125 US for the pair. Minimal wet sand and the result was pretty good. The lines are something that you have to live with at this point in the technology. They are studio accurate seats for a Space:1999 44" Cutaway Eagle I am working on.

Similar threads

- Replies

- 57

- Views

- 4,094

- Replies

- 6

- Views

- 766

- Replies

- 4

- Views

- 844