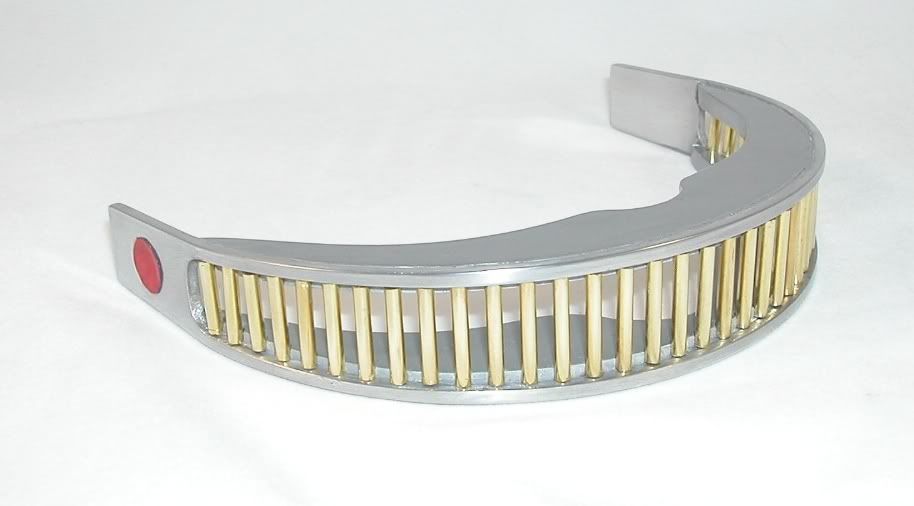

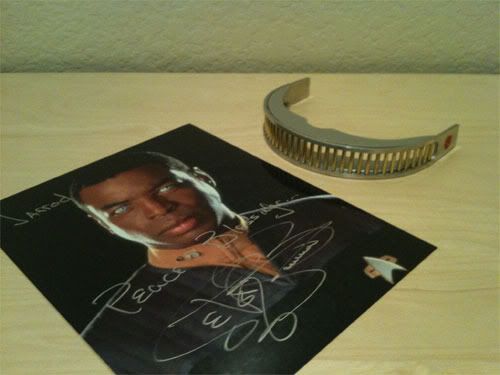

So I finished Droidboy's visor kit that I got acouple days ago and am very pleased with the outcome, he did a incredible job on this kit and cant say enough good things! The kit has been polished and painted and think it looks pretty good. Building this kit is kinda time consuming, but the main part to watch out for is cutting the brass rods, the brass is soft and if you dont take your time you can screw it up, I was just glad there were alittle extra included. I plan on poishing the rods up again one more time, but other than that the piece is finished, hope you like it! Sorry for the crappy pics

Last edited: